| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Food Safe

Be skeptical of claims of food safety from potters who cannot explain or demonstrate why. Investigate the basis of manufacturer claims and labelling and the actual use to which their products are put.

Key phrases linking here: unbalanced chemistry, food safety, food-safety, food safe, food-safe - Learn more

Details

In recent years potters and small manufacturers have become aware (or have been forced to become aware) that ceramics and pottery are not as inert as they once thought. A variety of potential health impacts exist to users of ware they make. These include flaking off of glaze chips (that could be ingested), harbouring of bacteria (in glaze cracks and pores of bodies or engobes), possible fracture or cracking of ware when suddenly heated (e.g. by hot coffee), superheating of ware in microwave ovens (presenting a burn hazard) and leaching of metals or other elements from the glaze surface (by hot, acidic or base liquids).

Perhaps the most public and serious of the issues is leaching. There is need for skepticism. Glaze recipes spread online often lose any non-functional labels they may have had. Potters who produce ware having a transparent, white or iron-colored liner on food surfaces are those most likely to be conscious of this topic. Those producing ware whose food surfaces are brilliantly colored (without a transparent overglaze), very matte, heavily crystallized or overly melted (and thus running) are the most likely to be unaware of this topic.

Although a ceramic glaze is akin to a glass, it actually can dissolve over time when in contact with liquids if its chemistry is not balanced and stable. This is not really a problem if the glaze is a white or transparent and does not contain any elements that are harmful (e.g. feldspars, kaolin, silica, calcium carbonate, talc). But if it contains heavy metal oxide colorants, barium, lithium or lead these present a problem. It is possible that a glaze containing all of these can be stable and will not dissolve enough to be a hazard. But if the glaze does not have a balanced chemistry it certainly can leach metals into food and drink.

What does balanced mean? It means normal. Consider the some obvious questions:

-Every potter knows that 0.5 or 1% cobalt oxide can produce a strong blue in almost any glaze. What if a recipe contains 5% cobalt? This is a red light, the extra cobalt could very well precipitate from the melt during cooling and crystallize rather than form part of the glaze matrix.

-Does the glaze form crystals on its surface during firing? Crystals in glazes are often unstable and leach.

-We expect to see 3% lithium carbonate in a recipe. What if there is 10%? What if there is 30% barium instead of 5%. Or 20% manganese dioxide instead of 5%? These are obvious issues and many a glaze fails this simple appraisal.

-What if there is only 1% cobalt in a glaze base that melts alot (and runs off the ware if applied too thick)? Likely that glaze does not contain enough SiO2 and Al2O3 (the former is the glass and the latter the stabilizer, all functional glazes must have adequate levels of these).

-What if the glaze is a matte and does not even melt properly? Any colorants in it are going to leach.

-What if a glaze contains 60% feldspar instead of the normal 30%? Feldspar is not hazardous, but it is the base of the glaze into which a hazardous metal oxides can be added to get color. If the host glaze into which the colors are added is not balanced they are likely to leach.

A special class of glaze colorants are stains. These powders have been compounded by mixing metal oxides with stabilizers and firing them at temperatures in excess of what a normal glaze would be fired to. The cooled sintered material is then ground into a powder. In theory, these stain particles do not dissolve into the glaze melt so safety issues are mitigated. However some stains produce very bright reds, yellows and oranges, they are very useful because these colors are difficult or impossible to achieve using metal oxides alone. These stains are also much less stable than others and have lower temperature limits. When used above their recommended temperature some of the toxic metals they contain (e.g. cadmium) will dissolve into the glaze melt and become leaching hazards. Cone 6, for example, can be beyond the range of common encapsulated stains.

Balance is also sought in the chemistry of a recipe. Insight-live.com, for example, can display the oxide chemistry of recipes you enter. But caution is needed. Many people say that safe glazes have a specific chemistry profile and one can recognize predisposition to leaching by simply viewing a chemical formula (to see if certain oxides fall outside limits). There is only some truth to this. For example, we might expect to see 4.0 SiO2 in a middle-temperature glaze, but if a recipe only has 1.5 there is a good chance a stable glass has not been formed. Of course, high percentages of oxides like BaO, MnO, PbO, Li2O would be potential issues, but the high percentages of their source materials would be obvious in the recipe anyway. The point is that absolute limits for all oxides (to prevent leaching) cannot be established, the chemistry is much more complex than that. Besides, this would drastically narrow the range of acceptable compounds from which to make glazes. Remember, leaching is easy to test (see the links on this page) and anyone can do it. Thus, a better application of chemistry is to give direction for change if a glaze fails a leaching test. Still, there is value in being aware of obvious chemistry irregularities (against common base recipes for the same temperature). You will find articles and videos on this site addressing this.

Crazing is often seen by potters as a visual asset, but from a safety point of view, crazed ware is unacceptable. Even hobby glaze manufacturers regard it as a surface defect (or texture) that can potentially trap bacteria. The crazing severely weakens ware and provides sites where water can enter and saturate the porosity of the body below. In addition to harboring bacteria the cracks provide weakness points from where thermal shock can propagate them deeper into the ware. Simple awareness of crazing is a strong measure anyone can take to improve safety of ware they produce. Crazing happens when glazes are under tension, stretched on to ware. This is fixed by adjusting the recipe to lower the thermal expansion (many articles and videos on this site show how to do this).

Simple methods of physical testing are within the means of everyone. For leaching, a slice of lemon left against the glaze (or some pure lemon juice) overnight will reveal differences in color or surface character if leaching is occurring. Simple visual inspection will reveal crazing or shivering. If a piece of functional ware is used and put in the dishwasher every day crazing will almost certain appear if the glaze is under tension. An ice-water and boiling-water immersion test is even better to reveal if these problems will happen over time.

Related Information

Commercial glazes on decorative surfaces, your own on food surfaces

This picture has its own page with more detail, click here to see it.

These cone 6 porcelain mugs are hybrid. Three coats of a commercial glaze painted on the outside (Amaco PC-30) and my own liner glaze, G2926B, poured in and out on the inside. When commercial glazes (made by one company) fit a stoneware or porcelain (made by another company) it is by accident, neither company designed for the other! For inside food surfaces make or mix a liner glaze already proven to fit your clay body, one that sanity-checks well (as a dipping glaze or a brushing glaze). In your own recipes you can use quality materials that you know deliver no toxic compounds to the glass and that are proportioned to deliver a balanced chemistry. Read and watch our liner glazing step-by-step and liner glazing video for details on how to make glazes meet at the rim like this.

A functional matte liner glaze is possible - with care.

This picture has its own page with more detail, click here to see it.

Ravenscrag G2928C matte liner glaze is on the insides of these mugs. Like our G2934 recipe, this matte glaze needs to be fired to a real cone 6 and fired in the C6DHSC drop and hold and then slow-cooled schedule. If cooled too slowly the surface could be too matte would be subject to cutlery marking (especially on the inside bottoms). If cooled too quickly it will be too glossy. When firings cool slowly just because they are tightly packed the degree of matteness can be tuned by blending in just enough glossy glaze to make the surface smooth enough to be functional while still matte enough to be attractive to the eye and the touch.

What can you do using glaze chemistry? More than you think!

This picture has its own page with more detail, click here to see it.

There is a direct relationship between the way ceramic glazes fire and their chemistry. These green panels in my Insight-live account compare two glaze recipes: A glossy and matte. Grasping their simple chemistry mechanisms is a first step to getting control of your glazes. To fixing problems like crazing, blistering, pinholing, settling, gelling, clouding, leaching, crawling, marking, scratching, powdering. To substituting frits or incorporating available, better or cheaper materials while maintaining the same chemistry. To adjusting melting temperature, gloss, surface character, color. And identifying weaknesses in glazes to avoid problems. And to creating and optimizing base glazes to work with difficult colors or stains and for special effects dependent on opacification, crystallization or variegation. And even to creating glazes from scratch and using your own native materials in the highest possible percentage.

Why are these crazing lines dark like this?

This picture has its own page with more detail, click here to see it.

This is an example of serious crazing in a glaze. The lines have gotten darker with use of the bowl! That means the color is organic, from food. This cannot be healthy.

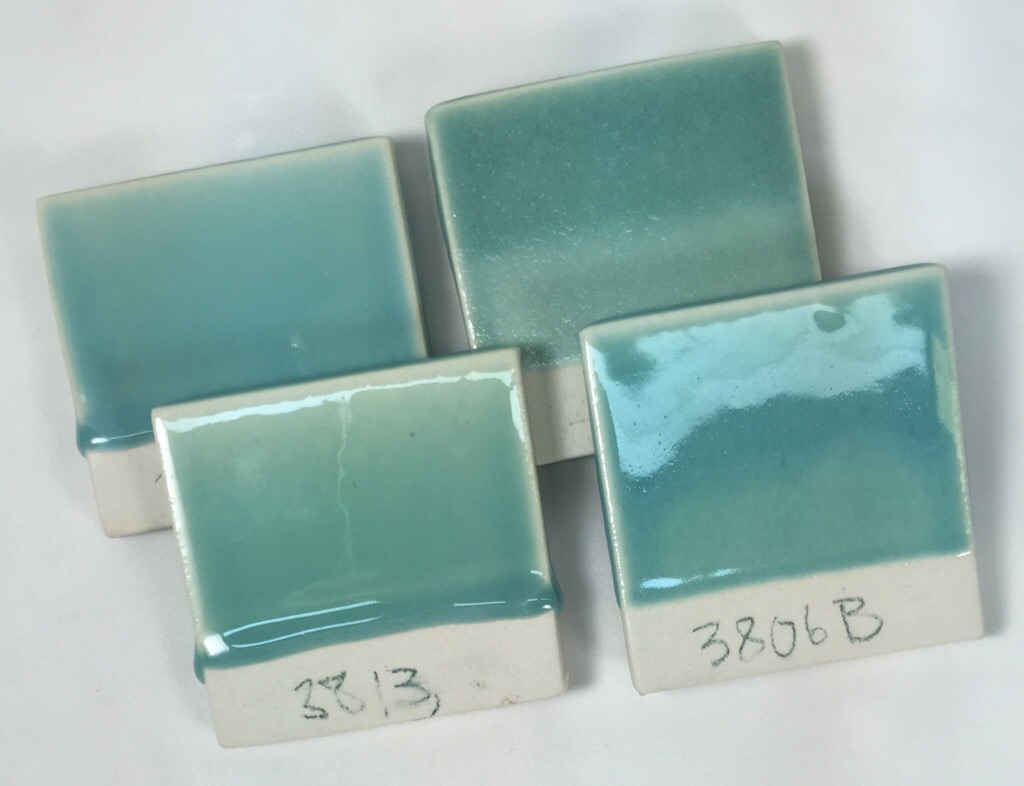

Copper does not necessarily cause glazes to leach if used in moderate amounts

This picture has its own page with more detail, click here to see it.

These are four cone 6 glazes of diverse chemistry. They have varying melt fluidities. They are soaked (halfway up) in lemon juice overnight. None show any evidence of surface changes. All contain 2% copper carbonate. If the copper was increased, especially to the point of going metallic or crystallizing, the leaching test would produce different results (especially on the ones that are running, they lack SiO2 and Al2O3). So, if you use copper sensibly (in moderate amounts), there is a good chance of making a glaze that resists leaching.

How much rutile can a glaze take before it becomes unstable?

This picture has its own page with more detail, click here to see it.

The 80:20 base GA6-A Alberta slip base becomes oatmeal when over saturated with rutile or titanium (left: 6% rutile, 3% titanium; right: 4% rutile, 2% titanium). That oatmeal effect is actually the excess titanium crystallizing out of solution into the melt as the kiln cools. Although the visual effects can be interesting, the micro-crystalline surface is unpleasant to touch and susceptible to cutlery marking and leaching (not as stable or durable as in glazes which are pure amorphous glass). For functional ware, rutile glazes are among the most troublesome to keep consistent, one way of avoiding problems is keeping the percentage as low as possible while still getting the desired variegation (of course that will vary depending on the melt fluidity of the glaze, more highly fluid ones can handle more rutile or titanium).

If your glaze can handle more silica and melt just as well then add it!

This picture has its own page with more detail, click here to see it.

The cone 6 G1214M glaze on the left melts well. Can it benefit from a silica addition? Yes. The right adds 20% yet still melts as well, covers better, is more glossy, more resistant to leaching, harder and has a lower thermal expansion.

A good matte glaze. A bad matte glaze.

This picture has its own page with more detail, click here to see it.

A melt fluidity comparison between two cone 6 matte glazes. G2934 is an MgO saturated boron fluxed glaze that melts to the right degree, forms a good glass, has a low thermal expansion, resists leaching and does not cutlery mark. G2000 is a much-trafficked cone 6 recipe, it is fluxed by zinc to produce a surface mesh of micro-crystals that not only mattes but also opacifies the glaze. But it forms a poor glass, runs too much, cutlery marks badly, stains easily, crazes and is likely not food safe! The G2934 recipe is google-searchable and a good demonstration of how the high-MgO matte mechanism (from talc) creates a silky surface at cone 6 oxidation the same as it does at cone 10 reduction (from dolomite). However it does need a tin or zircon addition to be white.

Inbound Photo Links

Links

| Tests |

Glaze Leaching Test

Simple tests to evaluate the stability of a ceramic or pottery glaze against leaching metals in food or drink. |

| Tests |

Boiling Water:Ice Water Glaze Fit Test

Ceramic glazes that do not fit the body often do not craze until later. This test stresses the fit, thus revealing if it is likely to craze later. |

| Tests |

300F:Ice Water Crazing Test

Ceramic glazes that do not fit the body often do not craze until later. This progressively stresses the fit until failure point, thus giving it a score |

| Glossary |

Dishwasher Safe

Dishwasher safety is a concern in ceramic table ware, especially if the ware has been imported or made by a small company or potter. |

| Glossary |

Microwave Safe

Microwave safety is a concern in the production of function ceramic ware. |

| Glossary |

Co-efficient of Thermal Expansion

The co-efficient of thermal expansion of ceramic bodies and glazes determines how well they fit each other and their ability to survive sudden heating and cooling without cracking. |

| Glossary |

Thermal shock

When sudden changes in temperature cause dimensional changes ceramics often fail because of their brittle nature. Yet some ceramics are highly resistant. |

| Glossary |

Encapsulated Stain

This is a type of stain manufacture that enables the use of metal oxides (like cadmium) under temperature conditions in which they would normally fail. |

| Glossary |

Functional

A term used in ceramic to express the degree to which an item is safe and stands up to everyday use. Functionality embodies strength, hardness, resistance to acid attack and thermal shock, etc. |

| Glossary |

Liner Glaze

Liner-glazing is a way to assure that your ware has a durable and leach resistant surface. It also signals to customers that you care about this. |

| Glossary |

Glaze Durability

Ceramic glazes vary widely in their resistance to wear and leaching by acids and bases. The principle factors that determine durability are the glaze chemistry and firing temperature. |

| Glossary |

Limit Recipe

"Recipe logic" is the ability to sanity-check ceramic glaze recipes on sight, by noting that materials present and their relative percentages. |

| Glossary |

Dinnerware Safe

In pottery, the terms dinnerware safe and food safe, are not the same. Perhaps the best way to understand the former is to consider what the opposite might be. |

| URLs |

https://www.astm.org/d4236-94r21.html

ASTM D-4236 - Standard Practice for Labeling Art Materials for Chronic Health Hazards - It is not what you think! A standard that "applies exclusively to art materials packaged in sizes intended for individual users of any age or those participating in a small group". It "concerns those chronic health hazards known to be associated with a product or product component(s) when it is present in a physical form, volume, or concentration that in the opinion of a toxicologist has the potential to produce a chronic adverse health effect". The word "toxicity" is not mentioned on the page nor any methods for determining such. Furthermore, the labelling refers to hazards to which the potter is exposed in applying the glaze to the ware, long term, in small hobby quantities. IT DOES NOT ADDRESS leaching hazards the ware presents to users of the pottery. Even then, the standard states that "it is the RESPONSIBILITY OF THE USER ... to establish appropriate safety, health, and environmental practices ... based upon knowledge that exists in the scientific and medical communities". It also admits that "since knowledge about chronic health hazards is incomplete and warnings cannot cover all uses of any product, it is not possible for precautionary labelling to ensure completely safe use of an art product." It is interesting that one manufacturer displays this warning on pages relating to dipping glazes and accessory products (which are used by manufacturers): "Safety Warning: Tableware producers must test all finished ware to establish dinnerware status, due to possible variations in firing temperature and contamination." This warning does not appear on brushing glazes, even the reactive metal-saturated ones that potters and hobbyists use! |

| URLs |

https://www.scarva.com/en/Is-This-Glaze-Food-Safe/cc-40.aspx

Scarva Pottery Supply glaze food safety information page. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy