| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Zircon

Alternate Names: Zirconium Silicate

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| ZrO2 | 67.21% | 1.00 | |

| SiO2 | 32.79% | 1.00 | |

| Oxide Weight | 183.34 | ||

| Formula Weight | 183.34 | ||

Notes

Zirconium silicate (or zircon) is extremely stable (refractory, hard, dense). Large quantities of zircon are used by the tile, sanitaryware and tableware industries (to opacify glazes). Zircon sand (which is milled to produce zirconium silicate powders), is a major source for the production of zirconia ZrO2.

Individual zircon particles are angular, very hard and refractory and amazingly, they do not readily dissolve into glaze melts even when ball milled to exceedingly small particle sizes. Manufacturers differentiate products by different methods of grinding and purifying the sand (particle size, shape, distribution, removal of impurities). Their equipment is able to process product, in quantity, down to 5 micron particle size and enough uniformity to prevent issues like agglomeration. A consequence of this is that high-energy mixing of glaze slurries is required to separate the particles. 325 mesh is considered a coarse grade, not suitable to opacify glazes (although in glaze frits it can be suitable).

Zircon is the generic name for zirconium silicate, the trade names are different (for example, Zircopax, Zircosil, Ultrox, ). The refractive index of zircon is high (particularly with micronized zircon, sized less than 5 microns). Notwithstanding this, some sources list Zircon as a source of SiO2 in glazes (meaning that it does decompose). This view is plausible since smaller amounts of zircon do not opacify glazes, in fact they are purposely added to raise refractive index to encourage transparency and high gloss. That means it dissolves when percentages are low and precipitates to opacify when they are higher. Interestingly, it dissolves so well at low percentages that it is sometimes added to clear glazes to make them more transparent (because it has a high refractive index).

Zircon is normally used in glazes for opacification (converting a transparent glaze to an opaque). The silicate form or zirconium does not matte glazes (like pure zirconium oxide, actually, zirconium dioxide, does). The exact amount needed varies between different glaze types. 10-12% is normal, but up to 20% may be required to opacify some transparent glazes. When the saturation point is achieved crystallization begins to occur. It is most effective at low temperatures. Tin oxide can be a more effective opacifier than zircon (it has various advantages and disadvantages).

High amounts of zircon opacifier can cause cutlery marking (because of abrading angular micro-particles projecting from the glaze surface).

As a glaze opacifier, the white color produced by zirconium silicate is often characterized as 'toilet bowl white'. Tin oxide, by contrast can produce more of a blue-white, but tin is subject to alteration of the color (toward pink) if there is any chrome in the kiln atmosphere. If the shade of white is too harsh, it can be toned by shifting part of the opacification burden to tin or by adding a tiny amount of stain (e.g. blue, brown, grey).

The low expansion or zircon will tend to reduce crazing in glazes. In a non-crazed glaze, the presence of sufficient zircon can reduce thermal expansion enough that there is a danger of shivering (the glaze formulation may need to be adjusted to accommodate, e.g. more Zircon lowers glaze thermal expansion). It is best to exclude the chemistry of the zircon materials from participation in glaze chemistry calculations, treating it simply as an addition (then take into consideration its effect on glaze properties on a physical rather than chemical level).

Zircon stiffens the glaze melt (increases surface tension) and this often needs to be taken into account (even though the chemistry might suggest it is sufficiently fluid). Glazes lacking melt fluidity can experience problems with crawling, blistering and pinholing since they have less ability to heal disruptions. Adjustment of the glaze chemistry may be needed (increasing the flux content while maintaining the SiO2:Al2O3, for example).

Because of its high thermal stability, zircon is also employed in making various hi-tech refractories, porcelain bodies, coatings and materials, even dentures. Calcined alumina is an alternative in fabricating super refractories but it has much higher thermal expansion and greater heat conductivity.

Zircon has become so expensive that major manufacturers are considering, or are already diluting their products with other materials (like kaolin). So 'heads up' if your glaze is not as opacified as it was before! Also, use care in pretesting zircon materials, they vary in quality. Some companies are marketing their materials as "zirconium substitutes" whereas the material is just zirconium silicate.

Related Information

How do you turn a transparent glaze into a white?

This picture has its own page with more detail, click here to see it.

Right: Ravenscrag GR6-A transparent base glaze. Left: It has been opacified (turned opaque) by adding 10% Zircopax. This opacification mechanism can be transplanted into almost any transparent glaze. It can also be employed in colored transparents, it will convert their coloration to a pastel shade, lightening it. Zircon works well in oxidation and reduction. Tin oxide is another opacifier, it is much more expensive and only works in oxidation firing.

The action of Zircopax vs Tin Oxide at cone 10R

This picture has its own page with more detail, click here to see it.

On Plainsman H443 iron stoneware in reduction firing. Notice Tin does not work. Also notice that between 7.5 and 10% Zircopax provides as much opacity as does 15% (Zircon is very expensive).

Adding Zircopax to G2571A dolomite matte

This picture has its own page with more detail, click here to see it.

On the left: G2571A dolomite matte fired at cone 10R. Right: 10% Zircopax has been added. Both are on a buff stoneware (H550 from Plainsman Clays).

Zircon glazes cover well but they have a problem

This picture has its own page with more detail, click here to see it.

This sanitary ware tank lid was made in China. Notice how thick the white glaze is being applied to cover the iron containing body below. This is a testament to how opaque a zircon opacified glaze can be. Zircon often causes crawling (likely due to a combination of the effects of its fine particle size on drying properties and its tendency to stiffen the melt). Extra measures and constant attention to detail (e.g. glaze thickness, slurry rheology, avoidance of sharp contours on ware) are needed with such glazes.

Increasing zircon percentages in a transparent glaze on a brick clay body

This picture has its own page with more detail, click here to see it.

These are fired around cone 8. On the far right is 15% zircopax (left has none). Zircon is however very expensive and its use on bricks has to be rationalized, or at least minimized. In this case a white engobe applied first would greatly reduce the zircon percentage needed.

The difference between vitrified and sintered

This picture has its own page with more detail, click here to see it.

The top fired bar is a translucent porcelain (made from kaolin, silica and feldspar). It has zero porosity and is very hard and strong at room temperature (because fibrous mullite crystals have developed around the quartz and kaolinite grains and feldspar silicate glass has flowed within to cement the matrix together securely). That is what vitrified means. But it has a high fired shrinkage, poor thermal shock resistance and little stability at above red-heat temperatures. The bar below is zirconium silicate plus 3% binder (VeeGum), all that cements zircon ceramics together is sinter-bonds between closely packed particles (there is some glass development from the Veegum here). Yet it is surprisingly strong, it cannot be scratched with metal. It has low fired shrinkage, low thermal expansion and maintains its strength and hardness at very high temperatures.

White spots and blisters in a high zircon glaze at cone 6

This picture has its own page with more detail, click here to see it.

This is also a common problem at low fire on earthenware clay (but can also appear on a buff stonewares). Those white spots you see on the beetle also cover the entire glaze surface (although not visible). They are sites of gas escaping (from particles decomposing in the body). The spots likely percolate during soaking at top temperate. Some of them, notably on the almost vertical inner walls of this bowl, having not smoothed over during cool down.

What can you do? Use the highest possible bisque temperature, even cone 02 (make the glaze thixotropic so it will hang on to the denser body, see the link below about this). Adjust the glaze chemistry to melt later after gassing has finished (more zinc, less boron). Apply a thinner glaze layer (more thixotropy and lower specific gravity will enable a more even coverage with less thickness). Instead of soaking at temperature, drop 100 degrees and soak there instead (gassing is much less and the increasing viscosity of the melt overcomes the surface tension). Use a body not having any large particles that decompose (and gas) on firing. Use cones to verify the temperature your electronic controller reports.

3% and 2% Zircopax added to G2926B cone 6 clear. Why?

This picture has its own page with more detail, click here to see it.

If you are interested in the most functional possible surface, consider a 2% zircon addition to your transparent glaze recipe (the outside glaze on these mugs is a copper blue, but that is not the one we are interested in). The clear glaze on the insides of these two identical cone 6 porcelain mugs has 3% and 2% zircon added. It is not being added to opacify, it is being added to toughen the surface and reduce the thermal expansion. The presence of the 2% zircon has not affected the gloss or transparency of the glaze on the right. However, the 3% on the left has opacified it just slightly and made the surface a little silky. So that is too much for this glaze (although it might be OK if the melt fluidity was higher).

Zircopax as a fining agent to de-bubble a stained glaze

This picture has its own page with more detail, click here to see it.

The cone 03 porcelain cup on the left has 10% Cerdec encapsulated stain 239416 in the G2931K clear base. The surface is orange-peeled because the glass is full of micro-bubbles that developed during the firing. Notice that the insides of the cups are crystal-clear, no bubbles. So here they are a direct product of the presence of the stain. The glaze on the right has even more stain, 15%. But it also has a 3% addition of Zircopax (zircon). Suppliers of encapsulated stains recommend a zircon addition, but are often unclear about why. Here is the reason: It is a "fining agent".

The glaze with less stain + 2% Zircopax is brighter than the one with more stain!

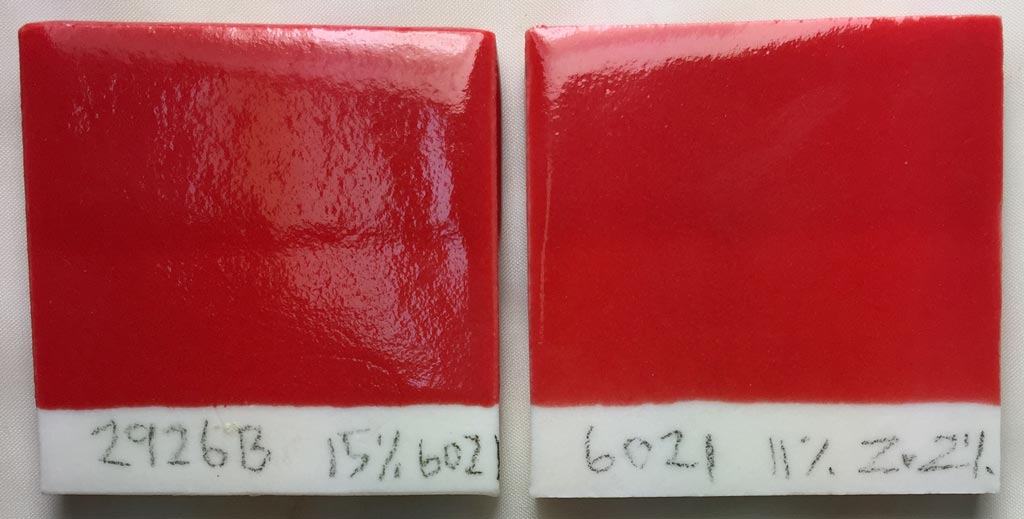

This picture has its own page with more detail, click here to see it.

These are cone 03 porcelains with G2931K clear glaze base plus Mason 6021 encapsulated stain (which is very expensive). The one on the left has 15% stain added. The one on the right is slightly less dense red but has only 10% stain plus 2% zircon (zircopax). Notice the zircon has smoothed the surface also, this is a known benefit of using it with encapsulated stains. The 2% addition is not enough to opacify, the color remains deep and translucent. But the surface is still not completely smooth and glassy as is the base transparent glaze on its own. This can be improved using a drop-and-hold firing schedule.

G2934 Cone 6 Matte with 10% Zircopax and 5% tin oxide

This picture has its own page with more detail, click here to see it.

The body is Plainsman M390. The firing schedule is Plainsman PLC6DS.

5% titanium dioxide in G2934Y matte, G1214Z1 matte, G2926B glossy

This picture has its own page with more detail, click here to see it.

The body is Plainsman M390. The firing schedule is Plainsman PLC6DS.

G1214Z1 at cone 6 with 10% Zircopax and 5% tin oxide

This picture has its own page with more detail, click here to see it.

The body is Plainsman M390. The firing schedule is Plainsman PLC6DS. The tin is on the right.

G2926B cone 6 transparent with 10% Zircopax and 5% tin oxide

This picture has its own page with more detail, click here to see it.

The body is Plainsman M390. The firing schedule is Plainsman PLC6DS.

Zircopax, tin oxide, titanium as opacifiers in four base glazes

This picture has its own page with more detail, click here to see it.

The body is Plainsman M390. Firing is the cone 6 PLC6DS schedule. Each horizontal row is a commonly-used base glaze. The top one is a magnesia matte, the next one down is a calcia matte, row 3 is G2926B glossy and row 4 is Ravenscrag Slip+frit. The two mattes behave very differently from each other with the additions of opacifier. Thickly applying an opacified glaze will obviously affect visual character (column 4). Tin oxide fires whiter than zircon (e.g. Zircopax). If you like the G2934 recipe, consider the G2934Y variant for better melting.

Links

| URLs |

http://mineral.galleries.com/minerals/silicate/zircon/zircon.htm

The Mineral Zircon |

| URLs |

http://en.wikipedia.org/wiki/Zircon

Zircon at Wikipedia |

| Materials |

Ultrox

|

| Materials |

Zirconium Dioxide

|

| Materials |

Opax

|

| Materials |

Calcined Alumina

|

| Materials |

Magnesium Zirconium Silicate

|

| Materials |

Zircopax

Zirconium silicate, its principle use in ceramics is as an opacifier in glazes. It is an expensive material, but less so than tin oxide. |

| Materials |

Zirconium Spinel

|

| Materials |

Superpax

|

| Materials |

Calcium Zircon Silicate

|

| Materials |

Tin Oxide

Its principle use in ceramics is as an opacifier in glazes. It is very expensive. |

| Materials |

Zircopax Plus

|

| Hazards |

Zirconium Compounds Toxicity

|

| Typecodes |

Opacifier

Opacifiers are powders that turn transparent glazes opaque by various chemical and physical mechanisms (and combinations of mechanisms). |

| Typecodes |

Low Expansion Material

Materials used to make bodies requiring low expansion (e.g. flameware, refractories). The individual particles of these materials have low expansion. Some of theme even expand at certain temperature ranges. |

| Typecodes |

Generic Material

Generic materials are those with no brand name. Normally they are theoretical, the chemistry portrays what a specimen would be if it had no contamination. Generic materials are helpful in educational situations where students need to study material theory (later they graduate to dealing with real world materials). They are also helpful where the chemistry of an actual material is not known. Often the accuracy of calculations is sufficient using generic materials. |

| Oxides | ZrO - Zirconium Oxide, Zirconia |

| Oxides | ZrO2 - Zirconium Dioxide |

| Glossary |

Opacity

Opacity of ceramics glazes is normally achieved by adding an opacifier like tin oxide or zircon. However, there are chemical profiles that can turn transparent glazes milky and make it cheaper to opacify them. |

| Glossary |

Refractory

In the ceramic industry, refractory materials are those that can withstand a high temperature without deforming or melting. Refractories are used to build and furnish kilns. |

| Glossary |

Crucible

In ceramics, potters make crucibles to melt frits, stains and other materials. Crucibles are made from refractory materials that are stable against the material being melted in them. |

| Glossary |

Variegation

Ceramic glaze variegation refers to its visual character. This is an overview of the various mechanisms to make glazes dance with color, crystals, highlights, speckles, rivulets, etc. |

| Temperatures | Zircon melts, slowly dissolves (1550-) |

Data

| Hardness (Moh) | 7.5 |

|---|---|

| Frit Softening Point | 2700C |

| Solubility | Insoluble in water, weakly soluble in acids |

| Density (Specific Gravity) | 4.3-4.7 |

| Density (Specific Gravity) | 4.56 |

Mechanisms

| Body Thermal Expansion | A very low expansion material. |

|---|---|

| Glaze Opacifier | Zirconium silicate is by far the most popular opacifier in glazes. It is available from many manufacturers. Opax, Ultrox, Zircopax and Superpax are examples of trade names of zirconium silicate and zirconium oxide products. The finer the milling of the material the better the opacity and the cleaner the color that will be produced. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy