| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Albany Slip

Alternate Names: New York Slip, Albany Clay

Description: High iron silty low melting clay

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| CaO | 5.81% | 0.48 | |

| K2O | 3.20% | 0.16 | |

| MgO | 2.71% | 0.31 | |

| Na2O | 0.80% | 0.06 | |

| TiO2 | 0.40% | 0.02 | |

| Al2O3 | 14.63% | 0.66 | |

| SiO2 | 57.82% | 4.42 | |

| Fe2O3 | 5.21% | 0.15 | |

| LOI | 9.41% | n/a | |

| Oxide Weight | 416.11 | ||

| Formula Weight | 459.33 | ||

Notes

Albany was a low plastic silty clay that was mined in Albany, New York for many decades. It melts to a glossy chocolate brown glaze at cone 8-10. It was a very popular glaze ingredient for dark colors and tenmoku and iron crystal effects. In the early 20th century it was used extensively on heavy utilitarian stoneware across North America and even on electrical insulators. Glazes could be formulated very easily using this material as a starting point since it was already balanced and had good slurry properties. Potters especially adopted this material and it appears in thousands of recipes used across North America.

There are a number of substitutes for Albany and anyone with ceramic chemistry calculation software can easily speculate on a mix of materials that matches the chemistry on paper. However keep in mind that judging the similarity to Albany is a complex issue of mineralogy, physical properties and chemistry and it depends on the reliability of the information at hand on what Albany actually was.

Related Information

This picture has its own page with more detail, click here to see it.

Lithium, albany glaze at cone 5 using original albany slip

Melt fluidity of Albany Slip vs. Alberta Slip at cone 10R

This picture has its own page with more detail, click here to see it.

This is a GLFL test, it employs a slipcast melt flow tester to show the flow patterns of two glazes (or materials), side-by-side. Albany Slip was a pure mined silty clay that, by itself, melted to a glossy dark brown glaze at cone 10R. By itself it was a Tenmoku glaze at high temperatures. Alberta Slip is a recipe of mined clays with added refined minerals that give it a similar chemistry, firing behavior and raw physical appearance. As you can see, the melt fluidity is very similar.

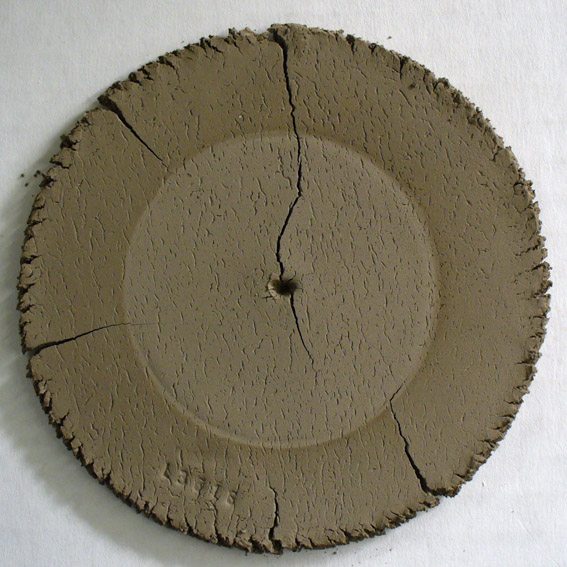

Albany Slip DFAC dried disk

This picture has its own page with more detail, click here to see it.

This shows the soluble salts in the material and the characteristic cracking pattern of a DFAC test disk when made from a low plasticity clay. Notice the edges have peeled badly during cutting, this is characteristic of very low plasticity clays.

90:10 Albany:Frit and Alberta:Frit comparison

This picture has its own page with more detail, click here to see it.

These are three runs of Alberta Slip being compared with the original Albany Slip. These are ten-gram GBMF test balls fired on porcelain tiles at cone 6. This test shows how the material flows, how much gases of decomposition it generates and how well it allows them to escape. As you can see, they are very similar in melting behavior.

Melt fluidity and coverage: RedArt Slip vs. Albany Slip vs. Alberta Slip

This picture has its own page with more detail, click here to see it.

These three melt flows and mugs were fired at cone 6 (using the C6DHSC firing schedule). The benchmark recipe is 80% clay and 20% Ferro Frit 3195 (our standard GA6-B recipe).

-The center melt flow (and matching buff stoneware mug below) employ the original Albany Slip.

-The one on the right employs Alberta Slip. Notice that, although having a very similar melt flow, it needs an iron oxide addition to darken the color (e.g. 2%).

-The one on the far left uses an Albany Slip substitute made from 80% Redart, 6.5% calcium carbonate, 6.5% dolomite and 6.5% nepheline syenite (our code L3613D). The chemistry of RedArt is different enough from Albany that some compromises were needed to avoid over-supplying the iron even more (and firing darker yet). Although this Redart version runs in a very similar pattern on the melt flow, the character of the glaze on the mug reveals it needs a little more melting (increasing the frit percentage would take care of that).

Alberta Slip GA6-B base darkened with iron oxide

This picture has its own page with more detail, click here to see it.

Fired to cone 6 using the C6DHSC schedule. Top: GA6-B. This recipe is 80% Alberta slip and 20% Ferro Frit 3195 (we used to use frit 3134 but have found frit 3195 works much better). Bottom: We added 1, 2, 3 and 4% iron oxide. At about 2%, the color matches the rich reddish effect you would get if you used an 80:20 Albany:3195 recipe (without an iron addition). An added benefit is that the iron acts as a fining agent to remove micro-bubbles to achieve better transparency.

Gunmetal black mug demos liner glazing:

Safe glaze inside, pigmented matte outside.

This picture has its own page with more detail, click here to see it.

The outside glaze is G2934Y cone 6 black. I use the C6DHSC slow cool firing schedule to get this degree of matteness in the black. The body is the natural MNP (Mother Nature's Porcelain), it vitrifies to zero porosity around cone 4 (yet is stable to cone 8). At cone 6 it produces incredibly strong ware and works well with these two glazes. The inside liner glaze is GA6-B (made using real Albany Slip rather than Alberta Slip in this case). Although the melt characteristics of these two glazes are so different they can be applied to meet in a perfect line at the rims of pieces. Food safety labelling is not what you think it is - do liner glazing to be safe.

Here is why Albany Slip was hard to use: Crawling

This picture has its own page with more detail, click here to see it.

This glaze is 85% Albany Slip and 20% Ferro Frit 3195. These bisque tiles were dipped in a brushing glaze version of it (just water and powder). The glaze is applied quite thin on the front tile and thicker on the back one. The material gelled slurries and required a lot of water to make them thin enough to use. For assured success, this or any glaze that had a high percentage required mixing the raw Albany Slip with a calcined Albany Slip (which people had to make on their own).

A classic Albany glaze that often shivers

This picture has its own page with more detail, click here to see it.

These mugs have experienced very serious shivering. This is an Albany Slip glaze with 10% lithium carbonate, it is known to have a very low thermal expansion. This problem can be solved by reducing the amount of lithium or adding high-expansion sodium or potassium. However these fixes will likely affect the appearance.

Melt fluidity of Albany Slip vs. Arroyo Slip at cone 10R

This picture has its own page with more detail, click here to see it.

Amaco achieves the stunning look of PC-32 Albany Brown glaze using lithium

This picture has its own page with more detail, click here to see it.

Left is G3933A, an Alberta Slip based glaze. Right is Amaco PC-32, Albany Slip Brown. They are likely using a similar base recipe, but the difference is added lithium carbonate to supercharge the melting. That converts it to a type of reactive glaze (one that changes its appearance with differing thicknesses). Where thick in the recesses it crystallizes to a much lighter color. On contours, it runs thinner amplifying the brown body color. The use of lithium explains why PC-32 is more expensive. Lithium prices are rising so fast it may not continue to be practical for manufacturers to continue making some lithium glazes (hopefully this one is safe since the percentage is relatively low).

Links

| URLs |

http://www.sheffield-pottery.com/Albany_Slip_Substitute_and_Sheffield_Slip_s/189.htm

Sheffield Slip substitute |

| URLs |

http://albertaslip.com

AlbertaSlip.com |

| URLs |

http://albanyslip.com

AlbanySlip.com |

| Materials |

Jasper Slip

|

| Materials |

Barnard Slip

|

| Materials |

SG-328

|

| Materials |

Ohio Slip

|

| Materials |

Arroyo Slip

|

| Materials |

Sheffield Slip

|

| Materials |

Alberta Slip

Albany Slip successor - a plastic clay that melts to dark brown glossy at cone 10R, with a frit addition it can also host a wide range of glazes at cone 6. |

| Materials |

Ravenscrag Slip

A light-colored silty clay that melts to a clear glaze at cone 10R, with a frit addition it creates a good base for a wide range of cone 6 glazes. |

| Materials |

Odenwalder Clay

|

| Materials |

Fremington Clay

|

| Typecodes |

Clay Other

Clays that are not kaolins, ball clays or bentonites. For example, stoneware clays are mixtures of all of the above plus quartz, feldspar, mica and other minerals. There are also many clays that have high plasticity like bentonite but are much different mineralogically. |

| Recipes |

GA10x-A - Alberta Slip Base for cone 10 oxidation

Alberta Slip creates a glossy transparent brown at cone 10 with the simple addition of 10% frit. |

| Recipes |

GA10-A - Alberta Slip Base Cone 10R

Alberta Slip at 60:40 calcine:raw makes a great tenmoku-like glaze at cone 10R |

Data

| Sieve Analysis Wet | on 60 mesh: 0 on 120 mesh: 1.0% on 200 mesh: 5% |

|---|---|

| Frit Softening Point | 1170C |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy