| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Fining Agent

Individual tiny bubbles in a glaze melt can coalesce around the undissolved particles of a fining agent, the growing bubble swallowing others around it and finally exiting at the surface.

Key phrases linking here: fining agent - Learn more

Details

"Fining" is a term used in winemaking where it is common to add bentonite or kaolin, as the tiny particles settle they act as coalescing points for undesired particles, these thus settle with them. This concept has application to ceramic glazes where tiny bubbles, even microscopic, are the impurity to be removed. Of course, the fining must be done while the glaze is molten and the particles around which bubbles coalesce must not melt themselves. This process improves the transparency of the fired glaze by decreasing the bubble population, fewer large bubbles enable much better clarity than millions of micro-bubbles that form clouds. The fining process can also increase bubble size enough that many more will break at the surface (ideally the melt heals to reflatten it). A thinner glaze layer helps to dissipate more bubbles at the surface.

All transparent glazes are subject to the problem of bubbling (including commercially prepared products). The problem is most serious when underglaze decoration becomes obscured by micro-bubble clouds in the transparent overglaze. Dark burning bodies generate the most bubbles and present the greatest problem to achieving transparency in a covering glaze.

We, and customers, have had success with two agents: Zircon and iron oxide (red or yellow) in 1 and 2% additions. Although alumina is a potential fining agent, we have not had success with it (perhaps because of now having a fine enough grade). Of course, iron impacts color, shifting the color transparent amber or muddying the color of added stains (so its use appears to be limited to red burning bodies, especially low fire). If you have success with other materials please contact us so we can update this page.

Related Information

Iron oxide as a fining agent to debubble a low fire transparent

This picture has its own page with more detail, click here to see it.

These terra cotta clays were bisque fired at cone 04 and glaze fired to 04 using the 04DSDH schedule. The glaze is G1916Q, an expansion-adjustable cone 04 clear. That schedule alone is often enough to get transparent, defect free glazes in many situations. But not in this case. The solution was to add a fining agent. In this case we added 2% red iron oxide (to the top glaze). The particles of iron floating in the melt acted as a congregating points for bubbles, helping them to escape. And we got a bonus: a more interesting aesthetic. A 1% addition also worked, but not as well (we have settled on 2% iron and screening the glazes to 100 mesh). Screening out the larger particles slightly degraded the fining performance (so we have to accept the tiny specks). Iron does not always workin other situations. Other fining agents we have used at cone 6 do not work in this situation (e.g. 2% Zircopax, Alumina). Of course, this glaze will fire amber on a white body.

Adding iron to a clear glaze has cleared the micro-bubbles!

This picture has its own page with more detail, click here to see it.

The glaze on the right is a transparent, G2926B, on a dark burning cone 6 body (Plainsman M390). On the left is the same glaze, but with 4% red iron oxide added. The entrained microbubbles are gone and the color is deep and much richer. It is not clear how this happens, but it is some sort of "fining" and is certainly beneficial. In other circumstances, we have seen big benefits with only 2% iron added.

The outside glaze has a fining agent that clears the bubble clouds

This picture has its own page with more detail, click here to see it.

This is a buff stoneware body, Plainsman M340. A L3954F black engobe was applied inside and upper outside at leather hard. The piece was fired at cone 6 using the PLC6DS schedule. The inside, totally clouded glaze, is G2926B. Outside is GA6-B Alberta Slip amber transparent. Normally, this inside glaze is crystal-clear on other bodies (and on this one without the black engobe). Clearly, the black stain in the engobe is generating tiny gas bubbles at the exact wrong time during the firing and the melt is unable to pass them. The outside glaze is on the same engobe, but the GA6-B glaze is demonstrating its ability to clear the micro-bubble clouding. It contains a lot of Alberta Slip, a material that is not finely ground like others. Particles across the range from 60-200 mesh are present, some of them appear to be acting as a fining agent to clear the bubbles.

There is a secret to the clarity of this terra cotta glaze

This picture has its own page with more detail, click here to see it.

The body is Plainsman L215 and the glaze is G1916Q. Both were thinly applied and fired using the 04DSDH schedule. The glaze has 2% iron oxide added and sieved to 80 mesh. The iron reddens the color and its particles act as a fining agent to reduce micro-bubble population. The one fired to cone 03 (left) is considerably stronger, better surviving the stress of successive impacts with a hammer. However, it has minute surface dimples, likely from decomposition beginning in the body. The mug on the right fired to cone 04, only slightly above the 05 bisque. The glaze surface is much better, almost crystal clear. A big advantage of cone 04 and cooler is that ware can be fired on stilts (enabling glazing the bottoms).

Zircopax as a fining agent to de-bubble a stained glaze

This picture has its own page with more detail, click here to see it.

The cone 03 porcelain cup on the left has 10% Cerdec encapsulated stain 239416 in the G2931K clear base. The surface is orange-peeled because the glass is full of micro-bubbles that developed during the firing. Notice that the insides of the cups are crystal-clear, no bubbles. So here they are a direct product of the presence of the stain. The glaze on the right has even more stain, 15%. But it also has a 3% addition of Zircopax (zircon). Suppliers of encapsulated stains recommend a zircon addition, but are often unclear about why. Here is the reason: It is a "fining agent".

Red stain in matte and glossy bases. Which looks best?

This picture has its own page with more detail, click here to see it.

The silky matte. 11% Mason 6021 encapsulated stain has been added to each. The one on the left is G2926B glossy base (it also has 2% zircopax as a fining agent for the micro-bubbles). But in the matte base on the right, G2934Y, no zircopax is necessary. It produces a stunning surface using this and other stains (including orange, yellow, black, purple), very pleasant to touch.

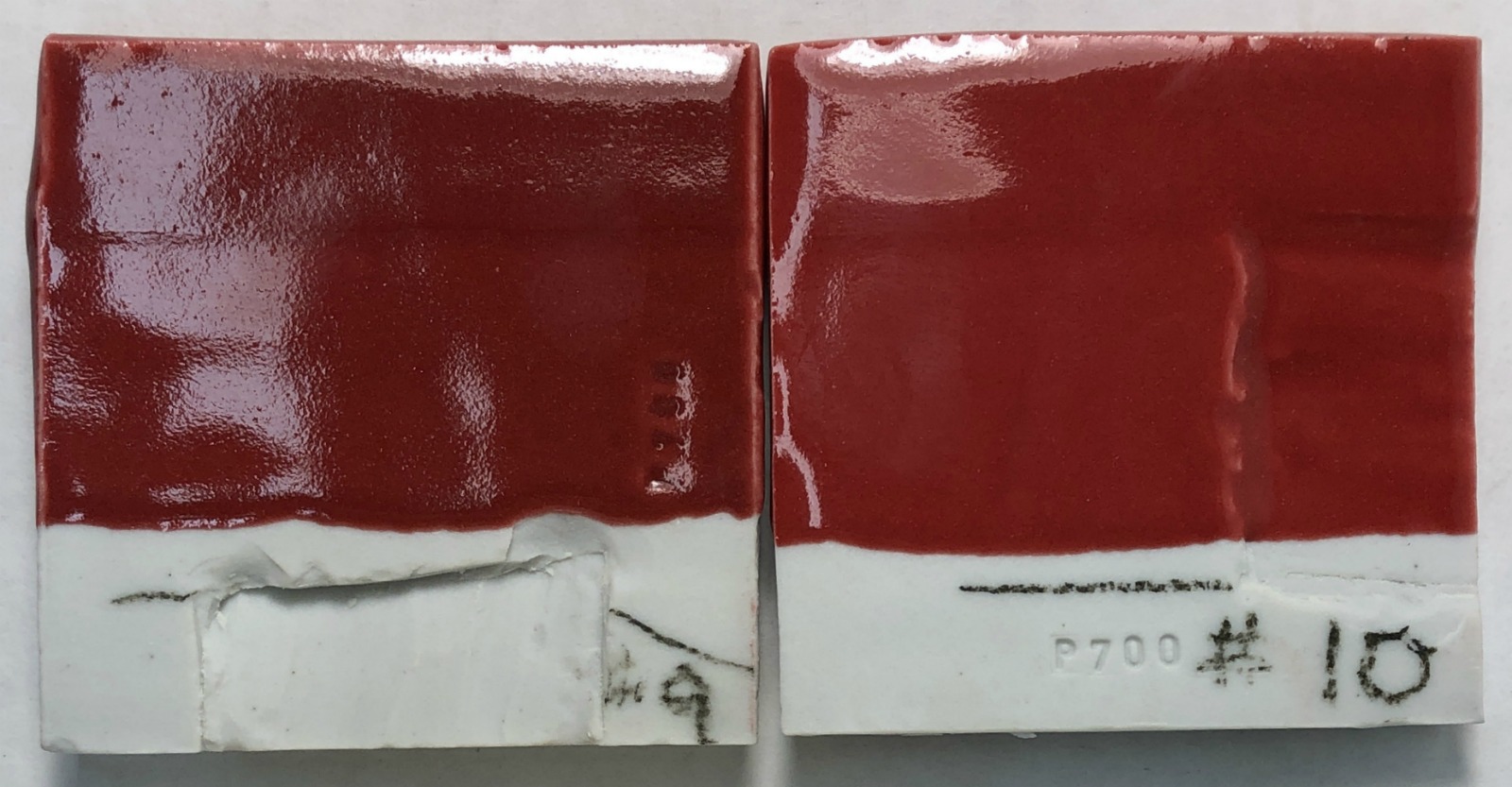

A cone 10R blood red - without copper but with risk

This picture has its own page with more detail, click here to see it.

This is G1947U clear glaze with 8% Mason 6021 encapsulated red stain added. The body is P700, a Grolleg kaolin porcelain. The one on the right, having significantly reduced clouding within, has one tiny addition: 2% Zircopax. It is acting as a micro-bubble fining agent, producing a brighter color and smoother surface. But there is a possible problem: These stains are not recommended for use above 2300F. Even though the color is very good, cone 10 is just on the edge of the limit temperature, so suitability for food surfaces would require careful testing for leaching cadmium.

Alberta Slip GA6-B base darkened with iron oxide

This picture has its own page with more detail, click here to see it.

Fired to cone 6 using the C6DHSC schedule. Top: GA6-B. This recipe is 80% Alberta slip and 20% Ferro Frit 3195 (we used to use frit 3134 but have found frit 3195 works much better). Bottom: We added 1, 2, 3 and 4% iron oxide. At about 2%, the color matches the rich reddish effect you would get if you used an 80:20 Albany:3195 recipe (without an iron addition). An added benefit is that the iron acts as a fining agent to remove micro-bubbles to achieve better transparency.

Links

| Glossary |

Glaze Bubbles

Suspended micro-bubbles in ceramic glazes affect their transparency and depth. Sometimes they add to to aesthetics. Often not. What causes them and what to do to remove them. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy