| Monthly Tech-Tip | No tracking! No ads! | |

Why use a frit to source KNaO at cone 10R?

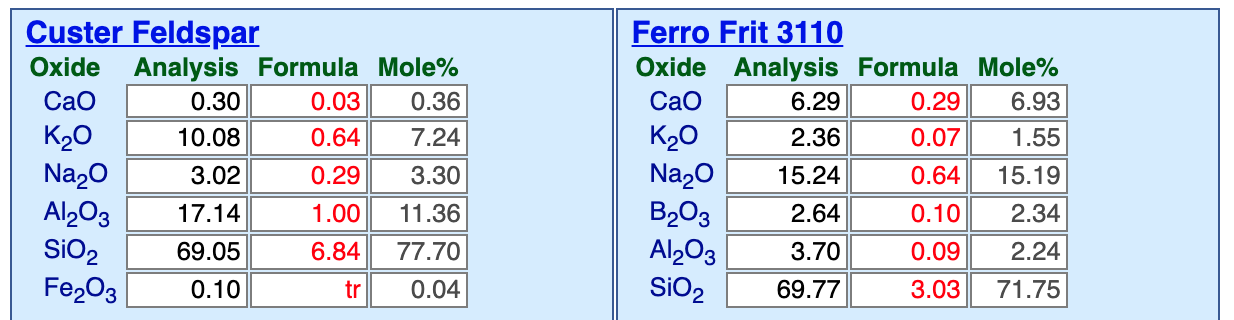

Here are side-by-side materials panels, in my Insight-live account, comparing Custer feldspar and Ferro Frit 3110. KNaO is not available as a pure raw material, ones that supply them, like these, also bring along other oxides (which, fortunately, are almost always needed anyway). Consider the advantages of Ferro Frit 3110 (other brands have a product of similar chemistry). The frit brings along some CaO, which means less calcium carbonate or dolomite are needed, and in the frit the CaO much more readily enters the melt. There is more KNaO in the frit, per gram, than feldspar. The frit has low Al2O3, which means alumina can be supplied by clay, imparting needed suspension and dry hardness. And, when clay supplies the alumina, it can be sourced as a mix of calcined-and-raw to tightly control working properties. The frit has a little boron, that gives it a kick to start melting earlier and impart better melt fluidity. Most of all, because it has been premelted, the frit will produce a much more fluid glass, helping to dissolve the quartz particles better. And, it will give better gloss and better reactions with matting agents. The calculation process of removing the feldspar and inserting the frit in its place is a good demonstration of the value of glaze chemistry.

Videos

Links

| Oxides | KNaO - Potassium/Sodium Oxides |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy