| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Pyrometric Cone

Cones are ceramic and bend through a narrow temperature range. They used to be actively used to determine when firings were completed but now are used to calibrate electronic devices.

Key phrases linking here: pyrometric cones, pyrometric cone, orton cones - Learn more

Details

A pyramid-shaped ceramic device made by Orton Ceramics, it is used to quantify the amount of heat delivered by a kiln. Cones are made from recipes of ceramic materials and minerals tuned to make them bend gradually through a target temperature range. In the past cones were used actively by being placed in kilns to be viewed during firing, their bending was taken as an indicator of when to begin the down ramp. Of course, the vast majority of manufacturers and potters use electronic controllers to fire nowadays, cones are thus used passively, the state of the cone being a guide to calibrate thermocouples and adjust controller programs for subsequent firings.

Self-supporting cones are much superior to standard cones (improperly set standards cones border on useless). Self-supporting cones automatically sit at the right angle and are easier to read.

A curious situation has developed in recent years among many who use electric hobby and pottery kilns. The controllers of these have built-in cone-fire modes that enable one-touch setup to launch a firing. Fewer and fewer people even bother using cones to verify firings. Many express complete surprise when they learn their kiln is firing much too high, for example. Some regard a conflict between cone and controller readings as a problem with the cones! Kiln companies themselves will even defend the accuracy of their automatic cone-fire mode when cones clearly indicate significant errors.

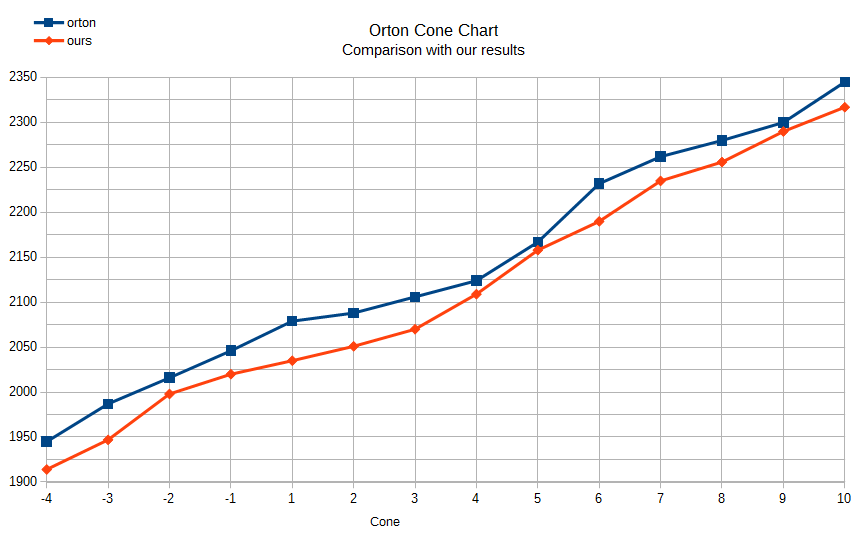

Hermann Seger studied the melt dynamics of oxide compounds and made the first cones. Edward Orton followed and laid the groundwork for the cones we use today. Shown here is a fragment of an Orton cone chart (showing temperatures common to traditional ceramics). Small cones were used in kiln sitters, mechanical devices that shut of a kiln when the cone deformed. Note that cones bend at different temperatures according to the rate of temperature rise. Hence, rather than measuring temperature, they theoretically quantify the combined effects of time and temperature.

While this sounds like the ideal measuring system for firing ceramics, there are many factors that muddy the water and make their interpretation difficult. An example is interpreting the temperature that a cone indicates (according to its degree of bend). This is important in lab situations where data is being recorded for plotting on temperature-vs-property graphs or a controller is being calibrated. Rate-of-rise is another issue, few companies or people fire at the slow rates indicated here (except for heavy sculptural and structural products). Kiln firing schedules always vary the rate-of-rise and different stages of the firing, typically showing down near the end to rates shown here.

Note this diagram: By the time a cone reaches three o'clock (3:00), it has travelled through 80% of the temperature range from start-of-bend to touching-down (different cones span differing numbers of degrees). This means a cone 6 at 3:00 is interpreted as 5.8. At 1:00, it is already 50% complete, that would be 5.5. As can be seen here, cones are most sensitive as they near the end of travel. The booklet "Cones and Firing" (that used to be available at ortonceramic.com) detailed the pyrotechnical theories of how cones operate. It cited a number of examples of the variation possible from the ways people commonly misset and misuse cones.

As noted, pretty well all potters and plant operators employ electronic kiln controllers now. The ceramic industry long ago adopted these devices in the pursuit of repeatable firings. We used to say that cones measure heat-work and thermocouples measure temperature, but now it is not so clear that a practical point of view. Controllers enable controlling the up and down ramps of firings, making for better repeatability in periodic kilns. Industry likes to have numeric data (for testing records and audit trails), these controllers provide that.

Continuous industrial kilns maintain a constant temperature in the middle of a long tunnel, and the speed of the ware-cars or conveyor through the kiln determines the firing curve each piece is subjected to. In this situation, the maintenance of a specific temperature at the hot zone is critical to consistent ware. This supplies plenty of motivation to maintain thermocouples and wiring well. And put cones on ware carts.

Years ago Buller's rings were also used as indicators of temperature achieved. These were precision dust-pressed and designed to shrink in a linear fashion with temperature increase. An advantage was that one device worked across a wide temperature range and expressed a discrete number representing the degree of firing. They didn't indicate when to shut the kiln off, rather what heat-work was achieved at shut off. For a number of years, we put these into firings each day beside the set of cones and recorded the value measured. For example, cone 10 yielded a Buller's ring value of 40. Cone 6 produced values from 27 to 29. The combination of rings and cones, coupled with collected historical data, enabled us to better interpret the temperature achieved in each firing.

Here is a chart, created from cone and ring records from thousands of firings, it cross-references cone-bend with temperature in our circumstances.

Related Information

Cones bending theoretically, cones bending actually

This picture has its own page with more detail, click here to see it.

Orton cones have become much less relevant in recent years. That being said they are still commonly used to calibrate kiln controllers. Most people just use one cone now (rather than the guard, firing and guide cones of the past). The problem illustrated in this diagram is our reason for doing that. At our typical firing rates, we found that bending the middle cone to 5 o'clock pretty well always started the guard cone. Orton said when that happens "you have exceeded the best time-temperature relationship". Thus, over time, we got into the habit of bending the firing cone to 3 o'clock (as shown in #1). Notice the situation in #2, that is not supposed to happen but often does. The first guide cone should be slumping, not just touching. And the guard cone should not be starting. Now we just use one cone bent to 5 o'clock to callibrate our electronic controllers.

Getting accurate firings in test kilns time after time.

This picture has its own page with more detail, click here to see it.

The blue line on this graph is from the Orton cone chart for 108F/hr. But those are not the target temperatures for test kiln cone firings. I use the red line to program the controller for each cone. Where is that red line from? I made it. The self-supporting cones I put in every firing verify it, time after time, for thousands of firings. Only fine-tuning is needed to adjust the top temperature if a cone so indicates. This happens as elements degrade or when they are replaced. Should you use that red line? No. Use self-supporting cones to establish your target temperatures and make your own line.

At what point is a self-supporting cone bent to the correct degree?

This picture has its own page with more detail, click here to see it.

Orton says “90 angular degrees is considered the endpoint of cone bending”. First, let's assume the normal: Examination of cones on kiln-opening to verify controller operation. Consider the cone on the left: The tip is touching. But it is also beginning to buckle, which means it was touching for a while before the firing ended. Who knows how long! The second one is not touching but has still fallen a little too far. Why do we say that? The third one, positioned on the Orton guide, has reached the recommended 90 degrees. This demonstrates a good reason why self-supporting cones are much better than standard ones: They are not touching when considered done. And standard cones, when set in a 3/4" plaque, have a less consistent bending behaviour.

How many degrees between these cone positions?

This picture has its own page with more detail, click here to see it.

I was consistently getting the cone on the left when using a custom-programmed firing schedule to 2204F (for cone 6 with ten minute hold). However Orton recommends that the tip of the self supporting cone should be even with the top of the base (they consider the indicating part of the cone to be the part above the base). So I adjusted the program to finish at 2200F and got the cone on the right. But note: This applies to that kiln at that point in time (with that pyrometer and that firing schedule). Our other test kiln bends the cone to 5 o'clock at 2195F. Since kiln controllers fire cone 6 at 2230 (for the built-in one-button firings) your kiln is almost certainly over firing!

The bending of an Orton standard cone 10

This picture has its own page with more detail, click here to see it.

People refer to the extent of cone-fall as numbers-on-the-clock or degrees. This cone is at 5 o'clock or 80 degrees. Notice that start-to-finish spans 35 degrees C (not all cones have this same 35 degree fall). As you can read on the temperature scale, 25+ degrees happen before it reaches 2 o'clock! From 5 to 6 o'clock is only 1 degree! This is a standard cone that requires a plaque, notice that the down-touching position is when it hits the top of the plaque. It follows from this that one can convert cone-bend to equivalent temperature. That being said, remember that cones measure heat-work, so the conversion is only valid for a 60C/hr rate-of-rise.

How to get more accurate firings time after time

This picture has its own page with more detail, click here to see it.

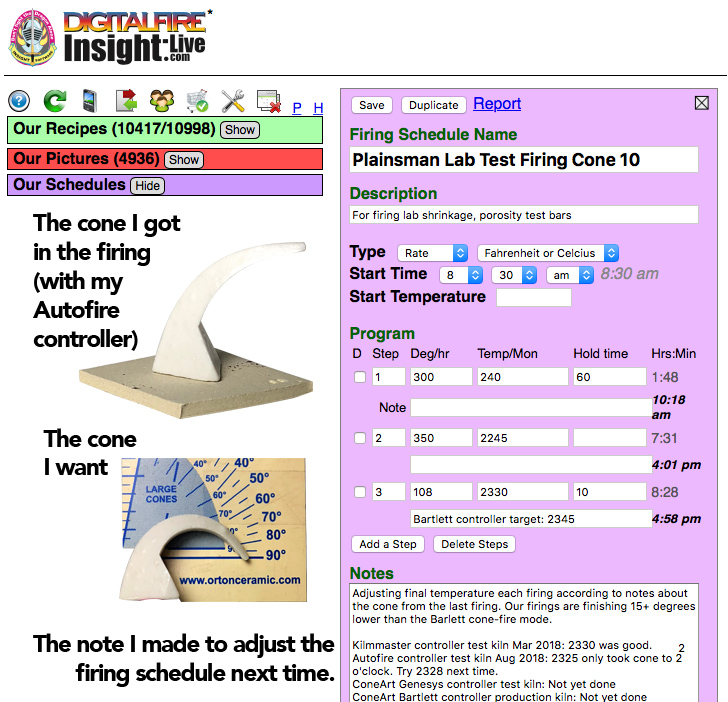

When we fire our two small lab test kilns we always include cones (we fire a dozen temperatures). I want the firing to finish when the cone is around 5-6 oclock. To make that happen I record observations on which to base the temperature I will program for the final step the next time. Where do I record these? In the schedules I maintain in our Insight-live.com group account. I use this every day, it is very important because we need accurate firings.

Low fire red cones inhabit their own volatile world

This picture has its own page with more detail, click here to see it.

Notice that from cone 06 to 04, the temperature difference between cones is far greater than at any other range. But this situation changes approaching cone 3, where the difference from one cone to the next drops and accelerates (thus the curved line). Firing a kiln accurate to cone 2, by cones, is difficult since the cone 1 and 3 guide and guard cones fall in a similar fashion. From cone 4 and up cones prove to be a much more stable indication of temperature and heat-work. Not surprisingly, it makes more sense to trust a pyrometer in the cone 02-3 range. Low fire terra cotta bodies vitrify in a similar manner.

Make your own pyrometric cones? Why not!

This picture has its own page with more detail, click here to see it.

Self-supporting cones are a must in each firing but they are expensive. Fortunately the shape of a self-supporting cone is easy to draw in 3D (I did it here in Fusion 360). It is a 25mm equilateral triangle base lofted to a 3mm one 65mm straight up on the front side. And then a cut-out across the front. By using 3D printed molds and plastic clay I can press these by the dozen. What about a recipe? Cones melt short of being glazes but beyond being porcelains. I chose L3685Z3 engobe as a starting point, it has a linear vitrification curve spanning a wide range. Approaching this on the material level, not as a chemistry project, I did three iterations of adding Ferro frit 3110 to the engobe. Shown here are the second, "A" and third, "B" (on the right is an Orton cone 6). B has too much frit, A does not have enough. You likely guessed what I did next: Mixed A and B. The result was almost perfect, bent just a little too much. If you would like this 3D file in Fusion 360 format, it is available in the Files manager in your Insight-live.com account.

Program your firings manually, calibrate the final temperature using cones

This picture has its own page with more detail, click here to see it.

Here is an example of our lab firing schedule for cone 10 oxidation (which the cone-fire mode does not do correctly). To actually go to cone 10 we need to manually create a program that fires higher than the built in cone-fire one. Determining how high to go is a matter repeated firings verified using a self-supporting cone (regular cones are not accurate). In our lab we keep notes in the schedule record in our account at insight-live.com. And we have a chart on the wall showing the latest temperature for each of the cones we fire to. What about cone 6? Controllers fire it to 2235, we put down a cone at 2200!

Cones bending badly

This picture has its own page with more detail, click here to see it.

We sometimes see customers doing this with cones: Putting them in the plaque backwards! Of course, they are not going to be accurate. Actually, self supporting cones are much better, they are idiot-proof because they enforce the 8 degree angle and bending direction.

What cones do at low fire is different

This picture has its own page with more detail, click here to see it.

The tip of the firing cone 03 on the left has just touched and it is beginning to deform. Yet the guard cone 02 is not moving at all and the cone 04 is practically melting. However the tip of the cone 7 firing cone on the right has not quite touched. But the cone 8 is already well on the way and the cone 6 touched not long ago. Yet cones separate by about 30 degrees in both ranges. Why the difference here? At low fire the kiln can climb quicker so less heat-work is done (that is what bends cones). Also, the iron-based low fire cones are more volatile and begin and complete their fall through a narrower range. So at low fire cones can be an absolute measuring device. But at high temperature their use is more about comparing behavior firing-after-firing and adjusting procedure by that experience.

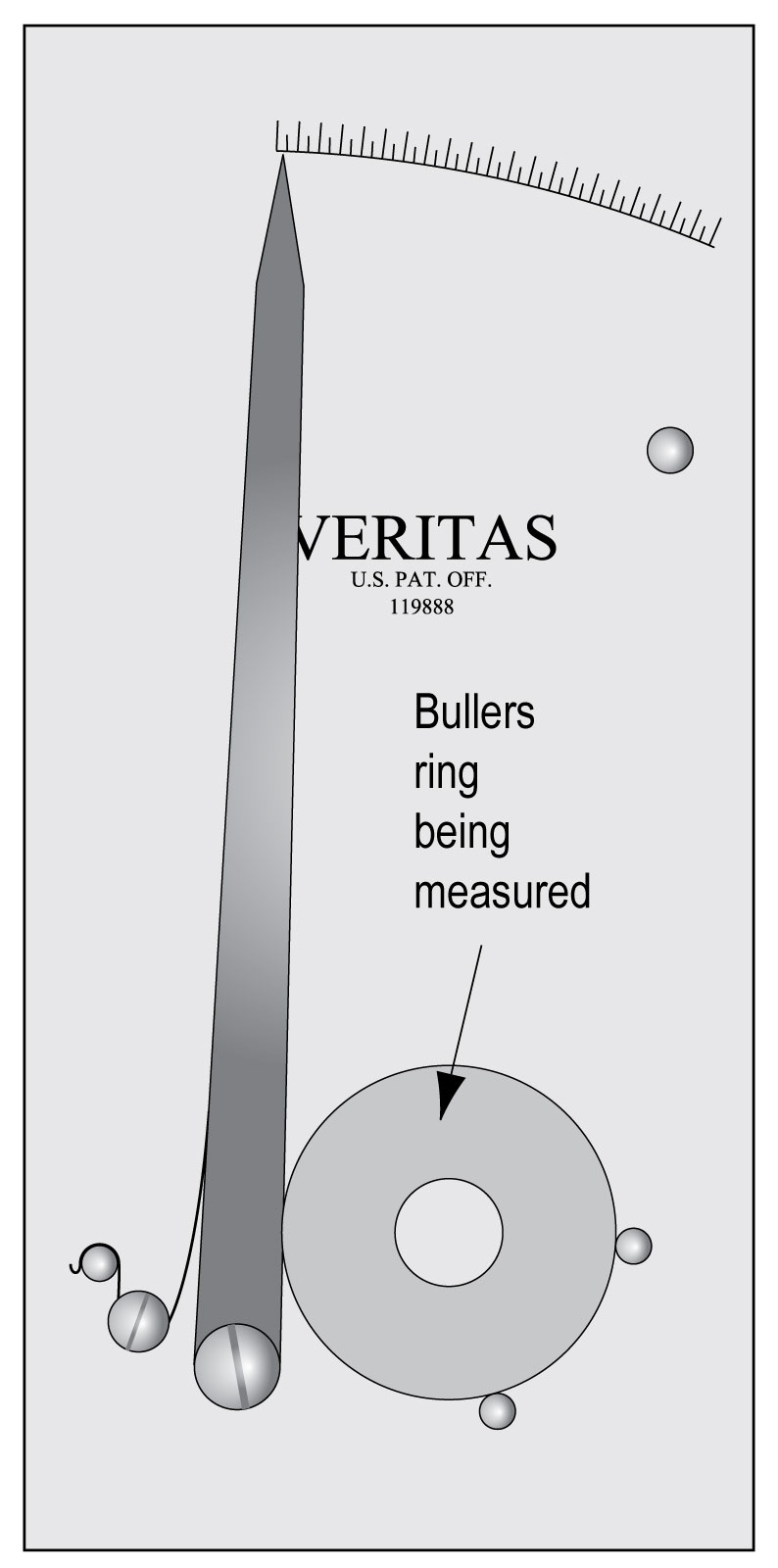

Bullers ring vs. cones for measuring kiln temperature

This picture has its own page with more detail, click here to see it.

This is a Veritas measuring device. It was used to measure the size of Bullers rings. The system was set up so that an unfired ring would measure close to zero (the difference from zero was added or subtracted from the final measure). These rings provided a measure of what temperature the kiln was (as opposed to cones which say what it is). Actually, many companies placed many rings in a firing and extracted them, one-at-a-time (using a metal rod), cooled them quickly and measured them; this gave an accurate indication of the current temperature. Some companies still use these today to verify electronic measuring devices. The Orton TempCHEK system is based on this same principles, but is much more refined (and much more accurate).

Links

| URLs |

http://www.ortonceramic.com

Orton Ceramic Website |

| URLs |

https://www.ortonceramic.com/files/2676/File/cones-and-firing-booklet.pdf

Orton "Cones and Firing" book Official PDF format guide from OrtonCeramic.com. |

| Glossary |

Kiln Controller

In ceramic kilns the firing schedule is typically managed automatically by an electronic controller. But that may not mean that ware gets automatically fired to the correct temperature and atmosphere. |

| Glossary |

Thermocouple

|

| Articles |

Electric Hobby Kilns: What You Need to Know

Electric hobby kilns are certainly not up to the quality and capability of small industrial electric kilns, being aware of the limitations and keeping them in good repair is very important. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy