| Monthly Tech-Tip | No tracking! No ads! | |

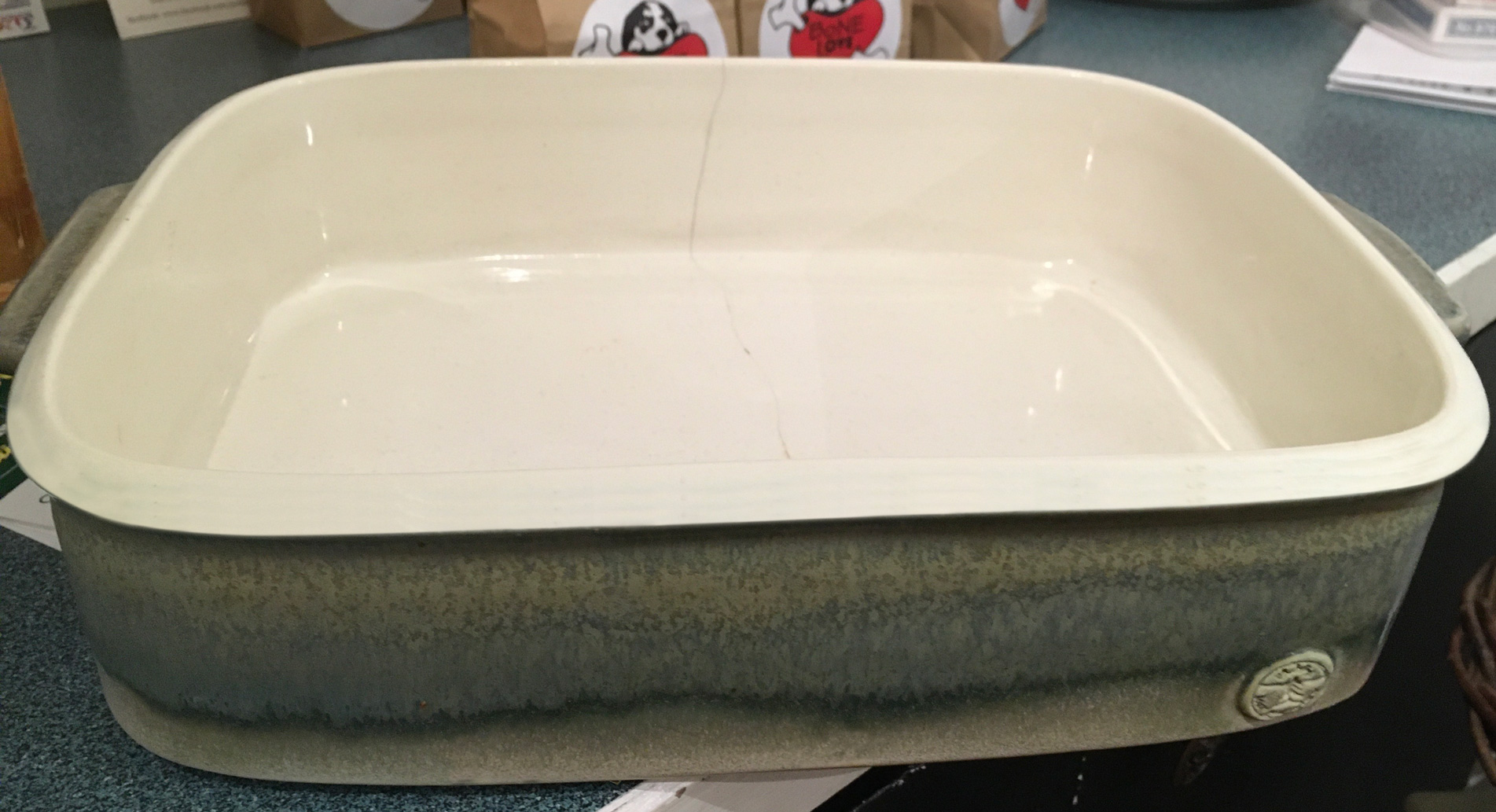

An example of dunting on a low, flat casserole shape

The firing crack from the rim down has released the stresses produced by uneven thermal contraction during cool-down in the kiln. Any factor that contributes to a temperature gradient within a piece will contribute to the likelihood of dunting. Cooling too quickly through quartz inversion, for example, can cause this in almost any piece. Pieces that are thick and heavy, or have uneven cross section (with thick foot and thin walls, for example) will certainly suffer gradients, even in slow cooling. A wide, flat bottom (that is heat-sunk by the a heavy shelf) will also increase the temperature gradient between the outer walls and the inner foot. If that wide piece has vertical walls that get direct radiant heat, especially if one part is more exposed to the elements, it will start a gradient during the up-ramp in the firing. And, on the down-ramp, it will "come back to bite you" with a crack.

Videos

Links

| Troubles |

Dunting and Cracking of Clay Bodies During Firing

Ceramic industry can fire much faster and deal with much heavier objects than potters can, how do they do it. The answer is they pay more attention to the basics, it is all common sense and good equipment. |

| Glossary |

Quartz Inversion

In ceramics, this refers to the sudden volume change in crystalline quartz particles experience as they pass up and down a temperature window centering on 573C. |

| Glossary |

Dunting

Dunting generally refers to firing cracks that occur in ceramic ware as it is cooled in the kiln. The reason is generally uneven cross section or too rapid cooling. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy