| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Characterization

In ceramics, this normally refers to the process of doing physical or chemical testing on a raw material to accurately describe it in terms of similar ones.

Key phrases linking here: characterization, characterizing, characterize - Learn more

Details

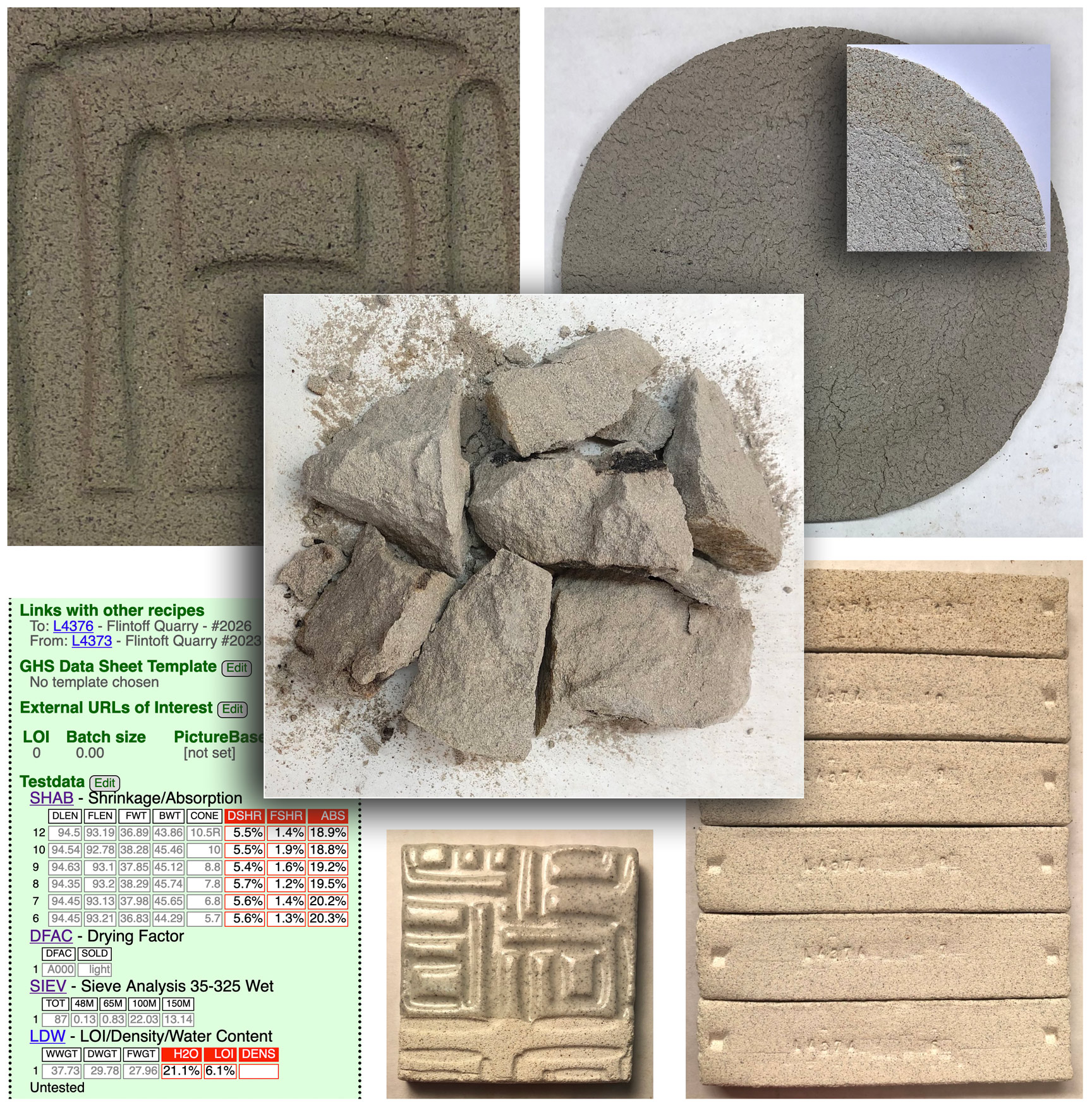

Characterizing a clay by making observations, doing physical tests, taking pictures and recording it all (with detailed notes).

Material knowledge is all-important in ceramics. The first hundred pages of almost any textbook on ceramic manufacturing are on clay properties. When ceramic materials are "understood", it is possible to control the properties of the bodies, glazes and engobes used in traditional ceramics. That is where "characterization" comes in. It is about understanding your materials. About being able to describe what a material is in terms that enable the determination of its suitability (most often in comparison to alternatives rather than in absolute terms). That is why product datasheets typically highlight material properties of interest to specific markets. Unfortunately, these are often focused on purchasing agents who want absolute numbers to compare brand names. But to technicians, data sheets full of numbers and acronyms often seem inadequate. At times, it even appears that companies do not really understand the products they manufacture for ceramics!

The ceramic world functions on "recipes". But often, much less effort is put into understanding them and their materials than should be. An example of this is the pursuit of substitutes for materials. These substitutes can be straightforward (e.g. switching one source of silica to another), but they often come with a complicated list of trade-offs. For example, switching from one kaolin to another in a porcelain: These often have very different properties (e.g. fired whiteness, plasticity, thixotropy). Other impacts are on body stickiness, drying performance, degree of maturity (with associated fired hardness and durability, translucency, thermal expansion).

Substituting materials becomes more complicated for secondary clays. It is common for people to substitute such materials in recipes simply because they have similar-sounding names! However, the chemical makeup is more difficult to connect with their physical and firing behavior. This is often because the materials are not as finely ground and their powders have populations of a variety of different mineral particles (which interact in complex ways). Consider red-burning stonewares: They may depend on recipes that contain refractory red clays countered with a controlled amount of feldspar or high-feldspar clays. Or they may be based on red clays that mature at low temperatures balance by other refractory clays or materials. Fired color is achieved by finding a balance between vitrification (for fired density and strength) and refractoriness (for red rather than brown coloration). With these, it is more difficult to maintain the same forming properties while adjusting for changes in fired maturity.

Consider a good example of the value of having characterized the clays you have access to: Suppose a plastic body that fires around 1200C (cone 6) is needed. You have a fine-grained silty clay that is somewhat plastic and fires more vitreous than required. You also have a fine-grained clay that is highly plastic and is too refractory for the required temperature. That makes it likely that a mix of these two materials will produce a usable body. Studying data sheets of these two materials would not make that evident, but knowing them, via your own characterization efforts, would make it so.

Textbooks treat the subject of characterization in an intimidating way, using terms like “photon scattering”, “RM diffraction”, “scanning microscopy” or “mass spectrometry”. These require expensive lab equipment, so they can seem pretty distant to potters or smaller operators. In reality, for traditional ceramics, all one really needs is simple physical tests. Knowing about these things typically falls into the realm of people designing a process, but not actually using it. The test procedures I am about to recommend will not be listed or studied in any college course. That being said, professors and students tell us that they are being sent here for practical testing methods!

Preparing a slurry, dewatering, making test bars, throwing and measuring the bars and particle size.

-Firing test bars at various temperatures to profile the surface color and character, fired shrinkage and porosity (e.g. the SHAB test) and glaze fit and response.

-Measuring the dry strength, dry shrinkage and drying performance (e.g. the DFAC test).

-Measuring the particle size, size distribution and level of contaminants (e.g. the SIEV test).

-Making ware using the material pure.

In glazes, the focus is often on the chemistry of the materials. Frits, for example, find their entire merit in their chemistry and switching from one to another is all about how similar the oxide chemistry is. Feldspars are a similar story.

While the chemistry of glaze materials is their most important characteristic, it is also important to study other properties. Consider some examples. Feldspar and kaolin source Al2O3, but the kaolin suspends the slurry and hardens the dried glaze (at least 15% of it is normally needed). Calcined alumina also sources Al2O3, but its physical form is highly refractory and it does not dissolve into the melt readily. Talc and dolomite both source MgO, wollastonite and calcium carbonate both source CaO, but the first (respectively) have a far lower LOI.

Related Information

Routine SHAB testing creates valuable historical drying and firing data

This picture has its own page with more detail, click here to see it.

Suddenly, ware is coming out of your production kiln warped or cracked or off color. Unless the answer is obvious, the first action should be to compare its drying and firing test data with past runs. If you are doing that as a routine, then SHAB test bars (and the test result data they bring) will already be available. These bars are tests of slip casting bodies, they can be made in a plaster mold and length-marked as shown. That data is a characterization of the clay body. The value of this kind of data-gathering becomes evident when a disaster happens (or better yet, is prevented). Clay bodies have plasticity, dry performance, dry strength, fired density, fired shrinkage, fired strength, etc. If you have historical data (accompanied by firing schedules, recipes, etc), you have an invaluable tool. Where does one gather the data? In spreadsheets? No, in a database. An account at Insight-live.com is specifically intended for this.

How to decide what temperature to fire this clay at?

This picture has its own page with more detail, click here to see it.

This is an extreme example of firing a clay at many temperatures to get wide-angle view of it. These SHAB test bars characterize a terra cotta body, L4170B. While it has a wide firing range its "practical firing window" is much narrower than these fired bars and graph suggest. On paper, cone 5 hits zero porosity. And, in-hand, the bar feels like a porcelain. But ware warps during firing and transparent glazes will be completely clouded with bubbles (when pieces are glazed inside and out). What about cone 3? Its numbers put it in stoneware territory, watertight. But decomposition gases still bubble glazes! Cone 2? Much better, it has below 4% porosity (any fitted glaze will make it water-tight), below 6% fired shrinkage, still very strong. But there are still issues: Accidental overfiring drastically darkens the color. Low-fire commercial glazes may not work at cone 2. How about cone 02? This is a sweet spot. This body has only 6% porosity (compared to the 11% of cone 04). Most low-fire cone 06-04 glazes are still fine at cone 02. And glaze bubble-clouding is minimal. What if you must fire this at cone 04? Pieces will be "sponges" with 11% porosity, shrinking only 2% (for low density, poor strength). There is another advantage of firing as high as possible: Glazes and engobes bond better. As an example of a low-fire transparent base that works fine on this up to cone 2: G1916Q.

Clay lab report. Is this really what you need?

This picture has its own page with more detail, click here to see it.

If you are trying to use local clays for brick or tile or even pottery production, characterizing the available materials is the first step. But how? This is the kind of data a lab might return - perhaps you wonder about its value? We feel traditional ceramics technology is fundamentally relative. A history of many reports like these, in context with other data, might be good for mining companies to determine if new stockpiles have any shifts in certain specific properties. Or a tile company evaluating a new ball clay. But as a way to understand the utility of a clay for a specific ceramic purpose, this contextless report is of little use. For example, the physical properties, the whole reason for using a clay, are unrelated to the chemistry. This is also a tunnel vision view, looking at only one temperature. On the other hand, simple procedures, like the SHAB test, provide a hands-on way to understand what a clay actually is.

Niko Leung finding and testing clays in Hong Kong

This picture has its own page with more detail, click here to see it.

She is using the DFAC test and SHAB test to systematically characterize each clay. Based on the results she will be able to either blend them or incorporate other materials (e.g. bentonite to add plasticity, feldspar to aid vitrification, kaolin or ball clay to impede vitrification, barium carbonate to precipitate solubles salts, silica to help with glaze fit, etc.). She is using code numbering to organize testing and material location records.

The top pile of clay can make one million coffee mugs. The bottom one can glaze ten million!

This picture has its own page with more detail, click here to see it.

These are raw clays behind the Plainsman Clays plant. The top one is a middle temperature stoneware. All it needs is a little bentonite (about 2-3%) to be a plastic, smooth, vitreous throwing body. If it was not mature at cone 6, that would be easy to fix by the addition of a little feldspar. Any fired-speck-producing impurities can be removed by using a propeller mixer to slurry it and then putting it through a screen (e.g. 60 mesh). After dewatering on a plaster table I am ready-to-go. And that bottom pile? That is the main ingredient in Ravenscrag Slip. All it needs is some feldspar and frit to be a base glaze at cone 6. It is non-plastic and easy to screen (although not really needed since it has few particulate impurities). Likely there are clays in your area you could use to make your own clay bodies and glazes also. The key is to characterize the material first so you know what type of body it would be best for and what to add to get it there.

Inbound Photo Links

Testing your own native clays is easier than you think |

I notice small details about the clays I test? Want to know why? |

Links

| Articles |

Low Budget Testing of Ceramic Glazes

There is more to glazes than their visual character, they have other physical properties like hardness, thermal expansion, leachability, chemistry and they exhibit many defects. Here are some simple tests. |

| Articles |

How to Find and Test Your Own Native Clays

Some of the key tests needed to really understand what a clay is and what it can be used for can be done with inexpensive equipment and simple procedures. These practical tests can give you a better picture than a data sheet full of numbers. |

| Articles |

Formulating a body using clays native to your area

Being able to mix your own clay body and glaze from native materials might seem ridiculous, yet Covid-19 taught us about the need for independence. |

| Glossary |

Physical Testing

In ceramics, glazes, engobes and bodies have chemistries and physics. Your formulation and quality control most likely need to focus on the physical properties. |

| Glossary |

Glaze Chemistry

Glaze chemistry is the study of how the oxide chemistry of glazes relate to the way they fire. It accounts for color, surface, hardness, texture, melting temperature, thermal expansion, etc. |

| Glossary |

Clay body

A term used by potters and in the ceramic industry. It refers to the earthenware, stoneware or porcelain that forms the piece (as opposed to the engobe and covering glaze). |

| Glossary |

Native Clay

A clay that a potter finds, tests and learns to process and use himself. To reduce the costs of importing materials manufacturers, especially in Asia, often develop processes for clays mined in their locality. |

| Projects |

Tests

|

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy