| Monthly Tech-Tip | No tracking! No ads! | |

Body is firing with less maturity. How did we fix it?

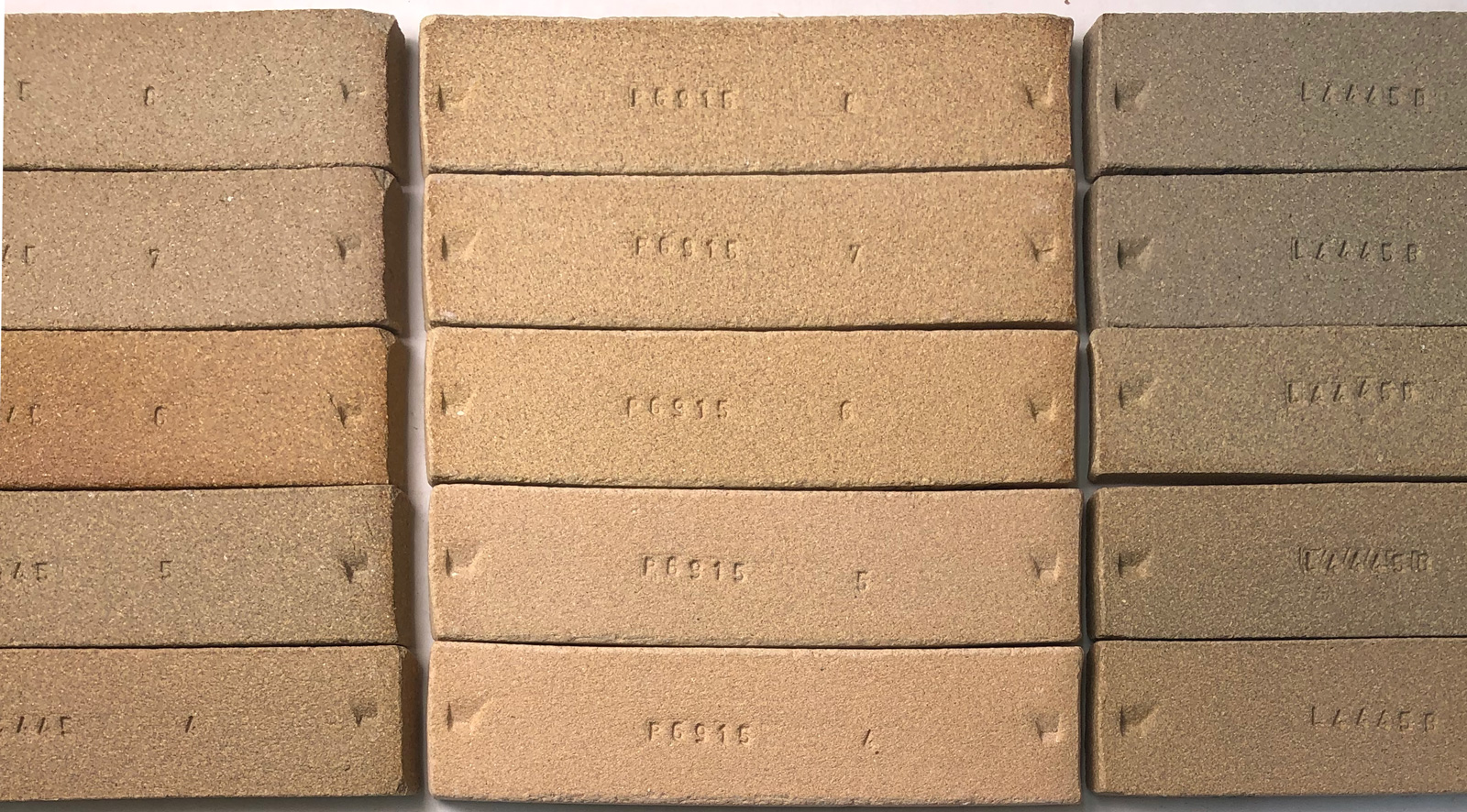

The centre set-of-test-bars shows Plainsman F-95, a cone 6 sandy coloured stoneware, fired from cone 8 down to cone 4. Because of a change in a low-fire red clay in the recipe it has become much more refractory (10%+ porosity at cone 6 instead of the normal 4-5%). We had made hundreds of boxes for a custom order (for these we are unable to exercise the same diligence in testing). Two approaches were tried make it fire more dense. For the left set-of-bars we prepared some plastic Gerstley Borate (it exhibits workability like a clay) and wedged that with the F-95 in a ratio of 5:95 (by weight). This greatly improved maturity, and color, bringing cone 6 porosity down to 6.5% (this is still too high, likely 7% would be needed). For the right set-of-bars we wedged in Plainsman L210 in a ratio of 15:85. That lowered the cone 6 porosity to 2.7%, too far (also darkening the color). So it appears that a 10:90 mix should be about right.

Videos

Links

| Glossary |

Vitrification

A process that happens in a kiln, the heat and atmosphere mature and develop the clay body until it reaches a density sufficient to impart the level of strength and durability required for the intended purpose. Most often this state is reached near zero p |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy