| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

A Low Cost Tester of Glaze Melt Fluidity

A One-speed Lab or Studio Slurry Mixer

A Textbook Cone 6 Matte Glaze With Problems

Adjusting Glaze Expansion by Calculation to Solve Shivering

Alberta Slip, 20 Years of Substitution for Albany Slip

An Overview of Ceramic Stains

Are You in Control of Your Production Process?

Are Your Glazes Food Safe or are They Leachable?

Attack on Glass: Corrosion Attack Mechanisms

Ball Milling Glazes, Bodies, Engobes

Binders for Ceramic Bodies

Bringing Out the Big Guns in Craze Control: MgO (G1215U)

Can We Help You Fix a Specific Problem?

Ceramic Glazes Today

Ceramic Material Nomenclature

Ceramic Tile Clay Body Formulation

Changing Our View of Glazes

Chemistry vs. Matrix Blending to Create Glazes from Native Materials

Concentrate on One Good Glaze

Copper Red Glazes

Crazing and Bacteria: Is There a Hazard?

Crazing in Stoneware Glazes: Treating the Causes, Not the Symptoms

Creating a Non-Glaze Ceramic Slip or Engobe

Creating Your Own Budget Glaze

Crystal Glazes: Understanding the Process and Materials

Deflocculants: A Detailed Overview

Demonstrating Glaze Fit Issues to Students

Diagnosing a Casting Problem at a Sanitaryware Plant

Drying Ceramics Without Cracks

Duplicating Albany Slip

Duplicating AP Green Fireclay

Electric Hobby Kilns: What You Need to Know

Fighting the Glaze Dragon

Firing Clay Test Bars

Firing: What Happens to Ceramic Ware in a Firing Kiln

First You See It Then You Don't: Raku Glaze Stability

Fixing a glaze that does not stay in suspension

Formulating a body using clays native to your area

Formulating a Clear Glaze Compatible with Chrome-Tin Stains

Formulating a Porcelain

Formulating Ash and Native-Material Glazes

G1214M Cone 5-7 20x5 glossy transparent glaze

G1214W Cone 6 transparent glaze

G1214Z Cone 6 matte glaze

G1916M Cone 06-04 transparent glaze

Getting the Glaze Color You Want: Working With Stains

Glaze and Body Pigments and Stains in the Ceramic Tile Industry

Glaze Chemistry Basics - Formula, Analysis, Mole%, Unity

Glaze chemistry using a frit of approximate analysis

Glaze Recipes: Formulate and Make Your Own Instead

Glaze Types, Formulation and Application in the Tile Industry

Having Your Glaze Tested for Toxic Metal Release

High Gloss Glazes

Hire Us for a 3D Printing Project

How a Material Chemical Analysis is Done

How desktop INSIGHT Deals With Unity, LOI and Formula Weight

How to Find and Test Your Own Native Clays

I have always done it this way!

Inkjet Decoration of Ceramic Tiles

Is Your Fired Ware Safe?

Leaching Cone 6 Glaze Case Study

Limit Formulas and Target Formulas

Low Budget Testing of Ceramic Glazes

Make Your Own Ball Mill Stand

Making Glaze Testing Cones

Monoporosa or Single Fired Wall Tiles

Organic Matter in Clays: Detailed Overview

Outdoor Weather Resistant Ceramics

Painting Glazes Rather Than Dipping or Spraying

Particle Size Distribution of Ceramic Powders

Porcelain Tile, Vitrified Tile

Rationalizing Conflicting Opinions About Plasticity

Ravenscrag Slip is Born

Recylcing Scrap Clay

Reducing the Firing Temperature of a Glaze From Cone 10 to 6

Setting up a Clay Testing Program in Your Company or Studio

Simple Physical Testing of Clays

Single Fire Glazing

Soluble Salts in Minerals: Detailed Overview

Some Keys to Dealing With Firing Cracks

Stoneware Casting Body Recipes

Substituting Cornwall Stone

Super-Refined Terra Sigillata

The Chemistry, Physics and Manufacturing of Glaze Frits

The Effect of Glaze Fit on Fired Ware Strength

The Four Levels on Which to View Ceramic Glazes

The Majolica Earthenware Process

The Potter's Prayer

The Right Chemistry for a Cone 6 Magnesia Matte

The Trials of Being the Only Technical Person in the Club

The Whining Stops Here: A Realistic Look at Clay Bodies

Those Unlabelled Bags and Buckets

Tiles and Mosaics for Potters

Toxicity of Firebricks Used in Ovens

Understanding Ceramic Materials

Understanding Ceramic Oxides

Understanding Glaze Slurry Properties

Understanding the Deflocculation Process in Slip Casting

Understanding the Terra Cotta Slip Casting Recipes In North America

Understanding Thermal Expansion in Ceramic Glazes

Unwanted Crystallization in a Cone 6 Glaze

Using Dextrin, Glycerine and CMC Gum together

Volcanic Ash

What Determines a Glaze's Firing Temperature?

What is a Mole, Checking Out the Mole

What is the Glaze Dragon?

Where do I start in understanding glazes?

Why Textbook Glazes Are So Difficult

Working with children

Trafficking in Glaze Recipes

Description

The trade is glaze recipes has spawned generations of potters going up blind alleys trying recipes that don't work and living with ones that are much more trouble than they are worth. It is time to leave this behind and take control.

Article

Ceramic suppliers can’t sell their stocks of books anymore. We supposedly don’t need them because we are all binging on Google, YouTube, Facebook and Instagram ceramics. And recipes on Glazy. It’s exploding. A lot is good, but one issue that can waste so much time is the “trafficking of glaze recipes” that don’t work. Many studios are "bucket morgues" of failed tests (and the powdered materials bought to try them). People spend money to mix ridiculous, expensive recipes, ones that end up in the garbage. Are you still addicted, going again and again for more punishment? Or did you find one that works — sometimes? But punishes you all the others? Are you really learning anything?

More than ever, as a person that wants to understand glazes, how to formulate, adjust and fix them myself; I am marginalized. Lonely. As a ceramic culture, we are getting more and more mentally lazy and wasting more and more money to make less and less technically acceptable ware. This article is a little disjointed and wandering, that reflects my lack of ability to step back far enough to understand fully what is happening to our craft and science.

Notwithstanding, there are gems out there to be found and adapted. But how can you find them while recognizing the time-wasters? Ask yourself: 1: What do I need? 2: What do I want?

Let’s answer #1 first. In production or hobby ceramics you need a base transparent that fits your clay body, reliably fires crystal clear without micro-bubbles, does not craze or scratch or mark or leach, has good application properties, whitens with zircon and colors with stains. Likewise for a matte base. These base recipes, along with knowing how to mix (control SG and thixotropy) and fire them is worth any effort to get. Not just because they can cover the functional surfaces and are well behaved but, as noted, the excitement of discovery can be satisfied by adding colourants, opacifiers and variegators. Or they can be coloured as a first coat on which to layer all sorts of commercial decorating products. Technically this may be all you need so you can stop reading here.

Admittedly you might have more specialized desires (e.g. a fluid melter, a low Al2O3 base for growing crystals). Or the color you want might require special chemistry in the base (e.g. significant BaO, presence or absence of ZnO or MgO, high levels of CaO). These are standalone recipes, exceptions to the base-with-additions approach. Are you really sure this is what you need? That the approach I described in the previous paragraph is not what you need? Could a simple stain addition to a base be all you need? Could you transplant the “mechanism” in the recipe that has caught your attention into your own clear glaze?

Ok, I get it. You really do need something special. First, don’t be naive, such recipes often come with baggage (like issues with crazing, leaching, hardness, running, consistency, application) so go in with both eyes open. So what is the best way to find one? Many people want a shortcut: throw the “google dice” and land directly on a reactive glaze that crystallizes, variegates, swirls and runs in rivulets, dances with wild colors or subtle effects that highlight every contour. Having no side effects! They want the buzz that kiln openings of such “street recipes” give. Unfortunately, the real world is just not like this. The people who share them fail to describe all the details to follow to make them look like the picture. Or they do not understand what they are sharing. It’s those pictures that get us addicted and coming back for more punishment!

- Thousands of people who were addicted for years wasted far more effort with garbage recipes than it would have taken to learn, organize, experiment and develop their own. Many ended up using the expensive "sticky goop" that comes in bottles and jars of commercial ready-made glazes. And how are most of those made? Additions of gums, stains, opacifiers and variegators to a transparent base!

- There is much value in developing the ability to spot the likely ‘mechanism’ that produces the visual character you see on a picture. Even if the publisher is not seeing it. Knowing this will enable transplanting it into your own base. Another benefit of mechanism recognition is avoiding recipes unworthy of even trying (e.g. crazers, leachers, pot breakers, stainers, settlers, those requiring intense babysitting).

Consider some of the reasons why a glaze recipe might not "travel" very well.

- Reactive glazes are often sensitive to firing temperature and/or cooling cycle. Some produce a matte of one color if cooled slowly and a gloss of another color if cooled quickly. Obviously, these should never get separated from their firing schedules. But that is exactly what happens. Even if you have the schedule what if the author’s idea of cone 6 is a built-in firing program that goes to 2220 but your cone-calibrated one goes to 2190? And, just because a kiln is programmed to heat up or cool down at a certain rate, that does not mean the elements and weight of the load will cooperate to do it.

- In a stable glossy base glaze, switching from one brand of feldspar, ball clay, kaolin or silica to another is not normally an issue. But talcs, calcium carbonates and dolomites are not consistent from brand to brand. And frits come in many brands and qualities and hundreds of chemistries that are poorly documented or not at all. The particle size of flux-sourcing materials can have a marked effect on reactivity and the particle sizes of refractory materials on their readiness to dissolve in the melt. Physical property differences in materials, whose chemistry is otherwise similar, can affect the slurry and application behaviour, which, in turn, affect the fired product. All of these issues are amplified for reactive glazes having fragile mechanisms.

- The glaze recipe may depend on a mechanism that the author is unaware of, does not explain or see the need to mention. A classic example is a glaze listed as “yellow” when actually it is a completely crystallized high iron glossy deep brown that depends on slow cooling. A glaze might be listed as a stable high gloss (because the author always cooled it quickly) whereas in actual fact it is a runny matte in normal firings (the author never put it on thick enough to see how much it melted and never looked at the chemistry to see how much it lacks Al2O3).

- Many (or most) glazes are dramatically affected by the nature of the clay they are applied to. Usually, the whiter, smoother, and more mature the clay body; the more vivid and brighter a glaze will be. Conversely, the darker, coarser, and more immature the body; the more subdued and dry the glaze will be. Notwithstanding, some glazes come alive on dark burning bodies. Others will turn matte on a vitreous body.

- Many recipes are sensitive to the thickness of application and whether they are on a vertical or horizontal surface. Different application techniques like spraying, pouring, and painting can fire different in character from what the small dipped samples indicate. Many glazes are profoundly affected by milling, especially if they contain materials of coarser particle size.

- So many flashy-looking pictures of recipes on social sites have high melt fluidity, often achieved by high sodium and/or potassium. But these bring baggage: high thermal expansion. That means crazing. When was the last time you saw a glaze recipe online outlining how to adjust its thermal expansion to fit different bodies?

- Many of these recipes can hide sinister things: They are not stable, metallic colors added to them will leach. They are not durable, they cutlery mark and scratch easily. It is even possible that the author doesn't really care or even know about issues like this. In fact, it is not unusual to see recipes having ridiculous amounts of things like manganese, lithium, barium or chrome.

- Fancy recipes can carry other baggage. Some recipe authors don’t mind pinholing or crawling, or using a glaze that is so powdery you can hardly handle or decorate the ware?

- What about chemistry calculation? Every glaze has a formula of oxides, some feel that oxide formulas travel a little easier than recipes. Still, most of the above problems will come into play anyway because you still have to derive a recipe of materials to supply those oxides, and if you are smart enough to adjust a found glaze, then why bother. It is just easier to make your own glazes using materials native to your area.

Misguided Trust

If you are a beginner in ceramics you might reason: "Why would anyone post a recipe online if they know it does not work?". However (noting the above-mentioned) they likely do not know it does not work. Or they are unaware that their narrow circumstances are, by coincidence, an enabler for a small window in which it does do something they like. Or they have a different idea of what "working" really means, maybe emphasizing aesthetics, possibly to the extent of totally ignoring functionality and practicality. Misguided trust in online recipes can discourage newbies who cannot find success with them, blaming themselves. It can even go further: Some people, who confront failure in trying a recipe for the first time, actually blame specific materials in the recipe, flaming manufacturers online "who cannot keep their products consistent". This kind of thinking is misguided, even if it were true that a recipe depends on a material being absolutely consistent, that kind of fragile recipe would not be worth using.

What is Much Better Than Recipes

Yes, there is something that travels even better than oxide formulas. It is the knowledge of what each oxide type contributes to a glaze, what each mineral type does to give it fired personality, and how they affect physical working properties. Each new recipe either confirms or fine-tunes your existing oxide-effect knowledge, or educates you in the effects of its special purpose source materials (i.e. colorants, opacifiers, crystal-forming agents) or unique formula (i.e. crystals from high CaO and low Al2O3 ). Each can be adapted to your own proven base recipes.

Add a smattering of line blending and trial and error adjustment, and you can make anything you want; adjust it any way you want. You can tell the glaze what to do. So why jump through hoops trying to pacify temperamental recipes that are always throwing tantrums in your kiln? You don't have to put up with that anymore.

Related Information

What has the trust in online recipes come to?

This picture has its own page with more detail, click here to see it.

These tests of a recipe called "Strontium Crystal Magic". The potter tried it on different bodies and firings. But instead of producing the magic crystals like the pictures, the surfaces fired totally matte. Reasoning "why would anyone put a recipe on line that does not work", she blamed one of the materials. Others fed that with rumours of claimed issues in its consistency. Admittedly, this glaze is meant for layering over others - but the source did not say that. This underscores misguided trust in trafficked recipes that most often lack sufficient documentation. Crystal glazes, by necessity, need to have a high melt fluidity. The crystals develop best with a specific cooling curve having a controlled fall at a narrow temperature range. Cool faster, they don't grow, slower and they matte the entire surface. Other factors, like clay body and glaze thickness are involved. People who post glaze recipes like this often do not document them well because they do not fully understand their mechanisms.

Tried and True recipes. Really?

This picture has its own page with more detail, click here to see it.

Books and web pages with flashy pictures are the centrepiece of an addiction-ecosystem to recipes that often just don't work. Maybe these are "tried" by a lot of people. But are they "true"? Most are so-called "reactive glazes", outside normal practice - to produce visual interest they run, variegate, crystallize, pool, break, tint, go metallic, etc. But this happens at a cost. And inside special procedures and firing schedules that need explaining. It is not obvious these are understood by the recipe authors or sharers. And these recipes are dated and contain troublesome and unavailable materials. We use frits now to source boron. Stains are superior to raw colorants, even in glazes like this. Many of these will craze badly. And many will not suspend in the bucket. And will run during firing. Reactive glazes have other common issues: Blistering, leaching, cutlery marking, fuming. Trying colors in differing amounts in different base recipes is a good idea. But the project is most beneficial when it shows color response in terms of quality recipes of contrasting chemistries. The point of all of this: Understand a few glazes and develop them, rather than throwing spaghetti against the wall hoping something sticks. Commercial reactive glazes are an alternative also.

Want bright orange? Use a stain in your own base transparent recipe.

This picture has its own page with more detail, click here to see it.

Orange is a very difficult color in ceramics. Inclusion stains are the only reliable method, they universally used in industry. But you could ignore that and try a bunch of recipes online. When they are presented on flashy web pages they can look tantalizing. But beware! Are the exotic materials you need to buy worth it. Will it actually fire orange? Will it craze or run or blister or leach or cutlery mark or crawl or settle like a rock in the bucket? It is much better to put an orange encapsulated stain into a transparent glaze you already know works on your clay. Then just experiment with percentage to get the color you want. Or, how about trying a premixed orange at low fire? Ware can be amazingly functional at low temperatures (e.g. cone 03-02) and bright colours labelled for cone 06 mostly work fine in that range.

Is that recipe you found online really what you think it is?

This picture has its own page with more detail, click here to see it.

It contains significant Frit P-25, I googled that to Digitalfire, it contains 1.8% fluorine! When much of that gases off during firing are you really equipped to deal with fluorine gas in your studio? One answer is to substitute my own frits (which of course do not contain fluorine). I did the calculations in my account at insight-live.com (see the recipes side-by-side). In the formula, I substituted the F (fluorine) for a mix of CaO/MgO. In the recipe, I substituted Ferro Frit 3110 (it is also a high-sodium frit) for the P-25, then I juggled the rest of the recipe to match up the oxides. More Gerstley Borate supplies the lost B2O3, more ball clay supplies the lost Al2O3 and less silica is needed (because the ball clay brought along more). I ended up with a recipe that is going to suspend much better (more clay) and was able to eliminate the whiting (because the rest of the new recipe is supplying more CaO). This recipe has a high thermal expansion, that means crazing. Would it not be easier to simply add a red stain to a clear glaze you already have that is working well on your clay bodies?

The fact that it applied like this was not worth mentioning?

This picture has its own page with more detail, click here to see it.

Recipes trafficked online seldom include important information. How could the author of this one not mention this problem? The slurry turns to a gel and fills with bubbles. And then you have to add water again. The extra water makes it shrink more, compromising the bond with the bisque so it peels away when overglazed. Later more water is needed because it gels again. After that it cracks on drying and the glaze crawls on firing. Is this really worth it? Actually, this recipe is fixable, the material at fault can be substituted (using a little glaze chemistry) to produce a much easier-to-use slurry.

The traffic in glaze recipes may burn your success!

This picture has its own page with more detail, click here to see it.

Do you mix your own recipes? That's great, but the right approach to DIY is important. Online recipes might look great on a fancy website, but what are the chances they will actually fire the way they look in the picture? Or work in your circumstances? Did the contributor know the mechanism or give any sort of directions or cautions? After trying many glazes you may think you have found one that works. But does it really? How does it hold up to limit recipes? Does it have a balanced chemistry? Is it erratic and unreliable in firing? Difficult to use? Does it leach or craze or shiver or pinhole or blister? Or make you endure other problems? Be critical and cautious about foreign recipes. Most often it is better to find a base recipe, adjust and perfect it to your clay body, then add colorants, opacifiers and variegators.

A good matte glaze. A bad matte glaze.

This picture has its own page with more detail, click here to see it.

A melt fluidity comparison between two cone 6 matte glazes. G2934 is an MgO saturated boron fluxed glaze that melts to the right degree, forms a good glass, has a low thermal expansion, resists leaching and does not cutlery mark. G2000 is a much-trafficked cone 6 recipe, it is fluxed by zinc to produce a surface mesh of micro-crystals that not only mattes but also opacifies the glaze. But it forms a poor glass, runs too much, cutlery marks badly, stains easily, crazes and is likely not food safe! The G2934 recipe is google-searchable and a good demonstration of how the high-MgO matte mechanism (from talc) creates a silky surface at cone 6 oxidation the same as it does at cone 10 reduction (from dolomite). However it does need a tin or zircon addition to be white.

Popular white engobe recipe that does not work at cone 6

This picture has its own page with more detail, click here to see it.

This is Odyssey slip, a engobe recipe that is trafficked on the web. It is recommended for low, medium and high fire ware. It is 30% Ferro Frit 3110 and 70% ball clay. This is a bi-clay strip, a sandwich of two plastic clays rolled into a thin slab and cut into a bar (to make the bar the Odyssey slip was dewatered to typical pottery clay stiffness). We are looking at the engobe side of an EBCT test (the other side is Plainsman M390). During the latter stages of the firing the engobe has begun to melt and blister and darken in color (which it should not be doing). During earlier stages of firing this engobe would certainly have had a higher shrinkage and would have bent the bar its way. But it is now bent the other way. That means the engobe could well be under compression (having a lower thermal expansion than the body). Or the body could simply have pulled it the other way when the engobe lost its rigidity. Either way, the engobe does not fit this body at this temperature.

Glaze recipes online waiting for a victim to try them!

This picture has its own page with more detail, click here to see it.

You found some recipes. Their photos looked great, you bought $500 of materials to try them, but none worked! Why? Consider these recipes. Many have 50+% feldspar/Cornwall/nepheline (with little dolomite or talc to counteract their high thermal expansion, they will craze). Many are high in Gerstley Borate (it will turn the slurry into a bucket of jelly, cause crawling). Others waste high percentages of expensive tin, lithium and cobalt in crappy base recipes. Metal carbonates in some encourage blistering. Some melt too much and run onto the kiln shelf. Some contain almost no clay (they will settle like a rock in the bucket). A better way? Find, or develop, fritted, stable base transparent glossy and matte base recipes that fit your body, have good slurry properties, resist leaching and cutlery marking. Identify the mechanisms (colorants, opacifiers and variegators) in a recipe you want to try and transplant these into your own base (or mix of bases). And use stains for color (instead of metal oxides).

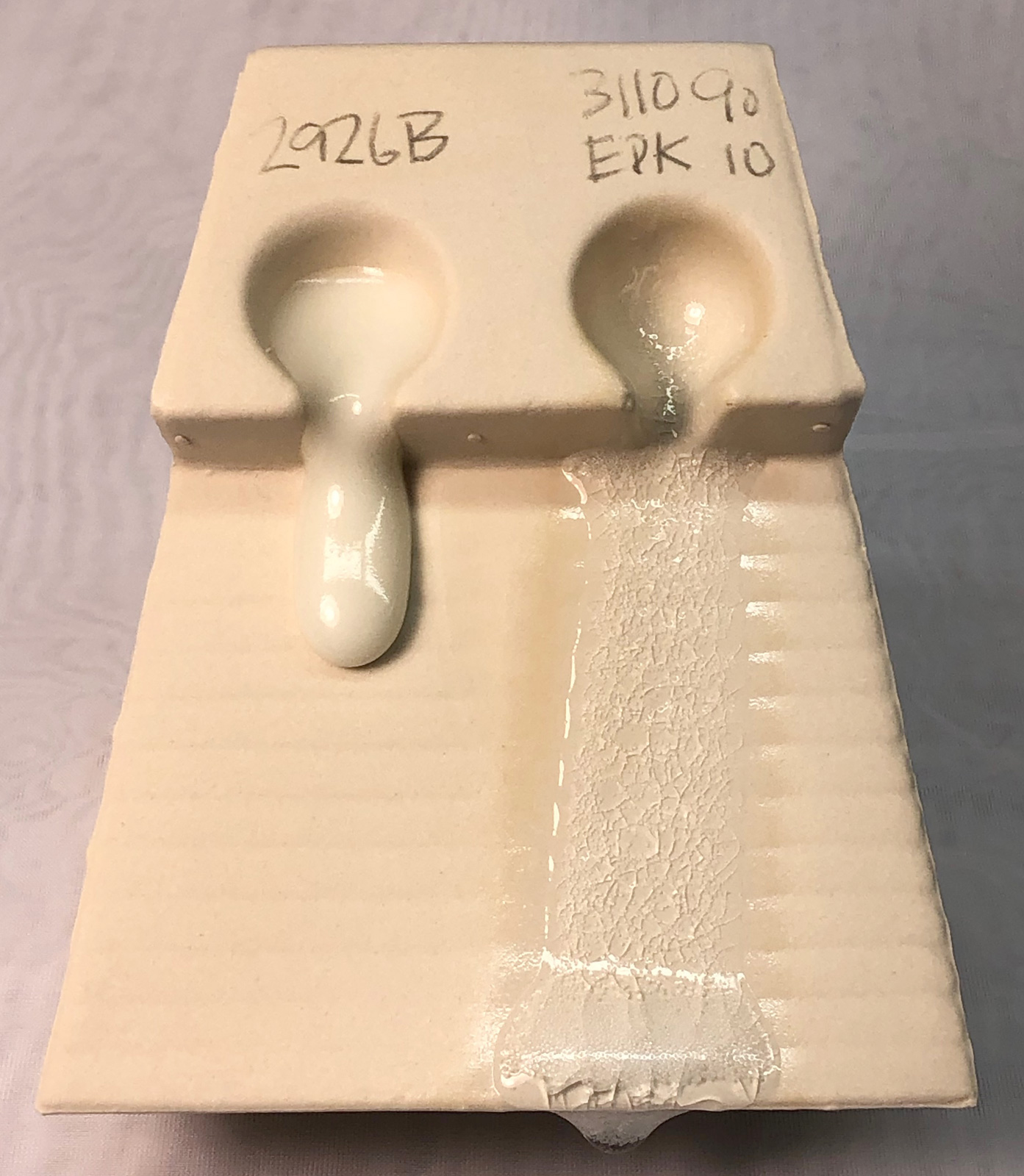

Cone 6 transparent way better without Gerstley Borate.

I surgically removed it to create G2926B!

This picture has its own page with more detail, click here to see it.

These are the original cone 6 Perkins Studio Clear (left) beside our fritted version (right). You cannot just substitute a frit for Gerstley Borate (GB), they have very different chemistries. But, using the calculation tools in my account at insight-live.com, I compensated for the differences by juggling other materials in the recipe. I even upped the Al2O3 and SiO2 a little on the belief they would dissolve in the more active melt the frit would create. I was right - a melt-flow GLFL test comparison (inset left) shows that the GB version flows less. Using this on ware exhibited another issue (after doing a IWCT test): Crazing. The very good melt flow on my G2926A fritted version is thus good news: It can accept more silica - the more silica, the more durable and craze resistant it will be. How much did it take? 10% more! That ultimately became the recipe for our standard G2926B cone 6 transparent.

Better to mix your own cover glazes for production?

This picture has its own page with more detail, click here to see it.

Yes. In this case the entire outside and inside of the mug need an evenly applied coat of glaze. For hobby this makes sense. But in production cover brushing makes less sense. The right pail has 2 gallons of G2934Y base with 10% Cerdec yellow stain: $135. Cost of brushing jars with the same amount: $600+! And each jar logs 10-15 minutes painting time plus waiting between coats. The one in the pail is a true dipping glaze (unlike many commercial ones that dry slowly and drip-drip-drip). This one dries immediately after dipping in a perfectly even layer (if mixed according to our instructions). And a bonus: This pail can be converted to brushing or base-layering versions using CMC gum.

Here is a good start to doing serious ceramic production at home

This picture has its own page with more detail, click here to see it.

This is what you need to be independent, to create your own manufacturing company in your garage in 2021 Some of the prices are "instead of" rather than additive. There are many approaches to glazes, the more you are willing to learn the better you will be able to make your own (and save a lot). We recommend the cone 6 range using a small test kiln (like this 220v ConeArt GX119, don't scrimp on this, go for quality and the practicality of a Genesis controller). A kiln you can fire often and inexpensively is a key enabler to learning, developing techniques, products, designs, durable and decorative surfaces, solving problems. It can be fired multiple times a day. And it is big enough for mugs and similar sizes. It will get you into the habit of using some of your creativity for experimenting. It will give you the successes early on that will inspire you to press on learning. When you are ready, then get a big kiln and hit-the-ground-running. This potter's wheel is the best available and will last a lifetime, these often appreciate in value over time. And, build yourself a good plaster table. You will use it constantly. Not shown here is a propeller mixer, also an important tool. And you will need a sink equipped with a sink trap (Gleco Trap).

My head was in the clouds and I appreciate the grounding!

This picture has its own page with more detail, click here to see it.

She was searching for a a matte, mottled white, rustic. For functional surfaces. And it contained this frit. The source from which she got it did not mention the barium content. Barium is certainly not a requirement to achieve a matte surface at cone 6, there of lots of ways to do it. And there are multiple matte mechanisms that can be exploited.

Trying to avoid knowing anything about glaze chemistry? Be ready for drama!

This picture has its own page with more detail, click here to see it.

Maybe you don't think it is necessary to know anything about glaze chemistry to be a potter. Or a technician at a production facility. This thinking depends on how much mystery you mind tolerating. Because the reason for many of the problems you will encounter with glazes relates fundamentally to their chemistry. Perhaps you have other "social" actors in your sphere who also specialize in the "know as little technical stuff as possible" mindset. Who treat glazes like acrylic paint that comes in tubes - it is just color! From these people, you will get buying advice on expensive jars of tacky-looking "goop" that you have to laboriously paint on in layers. Or it will mean you'll be more likely to get trapped on the recipe treadmill, addicted to the traffic of recipes that never seem to work.

The first of 15 "Fool-Proof Recipes" wrecked my kiln shelf!

This picture has its own page with more detail, click here to see it.

This is recommended in the booklet "15 Tried and True Cone 6 Glaze Recipes". This melt flow tester compares it with a typical cone 6 glossy, G2926B. This recipe is 90% Frit 3110 and 10% kaolin and their booklet recommends adding stains to it. But anyone knowing a little about this frit knows it would run off this flow tester even before bisque temperatures. It is crazy to recommend this. Even as a crackle. For cone 6 it needs to be diluted much more, not just with kaolin but also silica. I knew this would run but I underestimated its melt fluidity. I put a large tile below the tester to catch overrun, yet the melt ran off that and a big blob melted through the kiln wash and so far into the zircon shelf I could not chip it off! I cannot imagine how many people have tried this on vertical surfaces and had the same thing happen. The lesson: Use common sense when looking at recipes, then you don't even need to waste time testing them. Even if their authors did not!

Knowing about recipe limits could save you the work of testing this glaze

This picture has its own page with more detail, click here to see it.

This is an example of a recipe being trafficked online that raises red flags just looking at it. Before dismissing the following I can tell you that I deal with hundreds of customer glaze issues a year and people expect recipes to work as shown if no documentation is included, many also assume functionality.

The first red flag: There is no silica! That means this is a low fire glaze masquerading as middle temperature, so it is going to run during firing (run a lot). It will also mean poor durability. There is a ton of feldspar, that means a high level of sodium. Without low-expansion MgO to counterbalance its high thermal expansion the glaze is likely going to craze badly. The mechanism of the crystallization is titanium over-supply, this has triple the maximum I would ever put in a glaze. The crystallization happens during cooling in the kiln (producing the visual effect being sought). But the the surface produced will cutlery mark and stain, probably very badly. Given the unbalanced chemistry this has, any colorant added will likely be leachable! I tested it and all my fears were realized. My slow-cool firing made the surface so dry it was very unpleasant to touch. Maybe this needs fast cooling. But who knows, there are no notes. This does not appear to belong on any functional ware, inside or outside. Someone noted that people use this to produce layering effects (see links). That begs documentation on how that wold work. Without gum would it lift and crawl as layers are added over it. Would you have to overlay every square inch? Would it still craze? All the how-to information needed to make it work are more important that the recipe itself.

Is the N505 cone 6 matte glaze recipe what you think it is?

This picture has its own page with more detail, click here to see it.

This recipe is from page 2 of the booklet: "15 Tried & True Cone 6 Glaze Recipes". Click the following code, G3955, to see more information on how it compares with G2934 and G1214Z1 mattes. This flow test and these test tiles were in the same kiln, fired at cone 6 using our PLC6DS schedule. The defining characteristic of N505 is its extreme melt fluidity - it runs because it is overtired at cone 6. Still, the surface on the tile (lower right) is arguably more interesting than G2934. Some felt pen marking reveals why: The micro surface is much rougher. To its credit, although it does stain easier, it can still be cleaned with effort.

From the chemistry, shown on Insight-Live side-by-side screenshot. It has very low Al2O3 and SiO2 - that turns on some red and yellow lights. One could hope to have melt fluidity and great functionality, but they pretty well never go together. This glaze should fire glossy - the 6% magnesium carbonate is the mechanism of the matteness - MagCarb is super refractory, it may not be dissolving in the. melt. The glaze should cutlery mark (although it seemed hard in our testing). Most important, low Si:Al levels always carry the risk of leaching - exercise caution adding any significant percentage of heavy metal pigments. Crazing is another possible issue over melted glaze.

Michael Cardew might be turning over in his grave!

This picture has its own page with more detail, click here to see it.

This post got a lot of negative reaction on social media. To be clear, I work both sides of the fence, making my living on selling prepared glazes and clay bodies but I get my satisfaction being closer to the materials and processes. That is what enables me to give customer support. I am not an artist, ceramic art is outside the scope of this page. For part of my life in the craft of pottery I am also guilty of what I lament below. In all my years dealing with customer traffic at our store I have never once had a customer that was offended by seeing new clay and glaze recipes we are discovering in the studio and lab, that are better and cheaper than prepared ones. But online some are somehow offended by what follows. 80 manufacturers are selling convenience and encouraging disconnection - although I work for one of them I am a voice of caution about this.

This book was once a “Bible” of hobby and professional potters. They were independent and resourceful. They made their own clays and glazes, knew the materials, built their own kilns. Now we scan social media sites for ideas on layering expensive prepared goopy brushing glazes and hope they melt together into something presentable. Many have even forgotten how to wedge clay properly. We describe processes using mystical art language and exchange likes and poor advice on social media. Those who still know how to retotal a recipe and venture into mixing their own often end up in the online trafficking of an endless parade of recipes that don’t work. Now we even outsource design to AI. Even Nigeria, the very country about whom Cardew wrote, has lost its pottery tradition.

I never appreciated the book back there. Even though he came to visit us in 1973. I have always just taken whatever clay I needed out of our warehouse, but now that I very often make my own clay it really resonates. I got this copy on eBay, I value it as an inspiration to be more closely connected with the planet and the minerals it gifts us (of course I would not do everything as he does). He was no dinosaur, he understood and taught glaze chemistry and material mineralogy, his work was the basis for many prepared glazes we buy today. "Progress" is defined by some as convenience products that make modern ceramics easy. But I believe that, for many, progress is arming yourself with a little more understanding - it enables making better quality ware, in less time, for less expense and time than with prepared products.

Links

| Glossary |

Glaze Recipes

Stop! Think! Do not get addicted to the trafficking in online glaze recipes. Learn to make your own or adjust/adapt/fix what you find online. |

| Glossary |

Base Glaze

Understand your a glaze and learn how to adjust and improve it. Build others from that. We have bases for low, medium and high fire. |

| Glossary |

Limit Recipe

This term refers to sanity-checking ceramic glaze recipes by noting whether materials present or their relative percentages fall outside typical norms for functional ware. |

| Glossary |

Trafficking

At Digitalfire we use the term "recipe trafficking" to describe the online trade in ceramic and pottery glaze recipes that can waste your time and cost you lots of money. Better to learn to understand glazes. |

| Articles |

What is the Glaze Dragon?

At Digitalfire we use a Dragon to personify the kinds of thinking that prevent potters, educators and technicians from understanding and therefore controlling their ceramic glazes. |

| Articles |

A Textbook Cone 6 Matte Glaze With Problems

Glazes must be completely melted to be functional, hard and strong. Many are not. This compares two glazes to make the difference clear. |

| Projects |

Recipes

|

| Media |

Analysing a Crazing, Cutlery-marking Glaze Using Insight-Live

A high-nepheline, zero-silica cone 8 silky matte pottery glaze is cutlery marking and crazing. Let's take a closer look and determine why? |

| Media |

Getting Frustrated With a 55% Gerstley Borate Glaze

I show you why people love/hate this material and how I substituted it for Ulexite in this crazy recipe to make a far easier-to-use slurry that fires identical. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy