| Monthly Tech-Tip | No tracking! No ads! |

URL: Wikipedia page about flip-top, swing-top, bail-latch stoppers that employ a wire mechanism and seal for closure of bottles and jars.

Click the link below to go to this page

https://en.wikipedia.org/wiki/Flip-top

The mouth of the bottle is sealed by a stopper, usually made of porcelain or plastic, fitted with a rubber gasket and held in place by a permanently attached wire bail. The bottle can be opened and resealed repeatedly without the use of a bottle opener. The flip-top was the dominant method of sealing beer and mineral water bottles prior to the invention of the crown cork.

Related Information

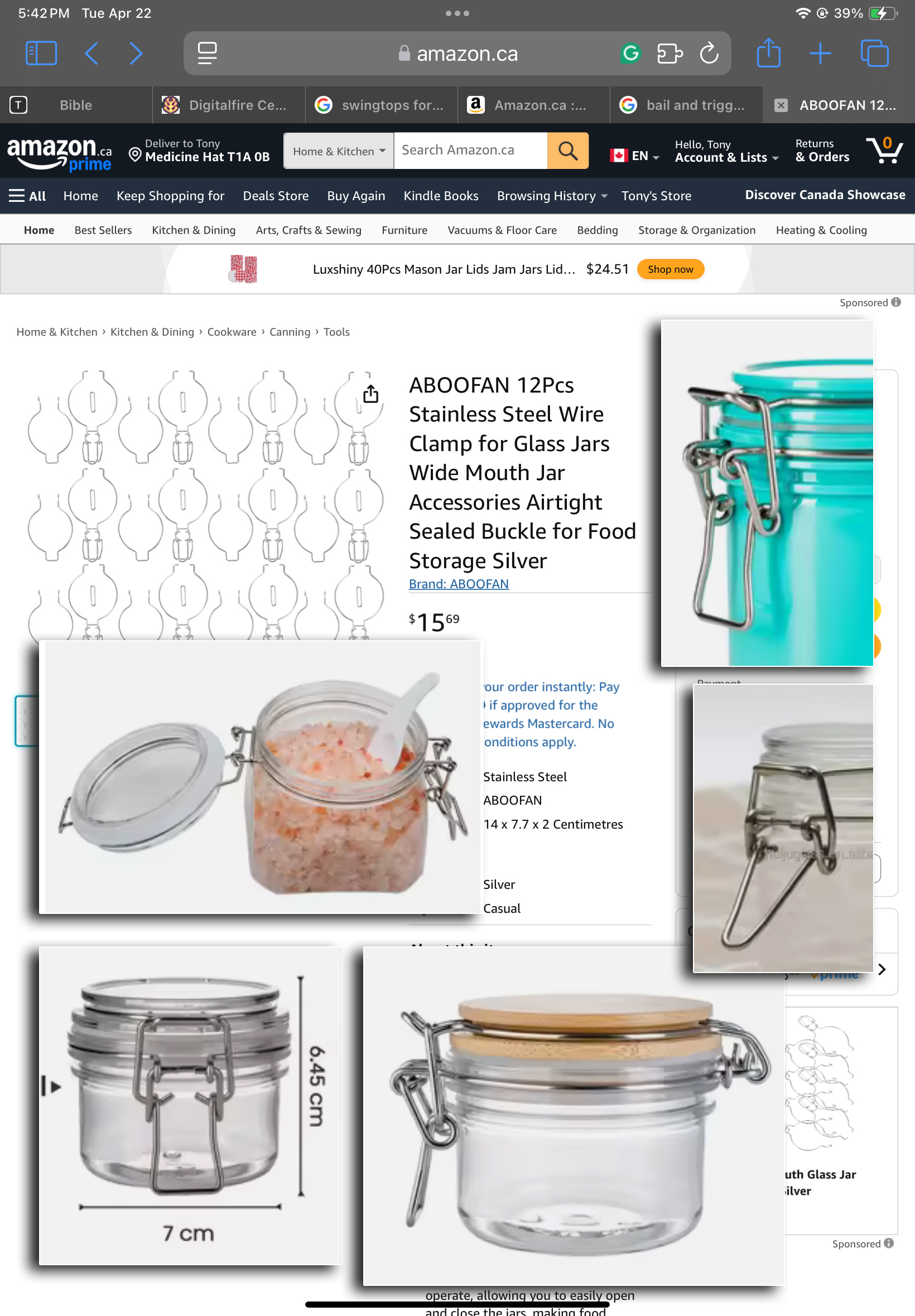

Bail-and-Latch wire clamp mechanism

Here is what they are, how to get them

This picture has its own page with more detail, click here to see it.

These enable a tight seal on glass jars. By using the 3D design and printing methods described on this site, slip-cast ceramic jars can be made to work with these.

Bail and latch fasteners have been used on glass jars since the late 1800s. They were supplanted by Mason jars (flat disk + screw band). But, the bail and latch design is still in use today because it is reliable, gives a nice airtight seal without needing complex parts and has decorative appeal.

3D printed test jar with bail-and-latch fastener

Available on the Downloads page

This picture has its own page with more detail, click here to see it.

I have had a dream of being able to slip-cast jars with this type of fastener. Until now, I did not even know what they are called or anything about their history. Now I do.

The first step was to design and 3D print a prototype. After three iterations, I found the best measurements for these bails, for use without a silicone or rubber sealing ring, to be 19.5mm vertically between the rings, a lid ring seat diameter of 79mm and a rim ring seat diameter of 87.5mm. With this batch of hardware, the ring recess on the lid has to be offset by about 2mm for the lid to fit best.

It is going to be a challenge to create slip casting test molds to make jars out of ceramic instead of glass - the latter does not shrink out of the mold while clay has both drying and firing shrinkage. That being said, 3D printing enables quickly changing a mold design and size, reprinting in PLA and remaking a plaster mold. 3D printing also enables making holders, cutters and jigs to tool the diameters precisely at the leather hard or dry stage. After that, precise firing along with monitoring of clay firing shrinkage should enable success. After that: Embossed designs cast into the flat walls.

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy