| Monthly Tech-Tip | No tracking! No ads! |

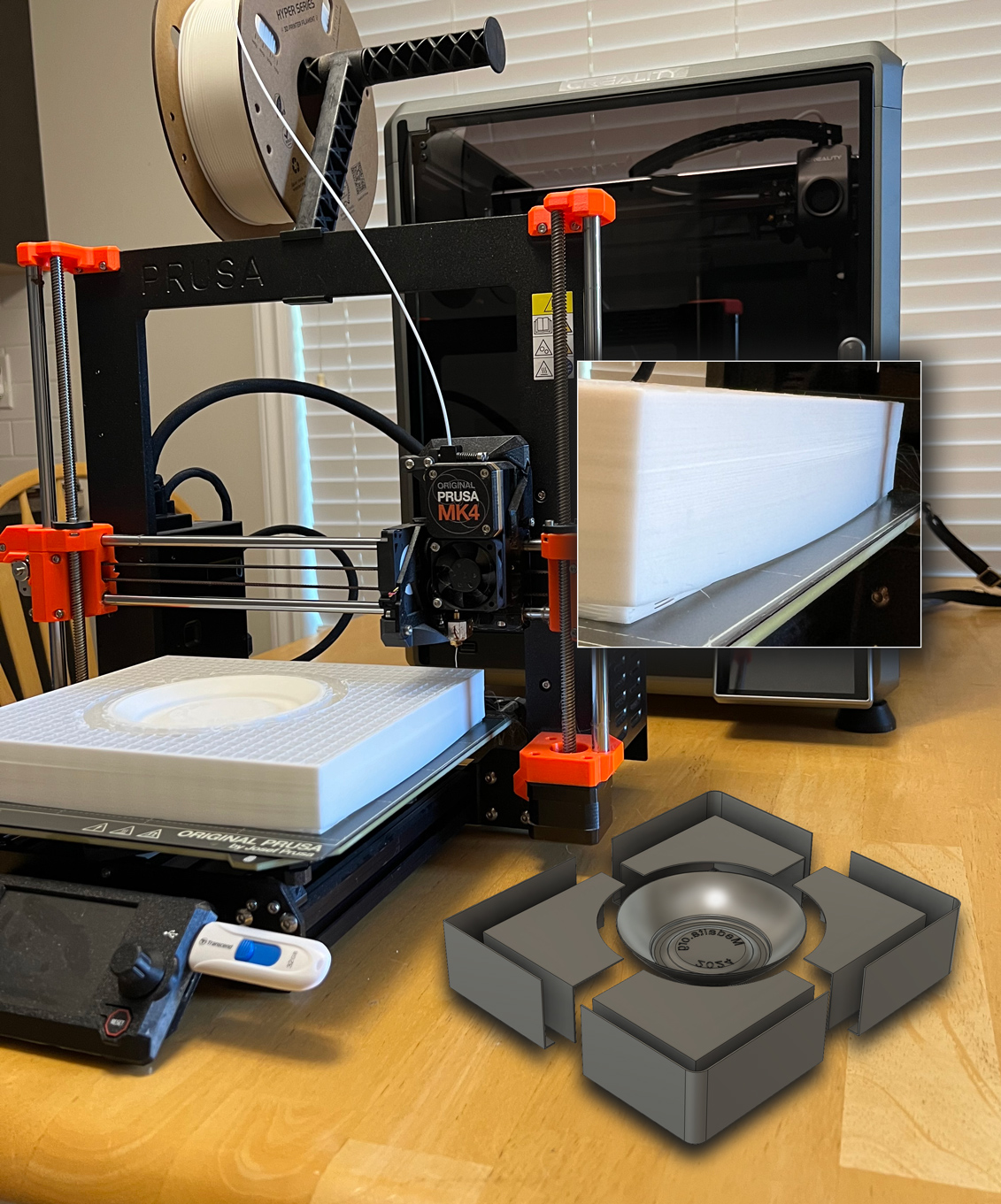

Warping of PLA under heat of plaster set

When cutting a larger object into multiple pieces it is important to have an assembly plan.

In this case I have glued at the pieces together (and filled and sanded the joins) and plan to fill the two on the left with plaster to make them rigid.

I should have 3D printed inserts to cap these ends instead. The printer can produce a very precise fit and they can be super-glued in.

Related Pictures

Warping during a large print - one solution is multiple pieces

This picture has its own page with more detail, click here to see it.

I am attempting to 3D print a shell for making a rubber block mold (the base of a Medalta ball pitcher). This is almost at the limit of what will fit on the print-bed. It would take 30 hours. But at about 10 hours it did this: All four outer corners warped upwards. I have a larger printer but it will do the same thing! What is the solution? Cut it up into smaller pieces and print each of them at the best orientation (bottom right), this saves significant printing time and achieves better quality. For this piece, the inside surface on the center section is most important, printing it upright with printed support took about 4 hours. All the other pieces print in about 1 hour each. Tape (either masking or MicroPore) can be used effectively to hold everything together for super-gluing or epoxy. Much of the tape can be left in place during the pour. The rubber form has thin 1cm walls, but these are supported by side-rails when plaster is poured.

Videos

Links

| Typecodes |

3D printing problems

3D design and printing for mold making in ceramics bring exciting new capabilities. Awareness of the issues and knowing how to mitigate each is a must. 3D is resetting all fabrication industries and engineers are solving every problem, you can too. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy