| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Slipware

Slipware, in the UK, is terra cotta pieces decorated at leather hard with thixotropic high ball clay slips, then bisque fired and clear glazed with lead bilisicate.

Key phrases linking here: slipware - Learn more

Details

The term "Slipware" can refer to a specific pottery tradition in the UK or to the general technique of decorating leather-hard ware with colored slips (and optional incising, carving afterward).

The UK slipware tradition dates back centuries. Terra cotta clays, either commercial or "wild" are employed, often mixed with other materials to adjust fired maturity, color, surface and texture. Ware is commonly fired at higher than the typical cone 06-04 in either electric or gas kilns, temperatures around 1100°C (2000°F), or cone 03, are common (surface density visible on some photos indicate even higher temperatures). The slipware process enables taking advantage of the far superior fired strength that terra cotta offers at temperatures much much lower than stoneware while still permitting all manner of bright colors and a durable high-gloss surface.

Bright-colored ceramic slips and engobes are used to cover and decorate leather hard pieces (by pouring, dipping, brushing, splashing, slip trailing, scoring, marbling, combing and even finger painting). Sgraffito techniques are also common. Slips are mostly ball clay, a refractory material. On their own the slips do not fuse or interact with each other during bisque or glaze firings. But they do interact with what goes on top: A clear overglaze made using lead sesquisilicate and lead bisilicate frits suspended with kaolin or ball clay (e.g. an 85:15 mix). This glaze is the "secret weapon", the real enabler of the process.

The slip being used is applied as a thick layer, akin to an engobe. But the thickness is possible, especially on vertical surfaces, because of very high thixotropy and low specific gravity (very high water content). While the refractory slips are capable of high opacity even though they do dry down to a very thin layer, so thin that body texture is preserved. The secret is very high percentages of ball clays, creating the naturally thixotropic character that holds things in place after application. In our tests, an 80:20 mix of ball clay and feldspar creates a suitable slurry with a 2:1 water:powder ratio. Think about this for a minute: 2:1 is double the amount of water of a typical dipping glaze slurry! How can this work? Because the slips are applied to leather hard ware and they dry down to a very thin layer. Needless to say, such a high water content will rewet a leather hard body and take a long time to dry (during which time ware cannot be covered, a chamber must be used in dry climates).

Some potters view the body as just the vehicle to hold the slip, hiding it as much as possible under multiple layers. Others purposely expose areas, tuning body recipe, firing temperature, atmosphere and flashing to achieve an aesthetic. however, the nature of the process does not enable covering all surfaces with slip (e.g. the insides of closed containers, the outsides of bowls). Fortunately, the leaded clear glazes covers both slipped and non-slipped surfaces with a brilliant clear finish. Functional or even stoneware strength comes as a natural consequence of firing terra cotta type bodies above the traditional low fire range below cone 04. Of course, potters must be wary of dangers with this, pushing terra cotta too high in the kiln can lead to warping, bloating, pinholing, glaze blisters, etc.

The tradition of slipware elevates it well beyond that of functional terra cotta, making it both an art form that can be highly collectable and desired and highly functional and durable. Slipware pottery is specifically taught in college programs and well-known slipware masters are highly regarded. Important family, community and national events are often commemorated on custom-made slipware pieces. Potters purchasing the clay bodies would not expect to pay any less than they would pay for stoneware clay bodies.

In the UK the lead-based glaze is not viewed as an issue, ware is commonly used for functional use and the workplace hazards for the potter are considered the same as for other types of frit. When viewed as a whole, the slipware process is seen as greener because kilns are fired to much lower temperatures, clay bodies are processed less and employ local materials and there is no need for expensive packaged glazes. Slipware potters coming to North America are surprised that they cannot get the leaded frits and they are surprised at how energy-wasteful and planet-impacting our methods are and how much we depend on our suppliers for every little thing. The unavailability of the frits is a frustration for them because it is almost impossible to achieve the same level of gloss, transparency and thermal expansion compatibility using glazes made with boron frits.

That being said, commercial transparent glazes in North America from Amaco, Duncan, Spectrum employ fritted sources of boron, lithium and zinc and fire crystal clear. All of them have the potential of working on slipware. However, their products are primarily sold as brushing glazes. Even though these companies make dipping versions, their definition of a dipping glaze is quite different than what a potter might want (e.g. they dry very slowly and drip, drip, drip). You can make your own non-leaded clear glaze using the G1916Q and G3879 base recipes. Both have 85% or more frit so they are not inexpensive. Both will work well at cone 03. Both are well documented online (technically and practically) and both have variant recipes so you can adjust properties like thermal expansion. All of this being said, hopefully we can still find a way to use lead again!

Exciting development may be coming in 2026: One of our customer is doing his masters thesis on am affordable way to make crystal clear safe glazes without the use of lead. We are hoping to release details.

Related Information

Freshly slipped jug demonstrates the importance of thixotropy

This picture has its own page with more detail, click here to see it.

These thickly applied clay slips are defying gravity! This piece has just been engobed using a thixotropic brown slip. The white was applied over that by pouring and the decoration done by scoring and dripping. Both slips are very high in ball clay, no additive is necessary to make them thixotropic. The gelled state persists even with double or more the amount of water that would be in a glaze slurry. The rheology of both of these slurries, the brown underlayer and of the white overlayer, is the entire secret of how this is even possible. People who want to understand why things work come to digitalfire.com, one reader said the following about this page: "Thank you SO much for sharing this information, I have been searching for exactly what you are talking about here!" Photo courtesy of Russell Kingston, Lynmouth Slipware Pottery.

Freshly decorated pieces of slipware

This picture has its own page with more detail, click here to see it.

These pieces are said to be "freshly slipped". Clearly, it is necessary to stand clear when this is being done! The white is first applied by dipping and the brown decorative elements are added using trailing, dripping and splashing techniques. The thixotropic nature of the thickly applied slip is very evident, were it not for this gravity would quickly kill the design. The slip is mostly plastic ball clay, it slowly dries until reaching the same water content as the body. The body and slip then dry and shrink as a unit. The mix of feldspar and ball clay have the natural consequence of being thermal expansion compatible with the body (since their mineralogies are similar). At low temperatures the firing shrinkage of neither is very high so that, coupled with the thinness of application, permits their fired union. Photo courtesy of Russell Kingston, Lynmouth Slipware Pottery.

UK Slipware: A Tradition of Terra Cotta and Lead Glaze

No borosilicate glaze can do this

This picture has its own page with more detail, click here to see it.

The traditional UK slipware is possible because of the brilliant gloss and hyper transparency of glaze made using lead bisilicate frits. The lead glaze interacts with the colors in underlying slips, dissolving and feathering them (as enabled by the time and temperature of the kiln). Interactions with iron produce warm colors. Ware is bisque fired after the decorating and drying (lower left), then dipped in the leaded glaze. Photo courtesy of Russell Kingston, Lynmouth Slipware Pottery.

A slipware terra cotta jug

This picture has its own page with more detail, click here to see it.

Made by Russell Kingston, Lynmouth Slipware Pottery.

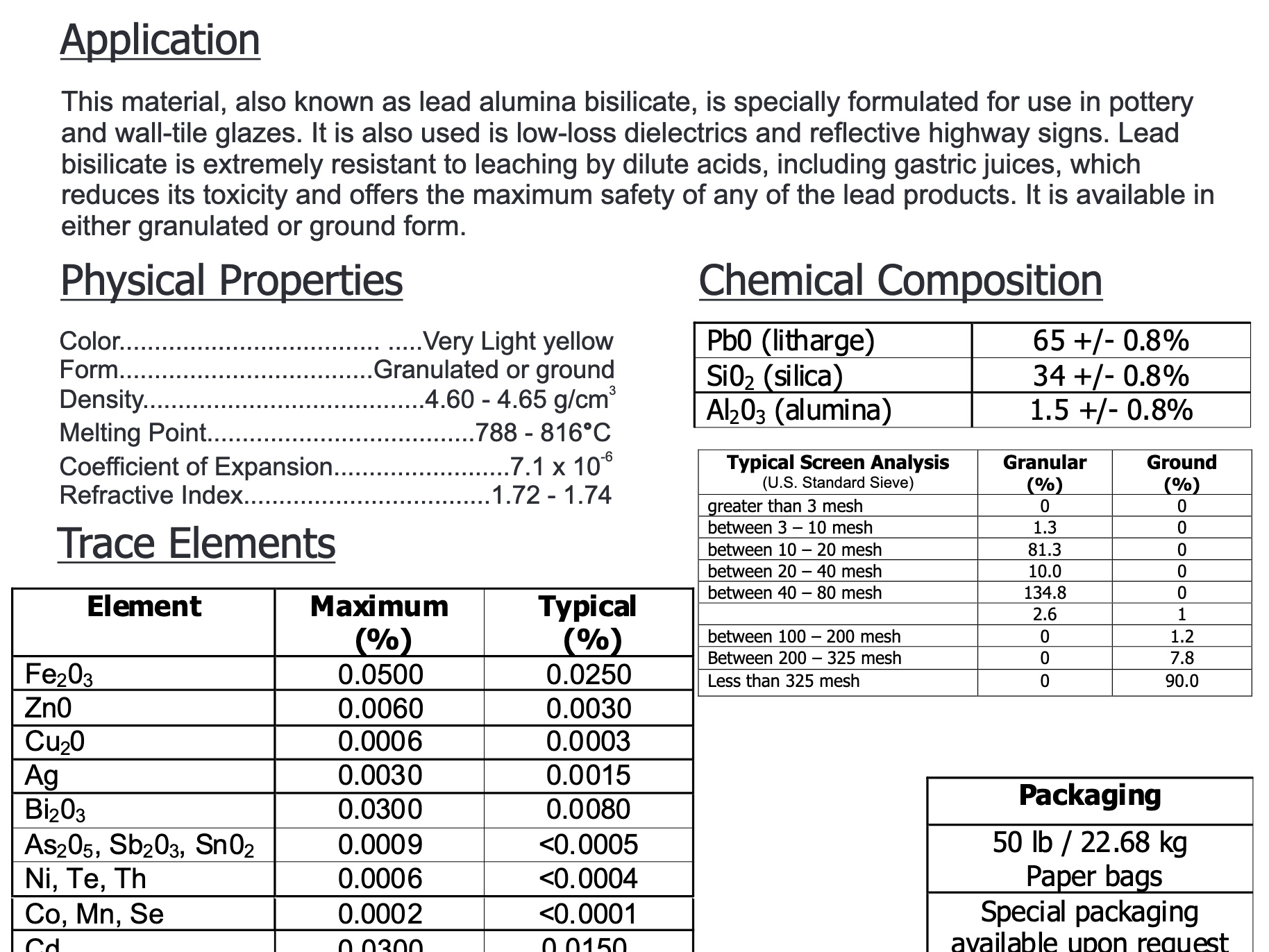

Lead bisilicate frit data sheet claims high resistance to leaching

This picture has its own page with more detail, click here to see it.

Notice it is specifically "formulated for use in pottery glazes". And that "Lead bisilicate is extremely resistant to leaching by dilute acids, including gastric juices, which reduces its toxicity and offers the maximum safety of any of the lead products." In many countries, the use of lead glazes is still considered normal and safe. There is zero use of lead in pottery glazes in North America. Is it possible that we have tarred all lead products with the same brush? Could we at least be using it on non-functional decorated surfaces of low-fire stoneware? This would drastically reduce the energy consumption of kilns.

Large wood-fired slip-decorated vessels by Kate Johnston of NC

This picture has its own page with more detail, click here to see it.

Kate’s pots are made with local materials, boldly carved with organic patterns inspired by Art Deco design, and fired in a large wood-burning kiln. Kate shows her pots internationally and has lectured and taught throughout the USA.

Links

| URLs |

https://thepotterywheel.com/slipware/

Lead Glazed Slipware - A longstanding tradition in the UK |

| URLs |

https://fitchandmcandrew.co.uk/

Fitch and McAdrew Slipware Producers website |

| URLs |

https://clivebowen.co.uk/

Clive Bowen wood fired earthenware website Clive Bowen was born in Cardiff in 1943. He studied painting and etching before taking up a pottery apprenticeship. He has been making wood-fired earthenware at Shebbear Pottery since 1971 |

| URLs |

http://www.russellkingstonceramics.co.uk/

Russell Kingston, Lynmouth Slipware Pottery Russell Kingston makes Devonshire Slipware (roots in medieval North Devon). Slip is dipped, poured, brushed, trailed and splashed with animated movements. Colour is achieved using oxides in slips. The terra cotta pots are then fired in a large homemade gas kiln in oxidation about 1100c (cone 03). |

| URLs |

https://www.instagram.com/jessicaturrell_ceramics/?hl=en

Jessica Turrell, Slipware potter in the UK Jessica specializes in the North Devon style of slipware. She makes functional, country-style pottery using earthenware clay. |

| URLs |

https://patiadavis.co.uk/

Patia Davis Slip Decorated Earthenware Slip-decorated earthenware fired to 1120C (cone 1). She works slip wet onto leather hard, layering pours, drips, trails, feathering, and brush marks. |

| Glossary |

Terra Cotta

A type of red firing pottery. Terra cotta clay is available almost everywhere, it is fired at low temperatures. But quality is deceptively difficult to achieve. |

| Glossary |

Lead in Ceramic Glazes

Lead is a melter in ceramic glazes and performs exceptionally well and must be misused to be toxic. It is also now environmentally pervasive. It is toxic and cumulative at any level of exposure. |

| Glossary |

Zero3

The designation for a group recipes for body, glaze and engobe (by Tony Hansen), that potters can use to make low fire stoneware and fritware porcelain at 1100C (2000F) or cone 03. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy