| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Liner Glazing

Step-by-step to apply inside and outside glazes to a pottery mug and get them to meet at a clean line at the rim.

Key phrases linking here: liner glazing step-by-step, liner glazing, liner glazed - Learn more

Details

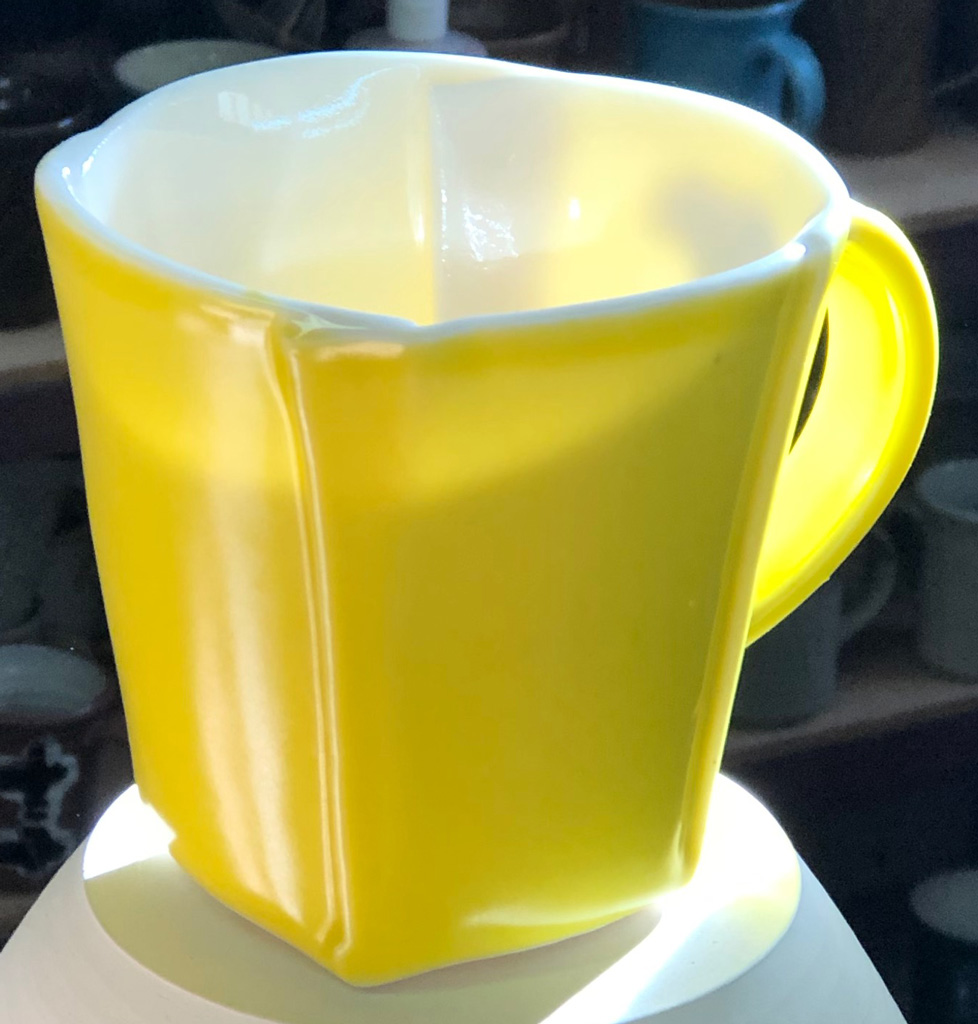

Mug has been liner glazed, waxed and cut/trimmed but not yet sponge-cleaned for dipping the outer glaze

This page describes the technique of glazing pottery to make an inside and outside glaze meet in a clean line at the rim. The technique is common in commercial ware and requires precision to execute well. It is not only aesthetic but also functional - more durable and food safe glazes are appropriate on food surfaces. Separate glazing operations for inside and outside surfaces are also a practical production technique (e.g. for thin-walled pieces that would waterlog on a complete dip, where separate people or teams cooperate in glazing each piece).

- Use glazes that do not have too much melt fluidity (run too much during firing), or they may bleed into each other across the join.

- Use a thixotropic dipping glaze, don't put up with problems of excessive dripping, settling in the bucket and slow drying.

- Form the mug (on the wheel) such that the lip flares out a little, this will reduce dripping down the outside on the outpour. Also, round the lip so the glaze join line occurs on a rounded contour.

Step-by-Step

- Fill the bisque mug with liner glaze. Pour it out in a circular motion and then dip the lip. Hold it there long enough to get the thickness needed:

- After the glaze has dried sufficiently, use a banding wheel to wax up the inside (starting about an inch down) and just up around the top of the lip.

- Using a sharp knife (e.g. Olfa cutter) in one hand and rotating the mug with the other, cut away the glaze (down to the bisque) up to the highest point on the lip (the best cut with the least dust is done when the glaze is still damp). Clean up any remaining glaze around the outside of the rim using a fettling knife. Now the inside glaze terminates at a perfect wax-covered edge at the lip.

- Using a damp sponge, clean any remaining glaze off the outside up to the wax line. This is not always necessary, but note that the poorest surface to receive the outer glaze is one that is dry and has residue from not being cleaned off completely (pinholes and crawls occur). The second poorest surface is one that has residue but is still too wet from the inside pour (often true if the piece is thin walled). The best surface is one that is slightly damp and clean.

- Glaze the outside. Keep your hands damp so they will not stick to the wax (and pull off sections as you touch it). Push the lip of the mug into the glaze 5-10mm (being careful to hold the mug level as you do this). Shake off the drips and immediately turn it over, put your hand inside, clamp against the inner surface and push it into the glaze right down to the rim (to overlap the lip dip just made). It may be tricky at first to push the mug down far enough and avoid glaze spilling inside.

- Set the mug on a turntable to sponge away any drips left over the wax-covered areas on the inside top of the lip.

- Clean the foot and set it out to dry.

Related Information

Liner Glazing a porcelain mug

The process of applying a liner glaze to the inside of a piece (by pouring), applying wax emulsion up the top inside and over the rim (using a turntable and brush), removing the glaze up the outside to mid-rim and finally dipping the rim and outside into the other glaze.

Meet two glazes at the rim using wax emulsion. Why? How?

This picture has its own page with more detail, click here to see it.

Reactive glazes (melt-mobile, crystallizing or heavily pigmented) are the least suitable for food surfaces because they have the potential to leach metals. Liner glazing ware is an excellent way to deal with this problem. Not only does this approach improve functionality but it can be aesthetically pleasing and practical in production.

This liner is GA6-B, a pottery glaze recipe we promote with confidence. Not only is it less likely to be leaching metals but also less likely to craze - this assures water tightness on non-vitreous bodies and eliminates any potential for bacteria growth in the cracks (especially if the body has porosity). Unfortunately, glazes that leach are also likely to stain and cutlery mark - these add more reasons why they are most often unsuitable for food surfaces.

The straightness of the dividing line is affected by both the application technique and the degree to which the two glazes bleed into each other and run. Read and watch our liner glazing step-by-step and liner glazing video for details on how to do this - it is practical for any potter or hobbyist (or even in production). And tap/click the picture above for other examples of this.

Beautifully finished mug from Tim Hortons

This picture has its own page with more detail, click here to see it.

This was a limited edition heavy (450g or 1 lb) white stoneware mug for sale in Tim Hortons restaurants recently. It exhibits fine workmanship and carries lessons for potters. Notice they employ a transparent food safe liner glaze. The outside decoration appears to have been done at the leather hard stage using a colored engobe, wax resist and ceramic transfers. The entire piece was likely dipped in a transparent glaze (in the bisque state). The handle has a simple and functional shape that could be emulated using our handle mold making techniques. The simple flared body shape lends itself well to jiggering.

Mistake when liner glazing a mug

This picture has its own page with more detail, click here to see it.

The white inner liner glaze (that wraps over the rim) was not removed after the wax was applied. The outer glaze thus overlays patches of it near the rim. The meeting line has been blurred and the other glaze has run downward and crawled somewhat revealing patches of the inner one.

Liner glazing done right and wrong

This picture has its own page with more detail, click here to see it.

I already know that many with say they prefer the one on the right. However, the purpose of my liner glazing is to minimize liquid contact with glazes strongly pigmented with heavy metals. With the proper technique of applying a liner glaze, you can make the outside and inside ones meet in a straight line at the outer part of the rim rather than just have one spill over the other.

A fluid melt glaze bleeds much more into adjoining ones

This picture has its own page with more detail, click here to see it.

The outer green glaze on these cone 6 porcelain mugs has a high melt fluidity. The liner on the upper mug is G3806C, a fluid melt high gloss clear. The liner glaze on the lower one, G2926B, is high gloss but not highly melt fluid. Thus, when both the outer and inner glazes have high melt fluidity (upper mug), they bleed together forming a fuzzy boundary. But when even one of them is not, a crisp boundary is achieved (lower mug).

Inbound Photo Links

Gunmetal black mug demos liner glazing: Safe glaze inside, pigmented matte outside. |

Links

| Glossary |

Liner Glaze

Liner-glazing is a way to assure that your ware has a durable and leach resistant surface. It also signals to customers that you care about this. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy