| Monthly Tech-Tip | No tracking! No ads! |

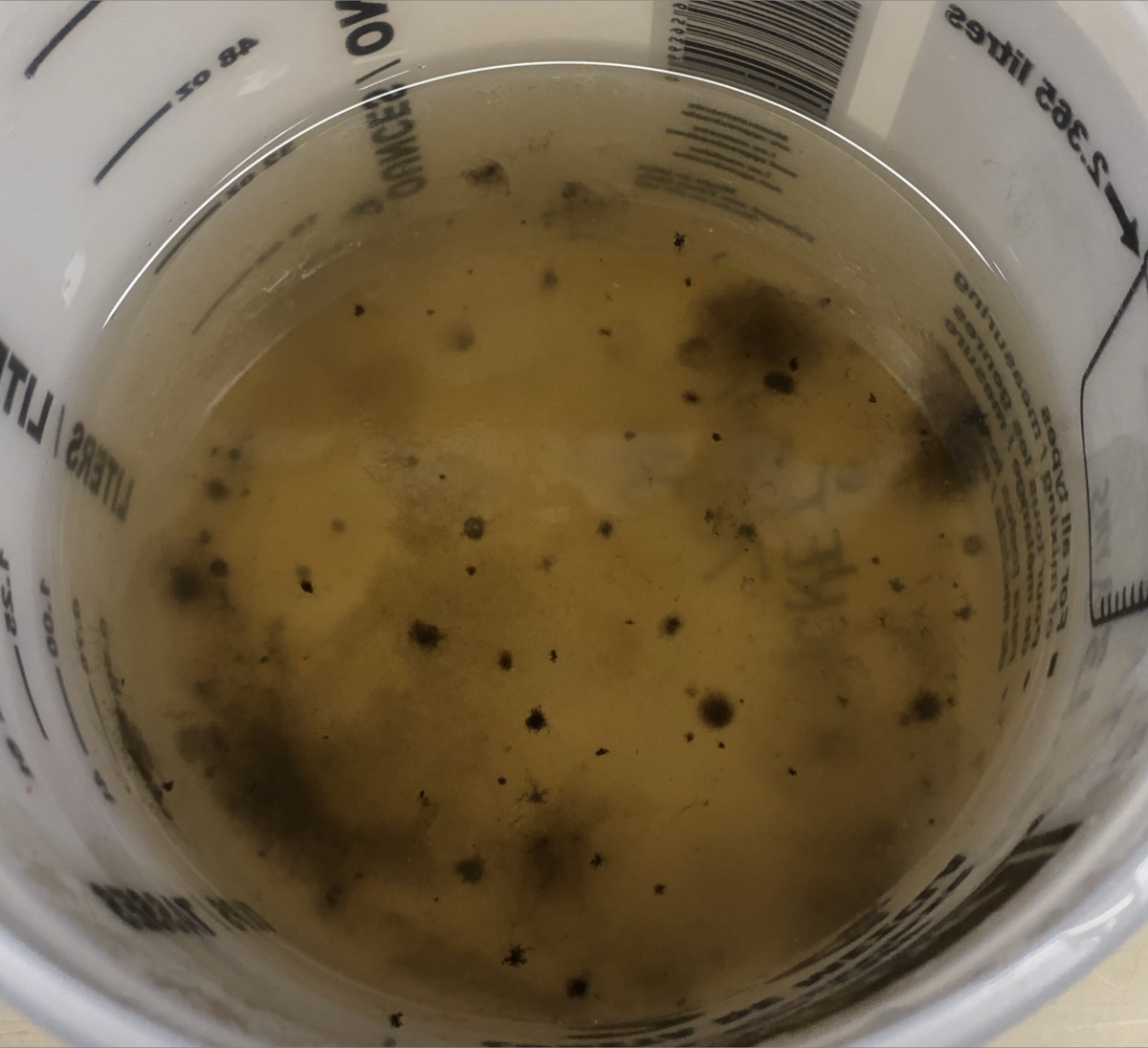

CMC gum solutions can go bad

That is why glazes containing CMC often need a biocide if they are going to be stored for extended periods. We made this one. The gallon jar of Laguna gum solution sitting next to this did not go bad, that means they have added some sort of anti-microbial agent.

Related Pictures

What should the consistency of CMC gum solution be?

This picture has its own page with more detail, click here to see it.

This is CMC gum 35g/liter gum solution after it has been thoroughly hot-mixed and cooled to about 30C. As it cools further and sits it thins. Gum solutions can have a higher CMC content, up to double this, but they are more difficult to use.

Most often, gum solution is intended to augment the water when batching a recipe - not adding to a glaze slurry. This is because adding enough to have any effect on an already-mixed glaze thins it (so an equal amount or more water should first be removed). For example, consider converting a dipping glaze to a brushing glaze: Adding the equivalent of 1.5% CMC gum powder, via this gum solution, to a gallon of glaze would also add almost a liter of water. Better to blender mix in the CMC power. CMC gum is often used in consort with a gelling agent like VeeGum, enabling more water (this is done in many commercial bottled glazes).

Videos

Links

| Glossary |

Micro Organisms

Ceramic glazes and clay bodies can host micro organisms. They can be just a nuisance, a source of worry or can render a product useless. What should you do? |

| Materials |

CMC Gum

CMC gum is indispensable for many types of ceramic glazes. It is a glue and is mainly used to slow drying and improve adhesion and dry hardness. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy