| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Zero3

The designation for a group recipes for body, glaze and engobe (by Tony Hansen), that potters can use to make low fire stoneware and fritware porcelain at 1100C (2000F) or cone 03.

Key phrases linking here: zero3 stoneware, zero3 fritware, zero3 - Learn more

Details

The term "Zero3" was coined by Tony Hansen. It refers to recipes he developed that enable a potter to create red-burning stoneware and blue-white porcelain at cone 03. The white version was later supplanted by the Zero4 porcelain, it matures to equal strength at cone 04, a temperature much more commonly fired by potters. The red version was succeeding by our L4170B recipe.

July 2024: Costs have skyrocketed, this now prices out to about $20/lb to make! This is maybe 400-500% increase in the past 5 years.

The secrets to why the system (group of recipes) functions well:

-The porcelain and red earthenware body recipes incorporate a sodium frit to make them vitreous (for the red body, only 5% is needed, 20% for the white).

-The glazes employ common Ferro frits (four of them), the rationale for their recipes and chemistries are meticulously explained.

-Three clear glaze recipes were initially given (L, K, H), having thermal expansions that span a broad range. They are shown side-by-side (with chemistry). Users can blend these to get a good fit. Then can further develop them in their insight-live.com accounts. More recently the G3879 recipe is showing great promise.

-The firing schedule employs a drop-and-hold to ensure cloud-free transparent results.

-The porcelain Zero3 body employs a blue stain to make it look like a cone 10R porcelain.

-The engobes are well explained and tested. The page explaining them is the first online coverage of how to develop an engobe and the importance of fitting it well to a specific body.

-The system is well tested using commercial underglazes (which show through the clear to produce brilliant effects). It is well represented in an image search on google.

-The development project is ongoing and much of it exists as a share from the Plainsman Clays account on insight-live.com. That means whenever a change or addition is made to the testing records, it updates online automatically.

The recipes use common ingredients in North America and enable the potter to mix his own body, glaze and engobe. If you live elsewhere consider making a 50:50 mix of ball clay and frit 3110 (equivalents to it should be available everywhere), then wedging that together with a terra cotta body available to you. A 10:1 mix would produce a body having 5% frit.

Want to learn more? It is code numbered L3924C, all the details along with information on the G2931K base glaze are available.

Related Information

Firing a porcelain in less than 4 hours total

This picture has its own page with more detail, click here to see it.

This porcelain mug put into kiln at 8:45am and I was drinking coffee from it at 12:15! How? One way to fast-fire is to fire a lot lower. This is Zero3 porcelain made using Dragonite Halloysite (not quite as white-burning as New Zealand Halloysite). It is the L2934C recipe. It was fired to cone 03 and glazed with G2931K clear glaze (which has fired crystal clear and flawless). I fired at 1200F/hr to 1950F, held it for 15 minutes, cooled at 999F/hr to 1850F and held it for 30 minutes, then dropped as fast as the kiln would do. Is this really porcelain? Yes. And it is super strong. The frit in the recipe is magic, making it vitrify quickly and completely.

G2931K Zero3 transparent glaze on Zero3 Fritware Porcelain

This picture has its own page with more detail, click here to see it.

This is an all-fritted version of G2931F Zero3 transparent glaze. I formulated this glaze by calculating what mix of frits must be employed to supply the same chemistry of the G2931F recipe. The mug is made from the Zero3 porcelain body (fired at cone 03) with this glaze. This glaze fits both the porcelain and the Zero3 terra cotta stoneware. The clarity, gloss, fit and durability of this glaze are outstanding.

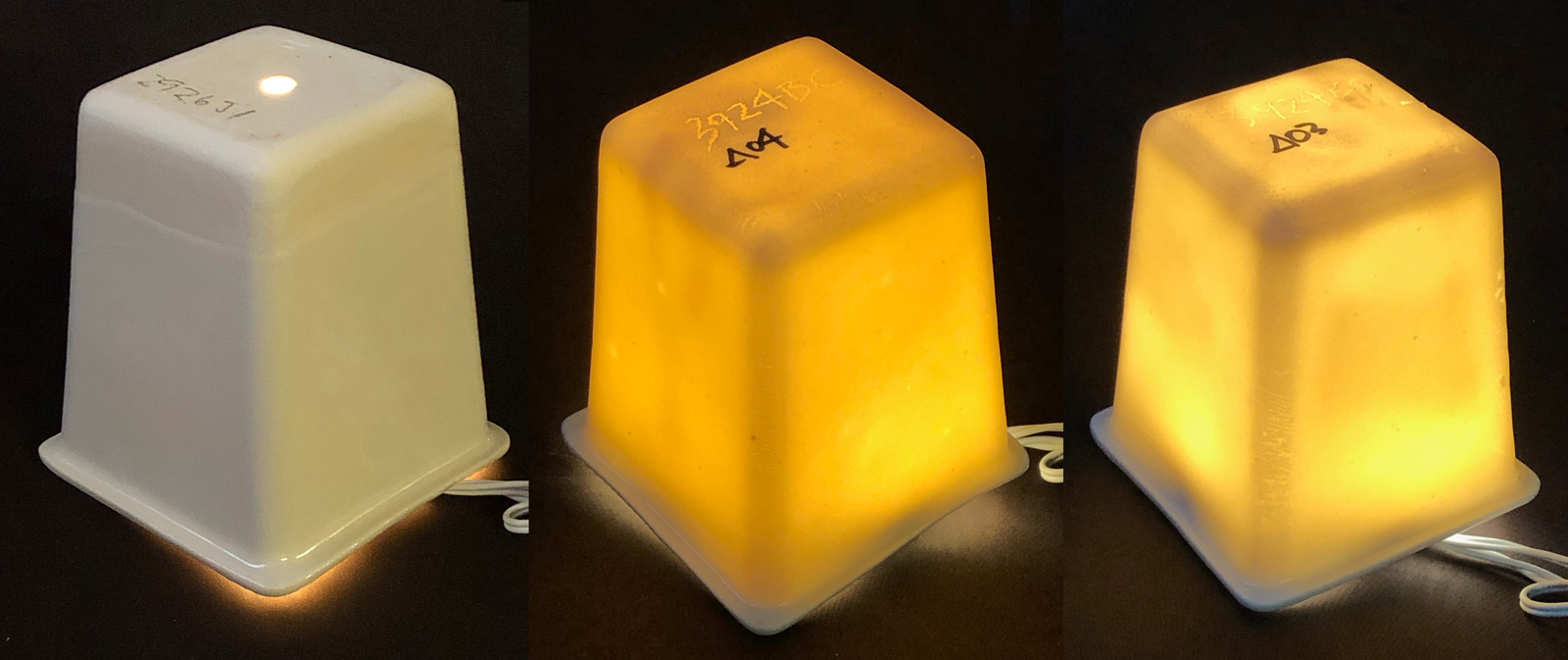

Zero3 casting porcelain at cone 04, 03

This picture has its own page with more detail, click here to see it.

Compared to a typical cone 6 porcelain, left, which has zero translucency, these are fired 10 cones lower. I am using the G3879 clear glaze and it is working very well.

Casting Zero3 Porcelain

This picture has its own page with more detail, click here to see it.

Look at how translucent this is! I can fire one of these in three hours, cold-to-cold. I am casting them with molds made using the 3D-printing process. Anyone could do this. Incredibly exciting. And with the G3879 glaze it looks awesome, just like bone china. Notwithstanding this, the Zero3 recipe has to be altered for casting. Initially I have reduced the VeeGum to 1% but it is still casting too slow. And it is not shrinking enough to pull away from the mold well. I am considering strategies on how to increase drying shrinkage and am going to add more frit to take it down to cone 04.

Which is stronger: Cone 10R mug or cone 03 mug?

This picture has its own page with more detail, click here to see it.

The mug on the left is high temperature Plainsman P700 (Grolleg porcelain). The other is Plainsman Zero3 fired at cone 03. Zero3 has a secret: Added frit which reduces the porosity of the terra cotta base (therefore increasing the density) dramatically. How? The frit melts easily at cone 03 and fills the interparticle space with glass, that glass bonds everything together securely as the piece cools. Although I do not have strength testing equipment right now, I would say that although the P700 mug likely has a harder surface, the Zero3 one is less brittle and more difficult to break.

Low fire heaven: Use commercial underglazes but make your own clear over glaze

This picture has its own page with more detail, click here to see it.

Decorate ware with the underglazes at the leather hard stage, dry and bisque fire it and then dip-glaze in a transparent that you make yourself (and thus control). These mugs are fired at cone 03. All have the same transparent glaze (G2931K), all were decorated with the same underglazes. Notice how bright the colors are compared to middle or high temperature. On the left is a porous talc/stoneware blend (Plainsman L212), rear is a fritted Zero3 stoneware and right is Zero3 fritted porcelain. When mixed properly you can dip ware in this glaze and it covers evenly, does not drip and dries enough to handle in seconds! Follow the Zero3 firing schedule and you will have ware of amazing quality.

Cone 10R porcelain (left) vs cone 03 porcelain (right)

This picture has its own page with more detail, click here to see it.

Want to make this incredible porcelain and glaze yourself? Read on. The mug on the left is a cone 10R (2350F/1290C) porcelain (#6 Tile kaolin and Nepheline Syenite) with G1947U clear glaze. The other is a fritted cone 03 (1950F or 1065C) porcelain (NZ Kaolin, Ferro Frit 3110) with G2931K clear glaze. We call the body/glaze/firing system "Zero3" (google it or use the links here). The Zero3 porcelain is blue-white instead of grey, the glaze is crystal clear, underglaze colors are so much more vibrant. This Zero3 mug was fired in 3 hours (cold-to-cold). It fits glazes really well, it is very strong and much more translucent. How is this possible? The magic of the frit, it melts so much better than nepheline. It is the most expensive body you will ever make. But from it you may create the highest quality ware you have ever made using the most plastic body you have ever thrown! Follow the instructions carefully.

Low fire stoneware, Zero3 body, with clear glaze

This picture has its own page with more detail, click here to see it.

Zero3 stoneware with G2931K clear glaze. The mug on right has Zero3 L3685U engobe under the glaze (on the inside).

Cone 03 bowl has the strength of high-fire porcelain

This picture has its own page with more detail, click here to see it.

This bowl is 18cm (7") tall and weighs 1.8kg (4 lb). The marbling was achieved by wedging together white and colored Zero3 fritware porcelains, then thrown on the potters wheel and tooled at leather hard stage. The base is much thicker than the lip yet the degree of maturity appears homogeneous (despite a firing to cone 03 in less than 4 hours). I broke this with a hammer and with difficulty, it has the same kind of vitrified character as a high temperature porcelain.

Links

| URLs |

https://insight-live.com/insight/share.php?z=8JFvDgDc3X

Plainsman Zero3 Glaze L,K,H and Firing Schedule |

| URLs |

https://insight-live.com/insight/share.php?z=5R9GFgEEYF

Zero3 porcelain/stoneware, engobe, clear glaze and firing schedule |

| Recipes |

G2931H - Ulexite High Expansion Zero3 Clear Glaze

A cone 03-02 higher expansion fritted clear glaze developed from Worthington Clear. |

| Recipes |

G2931K - Low Fire Fritted Zero3 Transparent Glaze

A cone 03-02 clear medium-expansio glaze developed from Worthington Clear. |

| Recipes |

L3924C - Zero3 Porcelain Experimental

|

| Recipes |

G3879 - Cone 04 Transparent Low-Expansion transparent glaze

A super transparent low fire base clear glaze created by reverse engineering a commercial product. |

| Recipes |

L3685U - Cone 03 White Engobe Recipe

A white burning body with enough added frit to produce a cone 03 stoneware or white slip for use on the matching red Zero3 stoneware. |

| Glossary |

Fritware

|

| Glossary |

Zero4

The designation for a group recipes for body, glaze and engobe (by Tony Hansen), that potters can use to make low fire stoneware and fritware porcelain |

| Glossary |

Slipware

Slipware, in the UK, is terra cotta pieces decorated at leather hard with thixotropic high ball clay slips, then bisque fired and clear glazed with lead bilisicate. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy