| Monthly Tech-Tip | No tracking! No ads! | |

Getting accurate firings in our test kilns time after time.

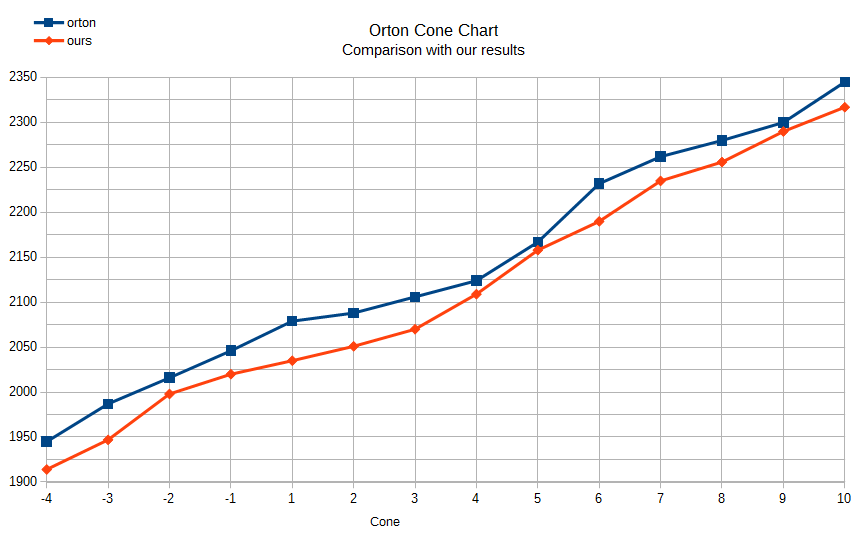

The blue line on this graph is from the Orton cone chart for 108F/hr. But those are not the target temperatures for our test kiln cone firings. We use the red line to program the controller for each cone. Where is that red line from? We made it. The self-supporting cones we put in every firing verify it, time after time, for thousands of firings. Only fine-tuning is needed to adjust the top temperature if a cone so indicates. This happens as elements degrade or when they are replaced. Should you use that red line? No. Use self-supporting cones to establish your target temperatures and make your own line.

Related Pictures

At what point is a self-supporting cone bent to the correct degree?

This picture has its own page with more detail, click here to see it.

Orton says “90 angular degrees is considered the endpoint of cone bending”. First, let's assume the normal: Examination of cones on kiln-opening to verify controller operation. Consider the cone on the left: The tip is touching. But it is also beginning to buckle, which means it was touching for a while before the firing ended. Who knows how long! The second one is not touching but has still fallen a little too far. Why do we say that? The third one, positioned on the Orton guide, has reached the recommended 90 degrees. This demonstrates a good reason why self-supporting cones are much better than standard ones: They are not touching when considered done. And standard cones, when set in a 3/4" plaque, have a less consistent bending behaviour.

Cones bending theoretically, cones bending actually

This picture has its own page with more detail, click here to see it.

Orton cones have become much less relevant in recent years. That being said they are still commonly used to calibrate kiln controllers. Most people just use one cone now (rather than the guard, firing and guide cones of the past). The problem illustrated in this diagram is our reason for doing that. At our typical firing rates, we found that bending the middle cone to 5 o'clock pretty well always started the guard cone. Orton said when that happens "you have exceeded the best time-temperature relationship". Thus, over time, we got into the habit of bending the firing cone to 3 o'clock (as shown in #1). Notice the situation in #2, that is not supposed to happen but often does. The first guide cone should be slumping, not just touching. And the guard cone should not be starting. Now we just use one cone bent to 5 o'clock to callibrate our electronic controllers.

Cones bending badly, cones bending goodly

This picture has its own page with more detail, click here to see it.

Ware is not turning out as expected and a potter needs to verify the temperature in the kiln. The standard cones on the upper right are misleading. The cone 7 is telling one story but the cone 6 and 5 another. On the lower right is a better way: Self supporting cones. They are always at the right angle and this set of three is bending as expected. To be a full cone 6 the middle one needs to bend just a little more until the tip is even with the top of the base (maybe 2 or 3 degrees). On the top set, the cone 6 is clearly totally flattened and the 5 is a pool of glass, this firing went way beyond cone 6.

Old-style hobby kilns with a sitter are usable if you become "the controller"!

This picture has its own page with more detail, click here to see it.

Yes. This kiln has a Dawson LT-3 kiln sitter (new ones have electronic controllers). It is a mechanical device with a safety timer and triggered latch on the external housing. A ceramic tube extends into the chamber where a pyrometric cone sits on supports with a rod on the top center. As the cone softens and bends the rod drops with it and eventually releases the shut-off latch. The utility of this depends on careful placement of the cone, sitter adjustment and keeping the rods and supports in good condition. Although not shown, these kilns had a pyrometer and one or more thermocouples (temperature gauge and heat sensing probes). Is a kiln like this useable today? Yes - if you become "the controller"! Learning to use a kiln like this involves monitoring cones on each shelf (self-supporting cones are recommended). By "babysitting" the switch settings (low, medium, high) during firings and creating paper logs (and graphs) to track the kiln's temperature against time over multiple firings you can evolve a schedule of switch-setting, from low-to-medium-to-high. It is possible to get the desired climb, even heat distribution, achieve the final temperature accurately and even implement drop-and-hold and slow cool firings. Vigilance of changes in the firing speed can be balanced by adjustments to the switch-change times.

Videos

Links

| Tests |

Shrinkage/Absorption Test

SHAB Shrinkage and absorption test procedure for plastic clay bodies and materials |

| Glossary |

Pyrometric Cone

Cones are ceramic and bend through a narrow temperature range. They used to be actively used to determine when firings were completed but now are used to calibrate electronic devices. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy