| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Soluble Salts

In ceramics, certain compounds in clays and glazes can dissolve into the water, then on drying these are left on the surface.

Key phrases linking here: soluble salts - Learn more

Details

In ceramics, certain compounds (e.g. calcium or magnesium sulphate) in clays and glazes can dissolve into the water, then on drying, are left on the surface as the water evaporates. The problem is most pronounced in red burning clays, but also common in ball clays and others. Wet processed materials normally do not have soluble salts.

Soluble salts are also almost always present in the water of ceramic slurries, these can be clearly evident as a brown coloration. This can be an issue when the solubles from a dirty clay are pulled into a plaster table and then contaminate a subsequent pour of a finer body. A highly vitreous porcelain, for example, could blister during firing due to this.

For more information, see the topic Efflorescence.

Related Information

Various cone 10R clays with soluble salts on the surface

This picture has its own page with more detail, click here to see it.

These disks concentrate the solubles on the outer edge (because of the way they are dried). Soluble salts can enhance the visual appeal of a fired clay but they can also do the opposite.

Soluble salts on a range of different cone 6 fired clay brown/tan bodies

This picture has its own page with more detail, click here to see it.

The concentrations are not serious and are typical of what you might find on a commercial body.

Soluble salts on cone 04 terra cotta clay bodies

This picture has its own page with more detail, click here to see it.

Low temperature clays are far more likely to have this issue. And if present, it is more likely to be unsightly. The salt-free specimens have 0.35% added barium carbonate.

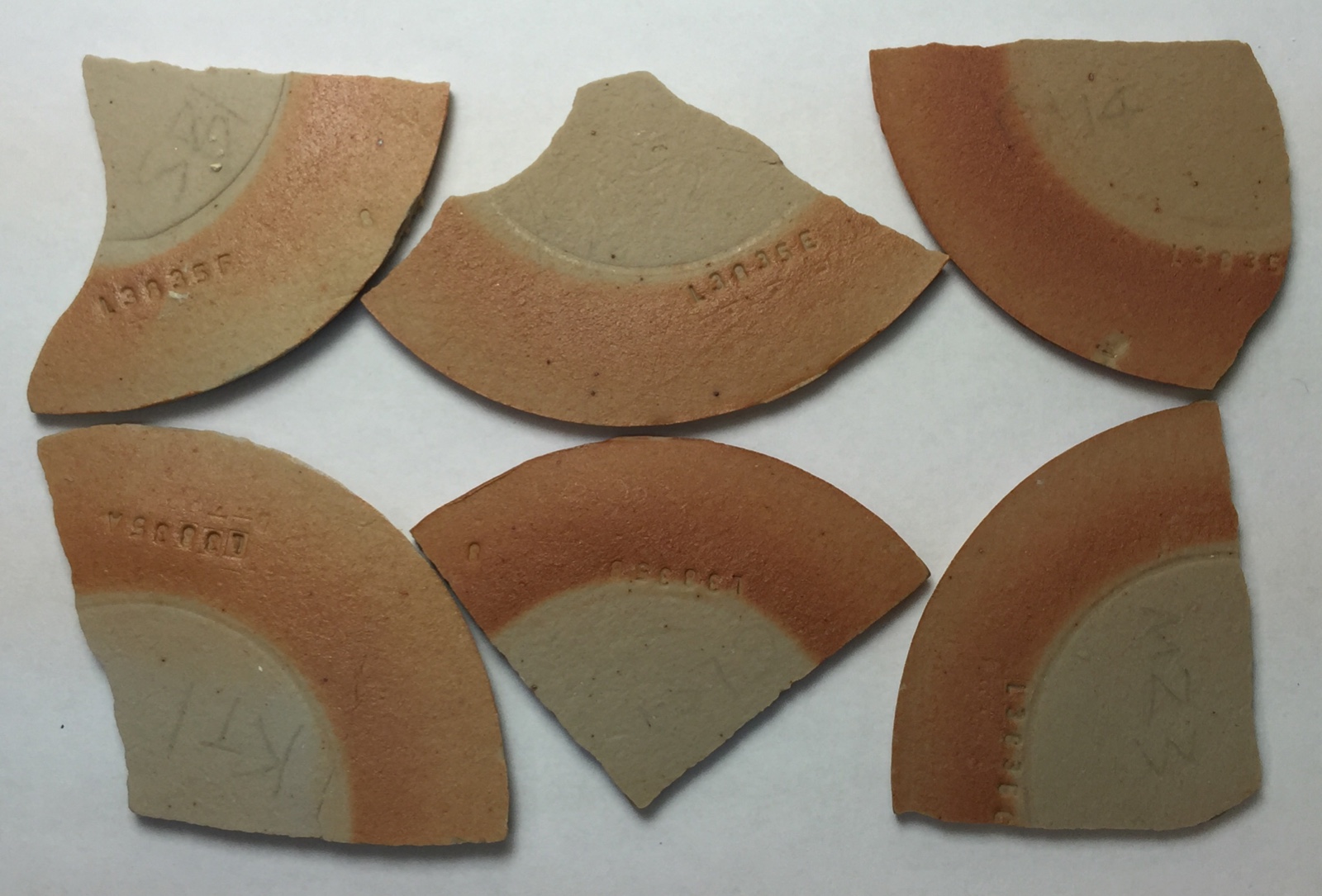

Soluble salts on six different common North American ball clays

This picture has its own page with more detail, click here to see it.

Each of these fired fragments is made from a mix of 65 ball clay and 35 nepheline syenite. These are the remnants of a DFAC test done on each (soluble salts concentrate on the outside edge of a disk as it is dried with the inside protected). Clockwise: Spinks Blend, 54S, OM4, M23, Gleason and KT1-4. Each of these ball clays produced a zero-porosity dense fired ivory porcelain at cone 6, they all have remarkably similar appearance. And they all have a high level of soluble salts.

How bad can efflorescence on terra cotta be?

This picture has its own page with more detail, click here to see it.

Like this! This terra cotta clay matures to good strength around 1950F. Notice how the soluble salts have concentrated on the outer and most visible surface. The piece was dried upside down so, of course, all the water had to escape through that route. A complicating factor is how handling of the piece at the leather hard stage has made it even more unsightly. This problem is common in many terra cotta materials but can also surface in others. A tiny addition of barium carbonate can precipitate the salts inside the clay matrix so they do not come to the surface on drying.

The magic of a small barium carbonate addition to a clay body

This picture has its own page with more detail, click here to see it.

Two bisqued terracotta mugs demonstrate efflorescence. The clay on the right has 0.35% added barium carbonate (it precipitated the natural soluble salts dissolved in the clay and prevented them from coming to the surface with the water and being left there during drying). The process is called efflorescence and is the bane of the brick and terra cotta tile industries. The one on the left is the natural clay. The unsightly appearance is fingerprints from handling the piece in the leather-hard state, the salts have concentrated in these areas (the other piece was also handled).

Which clay contains more soluble salts?

This picture has its own page with more detail, click here to see it.

Example of sedimentation test to compare soluble salts water extracts from suspended clay. This simple test also reveals ultimate particle size distribution differences in clays that a sieve analysis cannot do.

Soluble salts as a white powder on a commercial bentonite

This picture has its own page with more detail, click here to see it.

Bentonite is a super-plastic clay. This block of it took months to dry, the material really holds on to its water! It shrunk to about half the size and, of course, broke up into many pieces in the process (because bentonite has such a high drying shrinkage). That white powder is calcium sulphate, it is soluble and comes to the surface with the water as the clay dries. The finer the manufacturer grinds the material, the more salts are liberated. In most ceramic applications for commercial raw bentonites, these soluble salts are not an issue (but the iron content certainly can be). The reason these salts can be tolerated is that bentonite is normally employed in bodies and glazes in the 1-5% range.

Soluble salts on sculptural piece

This picture has its own page with more detail, click here to see it.

Original File: IMG_6016.jpg

Plucking in a cone 10R stoneware body having soluble salts

This picture has its own page with more detail, click here to see it.

The soluble salts have formed the brown coloration on the bare clay foot ring. While the actual salts layer is very thin, it is glassy and enough to glue parts of the base to the kiln shelf (the latter did not have adequate kiln wash or sand). The glaze line is close to the foot and this complicates the problem. There are a couple of solutions. Sand the foot ring at the dry stage to remove the soluble salt layer. Use a more refractory kiln wash that offers a powdery, non-stick surface.

Soluble salts on a porcelain mug are causing plucking

This picture has its own page with more detail, click here to see it.

Fired to cone 10R. The porcelain contains bentonite and a plastic kaolin, both are contributing iron-stained solubles that come to the surface during drying. They tend to concentrate on this foot ring. The solution is to employ a little barium carbonate in the porcelain recipe to precipitate the salts. These could also be sponged or sanded off in the dry state.

Brown soluble salts that appear after drying, but disappear on firing

This picture has its own page with more detail, click here to see it.

The soluble salts dissolved in the water of plasticity of this red body have migrated through the white engobe during drying of these earthenware cups. The cups were upside down so all the solubles have been left on the outside surface. The red body is made using a high percentage of Redart clay (a widely available commercial low-fire low-plastic clay in North America). It is plasticized using added ball clay. The brownish material is organic, because after bisque firing it has disappeared.

Inbound Photo Links

Cone 10R stoneware clay with and without barium carbonate |

Tiny barium addition to a buff stoneware transforms it |

Links

| Glossary |

Efflorescence

A common problem with dry and fired ceramic. It is evident by the presence of a light or dark colored scum on the dry or fired surface. |

| Glossary |

Plucking

A firing issue in ceramics where the foot rings of vitreous ware stick to the kiln shelf. Removing them leaves sharp fragments glued to the shelf. |

| Articles |

Formulating a body using clays native to your area

Being able to mix your own clay body and glaze from native materials might seem ridiculous, yet Covid-19 taught us about the need for independence. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy