| Monthly Tech-Tip | No tracking! No ads! | |

Grog

Grog is a term used in ceramics to describe crushed brick (or other fired ceramic) aggregate that is added to sculpture and structural clays to improve drying properties.

Key phrases linking here: grogged, grog - Learn more

Details

A granular material made from crushed brick, refractory rock, or other pre-fired ceramic product. Grogs are added to bodies to reduce drying shrinkage, firing shrinkage and thermal expansion; increase stability during firing, and add texture. Grogs can have particles that fall within a narrow range of sizes or they can be composed of ones from a wide range of sizes (generally, wide ranges impart density and faster drying but cut plasticity while narrow ranges preserve plasticity and dry strength while improving drying performance).

Grogs vary widely in price. A number of factors increase the price (and utility):

-Cleaner ones (lighter in color and freer of iron contamination)

-Having a low thermal expansion

-Having a narrow range of particle sizes or a specific particle shape

-Being low in contamination or high in homogeneity

-Refractory and resistant to deformation or melting at high temperatures

-Being dense, hard and low in porosity

Grogs thus can be very expensive (the crushing process tends to create fine powders instead). That being said, granular grades of rock are often available as by-products of mining and rock crushing operations, some ceramic manufacturers (e.g. tile companies) have found suitable ones that have resulted in dramatic savings in the cost of their clay body.

Sculpture bodies are well known for their high grog content, 20-30% is typical but much more is possible if the base body is superplastic and the grog asserts a low surface area. The abrasive feel of a sculpture body can change markedly depending the particle shape of the grog. Tile bodies can also contain even higher percentages (e.g. 50%), these enable the fastest possible drying with the lowest shrinkage and cracking rates.

It is possible to throw many grogged bodies on the potter's wheel in relative comfort if as many as possible of the following are true: the body base is fine and highly plastic, the grog is of a narrow range of smaller sizes, particles have a flatter or angular shape, the grog content is below 20%, the clay is soft.

It is possible to make special-purpose low shrinkage bodies having percentages of 90%+ grog (e.g. for investment casting). Of course, the range of sizes needs to be controlled to get high density since the principle structural mechanism involves packing of these particles (the clay and binders are only acting to bond the particles together for some sort of machine forming and subsequent kiln sintering).

Ovenware and flameware bodies used by the pottery community often contain high grog percentages (the high porosity of the body is tolerated). The grog is viewed as the principal mechanism to impart resiliency against thermal shock failure. Such bodies (or even the grog particles themselves) normally do not have inherently low thermal expansion (testified by the fact that normal glazes fit without crazing), they simply contain so much aggregate that any micro-crack that gets started is terminated immediately by the particles in its vicinity.

Grog additions do not always mean that a clay body will dry better (with fewer cracks). There is a threshold percentage and particle size for benefit. In many cases, the grog addition can actually weaken the leather hard and dry strength, failure still occurs but the cracks simply follow a more jagged path.

Grogs can be added for reasons other than drying performance improvement, texture being the most obvious. But grogs also enable bodies to reabsorb a certain amount of water during forming operations. This can be helpful when making larger sculptural pieces.

Related Information

Grog before it is ground. Yes, it is bricks.

This picture has its own page with more detail, click here to see it.

Pure grog (brick aggregate) is made by crushing bricks to produce a particulate material that is added to sculpture clay bodies to reduce their drying shrinkage (to reduce drying cracks) and impart texture. Brick manufacturers always have a certain percentage of reject and actually grind the reject bricks and clay together. These are structural high temperature stoneware bricks in a stockpile at Plainsman Clays.

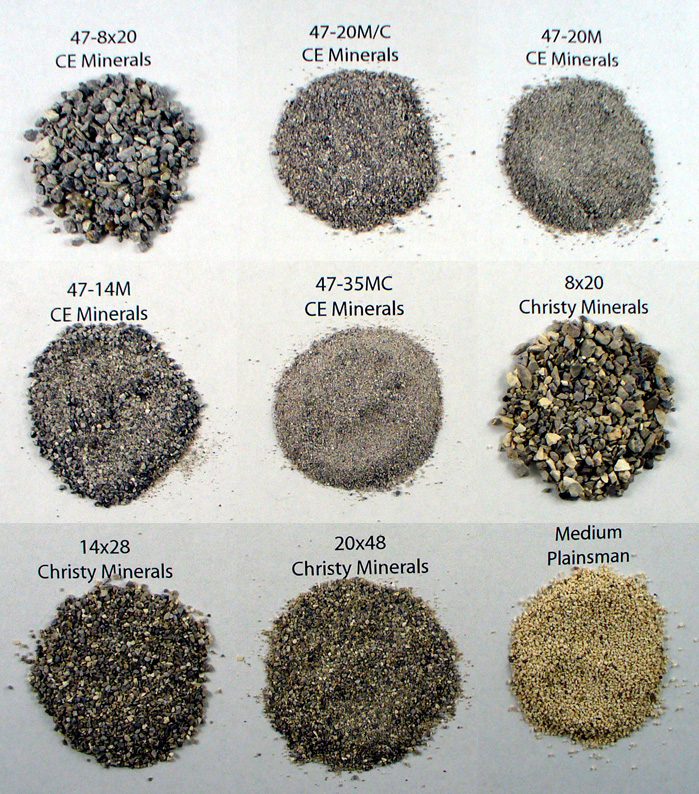

Various grogs available in North America

This picture has its own page with more detail, click here to see it.

Examples of various sized grogs from CE Minerals, Christy Minerals, Plainsman Clays. Grogs are added to clays, especially those used for sculpture, hand building and industrial products like brick and pipe (to improve drying properties). The grog reduces the drying shrinkage and individual particles terminate micro-cracks as they develop (larger grogs are more effective at the latter, smaller at the former). Grogs having a narrower range of particle sizes (vs. ones with a wide range of sizes) are often the most effective additions. Grogs having a thermal expansion close to that of the fired body, a low porosity, lighter color and minimal iron contamination are the most sought after (and the most expensive).

Four types of aggregate used at Plainsman Clays

This picture has its own page with more detail, click here to see it.

The SIAL grog is made by RHI Refractories. Christy is from Christy Minerals. The Mullite is not really a grog but neither is it a powder, it is made by Mulcoa Refractories.

Large particle grogs are difficult to produce

This picture has its own page with more detail, click here to see it.

These particles are from a grog that has been milled and separated into its constituent sizes in the lab. As you can see it has a wide range of particle sizes, from 48 to finer than 200 mesh. When fired ceramic (like bricks) is ground the finer sizes often predominate. Because the coarser grades have a lower yield they can be much more expensive and harder to get. But they are the most effective in reducing the drying shrinkage and fired stability of structural and sculptural bodies.

Grog particles from a sculpture clay body

This picture has its own page with more detail, click here to see it.

Here is the oversize (from Plainsman MSculp) on the four coarsest screens we use to do particle size distributions on clay bodies. There are very few intermediate sizes between the very fine particles of the base body and the coarse particles of the grog and sand. Contrary to what I have thought up until now, lately we have found that this approach makes for greater plasticity, better drying and less water splitting than if the grog and body contain a range of coarse to very fine particles. It also feels smooth on the wheel.

Grog particles having a narrow particle size range

This picture has its own page with more detail, click here to see it.

A closeup of 35-48 mesh grog particles (courtesy of Plainsman Clays). Grogs are added to clay bodies to impart better drying properties. Grog particles perform their drying-shrinkage-reducing function (for plastic bodies) best when they have an angular rather than round shape.

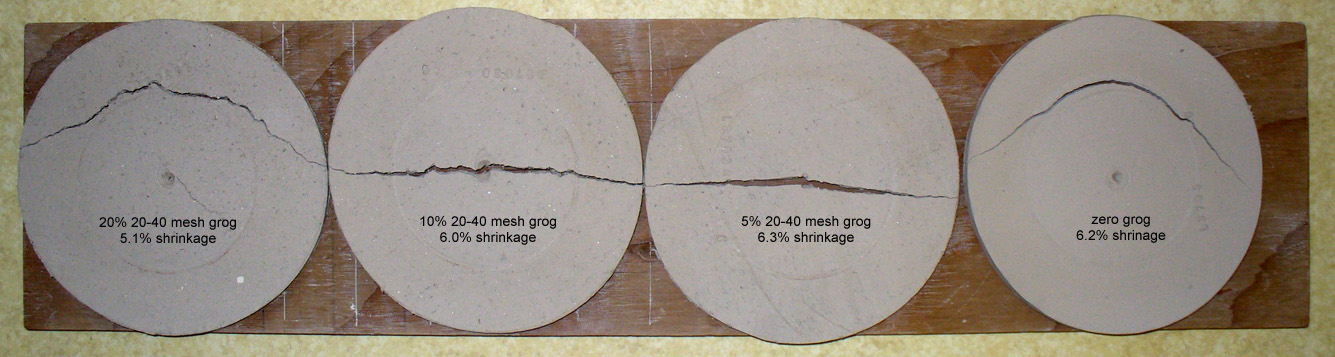

Grog does not always have the intended effect

This picture has its own page with more detail, click here to see it.

These DFAC test disks (drying performance) show that minor additions of grog do not reduce the fired shrinkage of this medium fire stoneware much. Nor do they improve its drying performance. Even at 20% grog, although the addition has reduced drying shrinkage and narrowed the crack somewhat, it is still there and even resembles the zero-grog version. A possible reason is that this body is coarse-particled, having a relatively small total particle surface area. The addition of the grog has significantly increased the total area.

Make your own molochite porcelain body

This picture has its own page with more detail, click here to see it.

The grogs shown here are Molochite 16/30, Christie Minerals STKO 22S and F65 Silica Sand. I wedged 150g of the molochite into 2300g of pugged porcelain (Plainsman M370). This calculates to 7.5% grog (based on 22% water content of the pugged clay). This produced the texture shown. Wedging a grog (or silica sand) into a soft clay body is easy, just sprinkle it on the table and wedge the clay over it. With each push it picks up more, the process is amazingly effective at quickly producing a homogenous material. If the clay is stiff, just moisten the aggregate. Knowing that pugged clays have about 20% water it is easy to calculate a grog addition: A 5 kg slug of clay thus contains 4 kg of powder. To add 10% grog you would add 400g. To add 10% of the total it would be 4000*10/90=444g. How much did this 7.5% grog reduce the drying shrinkage of this body? About 0.5%.

How can Craft Crank sculpture clay be so plastic and smooth with this much grog?

This picture has its own page with more detail, click here to see it.

The super-smooth clay on the left is "Industrial Crank" from Potclays in the UK, I have removed the grog (our test code number L3868). First I did our standard tests on that body, then I dried some, slaked it in water, screened the grog out and then dewatered the remaining clay to plastic form. The grog yielded weighed the same as the clay portion of the recipe yet this body is known for amazing workability and toughness! How is that possible with so much aggregate in the recipe? The base clay body is extremely smooth, sticky and highly plastic. Mixtures of just ball clay and feldspar (e.g. 75:25) will yield this type of material, some ball clays will produce as little as 6% drying shrinkage using this ratio. The grog they use is also special: The particles have angular shapes and a narrow range of sizes, from about 35 mesh to 70 mesh (most is of the coarsest size). This narrow range of sizes means dramatically less particle surface area. These factors produce much less disruption of the plastic properties of the base clay. How could you make a body like this? Slurry up about 75% ball clay and 25% feldspar and wedge the grog into that.

How could only a 5% fine grog body be suitable for such large pieces?

This picture has its own page with more detail, click here to see it.

Louise Solecki Weir working on one of her large sculptures. Sculptors can be passionate about the clay they use. For good reason, they have a lot to lose. While it might seem that Louise would be most concerned about drying shrinkage and drying performance (resistance to drying cracks), not so. To her, the ability to re-wet sections that dry out is paramount. And she has learned to overcome drying challenges posed by the high plasticity to benefit from the smooth texture, workability and rewetability it offers. How plastic is this clay (Plainsman F96)? It is a five-equal-parts-mix of silica sand/grog, ball clay, Lincoln fireclay, a low fire red clay and a medium fire red clay (there is no feldspar or silica). All four of the clays are highly plastic to super plastic. The body's drying shrinkage would be 8% if it was not for the 20% aggregate (a mix of fine 75 mesh sand with a small complement of fine 40 mesh grog) that reduce it to 6.5%. These offer a far higher surface area than coarse grog and provide channels for water to re-enter.

Wow, what a surface. How?

This picture has its own page with more detail, click here to see it.

A cone 10R sculpture clay containing 40% ball clay, 10% kaolin, 10% low fire redart (for color and maturity), some quartz and 25% 20x48 grog. This fine grained base produces a body that feels smoother than it really is and is very plastic. It is even throwable on the wheel.

Mugs made from a sculpture clay? Yes!

This picture has its own page with more detail, click here to see it.

These mugs are made from a vitreous cone 10R sculpture clay (Plainsman Native Sculpture, a successor to our previous RedArt based body P5867). The grog is the lighter colored specks against the background of a quite vitreous dark burning and smooth clay. This body thus has much more fired strength than the average much more porous sculpture body.

A sculpture bodies gets a lot more interesting surface

This picture has its own page with more detail, click here to see it.

This is an example of how soluble salts can enhance the appearance of the fired surface of a cone 10R clay. This sculpture body is a vitreous dark brown burning base having lighter colored 20 mesh grog particles. The one on the left uses native stoneware clays that contain natural flux-containing solubles that migrate to the surface during drying. When fired they act like an extremely thin layer of glaze, producing a darker sheen on the surface. The thickness (and thus color) varies with contour and exposure of the surface during drying. The inside of the cone has no solubles at all.

Perlite in a grogged sculpture body

This picture has its own page with more detail, click here to see it.

This body is a plastic fireclay base having 13% 20/48 grog and 10% 65 mesh silica sand. But the texture is far coarser than one would expect. That is because it has 4 cubic feet of perlite per thousand pound batch. If desired the surface can be trowel smooth. This works well partly because the perlite particles are soft and easy to crush.

A flameware recipe. Are they kidding?

This picture has its own page with more detail, click here to see it.

This is made from a recipe promoted by a popular website (equal parts of talc, ball clay and grog). Are they serious? How could the page fail to mention how coarse this is? How is it possible to throw something like this. Wouldn’t ware be porous and weak? Is this an attempt to make cordierite? But that needs special firing. Maybe the idea is that anything with this much grog can automatically be ovenware!

A flameware body recipe being tested for thermal shock. Is this a joke?

This picture has its own page with more detail, click here to see it.

A recommended flameware recipe from a respected website (equal parts of 35 mesh grog, talc and ball clay). It looks good on paper but mix it up for a surprise! The texture is ridiculously coarse. Recipes like this often employ fire clays and ball clays, but these have high quartz contents. In flame test like this a ball clay vessel could easily fail in 5 seconds. But this one is surviving still at the 90-second mark. Or is it? While porcelain pieces fail with a spectacular pop of flying shards, these open-porous bodies fail quietly (note the crack coming up to the rim from the flame). There was a potential to create cordierite crystals (the reason for the talc), but what potter can fire to cone 14 to make that happen? But the porosity of 12.5% would be difficult to deal with. On the positive side, you could likely continue using this vessel despite the crack, the coarse texture would make the crack seem like a minor inconvenience. The previous being said, heating here is asymmetrical, creating exponential stresses from hot to cold face. Ceramic can absorb differentials if the heat source were more evenly distributed radially from the bottom distributing centre-outward symmetrically.

Plainsman M390 plus 12.5% Christie STKO 22S grog

This picture has its own page with more detail, click here to see it.

This is the surface after trimming. M390 is normally smooth. It is plastic enough to be able to tolerate this grog without apparent loss in workability (still throwing well). And it does not feel overly abrasive on the wheel (unless your hand goes down onto the wheelhead). How is that possible? Although the particles of grog are large, they are not touching each other and readily press down into the clay.

Inbound Photo Links

Do you really need a grog body for sculpture? |

Links

| Glossary |

Sculpture

In ceramics, clays with added aggregate are free formed or molding into shapes that are slowly dried and fired in a kiln. The process requires much skill. |

| URLs |

https://shop.keramik.at/en/c/ola1-64/a/ola1-20790/blue/Sibelco-Clay-stoneware-Terrazzo-Blue-4020-light-blue---pigeon-blue.html

Terrazzo Blue - A super-grogged and speckled reduction firing body from Sibelco |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy