| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Trafficking

At Digitalfire we use the term "recipe trafficking" to describe the online trade in ceramic and pottery glaze recipes that can waste your time and cost you lots of money. Better to learn to understand glazes.

Key phrases linking here: trafficking, trafficked, glazy.com, glazy - Learn more

Details

At Digitalfire we use the term "trafficking" to describe the online trade and misguided trust in ceramic and pottery glaze recipes. Don't get addicted or trapped - they will waste your time, sap your motivation, cost you money, affect the quality of your ware and prevent you from pursuing avenues to make your ceramic practice greener and easier on Mother Nature. Better to learn how to create and adjust your own. To learn more visit the article link at the bottom of this page.

Related Information

Glaze recipes online waiting for a victim to try them!

This picture has its own page with more detail, click here to see it.

You found some recipes. Their photos looked great, you bought $500 of materials to try them, but none worked! Why? Consider these recipes. Many have 50+% feldspar/Cornwall/nepheline (with little dolomite or talc to counteract their high thermal expansion, they will craze). Many are high in Gerstley Borate (it will turn the slurry into a bucket of jelly, cause crawling). Others waste high percentages of expensive tin, lithium and cobalt in crappy base recipes. Metal carbonates in some encourage blistering. Some melt too much and run onto the kiln shelf. Some contain almost no clay (they will settle like a rock in the bucket). A better way? Find, or develop, fritted, stable base transparent glossy and matte base recipes that fit your body, have good slurry properties, resist leaching and cutlery marking. Identify the mechanisms (colorants, opacifiers and variegators) in a recipe you want to try and transplant these into your own base (or mix of bases). And use stains for color (instead of metal oxides).

Knowing about recipe limits could save you the work of testing this glaze

This picture has its own page with more detail, click here to see it.

This is an example of a recipe being trafficked online that raises red flags just looking at it. Before dismissing the following I can tell you that I deal with hundreds of customer glaze issues a year and people expect recipes to work as shown if no documentation is included, many also assume functionality.

The first red flag: There is no silica! That means this is a low fire glaze masquerading as middle temperature, so it is going to run during firing (run a lot). It will also mean poor durability. There is a ton of feldspar, that means a high level of sodium. Without low-expansion MgO to counterbalance its high thermal expansion the glaze is likely going to craze badly. The mechanism of the crystallization is titanium over-supply, this has triple the maximum I would ever put in a glaze. The crystallization happens during cooling in the kiln (producing the visual effect being sought). But the the surface produced will cutlery mark and stain, probably very badly. Given the unbalanced chemistry this has, any colorant added will likely be leachable! I tested it and all my fears were realized. My slow-cool firing made the surface so dry it was very unpleasant to touch. Maybe this needs fast cooling. But who knows, there are no notes. This does not appear to belong on any functional ware, inside or outside. Someone noted that people use this to produce layering effects (see links). That begs documentation on how that wold work. Without gum would it lift and crawl as layers are added over it. Would you have to overlay every square inch? Would it still craze? All the how-to information needed to make it work are more important that the recipe itself.

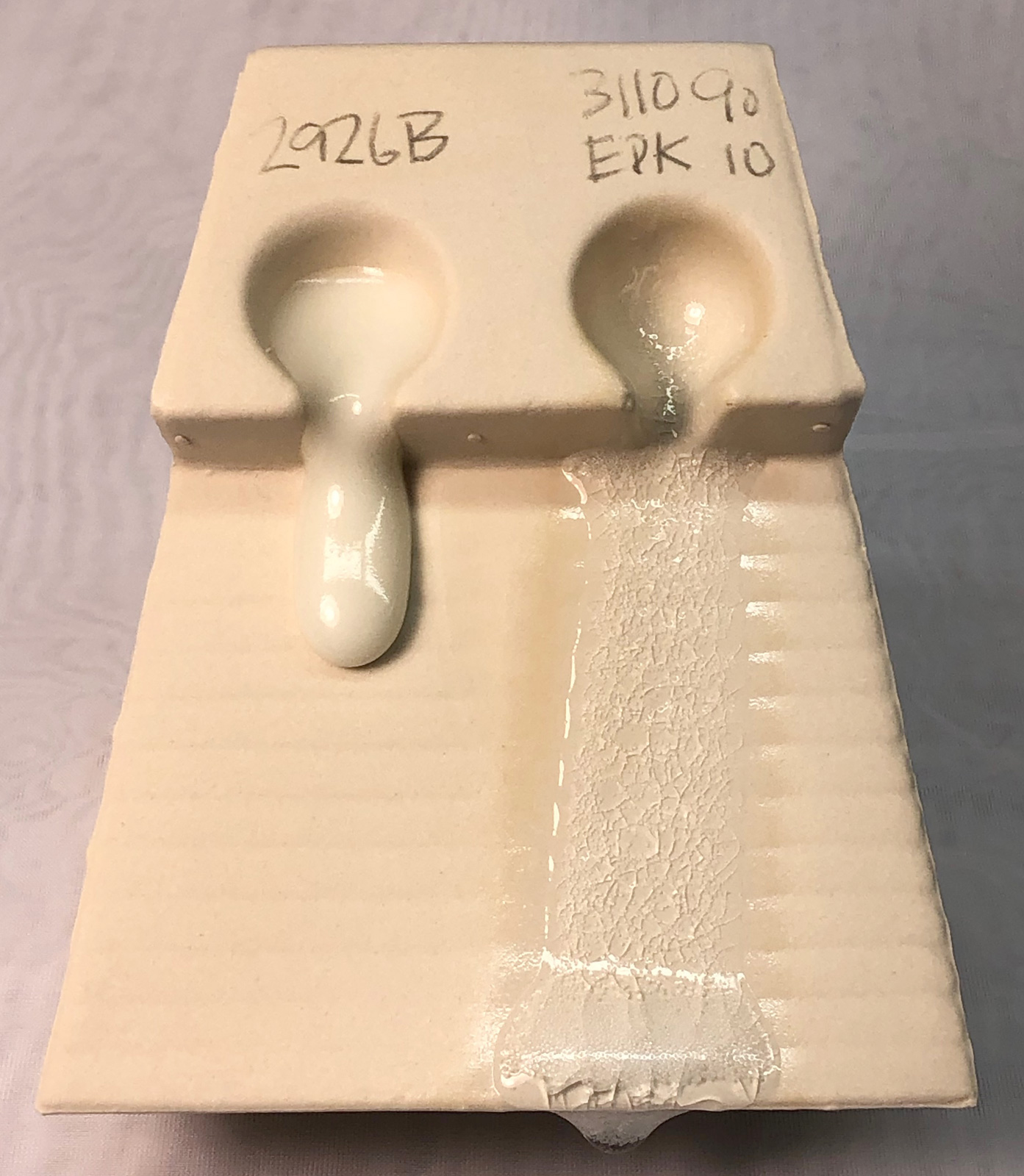

The first of 15 "Fool-Proof Recipes" wrecked my kiln shelf!

This picture has its own page with more detail, click here to see it.

This is recommended in the booklet "15 Tried and True Cone 6 Glaze Recipes". This melt flow tester compares it with a typical cone 6 glossy, G2926B. This recipe is 90% Frit 3110 and 10% kaolin and their booklet recommends adding stains to it. But anyone knowing a little about this frit knows it would run off this flow tester even before bisque temperatures. It is crazy to recommend this. Even as a crackle. For cone 6 it needs to be diluted much more, not just with kaolin but also silica. I knew this would run but I underestimated its melt fluidity. I put a large tile below the tester to catch overrun, yet the melt ran off that and a big blob melted through the kiln wash and so far into the zircon shelf I could not chip it off! I cannot imagine how many people have tried this on vertical surfaces and had the same thing happen. The lesson: Use common sense when looking at recipes, then you don't even need to waste time testing them. Even if their authors did not!

Tried and True recipes. Really?

This picture has its own page with more detail, click here to see it.

Books and web pages with flashy pictures are the centrepiece of an addiction-ecosystem to recipes that often just don't work. Maybe these are "tried" by a lot of people. But are they "true"? Most are so-called "reactive glazes", outside normal practice - to produce visual interest they run, variegate, crystallize, pool, break, tint, go metallic, etc. But this happens at a cost. And inside special procedures and firing schedules that need explaining. It is not obvious these are understood by the recipe authors or sharers. And these recipes are dated and contain troublesome and unavailable materials. We use frits now to source boron. Stains are superior to raw colorants, even in glazes like this. Many of these will craze badly. And many will not suspend in the bucket. And will run during firing. Reactive glazes have other common issues: Blistering, leaching, cutlery marking, fuming. Trying colors in differing amounts in different base recipes is a good idea. But the project is most beneficial when it shows color response in terms of quality recipes of contrasting chemistries. The point of all of this: Understand a few glazes and develop them, rather than throwing spaghetti against the wall hoping something sticks. Commercial reactive glazes are an alternative also.

Inbound Photo Links

Is the V.C. 71 pottery glaze a true matte? |

Imagine realizing that pottery you're selling is all going to craze! |

Links

| Articles |

Trafficking in Glaze Recipes

The trade is glaze recipes has spawned generations of potters going up blind alleys trying recipes that don't work and living with ones that are much more trouble than they are worth. It is time to leave this behind and take control. |

| Glossary |

Triaxial Glaze Blending

In ceramics many technicians develop and adjust glazes by blending two, three or even four l materials or glazes together to obtain new effects |

| URLs |

https://ceramicartsnetwork.org/freebies/guide/15-tried-and-true-cone-6-glaze-recipes

15 Tried and True Cone 6 Glaze Recipes PDF booklet from CeramicsArtNetwork.org. These are mostly not for functional pieces yet we find many people doing exactly that. Each of these are lessons in limit recipes and limit formulas. |

| Materials |

Gerstley Borate

Gerstley Borate was a natural source of boron for ceramic glazes. It was plastic and melted clear at 1750F. Now we need to replace it. How? |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy