| Monthly Tech-Tip | No tracking! No ads! |

Making Your Own Heavy Duty v1 Kiln Posts

The tools and supplies needed will enable other things too

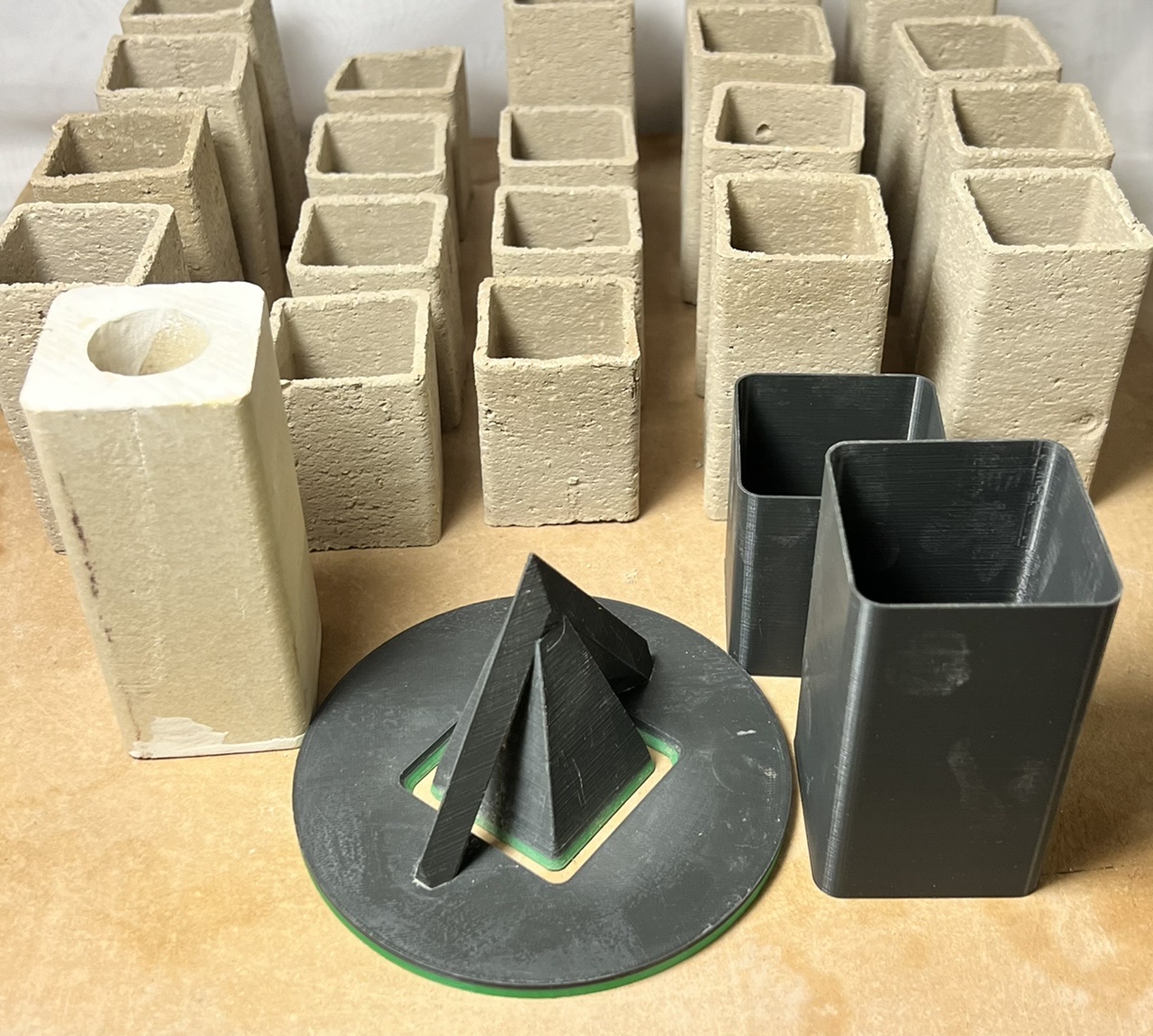

Supply chain issues during Covid made it difficult to get posts. I wondered if I could make my own. I have access to the same ceramic materials that post manufacturers use. The highest temperature we fire is cone 10. In the past, it was always a hassle to make the extruder die, but not anymore. An ordinary 3D printed PLA template will easily withstand the pressure in a hand extruder (even if printed with infill). The precision of the geometry is amazing. Notice that the floating centre has a tapered bridge to help clay knit together as it flows around it. What about a refractory plastic body? I started with L4543, it is cheap to make and dries quickly with minimal shrinkage (I slurry it up using a propeller mixer and dewater on a plaster table). To cut posts to length with a square end I print sleeves to slide them into.

Related Pictures

I Just Made These Kiln Posts Using a Hand Extruder

Get the v2 CAD drawing to do it yourself

Available on the Downloads page

This picture has its own page with more detail, click here to see it.

Shown is a hand extruder die (with a floating core). It was 3D printed in one piece using ordinary PLA. The posts weigh 23g/in (vs 81g/in for the commercial one shown). The posts were cut square-ended using the length sleves shown. Commercial regular posts will support the weight of a city bus, but we are supporting pottery - so a thinner more energy-efficient version seems appropriate. This drawing is more parametric than version 1, it enables setting the post width, wall thickness, draft of the float and position and angle of the float supports. This clay is normal pottery stiffness and contains ~20% grog and sand. We are experimenting with various refractory mixes (e.g. L4543).

Videos

Links

| Projects |

Making our own kiln posts using a hand extruder

3D printing has made really weird things possible, and this is one of them. You can make ones that are far more energy efficient that commercial versions. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy