| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Casting Slip

Casting slips are among the easiest clay bodies to make yourself. The ability to make and tune your own will open many doors in your production process.

Key phrases linking here: casting body recipes, casting bodies, casting slip, casting body - Learn more

Details

Anyone can make casting slip. Materials needed are available at any ceramic supplier. All you need is a good propeller mixer (with fine-grained speed control, able to run for at least 15 minutes, with enough power and a good propeller) and an understanding of deflocculation. If you are already buying a premixed powder, then shifting toward your own recipe will be much easier. Commercial stoneware or porcelain casting slips are not magic, they have recipes similar to those discussed below. Learning how to create a slurry having good casting properties can be a major step toward DIY, opening many new doors. If you can also learn CAD design and 3D printing there will be nothing you cannot make using the slip casting process.

Porcelains and White or Buff Stonewares

Typically, these bodies are 95% clay, silica and feldspar - it is not rocket science. Understanding what each material does enables tuning the recipe to get exactly what you need.

- Kaolin: Most kaolins are non-plastic and so are a natural fit for use in a casting body. White-burning ones are more expensive. Availability and price will likely determine which you use.

- Ball clay: All ball clays are highly plastic, they slow down casting and have less fired whiteness. A few larger particle size ones are available and producers target them to casting. Use one of those. White-burning ones are generally less plastic, thus more likely to be suitable.

- Feldspar: Likely you don't have many available, try the ones you can get.

- Silica: This should be available everywhere and it fires white, use a 200 mesh version.

- Bentonite: At most, only 1% is likely needed (if at all). Get one that is processed to at least 200 mesh.

- Talc: Fine-tune maturity (1-2% additions can markedly increase fired maturity).

L4807 Recipe for Cone 6 Whiteware/Porcelain (using the most suitable materials in the US)

OptiKast Kaolin 30

Silica 25

KT#1-4 Ball Clay 20

Nepheline Syenite 25

Talc 0.5

As a guide, consider using the slip mixing instructions on the M370 page at PlainsmanClays.com. However, since this uses larger particles clays it will likely require less deflocculant.

Recipe Tuning:

A good record-keeping system for this is essential (e.g. an account at insight-live.com). Keep a good record of every change you test. The casting process is very sensitive; small changes can produce big benefits in productivity and the types of ware you can make. A few guidelines:

- Increase ball clay at the expense of kaolin for better green strength, better mold release (but slower casting).

- Add bentonite when mold release is poor (it increases drying shrinkage, so shrinking pieces can pull themselves away from the mold surface).

- Increase Nepheline at the expense of clay for more fired maturity. If feldspar must be used, the body will be less mature so more will be needed.

- Glazes should not craze with 25% silica (if the body is mature). Glazes may fit with 20% silica, or even 15%, if so, then increase feldspar if more maturity is needed, otherwise kaolin.

- Add talc for better maturity (up to 2%, otherwise increase nepheline).

Terra Cotta casting body: L4170B (and derivatives).

Black cone 6 casting body: L4053B, L4768E, L3954F.

For cone 6 white translucent porcelain: L3778D recipe (with 1% or less bentonite).

Cone 6 buff stoneware: L3798G.

Cone 6 red burning body: L4005D.

Related Information

Why 3D design and printing is a better way to make slip casting molds

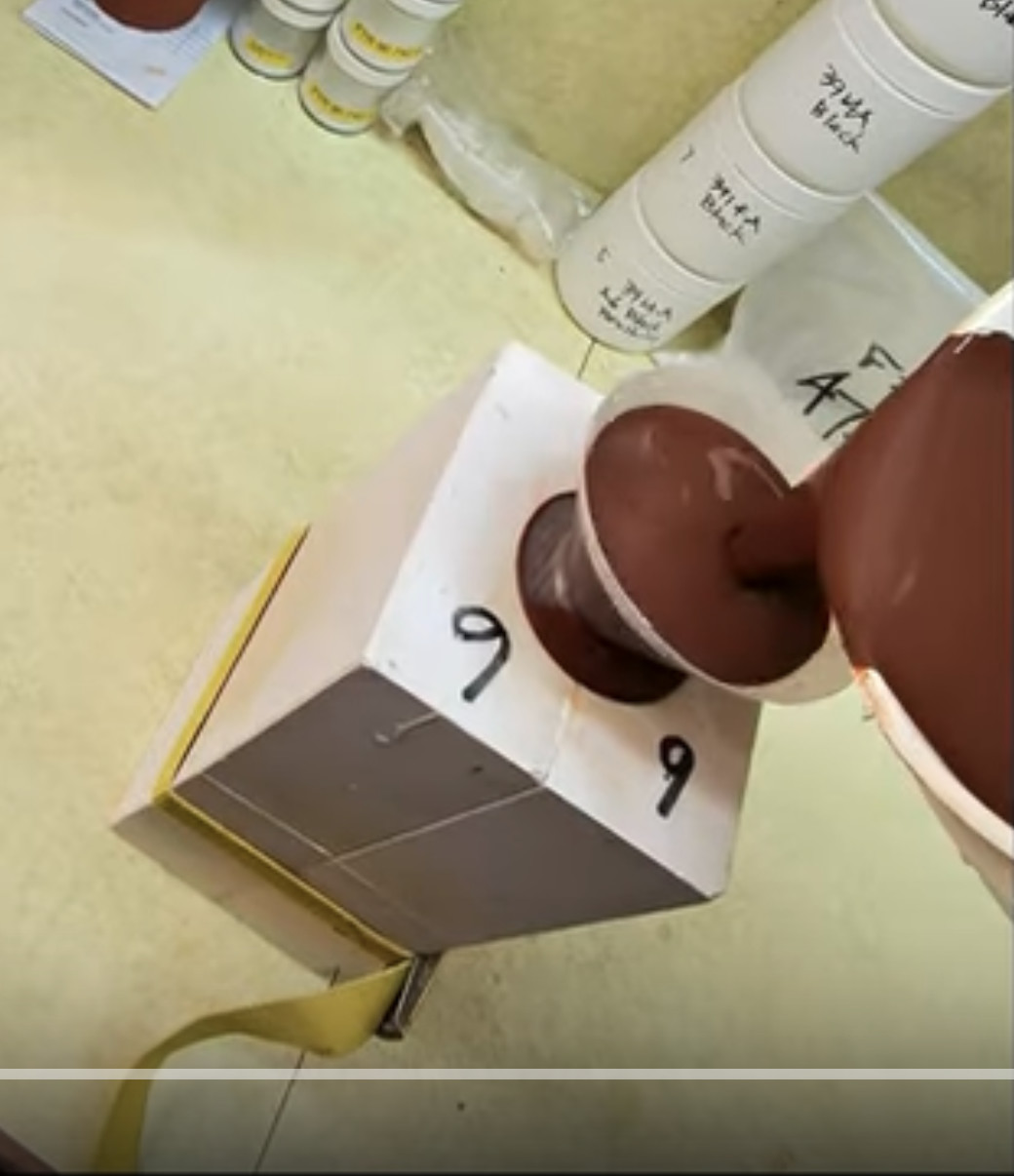

This picture has its own page with more detail, click here to see it.

I dread the traditional mold making process, the mess, all the supplies and tools involved. I am a potter, I make functional ceramics. I am not a mold-maker, but 3D design and printing have put it within my reach. This way more fun! There is no stopping this, it’s the future.

-I spend most time on design, pouring the plaster or rubber takes minutes.

-Many fewer tools and supplies are needed, the process is less messy, as easy as downloading a file, printing it and pouring in plaster - this is doable in my kitchen! I don't even need mold soap!

-Sanding of flat mating faces is possible (for better seams than I've ever had). This is because natches can be added later (using embeds).

-I can make my own natches and interlock schemes.

-No spare is needed, the 3D-printed pour spouts work better.

-The range of shapes seems limitless. Especially because designs can be split up into pieces, each printed in optimal orientation (and glued together).

-I make molds through multiple design-print iterations. 3D makes do-overs or changes in design as easy as a reprint and plaster-pour. So, I can make a mold just to test an idea!

Inbound Photo Links

v1 DIY Four-Part Mold Natch System Essential for 3D mold-making in ceramics |

Links

| Glossary |

Slip Casting

A method of forming ceramics. A deflocculated (low water content) slurry is poured into absorbent plaster molds. As it sits in the mold, usually 10+ minutes, a layer builds against the mold walls. When thick enough the mold is drained. |

| Glossary |

Casting-Jiggering

A process in ceramic production where items are slip-cast first and then finished using a jigger wheel. |

Video |

Slip cast a stoneware beer bottle

I will mix the slurry, assemble the mold, attach the 3D-printed pour spot, pour in the slip, pour it out, remove the spout, trim the lip, split the mold, extract the bottle and drill the holes for the swing-top stoppers. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy