| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

A Low Cost Tester of Glaze Melt Fluidity

A One-speed Lab or Studio Slurry Mixer

A Textbook Cone 6 Matte Glaze With Problems

Adjusting Glaze Expansion by Calculation to Solve Shivering

Alberta Slip, 20 Years of Substitution for Albany Slip

An Overview of Ceramic Stains

Are You in Control of Your Production Process?

Are Your Glazes Food Safe or are They Leachable?

Attack on Glass: Corrosion Attack Mechanisms

Ball Milling Glazes, Bodies, Engobes

Binders for Ceramic Bodies

Bringing Out the Big Guns in Craze Control: MgO (G1215U)

Can We Help You Fix a Specific Problem?

Ceramic Glazes Today

Ceramic Material Nomenclature

Ceramic Tile Clay Body Formulation

Changing Our View of Glazes

Chemistry vs. Matrix Blending to Create Glazes from Native Materials

Concentrate on One Good Glaze

Copper Red Glazes

Crazing and Bacteria: Is There a Hazard?

Crazing in Stoneware Glazes: Treating the Causes, Not the Symptoms

Creating a Non-Glaze Ceramic Slip or Engobe

Creating Your Own Budget Glaze

Crystal Glazes: Understanding the Process and Materials

Deflocculants: A Detailed Overview

Demonstrating Glaze Fit Issues to Students

Diagnosing a Casting Problem at a Sanitaryware Plant

Drying Ceramics Without Cracks

Duplicating Albany Slip

Duplicating AP Green Fireclay

Electric Hobby Kilns: What You Need to Know

Fighting the Glaze Dragon

Firing Clay Test Bars

Firing: What Happens to Ceramic Ware in a Firing Kiln

First You See It Then You Don't: Raku Glaze Stability

Fixing a glaze that does not stay in suspension

Formulating a body using clays native to your area

Formulating a Clear Glaze Compatible with Chrome-Tin Stains

Formulating a Porcelain

Formulating Ash and Native-Material Glazes

G1214M Cone 5-7 20x5 glossy transparent glaze

G1214W Cone 6 transparent glaze

G1214Z Cone 6 matte glaze

G1916M Cone 06-04 transparent glaze

Getting the Glaze Color You Want: Working With Stains

Glaze and Body Pigments and Stains in the Ceramic Tile Industry

Glaze Chemistry Basics - Formula, Analysis, Mole%, Unity

Glaze chemistry using a frit of approximate analysis

Glaze Recipes: Formulate and Make Your Own Instead

Glaze Types, Formulation and Application in the Tile Industry

Having Your Glaze Tested for Toxic Metal Release

High Gloss Glazes

Hire Us for a 3D Printing Project

How a Material Chemical Analysis is Done

How desktop INSIGHT Deals With Unity, LOI and Formula Weight

How to Find and Test Your Own Native Clays

I have always done it this way!

Inkjet Decoration of Ceramic Tiles

Is Your Fired Ware Safe?

Leaching Cone 6 Glaze Case Study

Limit Formulas and Target Formulas

Low Budget Testing of Ceramic Glazes

Make Your Own Ball Mill Stand

Making Glaze Testing Cones

Monoporosa or Single Fired Wall Tiles

Organic Matter in Clays: Detailed Overview

Outdoor Weather Resistant Ceramics

Painting Glazes Rather Than Dipping or Spraying

Particle Size Distribution of Ceramic Powders

Porcelain Tile, Vitrified Tile

Rationalizing Conflicting Opinions About Plasticity

Ravenscrag Slip is Born

Recylcing Scrap Clay

Reducing the Firing Temperature of a Glaze From Cone 10 to 6

Setting up a Clay Testing Program in Your Company or Studio

Simple Physical Testing of Clays

Single Fire Glazing

Soluble Salts in Minerals: Detailed Overview

Some Keys to Dealing With Firing Cracks

Stoneware Casting Body Recipes

Substituting Cornwall Stone

Super-Refined Terra Sigillata

The Chemistry, Physics and Manufacturing of Glaze Frits

The Effect of Glaze Fit on Fired Ware Strength

The Four Levels on Which to View Ceramic Glazes

The Majolica Earthenware Process

The Potter's Prayer

The Right Chemistry for a Cone 6 Magnesia Matte

The Trials of Being the Only Technical Person in the Club

The Whining Stops Here: A Realistic Look at Clay Bodies

Those Unlabelled Bags and Buckets

Tiles and Mosaics for Potters

Toxicity of Firebricks Used in Ovens

Trafficking in Glaze Recipes

Understanding Ceramic Materials

Understanding Ceramic Oxides

Understanding Glaze Slurry Properties

Understanding the Deflocculation Process in Slip Casting

Understanding the Terra Cotta Slip Casting Recipes In North America

Understanding Thermal Expansion in Ceramic Glazes

Unwanted Crystallization in a Cone 6 Glaze

Using Dextrin, Glycerine and CMC Gum together

Volcanic Ash

What Determines a Glaze's Firing Temperature?

What is a Mole, Checking Out the Mole

What is the Glaze Dragon?

Where do I start in understanding glazes?

Why Textbook Glazes Are So Difficult

Working with children

Description

Go in with both eyes open if you are planning to work with clay with a group of children! A lot can go wrong but it can be unforgettable for them when it goes right.

Article

Clay is Dirt!

It dries, it does not set. So it does not harden like plaster, if exposed to water it will turn back into mud. Wet clay is "plastic" (as opposed to "elastic", it willingly assumes a new shape). Clay particles are very tiny and flat, shaped like stop signs. They behave like water magnets because they are electrically charged opposite to water. Dried clay is not very strong. But when baked in a kiln it turns into a rock! Buffstone is an inexpensive clay and is good for beginners because it has added bentonite to slow down drying. Later students could progress to a white burning clay like Snow (glazes look better on it) or a terracotta red burning one like L215 (pieces are stronger).

Firing the Pieces

Potters make stoneware, they work at about 2200°F (1200°C). Potters measure temperatures by cone numbers, 2200°F is cone 6. Most schools make earthenware and fire to about 1850°F (1000°C, that is cone 04). Kilns last longer and fire much easier at earthenware temperatures. Although it is possible to paint glazes on pieces that are only dried, for children it is far better to do a bisque firing first.

- Make sure pieces are dry before firing (the kiln also needs to remove water you cannot see).

- Automatic firing in most kilns controllers can be too fast. It is best to manually program your kiln so you know how fast it is heating (kilns generally program in degrees F). Program it to heat up to about 250°F and hold there for a few of hours, even overnight (to drive out all water) before continuing upward to 1850°F at about 300F/hr.

- Bisque to cone 04 (1920F). Pieces can be stacked in bisque firings.

Glazes

First decide if pieces need to be glazed. Glaze are mixes of powdered minerals, clays and glasses, they melt and produce a very durable surface. But if the children are just making decorative items it might be better to finish them using acryllic paint (after bisque firing).

Glazes are water suspensions of inert powders, they are not toxic to use. Glazes can be freely mixed like paint. Bottled brushing glazes can be quite expensive (e.g. $20-30 per 1-pint jar). As you get more experienced you might consider buying the powders and making your own in a blender (we have instructions). It is also possible to make buckets for dipping (we also have instructions for that).

Almost all glazes can be fired from cone 06 (1800°F or 980°C) to cone 04 (1920°F) - and even higher (note that at earthenware temperatures the cone numbers count backward up to zero). We find it is easiest to fire both bisque and glaze at cone 04, in this way a firing can contain a mix of pieces.

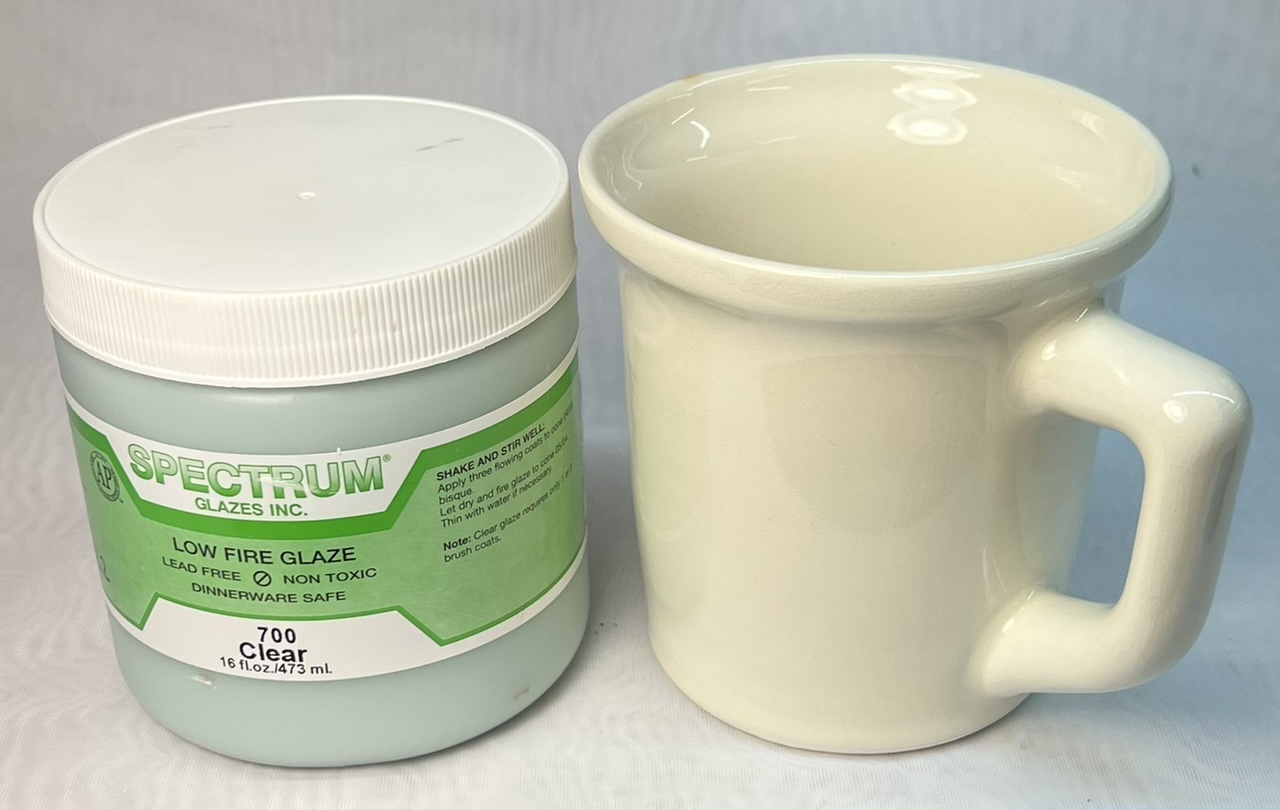

A commercial clear brushing glaze

- Note instructions/cautions on the glaze label. Add water if needed (even newly opened jars can be too thick). Apply in coats and let dry for each. Bisque-fired pieces are absorbent, so the layers will dry fairly quickly. It is better to paint on more thin coats than fewer thick ones, this gives more even coverage.

- Don't glaze the bottoms of pieces or they will glue to the shelf during firing. Sponge off any glaze that gets on the foot.

- Almost all glazes can be fired from cone 06-04 (04 is hotter).

- Getting a glaze on too thick could cause it to run during firing.

Safety

The hazard label: Clay is non-toxic, the label refers to silicosis. This happens when people breathe the dust over a period of many years (thus farmers, gardeners can get silicosis). Keep the floor clean.

Glazes: Use white or transparent glazes on food surfaces, brightly colored elsewhere.

Clay Shrinks When It Dries

Most clays shrink about 6%. So if one part of a piece dries (and shrinks first) then when the other part shrinks a crack will occur. In addition, because clays shrink pieces cannot be built around an armature and expected to dry on it (unless the armature can be removed).

- Dry things evenly (slow down fast-drying sections or speed up slow-drying ones).

- Drying things slowly usually means they dry more evenly (e.g. put a piece on a small board, drape a cloth over it and wrap it under the board). In wet climates pieces will dry much more slowly and also experience less cracking.

- To work on a piece again the next day, put it on a board, drape a cloth over it, put the whole thing it in a plastic bag and twist and fold the bag mouth under.

- Encourage the kids not to make things that are too thick or heavy. The more even thickness a piece is the easier it will be to dry it without cracks.

- If something needs to be made hollow it might be necessary to let it stiffen a little, cut it in half with a wire, hollow it out, then glue it back together with slip (see below).

Rolling Out Clay

It is best to flatten the clay as much as possible by hand first before trying to use a rolling pin (google "rolling clay slabs" for examples). Don't fold the clay when flattening it, it will crack on the folds. If you are doing a project (e.g. wrapping a slab around a form to make a cup or bowl) the students likely need a good slab. However, younger kids won't be capable of making one, the instructor may need to make these ahead of time, stacking them with plastic between them. Clay can be sticky, especially if it gets wet. Work on an absorbent surface (e.g. particle board, canvas board), no water is needed (that will just make a big mess).

Joining

"Slip" is used to join things (don't use water, it will cause splits). Slip is just the clay with extra water so it can be painted. Make it by crushing some bone-dry scrap clay (into pieces smaller than marbles), then put this in water. It will slake and settle on the bottom in a few minutes. Pour off the water and stir it. The thicker and more creamy it is the better. Or, flatten some clay in a small bowl, put a little water into it and stir it around with a brush to work up a thick creamy consistency.

Clay Dries Out if You Work To Long

Teach the children to plan what they want to make first. Then use a deliberate set of steps to achieve that. If they do not do this the clay will dry out too much as they work on it too long. Let them know it is OK to attempt a piece multiple times before they get success. Consider watching a few Youtube videos on handbuilding before introducing the clay to the class.

Inspiration

Google pictures for "clay animals", "clay houses" or "clay hand building". It is often a good idea to help the children make something they can use (like a bowl, plate or cup). Consider watching videos about ceramic masters to inspire the class (e.g. google "korean pottery masters", "Indian village potters", "African pottery").

Cleanup

Clays and glazes are all water based, insoluble and non-toxic. Glazes are not like paint, they dry like clay and can be rewetted, so they are easy to clean. Avoid putting clay or glaze slurries down the drain as the particles can settle in pipes. It is better to have a couple of pails of water and wash tools and boards using them. The particles will settle to the bottom. Just pour off the water the next day and either dispose of the mud or let it dry out and dispose of that.

Related Information

Using clay with children

This picture has its own page with more detail, click here to see it.

It is often said: "No good deed goes unpunished"! This can happen when doing a clay session with children. So there is a need to enter, with "both eyes open" to avoid a negative experience. If you can succeed they will get a unique tactile experience in a social setting. And they will experience the anticipation of waiting to see what the kiln will do with their creation. If the kiln gifts them a brightly colored durable piece, especially one that they can drink or eat out of, the experience and the object can stay with them for a lifetime. If you are an instructor inheriting a kiln and clay program for kids it can seem overwhelming, especially if your technical knowledge is limited. But there are some simple things you can do to assess the condition of the kiln in your facility and whether it is practical to attempt some clay sessions with the children in your trust. Click the link below to learn more.

Do these kiln elements need replacing?

This picture has its own page with more detail, click here to see it.

This 12 inch test kiln has done 910 firings. The element loops are laying down and nearly touching each other. If they are not changed soon the coils will touch the kiln will have hot spots. And the coils are expanding and getting tighter in the grooves, the longer we wait the more the grooves will be damaged when removing them. Although elements seem expensive, when costed on a per/firing basis they can be surprisingly inexpensive. Most hobby kilns service two elements with each relay and relays generally need to be replaced more often than elements. Consider, for example, replacing the elements on a Skutt 818. Being a smaller kiln it is well-powered in relation to size and elements can last up to 1000 firings (assuming 50:50 bisque and cone 6 firings). It has 4 elements and 2 relays (relays cost $65/ea, elements $95 each). The labor to replace is ~4 hours or $250 - total cost is about $750 (that is ~75¢ per firing or 32¢ per ft³). How about a larger kiln? An 8 ft³ Model 1222 has 5 elements and 3 relays and replacement is ~$1100. But its elements are only likely to last 200 firings. That yields a per firing cost of ~$5 and per ft³ of 65¢. But there is a much greater cost to consider: Old elements increase power consumption. An 818 uses 6.4 kwH and a 1222 uses 11.5 kwH - at our electricity cost of 14¢/kwH a firing costs ~$7 for the small kiln and ~$13 for the large one. But that is the cost when elements are new. When they need changing those numbers can more than double! An additional cost of old elements is ware consistency, the kiln cannot execute the firing schedule in the time programmed and this will likely affect the appearance of bodies and glazes.

Are you using your expensive kiln like a pop-up toaster?

This picture has its own page with more detail, click here to see it.

Put the pots in, select a cone, press start. It is time to rethink that approach! The Bartlett Genesis kiln controller is standard equipment on hobby and production electric kilns now. It is not meant to be run like a toaster! Good glazes are about much more than recipes, they are about firing schedules. None of the built-in "toaster schedules" have hold times on any segments, drop-and-hold sequences or controlled cools. Or even fire-to-cone accuracy. Yet such are a must for defect-free glazes, enhancing the effects of reactive glazes that must develop crystallization or variegation or firing accurately. It is easy to program: Tap the blue edit button to edit a program, tap a column of any segment to edit its value. Tap a segment number to delete or duplicate it. Search "bartlett genesis controller" on YouTube for videos on creating and editing a schedule.

A modern electric test kiln, a marvel of utility

This picture has its own page with more detail, click here to see it.

This is a ConeArt 119D, 0.57 cu ft, 11"x9" cone 10 test kiln. While there is 120v model, don't take a chance, go with 220v (actually ours is 208v). Ours fires 1000 times on a set of elements, mostly in the cone 4-7 range. The old BX controller is shown here, it is $300 cheaper, but don’t even think about getting that! Do not use your electric like a pop-up toaster, make it a technological enabler of custom firing schedules, get the Genesis GX. Having good control of firing is a key to success, and this is superior for that. These kilns are economical to fire. Big enough for 5 mugs, but I typically fire a dozen clay and glaze test specimens. We make our own super-thin shelves. The controller holds about 20 schedules, even controllable remotely (it is Wi-Fi connected). We can fire cone 04 up and down in three hours! Of course, since this type of kiln can enable so much more testing, a code numbering system is needed - and a place to record and search all the results: An account at insight-live.com.

Links

| Articles |

Electric Hobby Kilns: What You Need to Know

Electric hobby kilns are certainly not up to the quality and capability of small industrial electric kilns, being aware of the limitations and keeping them in good repair is very important. |

| Articles |

Where do I start in understanding glazes?

Break your addiction to online recipes that don't work or bottled expensive glazes that you could DIY. Learn why glazes fire as they do. Why each material is used. How to create perfect dipping and brushing properties. Even some chemistry. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy