| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

A Low Cost Tester of Glaze Melt Fluidity

A One-speed Lab or Studio Slurry Mixer

A Textbook Cone 6 Matte Glaze With Problems

Adjusting Glaze Expansion by Calculation to Solve Shivering

Alberta Slip, 20 Years of Substitution for Albany Slip

An Overview of Ceramic Stains

Are You in Control of Your Production Process?

Are Your Glazes Food Safe or are They Leachable?

Attack on Glass: Corrosion Attack Mechanisms

Ball Milling Glazes, Bodies, Engobes

Binders for Ceramic Bodies

Bringing Out the Big Guns in Craze Control: MgO (G1215U)

Can We Help You Fix a Specific Problem?

Ceramic Glazes Today

Ceramic Material Nomenclature

Ceramic Tile Clay Body Formulation

Changing Our View of Glazes

Chemistry vs. Matrix Blending to Create Glazes from Native Materials

Concentrate on One Good Glaze

Copper Red Glazes

Crazing and Bacteria: Is There a Hazard?

Crazing in Stoneware Glazes: Treating the Causes, Not the Symptoms

Creating Your Own Budget Glaze

Crystal Glazes: Understanding the Process and Materials

Deflocculants: A Detailed Overview

Demonstrating Glaze Fit Issues to Students

Diagnosing a Casting Problem at a Sanitaryware Plant

Drying Ceramics Without Cracks

Duplicating Albany Slip

Duplicating AP Green Fireclay

Electric Hobby Kilns: What You Need to Know

Fighting the Glaze Dragon

Firing Clay Test Bars

Firing: What Happens to Ceramic Ware in a Firing Kiln

First You See It Then You Don't: Raku Glaze Stability

Fixing a glaze that does not stay in suspension

Formulating a body using clays native to your area

Formulating a Clear Glaze Compatible with Chrome-Tin Stains

Formulating a Porcelain

Formulating Ash and Native-Material Glazes

G1214M Cone 5-7 20x5 glossy transparent glaze

G1214W Cone 6 transparent glaze

G1214Z Cone 6 matte glaze

G1916M Cone 06-04 transparent glaze

Getting the Glaze Color You Want: Working With Stains

Glaze and Body Pigments and Stains in the Ceramic Tile Industry

Glaze Chemistry Basics - Formula, Analysis, Mole%, Unity

Glaze chemistry using a frit of approximate analysis

Glaze Recipes: Formulate and Make Your Own Instead

Glaze Types, Formulation and Application in the Tile Industry

Having Your Glaze Tested for Toxic Metal Release

High Gloss Glazes

Hire Us for a 3D Printing Project

How a Material Chemical Analysis is Done

How desktop INSIGHT Deals With Unity, LOI and Formula Weight

How to Find and Test Your Own Native Clays

I have always done it this way!

Inkjet Decoration of Ceramic Tiles

Is Your Fired Ware Safe?

Leaching Cone 6 Glaze Case Study

Limit Formulas and Target Formulas

Low Budget Testing of Ceramic Glazes

Make Your Own Ball Mill Stand

Making Glaze Testing Cones

Monoporosa or Single Fired Wall Tiles

Organic Matter in Clays: Detailed Overview

Outdoor Weather Resistant Ceramics

Painting Glazes Rather Than Dipping or Spraying

Particle Size Distribution of Ceramic Powders

Porcelain Tile, Vitrified Tile

Rationalizing Conflicting Opinions About Plasticity

Ravenscrag Slip is Born

Recylcing Scrap Clay

Reducing the Firing Temperature of a Glaze From Cone 10 to 6

Setting up a Clay Testing Program in Your Company or Studio

Simple Physical Testing of Clays

Single Fire Glazing

Soluble Salts in Minerals: Detailed Overview

Some Keys to Dealing With Firing Cracks

Stoneware Casting Body Recipes

Substituting Cornwall Stone

Super-Refined Terra Sigillata

The Chemistry, Physics and Manufacturing of Glaze Frits

The Effect of Glaze Fit on Fired Ware Strength

The Four Levels on Which to View Ceramic Glazes

The Majolica Earthenware Process

The Potter's Prayer

The Right Chemistry for a Cone 6 Magnesia Matte

The Trials of Being the Only Technical Person in the Club

The Whining Stops Here: A Realistic Look at Clay Bodies

Those Unlabelled Bags and Buckets

Tiles and Mosaics for Potters

Toxicity of Firebricks Used in Ovens

Trafficking in Glaze Recipes

Understanding Ceramic Materials

Understanding Ceramic Oxides

Understanding Glaze Slurry Properties

Understanding the Deflocculation Process in Slip Casting

Understanding the Terra Cotta Slip Casting Recipes In North America

Understanding Thermal Expansion in Ceramic Glazes

Unwanted Crystallization in a Cone 6 Glaze

Using Dextrin, Glycerine and CMC Gum together

Volcanic Ash

What Determines a Glaze's Firing Temperature?

What is a Mole, Checking Out the Mole

What is the Glaze Dragon?

Where do I start in understanding glazes?

Why Textbook Glazes Are So Difficult

Working with children

Creating a Non-Glaze Ceramic Slip or Engobe

Description

It can be difficult to find an engobe that is drying and firing compatible with your body. It is better to understand, formulate and tune your own slip to your own body, glaze and process.

Article

Non-glaze slips (referred to as engobes when applied thickly) for pottery and tile decoration have long fostered great fascination. Almost everyone has marvelled at the simple beauty of terra cotta ware decorated with white slip and finished with a transparent glaze. Many potters are adapting this age old process to stoneware and porcelain. Industry, especially tile, routinely applies slips and engobes (e.g. white layers are put on darker burning dry tiles before applying glaze over top). They are almost universally used in the single fire process. This is logical since their key application is to cover over dark burning or dirty bodies made from local materials, in these cost conscious situations it makes little sense to fire more times than needed.

Pairing of engobe-thickness slips with a specific body is difficult so recipes travel even less well than glazes. They need to be drying, firing and thermal expansion compatible with both the underlying body and overlying glaze. Each of these should be tested individually. Compare this to a glaze being applied directly to a bisque body: you only need to focus on thermal expansion compatibility with the body; this is so much easier.

Consider the first major challenge: Adhesion with the body (both in drying and firing), getting the stuff to stick on! If the slip is applied thick enough and does not shrink at the correct rate or amount during drying and firing, cracks will develop or it will flake off. No matter what logic, theory or lab instruments might indicate or what others might advise, if cracking or flaking is occurring it is much more likely you need to react by adjusting the recipe appropriately than by adjusting the way it is prepared or applied. Different factors are involved in attaining compatibility for firing and drying and a change that improves one aspect of fitness may detrimentally affect another. While each material in the recipe is there for a drying, firing, adhesion, thermal expansion or aesthetic reason, it is also potentially detrimental to one or more other parts of the process; this means developing the right recipe is a real juggling act.

The most obvious use of a fine-grained white engobe is to cover a dark colored (and possibly coarse-grained) body so that brightly colored or lightly shaded glazes appear as they do on fine porcelain. The tile industry is by far the largest user of engobes, it is very common for them to use red burning clays (they are often locally available and fire much stronger than light burning clays at low temperatures). They cover the red bodies with a white burning opaque engobe. Obviously good adherence to the fired body is paramount, so the engobe needs frit or other melters to create a glass bond. Adherence will obviously be best on vitrified bodies where an interface can develop (if the body does not vitrify well extra frit will be needed to create a more glassy interface, but not so much that opacity is lost).

Dry Adherence, Shrinkage, Hardness; Slurry Suspension

- Non-glaze-slips have physical working properties that determine how well they paint, dip or spray; how well they adhere, how they drain after dipping, how fast they dry to reach the same water content as an underlying leather hard body (if applied at this stage), how thick they can be applied with each coat, whether double-coats can be applied, how well they stay in suspension during storage, how much they tend to gel, etc.

- It would seem logical that the body surface needs some roughness to give the slip a place to grab on to. While this is true with glaze application over bisque ware, it is not true with slip over dry body. But the slip is wet and any existing discontinuities on the dry body surface are going to be smoothed anyway by the wetness. Slip and body are both clays and they are sticky and thus have a natural affinity for each other.

- Both glazes and slips shrink during drying because they contain clay. While slips are applied thinly and bonding is not usually an issue, the drying and bonding of engobes is much more troublesome. They are much less glaze-like (and more clay-like), so it would seem that there would be more problems with cracking during drying (due to the shrinkage). However, in practice this does not need to be so. Engobes with even 10% bentonite (which you will never see in a clay body) will often work well on both leather hard and dry ware. The extra stickiness imparted seems to be a key to this phenomenon. Obviously, the same slip is not going to adhere well in all situations, you have to determine the formulation and when and how to apply it. For example, when engobes do not have enough plastic ingredients they flake off during drying.

- If it is being applied during leather hard stage, and of significant thickness, the slip must dry to the same water content as the body and then shrink together with the body, obviously that final shrinking period is going to reveal any difference between the two (if you intend to apply the glaze over the dry slip layer that will rewet it and test the bond again). Drying compatibility can be tested by simple observation, it is easy to tell the difference between slips that shell because do not shrink enough (when being applied to leather hard body) or crack because they are too plastic and shrink to much.

- While it is not practical to apply slips at engobe thickness to dry ware, they can often to applied thinly (by brushing) with little problem. In our experience even a 45% kaolin and 10% bentonite slip does not crack when painted on to dry ware. In fact, slips with no bentonite at all flake off. The stickiness of the slip seems to be important. Obviously, by observation you will see whether it cracks or flakes and adjust as needed. Kaolins shrink the least, ball clays much more. Kaolins are available in many ultimate particle sizes, the larger the size the lower the shrinkage will be (and the less hard the dry glaze will be). Organic binders can be employed to impart or augment hardening and adherence properties, but their burn off could bring trouble during firing (with slip adherence and glaze imperfections).

- A slip will not prevent the deposit of soluble salts (from the body), they will simply migrate through it and be left on its surface as water evaporates and leaves them behind. You thus need adequate barium carbonate in the body to precipitate them.

Fired Shrinkage and Adherence

The fired interface between slip and body will never be as good as one between glaze and body. This is potentially a weakness if the fired adherence of the slip is not evaluated and optimized. Since slips do not melt formulation is normally done on the recipe level (the physical properties must simply be observed, ceramic calculations are not really applicable).

- The fired slip layer may be loosely or tightly bonded to the underlying body. A slip containing glassy fluxes that melt and flow will form an interface with a vitrified body to securely hold it on (the body can also supply some glassy fluxes to form a better interface to the covering slip). If the body is not vitreous then even a glassy bonded slip of engobe thickness can disengage simply by taking some of the body surface with it. If the slip is not glassy then it can only hang on mechanically to any available surface irregularities. Thus it is very important to make sure that the slip has the same fired shrinkage as the body (even slight differences can compromise the bond).

- An engobe is too vitreous it can crack and pull away from the body in some places. How? It is normal for high-clay glazes to form some cracks as the temperature rises in the kiln, this is a by-product of the shrinkage associated with the early stage melting and densification of the ceramic powder. However as the glaze melts the cracks are healed back together. But with a engobe the liquid healing phase never arrives. There is thus a tightrope to walk between an engobe that is vitreous enough to form a bond but not so vitreous that it suffers early-stage melt shrinkage.

- There is a difference between the integrity of the bond when a tile comes out of the kiln and over the long haul of it's useful life. If the engobe and body did not shrink together there will be stress, if the kiln has not revealed it a simple chipping test might. The ability of a thickly applied slip to hang on through a firing and also resist mechanical chip testing is an even better test of firing shrinkage compatibility.

- A engobe has a characteristic firing shrinkage just as a body does. They must shrink together during cooling in the kiln in a way that does not introduce tension that can weaken the slip-body bond. Not only does the total shrinkage need to match, but the shrinkage curves need to be similar. Stress the bond to test and determine if the bond is the problem first. If not then it is a shrinkage mismatch, adjust in the right direction and test again.

- The fired shrinkage of a engobe can be increased by using more fluxes to impart greater vitrification or melting, or by using a finer particle sized clay. In many cases it is practical to make a pugged sample of the slip and make test bars for measuring the fired shrinkage, this is an excellent way to evaluate quantitatively the drying and fired effects of recipe changes.

Thermal Expansion

- To function together as a fired object body and slip must have a similar thermal expansion. It the covering slip layer on a ceramic piece is relatively thin there is usually no problem, but once it is applied thickly enough to function as an engobe then it must be considered a separate entity which has its own coefficient of thermal expansion. If the object is heated or cooled quickly during use the amount of expansion and contraction that occurs must be similar in slip and body. If sufficient incompatibility exists the engobe-body bond will be the point of failure and it can flake off at vulnerable sites (like edges and rims).

- When a glaze is applied over an egobe or slip more complexities arise. The slip is acting as a buffer layer and it must be expansion compatible with both the underlying body and the overlying glaze. How? Thermal expansion 'compatability' for a slip is different than for a glaze, a slip cannot be put under the same amount of compression because it is bonded much less intimately with the underlying body. For the same reason, overlying glazes also must not impose too much compression on the slip or they could break its bond with the body. Glazes may need to be of a lower expansion than if applied to the body directly. The difficulty of matching a slip for making functional ware that can survive constant heating and cooling may be very onerous (by comparison a floor tile experiences only moderate temperature changes during it's service). .

- You can test the likelihood of the ongoing integrity of the slip-body bond as related to thermal expansion: The IWCT test (which stresses it by suddenly cooling the surface) and the BWIW test (the sudden expansion on immersion into hot water will demonstrate whether the engobe is under too much compression).

Laydown and Application

You need a different mindset than with glazes to have success with engobes. Glazes smooth out when they melt, engobes do not. Like paint, the surface you apply is the one you get after firing. Thus drips, variations in thickness, roughness, pinholes, bubbles, etc are going to show. Normally a glaze over-layer is not going to be thick enough to cover over problems in the slip laydown, infact, slip irregularities can produce glaze defects. Application for tiles is straightforward since the surface is flat and horizontal, but for uneven shapes it is a lot more complicated. Here are some ideas.

- Consider ball milling

- Slips need to be flocculated to apply well. This generally means that they need enough water to flow well and then a flocculant addition to gel them so they hang onto the ware without moving after application.

- Slips need to be bubble free to apply in a flawless surface. Bubbles can develop as the they sit over time (they can be a product of material particle decomposition, for example). Mix under a variable speed mixer such that it sucks a whirlpool but does not suck air into the mix. If the speed is right, bubbles existing will break at the surface as they near it and you will have a silky smooth product to work with.

- Slips are more opaque than glazes and theoretically have better 'hiding power' to enable them to cover the body and mask its color and surface character (including smoothing an otherwise rough or coarse surface, obscuring an undesired color, hiding specks and surface imperfections (like those caused by iron impurities), tightening and sealing an otherwise porous and soft surface, and providing a whiter surface to brighten glaze colors). However in actual practice slips applied too thinly can have surprisingly little covering power.

- Spraying can work well but you need to have a sprayer that can function with a slip of the lowest possible water content. Gravity fed devices are good (the can is above the nozzle). If the slip is too viscous however it will lay down as droplets and give an uneven surface. Greater air pressure can help, but that will create more overspray and breathable mist and produce a pebbled surface. It can be a challenge to get a thick enough laydown that covers body imperfections. On one hand the multiple coats needed consume extra time while attempting to spray a thick-all-at-once layer can produce drips and a water-logged fragile item, not to mention a slip that might crack and pull away on drying. You may find that heating the ware (assuming you are spraying dry (unbisqued ware) will help dry the slip and enable you to apply a thicker more even and smoother layer. Like glaze, it is best to have a process where the slip dries quickly.

- Pouring the slip can work very well for some shapes (e.g. continuous waterfall type application). But it may only be practical for one coat application: your slip consistency, ware temperature, manner of application all must be right to avoid drips and overlap layers.

- Dipping is not entirely practical for engobe application to dried ware. While dipping a bisque fired object using tongs is a simple procedure that works very well, for a dry item it is not practical because items do not have the strength to be held by tongs and even if they did the water from the slip will cause the object to crumble from the stress of being handled. In the past heavy stoneware was done this way, it had the thickness strength to survive the handling. However these days no one can afford to fire heavy objects (and quality demands are higher). However ware at the stiff leather hard stage can be dipped in an engobe. This can work very well, however the engobe will rewet the entire piece (if walls are thinner) and it can take many hours to restiffen.

- Slip-thickness layers can be brushed on at various stages of the process. However this has issues. Thin-walled leather-hard ware will soften and become pliable to the point it cannot be handled (multiple coats can require lengthy stiffening times between them). Brush strokes will often be clearly visible (although sometimes desired). Porous bisquit will quickly dry the strokes, sometimes so fast that the brush actually sticks (making even coverage impossible). Bisque can be fired higher to avoid this issue but the higher density could mean slow drying. Even then, it can be difficult to get even coverage. Employing a gum is the way to make a slip paint on very well on bisque ware (see the link "Brushing Glazes" below).

The Recipe

Conceptually a recipe can be as simple as a porcelain body with enough added frit for adherence but no so much that glass development reduces the opacity. This can be a fine line. For example, only 15% Ferro Frit 3134 may flux it too much at cone 04. It is better to mix your slip as a recipe of ingredients that include those for the porcelain rather than just adding something to a powdered porcelain whose recipe you do not know, this will give you the needed flexibility to adjust.

For high temperature you should be able to flux using feldspar and other raw materials rather than frits (e.g. wollastonite, dolomite). Thus, an alteration of the standard 25 porcelain could be the 40% kaolin, 35% feldspar, 25% silica (I have combined the ball clay and kaolin to just kaolin (for extra whiteness), you may need to add a plasticizer like Veegum. If it can be more mature, try 40 feldspar at the expense of silica this time. For medium temperature a typical base porcelain recipe might be 40 kaolin/ball clay, 40 feldspar and 20 silica. Add 5% of a boron frit (like Ferro 3134). The idea is to tune it degree of maturity to get maximum melting without loss of opacity.

For more whiteness consider using a whiter kaolin or adding some zircopax (perhaps 5%, for opacity). If the slip is too plastic, use calcined kaolin for part of the clay complement if needed to cut drying shrinkage. If it is flaking off, then try adding Veegum (up to 10%). And as a last resort use gum to harden it and give better flow (however it is better to adjust or substitute clays to get the flow and drying properties needed, gummed slips dry slower).

A Few General Notes About Using Slip

- An additional test for the engobe body bond is simply to break a fired item into small pieces and examine the shards closely to see if fracture lines tend to prevail at the slip-body interface.

- While slips can act as mediums for stains and metal oxide colors, stains do not develop their color as well in slips (because of the lack of a glassy phase and because slips are opaque the only stain particles that influence color are those exposed at the surface). Like a glaze, a slip must have a chemistry that is compatible with the color system (each different stain system has its own needs and the slip may need to be tuned for specific systems). The recipe may even need to be adjusted with varying proportions of certain colors (e.g. refractory ones) to maintain the same degree of melt development.

- Understand your engobe. For example, with a problem like flaking off, we as users have to accept that engobes are not stuck on well at the best of times. And we are responsible for the recipe. There are so many things we can do in our formulation and process to make them fail and to make them resistant to failure. Even more important, it is our responsibility to understand the mechanisms of the engobing process as it relates to our recipe. If it is flaking, why? Are we monitoring its shrinkage and plasticity to be able to recognize differences, for example. It is better to ask the supplier: "Why does your clay have a 7% drying shrinkage now when it used to be 5%?", than to say "your clay is the reason my engobe does not work". We may still be the reason it does not work even if their material has changed a little. Our formulations should be tolerant of some change in the material rather than be formulated to be on the edge of "problem precipices".

Creating your own slip will take time, determination, and a methodical approach with plenty of adapting over time. Like glazes, it is far better to have one recipe you understand and control than mess around with 10 that you don't understand and don't work?

Related Information

Applying an engobe by pouring or spraying

This picture has its own page with more detail, click here to see it.

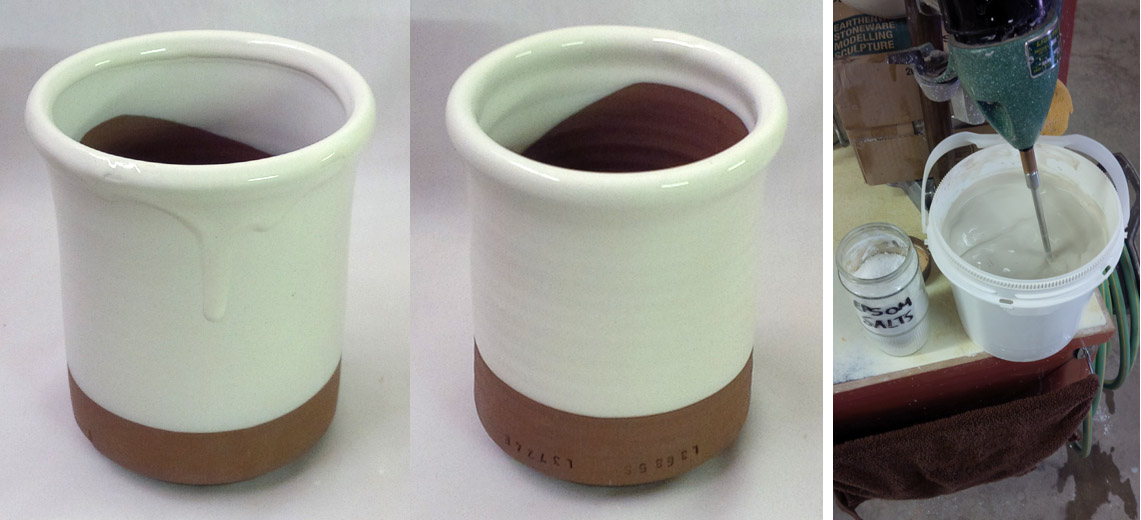

An example of an engobe (slip) applied to dry ware and then fired at cone 2. The one of the left has been poured, the right sprayed. Control of the thickness of engobes is important, thus the specific gravity and viscosity of the slurries are very important. Engobes are invaluable since a red or brown burning body can be made to fire white like porcelain (enabling much better glaze surface quality).

An extreme case of firing shrinkage mismatch between engobe and body

This picture has its own page with more detail, click here to see it.

Example of fritted white engobe over-fired to cone 2. During firing it has shrunk and the bond with the body has been completely compromised. The body has a firing shrinkage of about 6% but the slip is closer to 10%. Because glazes melt they do not have a firing shrinkage. But engobes do and it must be compatible with the body.

Here is why you don't want an engobe to melt

This picture has its own page with more detail, click here to see it.

Too much frit in an engobe and it will lose opacity and whiteness. The white slip on the left is an adjustment to the popular "Fish Sauce" slip recipe (L3685A: 8% Frit 3110 replaces 8% Pyrax to make it harder and fire-bond to the body better). The one on the right, L3685C, has 15% frit. Although applied at the same thickness, it is becoming translucent, moving it into glaze territory. That means it will have a far higher firing shrinkage than the body (a common cause of shivering at lips and contour changes). This slip is basically a very plastic white body. Since white burning slips are made from refractory materials they are not nearly as vitreous as red ones, at low fire they need help to mature and a frit is the natural answer. With the right amount of frit the fired shrinkage of body and slip can be matched and the slip will be opaque. This underscores the need to tune the maturity of an engobe to the body and temperature. Although zircon could be added to the one on the right to opacify and whiten it, that would not fix the mismatch in fired shrinkage between it and the body. And it would increase the price.

Bi-Clay strips test compatibility between engobe and body

This picture has its own page with more detail, click here to see it.

Slips and engobes are fool-proof, right? Just mix the recipe you found on the internet, or that someone else recommends, and you are good to go. Wrong! Low fire slips need to be compatible with the body in two principle ways: drying and firing. Terra cotta bodies have low shrinkage at cone 06-04 (but high at cone 02). The percentage of frit in the engobe determines its firing shrinkage at each of those temperatures. Too much and the engobe is stretched on, too little and it is under compression. The lower the frit the less the glass-bonding with the body and the more chance of flaking if they do fit well (either during the firing or after the customer stresses your product). The engobe also needs to shrink with the body during drying. How can you measure compatibility? Bi-body strips. First I prepare a plastic sample of the engobe. Then I roll 4 mm thick slabs of it and the body, lay them face-to-face and roll that down to 4 mm again. I cut 2.5x12 cm bars and dry and fire them. The curling indicates misfit. This engobe needs more plastic clay (so it dry-shrinks more) and less frit (to shrink less on firing).

Solving a difficult engobe flaking problem

This picture has its own page with more detail, click here to see it.

This demonstrates the difficulty you can encounter when trying to get an engobe working with a clay body. Here the slip/glaze is flaking off the rim of pieces at cone 04 (does not happen at 06). The front bi-clay bar demonstrates the white and red clays dry well together (the slight curve happened on the drying). They also fire well together (the curvature did not change on firing). The back two thin bars seem to demonstrate thermal expansion compatibility: a thick layer of glaze is not under enough compression to curve either bar during firing. While the white clay contains 15% frit and forms a good bond with the red body, that bond is not nearly as good as the one between the glaze and the white slip. Yet it is still flaking off the rim at the slip/body interface. Why? At first it seemed that failure was happening at quartz inversion (because the body had less quartz than the white slip). However now it appears that the combination of compressions of the slip and glaze are sufficient to break the slip-body bond on concave contours. The compression of the slip and glaze likely did not demonstrate well on the bars because at this low a temperature they are not vitreous enough to be easily curled.

Adding water actually made this white engobe run less? How?

This picture has its own page with more detail, click here to see it.

The white slip (applied to a leather hard cup) on the left is dripping downward from the rim (even though it was held upside down for a couple of minutes!). Yet that slurry was very viscous with a 1.48 specific gravity. Why? Because it was not thixotropic. The fix? I watered it down to 1.46 (making it runny) and added pinches of powdered epsom salts (while mixing vigorously) until it thickened enough to stop motion in about 1-2 seconds on mixer shut-off. But that stop-motion is followed by a bounce-back. That is the thixotropy. It is easy overdo the epsom salts (gelling it too much), I add a drop or two of Darvan to rethin it if needed. When the engobe is right it gels after about 10 seconds of sitting, so I can stir it, dip and extract the mug, shake to drain it and then it gels and holds in place. Keep in mind, this is a pottery project. In industry they deflocculate engobes to reduce water content. But a deflocculated slurry can still be gelled (if it is runny).

The same engobe. Same water content. What is the difference?

This picture has its own page with more detail, click here to see it.

The engobe on the left, even though it has a fairly low water content, is running off the leather hard clay, dripping and drying slowly. The one on the right has been flocculated with epsom salts (powdered), giving it thixotropy (ability to gel when not in motion but flow when in motion). Now there are no drips, there are no thin or thick sections. It gels after a few seconds and can be uprighted and set on the shelf for drying.

Creating a Body/slip Equilibrium in Terra Cotta Ware

This picture has its own page with more detail, click here to see it.

L3685X white slip (left mug) has 5% more frit than Y (right). The frit is a melter, creating more glass bonds to adhere it to the body (it also hardens it and darkens the color a little). But the frit also increases firing shrinkage, 'stretching' the white layer on the body as the kiln cools (the slightly curled bi-clay bar demonstrates that). However the glaze, G2931G, is under some compression (to prevent crazing), it is therefore 'pushing back' on the white slip. This creates a state of equilibrium. The Y slip on the right is outside the equilibrium, it flakes off at the rim because the bond is not good enough. Adding more frit, the other side of the balance, would put the slip under excessive tension, reducing ware strength and increasing failure on exposure to thermal shock (the very curled bi-clay bar in the front, not this clay/slip demonstrates the tension a poorly fitted slip could impose).

This pottery glaze is not flaking off - the underglaze is.

This picture has its own page with more detail, click here to see it.

Pure ceramic stain powders don't melt at typical pottery temperatures so they cannot bond with clay body surfaces. They don't suspend in water and don't harden on drying. Pure stains contribute only one ceramic property: Color! Commercial underglazes sold in jars dilute stains into a recipe of materials, a 'base medium', designed to impart the missing properties. Unfortunately, consider a problem: Blue stains are fluxes and potent at low percentages. Orange stains (and others) are refractory and require much higher percentages. But for convenience underglaze manufacturers will want to use the same medium and percentage pigment to make an entire line of underglazes. That causes the problem seen here - flaking is happening at the interface between the body and orange underglaze. This underglaze recipe needs more frit (or a more potent one) so that enough melting occurs to create a better bond. For some colors it can thus be an advantage to make your own underglazes.

Michael Cardew might be turning over in his grave!

This picture has its own page with more detail, click here to see it.

This post got a lot of negative reaction on social media. To be clear, I work both sides of the fence, making my living on selling prepared glazes and clay bodies but I get my satisfaction being closer to the materials and processes. That is what enables me to give customer support. I am not an artist, ceramic art is outside the scope of this page. For part of my life in the craft of pottery I am also guilty of what I lament below. In all my years dealing with customer traffic at our store I have never once had a customer that was offended by seeing new clay and glaze recipes we are discovering in the studio and lab, that are better and cheaper than prepared ones. But online some are somehow offended by what follows. 80 manufacturers are selling convenience and encouraging disconnection - although I work for one of them I am a voice of caution about this.

This book was once a “Bible” of hobby and professional potters. They were independent and resourceful. They made their own clays and glazes, knew the materials, built their own kilns. Now we scan social media sites for ideas on layering expensive prepared goopy brushing glazes and hope they melt together into something presentable. Many have even forgotten how to wedge clay properly. We describe processes using mystical art language and exchange likes and poor advice on social media. Those who still know how to retotal a recipe and venture into mixing their own often end up in the online trafficking of an endless parade of recipes that don’t work. Now we even outsource design to AI. Even Nigeria, the very country about whom Cardew wrote, has lost its pottery tradition.

I never appreciated the book back there. Even though he came to visit us in 1973. I have always just taken whatever clay I needed out of our warehouse, but now that I very often make my own clay it really resonates. I got this copy on eBay, I value it as an inspiration to be more closely connected with the planet and the minerals it gifts us (of course I would not do everything as he does). He was no dinosaur, he understood and taught glaze chemistry and material mineralogy, his work was the basis for many prepared glazes we buy today. "Progress" is defined by some as convenience products that make modern ceramics easy. But I believe that, for many, progress is arming yourself with a little more understanding - it enables making better quality ware, in less time, for less expense and time than with prepared products.

Links

| Materials |

Ravenscrag Slip

A light-colored silty clay that melts to a clear glaze at cone 10R, with a frit addition it creates a good base for a wide range of cone 6 glazes. |

| Articles |

Ravenscrag Slip is Born

The story of how Ravenscrag Slip was discovered and developed might help you to recognize the potential in clays that you have access to. |

| Troubles |

Crawling

Ask yourself the right questions to figure out the real cause of a glaze crawling issue. Deal with the problem, not the symptoms. |

| Glossary |

Ceramic Slip

The term Slip can have various meanings in traditional ceramics. |

| Glossary |

Once fire glazing

Refers to the practice of firing ceramics in one firing (rather than two) to produce a fully glazed product. This practice requires more technical expertise. |

| Glossary |

Mocha glazes

A technique used by ceramic artists to decorate pottery. It happens when bleeding occurs at the edges of a thin colored acidic mixture painted over a still-wet slip. |

| Glossary |

Brushing Glaze

Hobbyists and increasing numbers of potters use commercial paint-on glazes. It's convenient, there are lots of visual effects. There are also issues compared to dipping glazes. You can also make your own. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy