| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

A Low Cost Tester of Glaze Melt Fluidity

A One-speed Lab or Studio Slurry Mixer

A Textbook Cone 6 Matte Glaze With Problems

Adjusting Glaze Expansion by Calculation to Solve Shivering

Alberta Slip, 20 Years of Substitution for Albany Slip

An Overview of Ceramic Stains

Are You in Control of Your Production Process?

Are Your Glazes Food Safe or are They Leachable?

Attack on Glass: Corrosion Attack Mechanisms

Ball Milling Glazes, Bodies, Engobes

Binders for Ceramic Bodies

Bringing Out the Big Guns in Craze Control: MgO (G1215U)

Can We Help You Fix a Specific Problem?

Ceramic Glazes Today

Ceramic Material Nomenclature

Ceramic Tile Clay Body Formulation

Changing Our View of Glazes

Chemistry vs. Matrix Blending to Create Glazes from Native Materials

Concentrate on One Good Glaze

Copper Red Glazes

Crazing and Bacteria: Is There a Hazard?

Crazing in Stoneware Glazes: Treating the Causes, Not the Symptoms

Creating a Non-Glaze Ceramic Slip or Engobe

Creating Your Own Budget Glaze

Crystal Glazes: Understanding the Process and Materials

Deflocculants: A Detailed Overview

Demonstrating Glaze Fit Issues to Students

Diagnosing a Casting Problem at a Sanitaryware Plant

Drying Ceramics Without Cracks

Duplicating Albany Slip

Duplicating AP Green Fireclay

Electric Hobby Kilns: What You Need to Know

Fighting the Glaze Dragon

Firing Clay Test Bars

Firing: What Happens to Ceramic Ware in a Firing Kiln

First You See It Then You Don't: Raku Glaze Stability

Fixing a glaze that does not stay in suspension

Formulating a body using clays native to your area

Formulating a Clear Glaze Compatible with Chrome-Tin Stains

Formulating a Porcelain

Formulating Ash and Native-Material Glazes

G1214M Cone 5-7 20x5 glossy transparent glaze

G1214W Cone 6 transparent glaze

G1214Z Cone 6 matte glaze

G1916M Cone 06-04 transparent glaze

Getting the Glaze Color You Want: Working With Stains

Glaze and Body Pigments and Stains in the Ceramic Tile Industry

Glaze Chemistry Basics - Formula, Analysis, Mole%, Unity

Glaze chemistry using a frit of approximate analysis

Glaze Recipes: Formulate and Make Your Own Instead

Glaze Types, Formulation and Application in the Tile Industry

Having Your Glaze Tested for Toxic Metal Release

High Gloss Glazes

Hire Us for a 3D Printing Project

How a Material Chemical Analysis is Done

How desktop INSIGHT Deals With Unity, LOI and Formula Weight

How to Find and Test Your Own Native Clays

I have always done it this way!

Inkjet Decoration of Ceramic Tiles

Is Your Fired Ware Safe?

Leaching Cone 6 Glaze Case Study

Limit Formulas and Target Formulas

Low Budget Testing of Ceramic Glazes

Make Your Own Ball Mill Stand

Making Glaze Testing Cones

Monoporosa or Single Fired Wall Tiles

Organic Matter in Clays: Detailed Overview

Outdoor Weather Resistant Ceramics

Painting Glazes Rather Than Dipping or Spraying

Particle Size Distribution of Ceramic Powders

Porcelain Tile, Vitrified Tile

Rationalizing Conflicting Opinions About Plasticity

Ravenscrag Slip is Born

Recylcing Scrap Clay

Reducing the Firing Temperature of a Glaze From Cone 10 to 6

Setting up a Clay Testing Program in Your Company or Studio

Single Fire Glazing

Soluble Salts in Minerals: Detailed Overview

Some Keys to Dealing With Firing Cracks

Stoneware Casting Body Recipes

Substituting Cornwall Stone

Super-Refined Terra Sigillata

The Chemistry, Physics and Manufacturing of Glaze Frits

The Effect of Glaze Fit on Fired Ware Strength

The Four Levels on Which to View Ceramic Glazes

The Majolica Earthenware Process

The Potter's Prayer

The Right Chemistry for a Cone 6 Magnesia Matte

The Trials of Being the Only Technical Person in the Club

The Whining Stops Here: A Realistic Look at Clay Bodies

Those Unlabelled Bags and Buckets

Tiles and Mosaics for Potters

Toxicity of Firebricks Used in Ovens

Trafficking in Glaze Recipes

Understanding Ceramic Materials

Understanding Ceramic Oxides

Understanding Glaze Slurry Properties

Understanding the Deflocculation Process in Slip Casting

Understanding the Terra Cotta Slip Casting Recipes In North America

Understanding Thermal Expansion in Ceramic Glazes

Unwanted Crystallization in a Cone 6 Glaze

Using Dextrin, Glycerine and CMC Gum together

Volcanic Ash

What Determines a Glaze's Firing Temperature?

What is a Mole, Checking Out the Mole

What is the Glaze Dragon?

Where do I start in understanding glazes?

Why Textbook Glazes Are So Difficult

Working with children

Simple Physical Testing of Clays

Description

Learn to test your clay bodies and clay materials and record the results in an organized way, understanding the purpose of each test and how to relate its results to changes that need to be made in process, recipe and materials.

Article

Many technicians have amindset that is too narrow when it comes to dealing with clay body formulation. Compared to glazes, clay bodies and engobes are much more of an adventure in the mineralogy and physical properties of the materials. When glazes melt everything usually goes into solution in the melt, but the vitrification process is different. The differences in mineralogy; particle size, shape, size distribution and surface characteristics; body preparation, and ware forming methods; and firing history are examples of things that influence the final fired product.

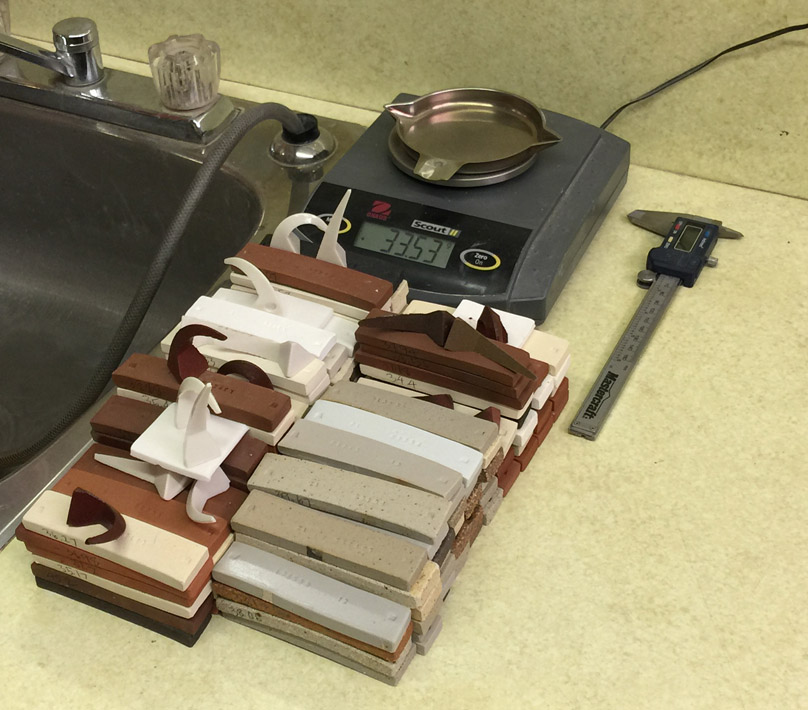

Consider these three simple tests that we find most practical for clay bodies: The SHAB test, LDW test and DFAC test. While these are easy to do it is tricky to organize all the data they produce (e.g. we are running these on dozens of clays at any given time, all in various stages of completion). Feeding the data into our insight-live.com account is the key to progressively learning from it.

This subject of physics reveals an interesting comparison between potters and industrial technicians. On one hand, the potter judges a body by how it feels in his hands, how it bends, stretches, pulls, how it behaves on the wheel, how it trims, how it dries, how it reacts visually with his glazes and fires in his kiln. But that potter may not be able to provide any data about things like fired density, thermal expansion, drying shrinkage, % water content, etc. On the other hand, a factory technician may have never hand-formed a ceramic object or even kneaded a piece of clay but he/she might be able to quote dozens of statistics about (as generated by testing devices). We advocate a middle ground: Hands-on experience applying the knowledge accumulated from affordable practical testing methods. Many body properties are immediately evident in the hands of an experienced potter and not quickly shown by instruments. Likewise, data from a test can really provide direction to resolve a problem or adjust a property.

Strangely, many large manufacturers in the ceramic industry do not actually have a standard testing and quality control program in place. It is common to rely completely on suppliers and their tech support. Troubleshooting manuals they supply speak the language of production-line workers with simple "if this happens do that" style instructions. What about people and companies who want to understand the why questions, become more independent? As noted, while many potter's textbooks are highly insightful and helpful there is no substitute for setting up a test program to accumulate some data.

Testing Categories:

Universal Standards

An example is the 50-volume Annual Book of Worldwide ASTM Standards (American Society for Testing and Materials). One of the volumes deals with refractories, glaze, and ceramic materials. The books are well organized and describe all test procedures in great detail. Just reference a test by number and you convey all details about how you achieve your results. However, these are not for the faint-of-heart. And they are not for people without the lab equipment called for.

Industry Specific Standards

Individual industries like construction, ferrous metals and electrical porcelain have outlined standard testing guidelines more specific to their needs, for example, ANSI (American National Standards Institute). Companies publish data sheets and advertising material in a format that voluntarily recognizes these standards.

Customer Required

Customers sometimes require manufacturers to document product quality and compliance (e.g. ISO 9000 which requires documentation on how tests are done, tolerances, noncompliance procedures, procedure change mechanisms, test equipment calibration schedules, proof of certification, etc). Unfortunately, the emphasis of all of this is on the production of documentation, not understanding the physics of the materials.

Internal

Many tests are internal to a company, intended to solve problems, maintain properties critical to production efficiency and cost, control reject rates, etc. In this situation, one is free to formulate any method that seems best for the circumstances. Technicians generally have to be flexible and make do with what is available, so standard methods are usually adjusted. These simple tests are sometimes the most revealing and practical.

Getting Started with Internal Testing

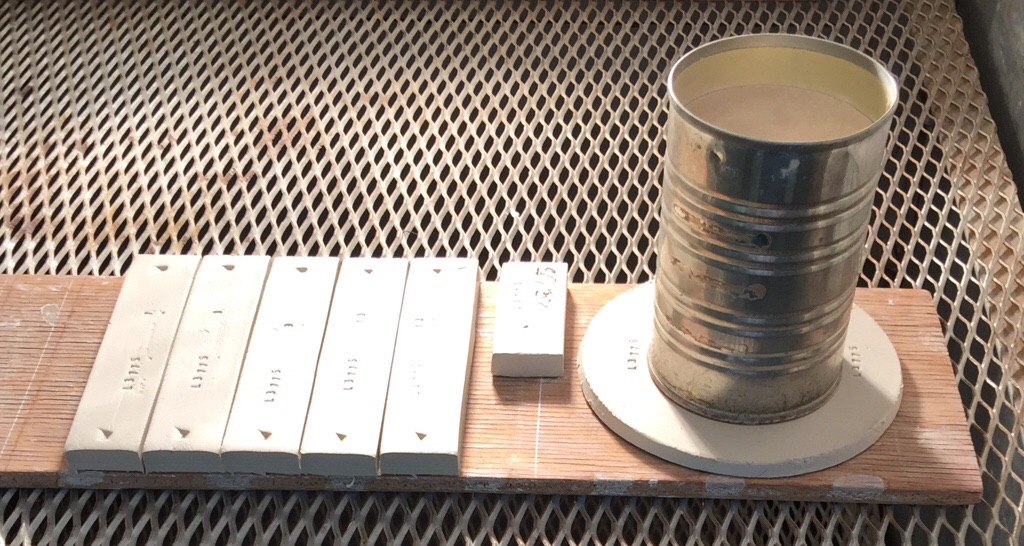

We recommend starting with one of the tests built into Insight-Live. It predefines many and the ones of interest to us here are the SHAB test (Shrinkage, Absorption), DFAC test (Drying Factor), SOLU test (Solubles) and LDW test (LOI, Density, Water Content). The procedures for these describe how to make and process the three simple specimens I showed you at the beginning of this chapter (shrinkage bars, H2O bars, drying disk). These provide a framework within which to begin gathering data and relating that to production needs.

The end-product of all your clay body testing work is to generate 'real numbers' that mean something; that can be compared with others to reach conclusions. So my advice is simple. Set up a little lab for yourself and take control of the physical properties of your clay bodies and materials.

Related Information

EPK fired test bars, data, certificate and the data

This picture has its own page with more detail, click here to see it.

All of the test bars have been fired in this project to characterize a shipment of EPK (from cone 7-10 and 10R bottom to top). The dry and fired lengths and the dry and fired weights testdata was measured and entered into our Insight-live account. The results are shown in the red-titled columns (the drying shrinkage, firing shrinkage, absorption). The weights from the sieve analysis are also shown. And the calculation of water content of the plastic material (a very high 33.4%) and LOI (14.5%). We also like to take and upload a photo of the oversize material from the sieve analyses (to compare with past shipments) and of their manufacturers certificate of analysis.

Notice the data that the manufacturer considers important to include on the certificate that they send with the shipment: Particle size, particle surface area and moisture content. Of course, they would not be able to do all the tests we do. But our product is affected by the properties of the material, so we have to test.

Clay lab report. Is this really what you need?

This picture has its own page with more detail, click here to see it.

If you are trying to use local clays for brick or tile or even pottery production, characterizing the available materials is the first step. But how? This is the kind of data a lab might return - perhaps you wonder about its value? We feel traditional ceramics technology is fundamentally relative. A history of many reports like these, in context with other data, might be good for mining companies to determine if new stockpiles have any shifts in certain specific properties. Or a tile company evaluating a new ball clay. But as a way to understand the utility of a clay for a specific ceramic purpose, this contextless report is of little use. For example, the physical properties, the whole reason for using a clay, are unrelated to the chemistry. This is also a tunnel vision view, looking at only one temperature. On the other hand, simple procedures, like the SHAB test, provide a hands-on way to understand what a clay actually is.

Kaolin changes raw color in second shipment

This picture has its own page with more detail, click here to see it.

These are SHAB test bars prepared from two different shipments of the same commercial kaolin (used in porcelain body production). The darker one is markedly more plastic also. This underscores the need to characterize the materials you use in production and maintain an ongoing testing program. This difference was actually easy to deal with: Reduction of the percentage of bentonite in the body.

Drying cracks in bricks - but no data to determine best response

This picture has its own page with more detail, click here to see it.

These bricks were being extruded in India and the plant was suffering drying cracks. A consultant recommended a high percentage addition of lignosulphonate, at a cost of $800/ton, as a solution. But before adding such a large expense, some obvious changes seemed in order first. The technician knew the plasticity index of the clay (a measurement used for soils) but he did not have records of its drying shrinkage, water permeability, drying strength or drying performance - when problems like this arise such data provides direction and help answer questions. For example, is cracking happening because of lack of drying strength or plasticity or because drying shrinkage is too high. The splitting along the corner of the extrusion is a clue that plasticity could be lacking - that could be solved by a small bentonite addition or reduction in grog. If permeability is low an increase in grog might be needed (if the pugmill can still extrude slugs with a smooth edge and corner). Notice the cracks that start from those splits (lower left). But also notice how the top edge has shrunk while the center section has not. That indicates the drying process is not tuned to subject all surfaces to equal airflow (sure enough, these are being dried outside in the sun and wind). Another factor is cross-section: The round holes create variations in thickness that exceed 300%, square holes with rounded corners would be better. Given the location, economic realities and past success this one change might be enough to make a big difference.

Fine tuning maturity of a buff stoneware: It is about the data

This picture has its own page with more detail, click here to see it.

We are reformulating the cone 10R stoneware (the top mug) to have the variegated surface of the lower one. The top one is more vitrified and thus has a more homogeneous grey color. While that makes it stronger it carries the danger of bloating with the materials we use and particle sizes we grind (and warping). We measure degree-of-vitrification using the SHAB test, that produces fired shrinkage and porosity data. The top mug has a porosity of 1.3% and the bottom one 2.5%. That higher porosity gives protection against bloating and the light/dark variegated aesthetic we also want. The nine test bars on the left each show their porosity/firing shrinkage and recipe (our materials have simple names like A2, A3, 3C, they include ball clays, silts, stonewares). We made these nine mixes trying to find a combination that yields the desired porosity but also does not have more than 7.5% drying shrinkage (to avoid drying cracks), is plastic enough for easy forming and does have too sandy of a texture. The second from the top is the best so far and has given clear direction for the next round of testing. These nine tests were fired at five temperatures producing 45 specimens to track and 180 measurements to make to get the final data (just for this SHAB test, others were done also). Our account at Insight-live.com makes it possible to track this plus 50 other projects on the go right now. And it makes it possible to make decisions based on data.

Links

| Tests |

Pyrometric Cone Equivalent

Make a pyrometric cone out of a clay or material to see what temperature it bends at |

| Tests |

Drying Shrinkage

Measure the amount a clay test bar shrinks as it dries |

| Tests |

Firing Shrinkage

Measure the amount a clay test bar shrinks as it is fired in a kiln |

| Tests |

Dry Strength (kgf/cm2)

Measure the tensile strength of a dried clay test bar |

| Tests |

LOI/Density/Water Content

LDW LOI, density and water content test procedure for plastic clay bodies and porcelains |

| Tests |

LOI (100-1000C)

Measure how much weight a dried clay test bar loses as it is fired in a kiln |

| Tests |

Sieve Analysis Dry

A measure of particle size distribution by vibrating a powdered sample through a series of successively finer sieves |

| Tests |

Shrinkage/Absorption Test

SHAB Shrinkage and absorption test procedure for plastic clay bodies and materials |

| Tests |

Sieve Analysis 35-325 Wet

A measure of particle size distribution by washing a powdered or slaked sample through a series of successively finer sieves |

| Tests |

Soluble Salts

Evaluate and compare the solubles salts content in clay bodies and materials |

| Tests |

Density (Specific Gravity)

Measure the density of a dried clay test bar |

| Tests |

Sieve Analysis Wet

A measure of particle size distribution by washing a powdered or slaked sample through a series of successively finer sieves |

| Tests |

Dry Strenth (Round Bars)

|

| Tests |

Dry Strength (Square Bars)

Measure the tensile strength of a square cross section test bar |

| Projects |

Tests

|

| Articles |

How to Find and Test Your Own Native Clays

Some of the key tests needed to really understand what a clay is and what it can be used for can be done with inexpensive equipment and simple procedures. These practical tests can give you a better picture than a data sheet full of numbers. |

| Articles |

Setting up a Clay Testing Program in Your Company or Studio

Set up a routine testing pipeline and start generating historical data that will enable your staff to understand your source materials and maintain, adjust and troubleshoot your clay body recipes. |

| Glossary |

Physical Testing

In ceramics, glazes, engobes and bodies have chemistries and physics. Your formulation and quality control most likely need to focus on the physical properties. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy