| Monthly Tech-Tip | No tracking! No ads! |

Old-style hobby kilns with a sitter are usable if you become "the controller"!

Yes. This kiln has a Dawson LT-3 kiln sitter (new ones have electronic controllers). It is a mechanical device with a safety timer and triggered latch on the external housing. A ceramic tube extends into the chamber where a pyrometric cone sits on supports with a rod on the top center. As the cone softens and bends the rod drops with it and eventually releases the shut-off latch. The utility of this depends on careful placement of the cone, sitter adjustment and keeping the rods and supports in good condition. Although not shown, these kilns had a pyrometer and one or more thermocouples (temperature gauge and heat sensing probes). Is a kiln like this useable today? Yes - if you become "the controller"! Learning to use a kiln like this involves monitoring cones on each shelf (self-supporting cones are recommended). By "babysitting" the switch settings (low, medium, high) during firings and creating paper logs (and graphs) to track the kiln's temperature against time over multiple firings you can evolve a schedule of switch-setting, from low-to-medium-to-high. It is possible to get the desired climb, even heat distribution, achieve the final temperature accurately and even implement drop-and-hold and slow cool firings. Vigilance of changes in the firing speed can be balanced by adjustments to the switch-change times.

Related Pictures

Do these kiln elements need replacing?

This picture has its own page with more detail, click here to see it.

This 12 inch test kiln has done 910 firings. The element loops are laying down and nearly touching each other. If they are not changed soon the coils will touch the kiln will have hot spots. And the coils are expanding and getting tighter in the grooves, the longer we wait the more the grooves will be damaged when removing them. Although elements seem expensive, when costed on a per/firing basis they can be surprisingly inexpensive. Most hobby kilns service two elements with each relay and relays generally need to be replaced more often than elements. Consider, for example, replacing the elements on a Skutt 818. Being a smaller kiln it is well-powered in relation to size and elements can last up to 1000 firings (assuming 50:50 bisque and cone 6 firings). It has 4 elements and 2 relays (relays cost $65/ea, elements $95 each). The labor to replace is ~4 hours or $250 - total cost is about $750 (that is ~75¢ per firing or 32¢ per ft³). How about a larger kiln? An 8 ft³ Model 1222 has 5 elements and 3 relays and replacement is ~$1100. But its elements are only likely to last 200 firings. That yields a per firing cost of ~$5 and per ft³ of 65¢. But there is a much greater cost to consider: Old elements increase power consumption. An 818 uses 6.4 kwH and a 1222 uses 11.5 kwH - at our electricity cost of 14¢/kwH a firing costs ~$7 for the small kiln and ~$13 for the large one. But that is the cost when elements are new. When they need changing those numbers can more than double! An additional cost of old elements is ware consistency, the kiln cannot execute the firing schedule in the time programmed and this will likely affect the appearance of bodies and glazes.

Getting accurate firings in our test kilns time after time.

This picture has its own page with more detail, click here to see it.

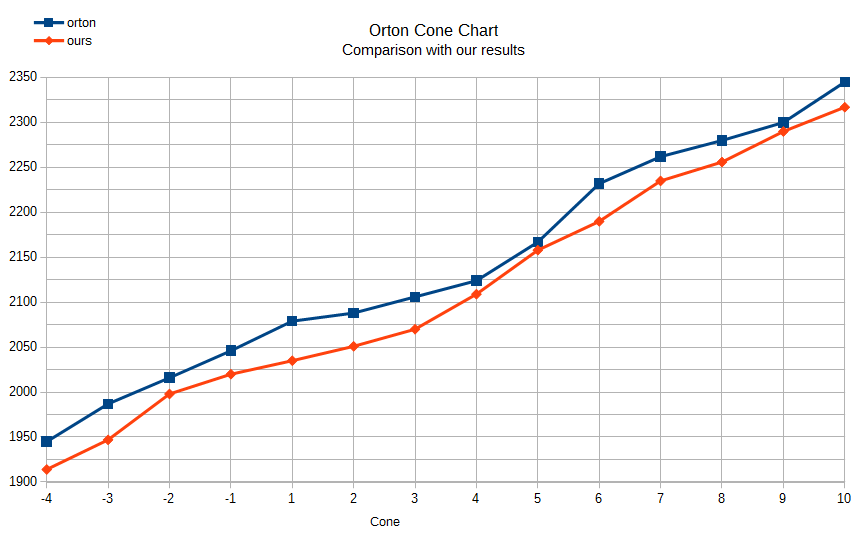

The blue line on this graph is from the Orton cone chart for 108F/hr. But those are not the target temperatures for our test kiln cone firings. We use the red line to program the controller for each cone. Where is that red line from? We made it. The self-supporting cones we put in every firing verify it, time after time, for thousands of firings. Only fine-tuning is needed to adjust the top temperature if a cone so indicates. This happens as elements degrade or when they are replaced. Should you use that red line? No. Use self-supporting cones to establish your target temperatures and make your own line.

Videos

Links

| URLs |

http://www.fireright.com/knowledgebase.html

FireRight.com - Resources to fire kilns This page has links to PDF files on kiln sitters (e.g. the Dawson LT-3). |

| URLs |

https://www.ortonceramic.com/autofire-slide

Orton Autofire AF Slide Standalone Kiln Controller The AutoFire Slide controller is a standalone variable PID temperature controller for any electric kiln. It has a user friendly touchscreen interface like the Barlett Genesis. It accepts Type K, N, S and R thermocouple inputs for operation up to 3308F. |

| Firing Schedules |

Cone 6 Drop-and-Soak Firing Schedule

350F/hr to 2100F, 108/hr to 2200, hold 10 minutes, freefall to 2100, hold 30 minutes, free fall |

| Glossary |

Kiln Controller

In ceramic kilns the firing schedule is typically managed automatically by an electronic controller. But that may not mean that ware gets automatically fired to the correct temperature and atmosphere. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy