| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

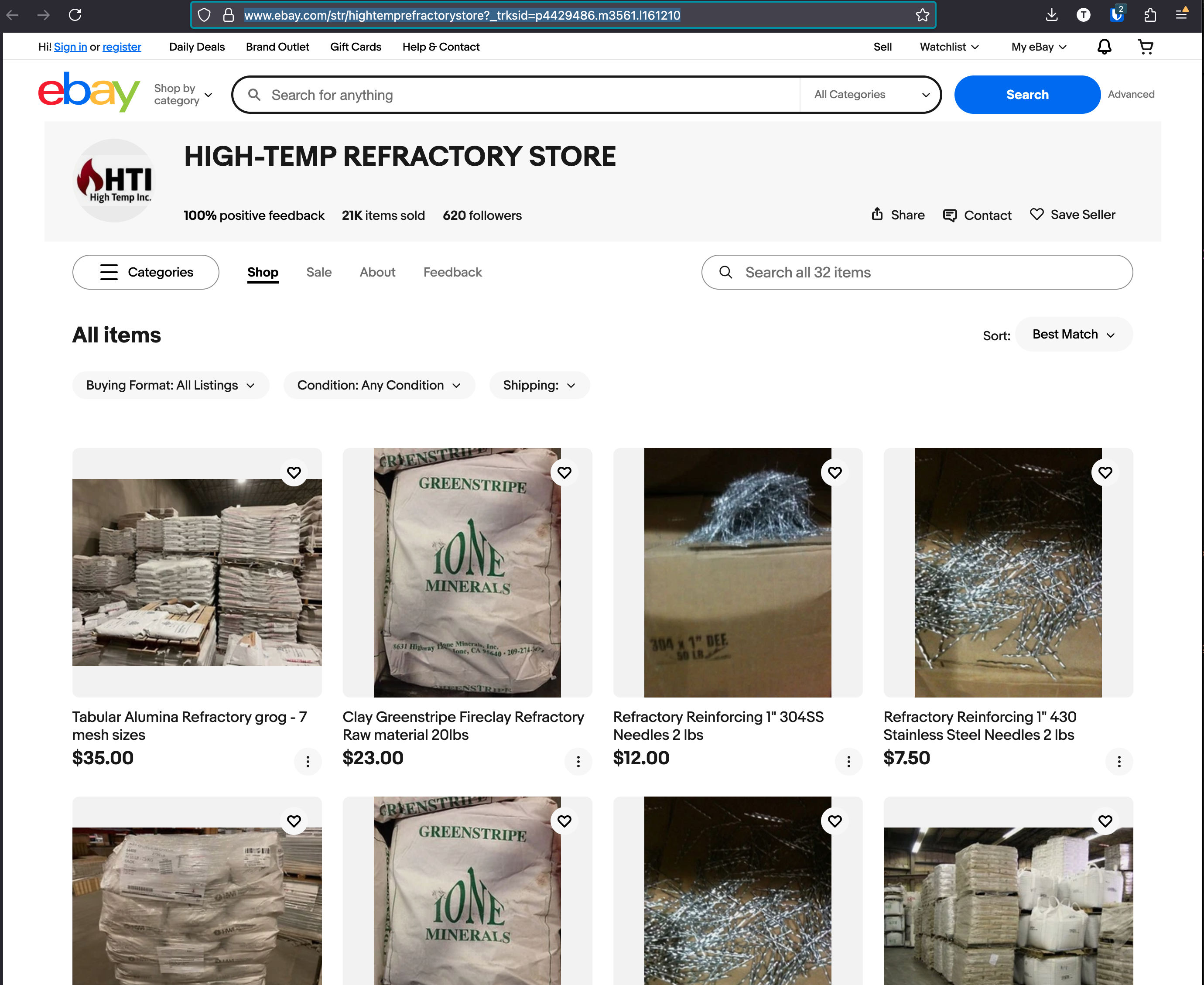

URL: How to make lightweight ceramic refractories - The answer is on a chatbot and ebay.com.

Click the link below to go to this page

https://www.ebay.com/str/hightemprefractorystore?_trksid=p4429486.m3561.l161210

Here is an example of the chatbot output. There is much useful info here, just apply some common sense.

There are a few proven ways to make lightweight alumina refractories (insulating firebricks, castables, boards, and linings) for high-temperature furnaces. Below I’ll give you the principles, tradeoffs, a couple of concrete workshop recipes (one insulating castable, one fiber board / lightweight block), step-by-step processing, expected properties, and safety notes so you can choose a route that fits your furnace temperature and mechanical needs.

Quick overview — design choices & tradeoffs

What “lightweight” means: lower bulk density (≈0.3–1.6 g/cm³) vs dense refractories (2.4–3.9 g/cm³). Lower density → much lower thermal conductivity and heat stored, but reduced mechanical strength, abrasion resistance, and sometimes chemical resistance.

Max service temperature: depends on alumina source and binder. For service ≲1400–1500°C you can use calcium-aluminate cements or phosphate binders; for 1500–1750°C you need high-alumina aggregates (tabular/fused alumina) and binders that don’t soften (or rely on ceramic bonding after high temp).

Lightweighting strategies:

add ceramic hollow spheres / alumina bubbles (preformed, good high-temp performance),

use organic sacrificial pore formers (EPS beads, starch, sawdust) and burn them out, leaving porosity,

use expanded natural minerals (perlite, vermiculite) — lower cost but lower max temp,

use ceramic fiber (Al₂O₃–SiO₂ blankets / fibers) or fiber reinforcement for boards,

produce foamed castables (gas-forming chemical foaming agents or mechanical foaming / gelcasting).

Binders: phosphate (acidic) binders, calcium aluminate cement (CAC), or refractory colloidal silica/sols. Choice affects setting, strength, and max temp. For highest temps use fusion of alumina aggregates and minimal low-melting binders.

Recipe A — Insulating alumina castable (workshop scale)

Good for furnace linings up to ~1500°C (adjustable). Uses alumina bubbles for low density.

Typical properties target: bulk density ≈ 0.6–1.2 g/cm³, thermal conductivity low, compressive strength moderate.

Ingredients (by weight, example batch ~10 kg solids):

Tabular/fused alumina coarse (T-64 / 90 µm–1 mm) — 3.5 kg

Reactive alumina (fine, <10 µm) — 1.0 kg

Alumina bubbles (hollow ceramic spheres, 0.2–1.0 mm) — 3.0 kg

Calcined kaolin or mullite fines (optional, improve thermal shock) — 0.5 kg

Phosphate binder (monoaluminum phosphate solution or a commercial refractory phosphate binder) — quantity to give ~6–8 wt% P₂O₅ equivalent in solids (follow supplier directions)

Water — as needed for castable consistency (~0.12–0.18 water/solids ratio)

Optional additives: deflocculant (sodium polyacrylate) small ppm, air entrainer or foam stabilizer if foaming, fiber (short alumina or ceramic fiber, 0.5–1.0 wt%) for crack control

Process:

Dry mix the solids (tabular alumina, reactive alumina, mullite) thoroughly. Keep alumina bubbles separate until after dry mix to avoid crushing them.

Prepare binder: if using monoaluminum phosphate, dilute to recommended concentration. If using CAC, slurry according to vendor.

Wet mix the dry solids with most of the water and deflocculant in a low-speed mixer. Add binder gradually.

Fold in alumina bubbles gently to avoid breakage (slow paddle, minimal shear). Add fibers last.

Cast into molds or trowel into the form. Vibrate lightly to remove large trapped air — but don’t over-vibrate (bubbles crushed).

Cure at ambient (or in humid curing box) per binder chemistry (phosphate bonds often set in hours; CAC needs moist curing 24–48 h).

Dry slowly: raise temp gradually to 100–150°C over 24–48 h to avoid steam blowouts.

Heat-treatment / burn-out organics (if any) at 400–600°C to remove binders/foam residues.

Bring to service: ramp to service temp gradually (e.g., 50–100°C/h up to 600°C, then adapt). Some systems get increased strength after thermal exposure as binders react/sinter.

Notes: For higher service temperature replace phosphate/CAC binder with colloidal silica and rely on sintering of reactive alumina (requires higher temp or prolonged firing). Alumina bubbles are costly but give best high-temp insulating performance and retain shape at high temperatures.

Recipe B — Lightweight alumina fiber board / block (good insulation up to 1400–1600°C)

Manufacture using refractory ceramic fibers (RCF) or Al₂O₃–SiO₂ fibers and a ceramic binder to make cuttable blanket/board.

Ingredients (by volume / practical approach):

Refractory ceramic fiber blanket (chopped to short fibers) or bulk Al₂O₃-SiO₂ fiber (50–80 wt%Al₂O₃ as required) — base insulation

Hollow ceramic microspheres (optional) or perlite for extra porosity

Colloidal silica (30–40 wt% solids) as binder (or sodium silicate) — small amount

Small amount of high-alumina fines to improve surface wear

Process (vacuum forming / filtration):

Make a slurry of chopped fibers + hollow spheres + fines in water with colloidal silica. Use deflocculant to keep slurry fluid.

Vacuum-form onto a porous mold or use a screen mold (like paper making) to get board thickness.

Press lightly, then gel/cure the binder (heat or pH change).

Dry slowly and cure binder (colloidal silica sets on drying/heating).

Final heat treat to binder cure temperature (400–800°C depending on binder). For long-term use at >1400°C choose fibers and binders rated for that temp (some organic binders will burn out).

Result: flexible or rigid board with very low density (0.1–0.8 g/cm³) and very low thermal conductivity, excellent for kilns as backup insulation but mechanically fragile.

Alternate / low-cost approaches

Expanded perlite / vermiculite + high-alumina binder: cheap and easy but max temp reduced (~1200–1300°C typical).

EPS or starch sacrificial pore former: mix polymer beads into mix, cast, then burn beads out — creates lots of porosity but must control pore size and avoid collapse during drying/firing.

Foamed castables: chemically foam the slurry (hydrogen evolution, surfactants) for very low density; requires careful control and stabilizers.

Processing & firing schedules (typical guidance)

Drying: slow. 20–24 h at 60–100°C, increasing slowly to avoid cracks.

Organics burnout: hold at 300–500°C to remove organics. Ramp rate 50°C/h or slower if thick sections.

First high-temp exposure / sinter: for phosphate/CAC systems you may not need full sinter; otherwise consider a 1200–1600°C soak if using reactive alumina to densify bonding (but this reduces porosity/insulation).

Ramp rates: controlled—avoid >200°C/h through critical ranges where bound water evolves (100–600°C). For thick/large items slow to prevent internal cracking.

Expected properties & numbers (approximate)

Low-density insulating castable with alumina bubbles: density 0.6–1.3 g/cm³, thermal conductivity 0.2–0.8 W/m·K (depending on temp), compressive strength 2–20 MPa. Service temp up to ~1500°C if components are high-alumina.

Fiber boards: density 0.1–0.8 g/cm³, very low conductivity 0.05–0.4 W/m·K, low strength, service temp depends on fiber chemistry (1400–1600°C common).

(These are ballpark figures — exact values depend on formulation and porosity.)

Practical tips & troubleshooting

Protect hollow spheres: handle gently; they’re fragile — add them late and stir minimally.

Avoid steam blowouts: dry slowly and vent molds; excess water in thick sections causes spalling.

Watch binder choice: phosphate binders set fast and give good green strength; CAC needs moist cure. For very high temp, minimize volatile/low-melting phases.

Thermal shock resistance: add fibers or small amounts of mullite aggregates to improve.

Quality control: cut small test specimens and measure bulk density, cold-crush strength, and do a first heat cycle to check for cracking or collapse.

Safety

Dust control: alumina and reactive alumina are very fine powders — use NIOSH P2/P3 or N95+ respirator, local exhaust ventilation, dust containment.

Binders: some phosphate solutions are acidic — handle with gloves/eye protection. CAC dust is alkaline; handle accordingly.

Burnout fumes: burning organics (EPS, binders) can release hazardous vapors — ensure proper ventilation or use a controlled kiln with venting.

High-temp hazards: standard kiln/furnace safety — hot surfaces, insulation handling precautions.

Final notes & suggestions

If you need a specific target (service temp, desired density, geometry, mechanical load), tell me that and I’ll give a tighter recipe and precise binder choices and firing schedule.

Sourcing: alumina bubbles and tabular alumina are specialty materials — prices vary; ceramic fiber and colloidal silica are more widely available.

Small-scale testing: always make small test blocks (vary bubble content 10–40 vol%) to find the density/strength balance that works for your furnace.

Related Information

Micro-fine Alumina powder on ebay.com

The secret to amazing refractories

This picture has its own page with more detail, click here to see it.

Links

| Glossary |

Refractory

In the ceramic industry, refractory materials are those that can withstand a high temperature without deforming or melting. Refractories are used to build and furnish kilns. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy