| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

A Low Cost Tester of Glaze Melt Fluidity

A One-speed Lab or Studio Slurry Mixer

A Textbook Cone 6 Matte Glaze With Problems

Adjusting Glaze Expansion by Calculation to Solve Shivering

Alberta Slip, 20 Years of Substitution for Albany Slip

An Overview of Ceramic Stains

Are You in Control of Your Production Process?

Are Your Glazes Food Safe or are They Leachable?

Attack on Glass: Corrosion Attack Mechanisms

Ball Milling Glazes, Bodies, Engobes

Binders for Ceramic Bodies

Bringing Out the Big Guns in Craze Control: MgO (G1215U)

Can We Help You Fix a Specific Problem?

Ceramic Glazes Today

Ceramic Material Nomenclature

Ceramic Tile Clay Body Formulation

Changing Our View of Glazes

Chemistry vs. Matrix Blending to Create Glazes from Native Materials

Concentrate on One Good Glaze

Copper Red Glazes

Crazing and Bacteria: Is There a Hazard?

Crazing in Stoneware Glazes: Treating the Causes, Not the Symptoms

Creating a Non-Glaze Ceramic Slip or Engobe

Creating Your Own Budget Glaze

Crystal Glazes: Understanding the Process and Materials

Deflocculants: A Detailed Overview

Demonstrating Glaze Fit Issues to Students

Diagnosing a Casting Problem at a Sanitaryware Plant

Drying Ceramics Without Cracks

Duplicating Albany Slip

Duplicating AP Green Fireclay

Electric Hobby Kilns: What You Need to Know

Fighting the Glaze Dragon

Firing Clay Test Bars

Firing: What Happens to Ceramic Ware in a Firing Kiln

First You See It Then You Don't: Raku Glaze Stability

Fixing a glaze that does not stay in suspension

Formulating a body using clays native to your area

Formulating a Clear Glaze Compatible with Chrome-Tin Stains

Formulating a Porcelain

Formulating Ash and Native-Material Glazes

G1214M Cone 5-7 20x5 glossy transparent glaze

G1214W Cone 6 transparent glaze

G1214Z Cone 6 matte glaze

G1916M Cone 06-04 transparent glaze

Getting the Glaze Color You Want: Working With Stains

Glaze and Body Pigments and Stains in the Ceramic Tile Industry

Glaze Chemistry Basics - Formula, Analysis, Mole%, Unity

Glaze chemistry using a frit of approximate analysis

Glaze Recipes: Formulate and Make Your Own Instead

Glaze Types, Formulation and Application in the Tile Industry

Having Your Glaze Tested for Toxic Metal Release

High Gloss Glazes

Hire Us for a 3D Printing Project

How a Material Chemical Analysis is Done

How desktop INSIGHT Deals With Unity, LOI and Formula Weight

How to Find and Test Your Own Native Clays

I have always done it this way!

Inkjet Decoration of Ceramic Tiles

Is Your Fired Ware Safe?

Leaching Cone 6 Glaze Case Study

Limit Formulas and Target Formulas

Low Budget Testing of Ceramic Glazes

Make Your Own Ball Mill Stand

Making Glaze Testing Cones

Monoporosa or Single Fired Wall Tiles

Organic Matter in Clays: Detailed Overview

Outdoor Weather Resistant Ceramics

Painting Glazes Rather Than Dipping or Spraying

Particle Size Distribution of Ceramic Powders

Porcelain Tile, Vitrified Tile

Rationalizing Conflicting Opinions About Plasticity

Ravenscrag Slip is Born

Recylcing Scrap Clay

Reducing the Firing Temperature of a Glaze From Cone 10 to 6

Setting up a Clay Testing Program in Your Company or Studio

Simple Physical Testing of Clays

Single Fire Glazing

Soluble Salts in Minerals: Detailed Overview

Some Keys to Dealing With Firing Cracks

Stoneware Casting Body Recipes

Substituting Cornwall Stone

Super-Refined Terra Sigillata

The Chemistry, Physics and Manufacturing of Glaze Frits

The Effect of Glaze Fit on Fired Ware Strength

The Four Levels on Which to View Ceramic Glazes

The Majolica Earthenware Process

The Potter's Prayer

The Right Chemistry for a Cone 6 Magnesia Matte

The Trials of Being the Only Technical Person in the Club

The Whining Stops Here: A Realistic Look at Clay Bodies

Those Unlabelled Bags and Buckets

Tiles and Mosaics for Potters

Toxicity of Firebricks Used in Ovens

Trafficking in Glaze Recipes

Understanding Ceramic Oxides

Understanding Glaze Slurry Properties

Understanding the Deflocculation Process in Slip Casting

Understanding the Terra Cotta Slip Casting Recipes In North America

Understanding Thermal Expansion in Ceramic Glazes

Unwanted Crystallization in a Cone 6 Glaze

Using Dextrin, Glycerine and CMC Gum together

Volcanic Ash

What Determines a Glaze's Firing Temperature?

What is a Mole, Checking Out the Mole

What is the Glaze Dragon?

Where do I start in understanding glazes?

Why Textbook Glazes Are So Difficult

Working with children

Understanding Ceramic Materials

Description

Ceramic materials are not just powders, they have a physical presence that make each unique and amazing. We cannot adequately describe the properties using just numbers, thinking in terms of generic materials is a key.

Article

When you first started in ceramics, you were probably amazed at the array of exotically named raw materials. At that time, they were just white powders that were weighed out to match the recipes on hand. There were so many materials that it seemed impossible to ever understand the function of all of them. Our instructors often ignored their individuality, focusing only on the fired visual and tactile properties of 'mysterious' mixes of them.

You probably noticed that textbooks sometimes contain a separate section dedicated to describing major raw materials. They invariably classified materials according to major groups and this simplifies understanding the individuals. Like many people, you may have hurriedly skipped these parts for the more interesting 'how-to' chapters. It didn't take long to find out that some textbooks on ceramics did not even describe basic materials like kaolin; others were narrow in their treatment of it. Some like Hamer's "Dictionary of Materials" are much better.

Now that you are learning the oxide viewpoint, materials will take on a whole new life. They become "sources of oxides". However, as we have seen, materials have a chemistry, a mineralogy, and a host of physical properties to recon with.

Consider the following as typical of what you would often get from a supplier if you asked for information on a material like Barnard Slip:

CaO 0.57, K2O 1.14%, MgO 0.68%, Na2O 0.57%, TiO2 0.23%,

Al2O3 7.60%, SiO2 47.01%, Fe2O3 33.90%, LOI 8.31%

They can give you plenty of other numbers also (numbers that are often inaccurate and out-of-date). What do these number this tell us? To be honest, very little! Is it really a clay? Is it plastic? Is the SiO2 combined with alumina and others or is it in the form of quartz particles? When does it melt? What is the particle size? What is the raw color? How is it possible for a clay to have such high iron? What really is this stuff mineralogically? Is it synthetic? Is it similar to yellow ochre? Is it practical for use in clay bodies? Where can I get it? Is it available in different grades and from multiple manufacturers?

If you are like me, you want practical information; you want to know what a material is. We need to know enough to be able to ask some intelligent questions. The materials area on this site database is addressing these very issues. Efforts are under way to accumulate the kind of information people want from manufacturers and to standardize the way it is presented.

Barnard Slip is an interesting example. Since I have not received a data sheet from a supplier I simply tested it myself. The results of this testing can be found in the Digitalfire Reference Library.

This is the kind of information we need about materials, isn't it?

Let's consider kaolin. This is quite different. There are hundreds available. In this case, we need a textbook description of what generic kaolin is, what it is used for, and why it is used in preference to other materials. It is much more than a simple source of Al 2O3 in glazes. Kaolin is the only practical source that does not bring fluxes also and that it is ideal because it is inexpensive, consistent, and imparts suspension and raw hardness properties. It is a popular body constituent because of its whiteness in comparison with ball clay and bentonite. Kaolin has a much larger particle size than either and its use improves drying performance by reducing drying shrinkage, enhances water penetration, and reduces fired shrinkage. Kaolins vary widely in their plasticity and they do not introduce soluble salts and coal the way ball clays do.

The key to wrapping your mind around the dizzying host of raw materials available is to learn them generically so that you can better evaluate the strengths and weaknesses specific name brands. Try to build first hand experience with a benchmark material of each type then relate the properties of new materials to those of the benchmark. In this way, you will develop flexibility and be able to become increasingly independent and capable.

In the materials area of this site we have adopted this concept of generic materials. Look up a material like kaolin, dolomite, feldspar, etc. to see an example. In time we will assign each generic description to an expert (or group of experts) in the field for maintenance. All name-brand materials will then be described in terms of the generics.

Related Information

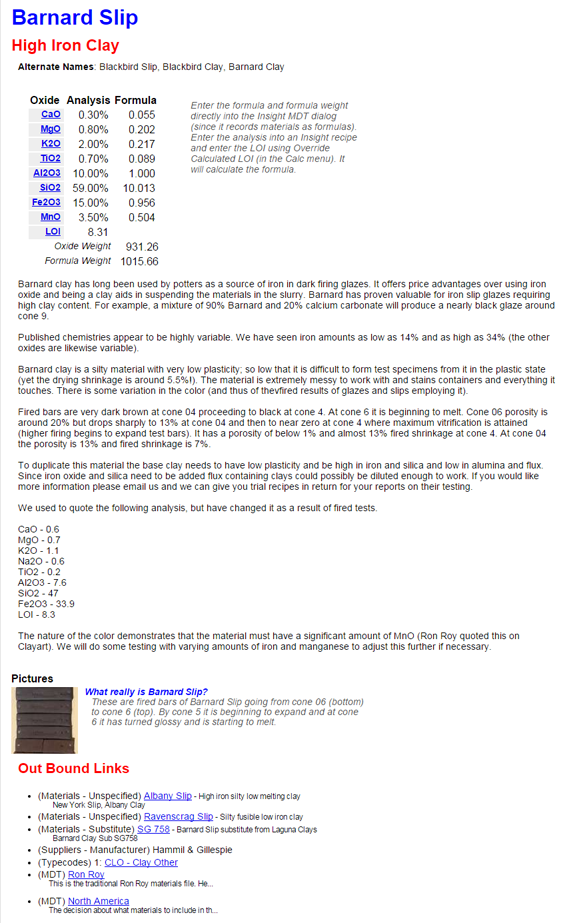

An example of a material report at the Digitalfire Reference Library

This picture has its own page with more detail, click here to see it.

Many of the materials listed are not described well or at all by their manufacturers. This is an example of where we had to do our home work, researching and rationalizing it to determine what information is likely more and less reliable. In many cases we simply do testing in our own lab.

Links

| Projects |

Minerals

|

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy