| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Porcelain

How do you make porcelain? There is a surprisingly simple logic to formulating them and to adjusting their working, drying, glazing and firing properties for different purposes.

Key phrases linking here: porcelain - Learn more

Details

Traditional utilitarian porcelains are comparatively white-burning and vitreous clay bodies that are normally made from feldspar, clay and quartz. During firing, the feldspar flows and dissolves many of the other particles into an increasingly viscous glassy melt that bonds the quartz particles and, and if temperatures are sufficient, provides the conditions to enable the flat kaolin crystals to convert to long mullite crystals. Porcelains normally have a smooth and pleasant surface (if fired to sufficient temperatures). Those low in titanium and vitrified well can be translucent. Porcelain clay bodies are made from fine-grained materials and lack the iron impurities of stonewares. They are usually fired above 1180C, the lower practical limit of feldspar as a vitreous body flux. Porcelains tend to warp during firing because they must be taken closer to the melting point to achieve the desired properties.

Porcelain bodies can be made to a wide range of plasticities. Plastic porcelain bodies have traditionally been much shorter (less plastic) than their stoneware or earthenware counterparts. But in recent years white-burning bentonites have made it possible to make even translucent porcelains plastic (those used by potters are much more plastic than those used in industry for machine forming). Porcelain casting slips achieve the whitest and most translucent results because they do not need to be as plastic (the plastic materials contribute the most iron, which darkens the color, and titanium, which impedes translucency). Typical porcelains are a mix of clays (kaolin, ball clay and plasticizers), feldspar (the melter) and quartz (the low-expansion filler and framework). By employing frits instead of feldspar it is possible to achieve vitrification at much lower temperatures. Dental porcelain, for example, is made from very high percentages of frit.

Porcelains contrast with refractories in that the fired matrix of the latter is just particles fused together at their points of contact (with voids between). The feldspars in porcelain form glasses that fill the voids, glue the silica or other refractory particles together and seal the matrix from the penetration of water.

A starting recipe for cone 10 is 50% clay (a mix of kaolin and ball clay) and 25% each of feldspar and silica - the so-called “25 Porcelain” (this recipe assumes a relatively pure kaolin having a chemistry close to theoretical and a potent feldspar). The more kaolin in the clay portion of the recipe the less plastic the body will be (but the whiter it will fire). Ball clay can be omitted if a plasticizer (like hectorite or bentonite) assists the kaolin (typically 5% or less). By switching the feldspar to nepheline syenite, maturity can be dropped a little. Increasing the feldspar to 35% can enable maturity at cone 6 (35% is the practical limit to allow enough space in the recipe for the needed silica and clay). Reducing the feldspar to 15% can raise the temperature needed for maturity to cone 12. Substituting a high-soda low-boron frit (e.g. Ferro 3110) for some or all of the feldspar can drop the temperature as low as cone 06. Be aware that reducing silica too much (e.g. down to 15%) could mean that glazes will craze. Porcelain recipes that fire very white while still being very plastic will be the most expensive. The most extreme example of a cost-is-no-object super-white porcelain is one that employs a zircon-opacified frit as the flux and a highly processed smectite as the plasticizer.

For maximum density (not always needed) porcelains should be fired to the temperature at which the porosity and fired shrinkage curves reach their minimum and maximum (respectively), or a little beyond that. If they are fired higher than that they become too unstable in the kiln. Development projects to create and maintain a porcelain recipe should do maturity testing at several cones above and below the intended firing temperature to get a complete view of the body's performance (use the SHAB test procedure).

In recent years a myriad of high-technology products have been created that stretch the traditional term "porcelain", these are beyond the scope of this website.

Related Information

Cross section view of the inside and outside glazed walls of a porcelain vessel

This picture has its own page with more detail, click here to see it.

Porcelains look much more glassy and melted than you might expect when viewed close up (this is cone 6 Polar Ice from Planisman Clays). The development of the glassy phase within the body creates a very good bond with the glaze. Actually it is a bonding zone where the glaze has melted into the body enough to create a transition rather than just a point of contact. The degree to which this transition develops determines the integrity of the bond. Of course, with porcelains it is far better developed than with stonewares and terra cottas.

A Grolleg based porcelain vs. a ball clay and American kaolin porcelain

This picture has its own page with more detail, click here to see it.

These mugs were fired in the same kiln load at cone 10R and have the same clear glaze, G1947U. The mug on the left is a Grolleg kaolin (52% Grolleg kaolin, 24% silica and 19% Mahavir feldspar, 5% bentonite). The one on the right is 15% M23 ball clay, 40% #6 Tile kaolin, 15% Nepheline, 25% silica, 3% bentonite. Clearly, the Grolleg porcelain fires so much whiter.

Two reasons why porcelain recipes need silica

This picture has its own page with more detail, click here to see it.

This is 70% kaolin and 30% feldspar. Fired at cone 6 with glaze G2926B. The fired body has a nice porcelaneous surface. But, right out of the kiln, it crazes like this! The dense craze pattern indicates a very serious fit problem. The thermal expansion of the kaolin:feldspar mix is much too low. Adding 25% low-expansion silica will solve the problem. The other issue is with the flat particle shape of kaolin. The throwing process has lined up the predominant kaolin particles concentric to the centre. During drying, and especially firing, more shrinkage occurs across them than along them. All ten of the cups made cracked like this! The solution is adding a filler, one with rounded particles to separate the kaolin plates. Silica is perfect, using the same 25% addition. The grains act like aggregate in concrete, strengthening the matrix and separating the clay particles, forcing them to orient more randomly.

Turbo-charge plasticity using bentonite, hectorite, smectite.

This picture has its own page with more detail, click here to see it.

These are porosity and fired shrinlage test bars, code numbered to have their data recorded in our group account at Insight-live.com. Plainsman P580 (top) has 35% ball clay and 17% American kaolin. H570 (below it) has 10% ball clay and 45% kaolin, so it burns whiter (but has a higher fired shrinkage). P700 (third down) has 50% Grolleg kaolin and no ball clay, it is the whitest and has even more fired shrinkage. Crysanthos porcelain (bottom, from China) also only employs kaolin, but at a much lower percentage, thus is has almost no plasticity (suitable for machine forming only). Do H570 and P700 sacrifice plasticity to be whiter? No, with added bentonite they have better plasticity than P580. Could that bottom one be super-charged? Yes, 3-4% VeeGum or Bentone (smectite, hectorite) would make it the most plastic of all of these (at a high cost of course).

Ball clay vs. Kaolin porcelain at cone 6

This picture has its own page with more detail, click here to see it.

Left: A porcelain that is plasticized using only ball clays (Spinx Gleason and Old Hickory #5). Right: Only kaolin (in this case Grolleg). Kaolins are much less plastic so bentonite (e.g. 2-5%) is typically needed to get good plasticity. The color can be alot whiter using a clean kaolin, but there are down sides. Kaolins have double the LOI of ball clays, so there are more gasses that potentially need to bubble up through the glaze (ball clay porcelains can produce brilliantly glassy and clean results in transparent glazes even at fast fire, while pure kaolins can produce tiny dimples in the glaze surface if firings are not soaked long enough). Kaolins plasticized by bentonite often do not dry as well as ball clays even though the drying shrinkage is usually less. Strangely, even though ball clays are so much harder and stronger in the dry state, a porcelain made using only ball clays often still needs some bentonite. If you do not need the very whitest result, it seems that a hibrid using both is still the best general purpose, low cost answer.

Cone 6 kaolin porcelain verses ball clay porcelain.

This picture has its own page with more detail, click here to see it.

Typical porcelains are made using clay (for workability), feldspar (for fired maturity) and silica (for structural integrity and glaze fit). These cone 6 test bars demonstrate the fired color difference between using kaolin (top) and ball clay (bottom). The top one employs #6 Tile super plastic kaolin, but even with this it still needs a 3% bentonite addition for plasticity. The bottom one uses Old Hickory #5 and M23, these are very clean ball clays but still nowhere near the whiteness of kaolins. Plus, 1% bentonite was still needed to get adequate plasticity for throwing. Which is better? For workability and drying, the bottom one is much better. For fired appearance, the top one.

Cleanest kaolin porcelain vs. ball-clay-only porcelain!

This picture has its own page with more detail, click here to see it.

These cone 6 clear-glazed porcelains demonstrate just how white you can make a porcelain if you use white burning kaolins and bentonites instead of ball clays. Both contain about 40% clay. The one on the left employs New Zealand kaolin and Veegum plasticizer, the one on the right Kentucky ball clays (among the whitest of ball clays in North America) and standard bentonite. Both are zero porosity. The glaze surface is a little more flawless on the right one (possibly because ball clays have a lower LOI than kaolins).

Do not rely on material data sheets, do the testing

This picture has its own page with more detail, click here to see it.

The cone 6 porcelain on the left uses Grolleg kaolin, the right uses Tile #6 kaolin. The Grolleg body needs 5-10% less feldspar to vitrify it to zero porosity. It thus contains more kaolin, yet it fires significantly whiter. Theoretically this seems simple. Tile #6 contains alot more iron than Grolleg. Wrong! According to the data sheets, Grolleg has the more iron of the two. Why does it always fire whiter? I actually do not know. But the point is, do not rely totally on numbers on data sheets, do the testing yourself.

Want to make a cone 10R super translucent porcelain? Think again.

This picture has its own page with more detail, click here to see it.

On the right is a porcelain used in China, renowned for its whiteness and translucency. On the left is a body made from Grolleg kaolin, this is commonly used by potters. They were fired in reduction. The tiny iron specks that potters do not even notice are enemy number for the blue-white porcelain like this. Although they might be small the reduction atmosphere makes them blossom out in full glory to ruin the piece. These specks come as contaminants in the materials (especially the silica) and they are easily picked up during fabrication. For very white bodies like this, it is incredibly difficult to prevent the specks. For a perfectly white flawless result, the entire factory must be dedicated to this one body; they use wet processing, magnets, filter pressing, stainless steel equipment and impeccable procedures.

A problem with super-white porcelain mugs

This picture has its own page with more detail, click here to see it.

These are made from Plainsman Polar Ice translucent NZ porcelain. The one on the right was used in the coffee room of the plant and washed between uses in a common manner (which is: not very much!). The stains are obviously not nearly as visible on a stoneware mug.

Could oxidation porcelain look like reduction blue porcelain?

This picture has its own page with more detail, click here to see it.

These clear glazed porcelain mugs are fired at cone 6. The one on the right has 0.2% Mason 6336 stain added to to G2926B base glaze. It matters which stain, some agglomerate and causes specking, this one disperses well.

With porcelains, poor plasticity gets worse at the leather hard stage

This picture has its own page with more detail, click here to see it.

This porcelain becomes quite brittle as it gets stiffer making it difficult to make these cuts in the foot ring. This creates extra sponging work when it is dry. It also means that dry strength will be low. Porcelains do not need to be this way, plenty of white burning bentonites are available (although they increase cost).

Why is this cone 6 glaze so different on these two different porcelains?

This picture has its own page with more detail, click here to see it.

Why the difference? The one on the right (Plainsman M370) is made from commodity American kaolins, ball clays, feldspars and bentonite. It looks pretty white-firing until you put it beside the Polar Ice on the left (made from NZ kaolin, VeeGum plasticizer and Nepheline Syenite as the flux). These are extremely low iron content materials. M370 contains low iron compared to a stoneware (less than 0.5%) that iron interacts with this glaze to really bring out the color (although it is a little thicker application that comes nowhere near explaining this huge difference). Many glazes do not look good on super-white porcelains for this reason.

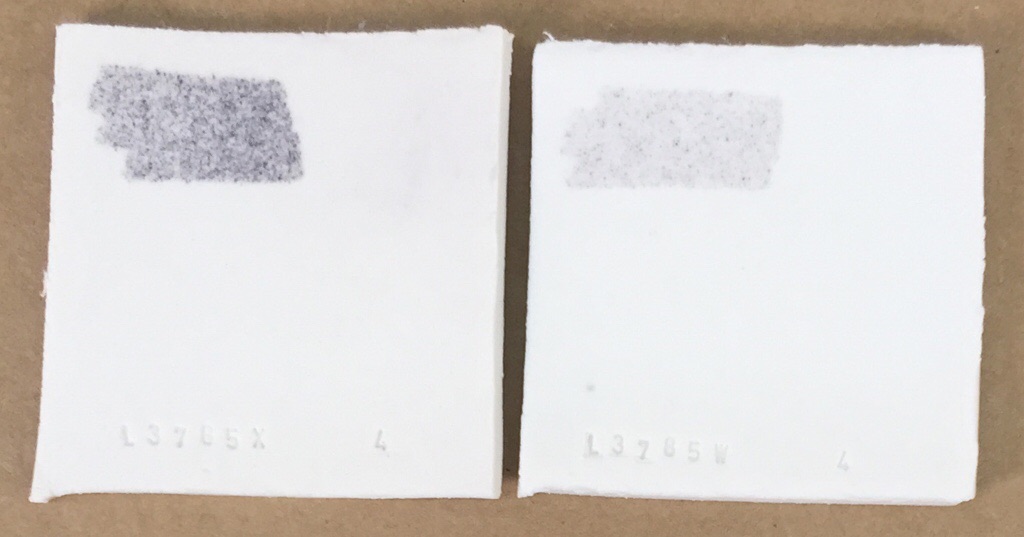

A novel way to compare degree of porcelain vitrification

This picture has its own page with more detail, click here to see it.

These two unglazed porcelain tiles appear to have a similar degree of vitrification, but do they? I have stained both with a black marker pen and then cleaned it off using acetone. Clearly the one on the right has removed better, that means the surface is more dense, it is more vitreous. In industry (e.g. porcelain insulators) it is common to observe the depth of penetration of dye or ink into the matrix as an indication of fired maturity.

The blue color in this porcelain develops more as maturity increases

This picture has its own page with more detail, click here to see it.

These fritted porcelain bars are fired at cone 06, 04, 03 and 02 oxidation (bottom to top). The body contains 0.2% blue stain. Notice that almost no color develops at the lowest temperature. Glass development is needed.

This is how much iron is in 50lb of the cleanest plastic porcelain you can make!

This picture has its own page with more detail, click here to see it.

The recipe: 50% New Zealand kaolin, 21% G200 Feldspar, 25% silica and 3% VeeGum (for cone 10R). These are the cleanest materials available. Yet it contains 0.15% iron (mainly from the 0.25% in the New Zealand kaolin, the VeeGum chemistry is not known, I am assuming it contributes zero iron). A 50 lb a box of pugged would contain about 18,000 grams of dry clay (assuming 20% water). 0.15% of 18,000 is the 27 grams of iron you see here! Even more surprising: This mug is a typical Grolleg-based porcelain using 5% of a standard iron-bearing raw bentonite. A box of it contains four times as much iron. Enough to fill that cup half full!

A tiny percentage of blue stain in a porcelain has amazing power

This picture has its own page with more detail, click here to see it.

The top porcelain bar has only 0.07% Mason 6336 blue stain added (vs. none in the bottom bar). This is a low fire frit-ware body fired at cone 03 in oxidation. At a slightly lower percentage (e.g. 0.05%) this porcelain will have the same color as a cone 10 reduction one (when covered with a transparent glaze). However adequate glass development is needed before the blue color develops.

Translucency of Polar Ice compared to another porcelain at cone 6

This picture has its own page with more detail, click here to see it.

On the top you can see the color difference. The other porcelain is made from a low TiO2 mix of typical North American kaolins, feldspars and bentonites. Bottom with a light inside: Polar ice on the left is far more translucent. Yet it is not overly mature, it resists fired warping remarkably well. And it is also more plastic (which seems impossible). There is a secret to the translucency that goes beyond the fact that it employs New Zealand kaolin and the percentage of feldspar it has. But I cannot tell you. But if you read this site carefully you will discover it in the most unlikely place!

Inbound Photo Links

Reduction and oxidation porcelains |

Why mid-fire Grolleg porcelain is ideal for both throwing and casting |

Links

| Glossary |

Plasticity

Plasticity (in ceramics) is a property exhibited by soft clay. Force exerted effects a change in shape and the clay exhibits no tendency to return to the old shape. Elasticity is the opposite. |

| Glossary |

Vitrification

A process that happens in a kiln, the heat and atmosphere mature and develop the clay body until it reaches a density sufficient to impart the level of strength and durability required for the intended purpose. Most often this state is reached near zero p |

| Glossary |

Earthenware

What is the difference between earthenware and a regular stoneware body? Earthenwares lack the glass development to fill voids and glue particles. |

| Glossary |

Translucency

A highly sought-after property in porcelain, fired close enough to melting to take on the glass-like property of passing light. Translucency implies tendency to warp during firing. |

| Glossary |

Clay

What is clay? How is it different than dirt? For ceramics, the answer lies on the microscopic level with the particle shape, size and how the surfaces interact with water. |

| Glossary |

Body glaze Interface

In ceramics, the zone of adherence between glaze to the underlying body is called the clay-glaze interface. The integrity of this interface is important to strength and functionality. |

| Glossary |

Maturity

A term used in the ceramics industry to signify the degree of vitrification in a fired clay. Mature clays are dense and strong, immature ones porous and weak. |

| Glossary |

Stoneware

To potters, stonewares are simply high temperature, non-white bodies fired to sufficient density to make functional ware that is strong and durable. |

| Glossary |

Vitreous

The fired state of a ceramic when sufficient heat in the kiln has produced the density and strength common, and expected, in stonewares and porcelains. |

| Materials |

Kaolin

The purest of all clays in nature. Kaolins are used in porcelains and stonewares to impart whiteness, in glazes to supply Al2O3 and to suspend slurries. |

| Materials |

Bentonite

Bentonite can make a clay body instantly plastic, only 2-3% can have a big effect. It also suspends slurries so they don't settle out and slows down drying. |

| Articles |

Formulating a Porcelain

The principles behind formulating a porcelain are quite simple. You just need to know the purpose of each material, a starting recipe and a testing regimen. |

| Minerals |

Smectite

A highly plastic clay mineral related to montmorillonite (bentonite), more correctly, the name of th |

| Media |

A 3-minute Mug with Plainsman Polar Ice

Tony Hansen takes you through the steps from opening the box and wedging the clay to taking the fired mug from the kiln. |

| Tests |

Shrinkage/Absorption Test

SHAB Shrinkage and absorption test procedure for plastic clay bodies and materials |

| Recipes |

L2000 - 25 Porcelain

Base 25x4 porcelain recipe |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy