| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

CELECG - Celestite Crystalline Glaze

FAAO - Fa's All-Opaque Crystalline Glaze

FAC5 - Crystal Number Five Glaze

FO - Octal Crystalline Glaze

G1214M - 20x5 Cone 6 Base Glossy Glaze

G1214W - Cone 6 Transparent Base

G1214Z1 - Cone 6 Silky CaO matte base glaze

G1215U - Low Expansion Glossy Clear Cone 6

G1216L - Transparent for Cone 6 Porcelains

G1216M - Cone 6 Ultraclear Glaze for Porcelains

G1916Q - Low Fire Highly-Expansion-Adjustable Transparent

G1947U - Cone 10 Glossy transparent glaze

G2000 - LA Matte Cone 6 Matte White

G2240 - Cone 10R Classic Spodumene Matte

G2571A - Cone 10 Silky Dolomite Matte glaze

G2826R - Floating Blue Cone 5-6 Original Glaze Recipe

G2826X - Randy's Red Cone 5

g2851H - Ravenscrag Cone 6 High Calcium Matte Blue

G2853B - Cone 04 Clear Ravenscrag School Glaze

G2896 - Ravenscrag Plum Red Cone 6

G2902B - Cone 6 Crystal Glaze

G2902D - Cone 6 Crystalline Development Project

G2916F - Cone 6 Stoneware/Whiteware transparent glaze

G2926B - Cone 6 Whiteware/Porcelain transparent glaze

G2926J - Low Expansion G2926B

G2928C - Ravenscrag Silky Matte for Cone 6

G2931H - Ulexite High Expansion Zero3 Clear Glaze

G2931K - Low Fire Fritted Zero3 Transparent Glaze

G2931L - Low Expansion Low-Fire Clear

G2934 - Matte Glaze Base for Cone 6

G2934Y - Cone 6 Magnesia Matte Low LOI Version

G3806C - Cone 6 Clear Fluid-Melt transparent glaze

G3838A - Low Expansion Transparent for P300 Porcelain

G3879 - Cone 04 Transparent Low-Expansion transparent glaze

GA10-A - Alberta Slip Base Cone 10R

GA10-B - Alberta Slip Tenmoku Cone 10R

GA10-D - Alberta Slip Black Cone 10R

GA10x-A - Alberta Slip Base for cone 10 oxidation

GA6-A - Alberta Slip Cone 6 transparent honey glaze

GA6-B - Alberta Slip Cone 6 transparent honey glaze

GA6-C - Alberta Slip Floating Blue Cone 6

GA6-D - Alberta Slip Glossy Brown Cone 6

GA6-F - Alberta Slip Cone 6 Oatmeal

GA6-G - Alberta Slip Lithium Brown Cone 6

GA6-G1 - Alberta Slip Lithium Brown Cone 6 Low Expansion

GA6-H - Alberta Slip Cone 6 Black

GBCG - Generic Base Crystalline Glaze

GC106 - GC106 Base Crystalline Glaze

GR10-A - Pure Ravenscrag Slip

GR10-B - Ravenscrag Cone 10R Gloss Base

GR10-C - Ravenscrag Cone 10R Silky Talc Matte

GR10-E - Alberta Slip:Ravenscrag Cone 10R Celadon

GR10-G - Ravenscrag Cone 10 Oxidation Variegated White

GR10-J - Ravenscrag Cone 10R Dolomite Matte

GR10-J1 - Ravenscrag Cone 10R Bamboo Matte

GR10-K1 - Ravenscrag Cone 10R Tenmoku

GR10-L - Ravenscrag Iron Crystal

GR6-A - Ravenscrag Cone 6 Clear Glossy Base

GR6-B - Ravenscrag Cone 6 Variegated Light Glossy Blue

GR6-C - Ravenscrag Cone 6 White Glossy

GR6-D - Ravenscrag Cone 6 Glossy Black

GR6-E - Ravenscrag Cone 6 Raspberry Glossy

GR6-H - Ravenscrag Cone 6 Oatmeal Matte

GR6-L - Ravenscrag Cone 6 Transparent Burgundy

GR6-M - Ravenscrag Cone 6 Floating Blue

GR6-N - Ravenscrag Alberta Brilliant Cone 6 Celadon

GRNTCG - GRANITE Crystalline Glaze

L2000 - 25 Porcelain

L3341B - Alberta Slip Iron Crystal Cone 10R

L3685U - Cone 03 White Engobe Recipe

L3724F - Cone 03 Terra Cotta Stoneware

L3924C - Zero3 Porcelain Experimental

L3954B - Cone 6 Engobe (for M340)

L3954N - Cone 10R Base White Engobe Recipe for stonewares

MGBase1 - High Calcium Semimatte 1 (Mastering Glazes)

MGBase2 - High Calcium Semimatte 2 (Mastering Glazes)

MGBase3 - General Purpose Glossy Base 1 (Mastering Glazes)

MGBase4 - Glossy Base 2 Cone 6 (Mastering Glazes)

MGBase5 - Glossy Clear Liner Cone 6 (Mastering Glazes)

MGBase6 - Zinc Semimatte Glossy Base Cone 6

MGBase7 - Raspberry Cone 6 (Mastering Glazes)

MGBase8 - Waxwing Brown Cone 6 (Mastering Glazes)

MGBase9 - Waterfall Brown Cone 6 (Mastering Glazes)

TNF2CG - Tin Foil II Crystalline Glaze

VESUCG - Vesuvius Crystalline Glaze

Insight-Live Shares

Insight-Live Shares (also referencing this recipe)

These add technical detail, development info, variations and improvements.

G1916Q - Low Fire Highly-Expansion-Adjustable Transparent

Modified: 2022-04-08 09:52:50

An expansion-adjustable cone 04 transparent glaze made using three common Ferro frits (low and high expansion), it produces an easy-to-use slurry.

| Material | Amount |

|---|---|

| Ferro Frit 3195 | 65.00 |

| Ferro Frit 3110 | 10.00 |

| Ferro Frit 3249 | 10.00 |

| No. 5 Ball Clay | 15.00 |

| 100.00 | |

Notes

This recipe can produce a super-transparent surface of high quality at cone 04. It has good application properties (if mixed properly, see below) and melts to a clear at cone 04-02. All of the frits are commonly available. Remember that cone 06 firing produces a poor glaze:body bond, we recommend firing cone 04 or 03 if possible (ware strength also increases greatly). This glaze can be made to fit pretty well any clay body (by adjustment in frit proportions). We recommend drop-and-hold firing, for example, the 04DSDH schedule.

There are three frits:

-Frit 3195 is almost a complete glaze on its own, it just needs a little kaolin. It fires slightly silky rather than completely glossy but with the addition of one of the frits below a high gloss is achieved. But it is somewhat above middle-of-the-road for thermal expansion (the 85:15 frit:clay variation, G1916J, will craze on most of our clay bodies).

-Frit 3110 is super high expansion and high gloss. Blend it with Frit 3195 it to deal with shivering.

-Frit 3249 is super low expansion and high gloss. Blend it with Frit 3195 to deal with crazing. In one variation we employ 30% of this and

For example, to fit Plainsman Buffstone at cone 04 we find that a 55:30:15 3195:3249:Ball Clay mix works well.

This frit-juggling strategy affords a wide range of adjustment for tuning the glaze fit to a body, a very important matter at low temperatures where crazing and shivering can occur with even slight thermal expansion misfit. In some situations using only Frit 3195 and ball clay might be ok. However, we recommend to 65:10:10 frit mix because the 3249 and 3110 cancel out each other's thermal expansion influence and increase the gloss of the otherwise silky 3195. The presence of 3249 also reduces boron blue issues. Stress-test the fit by subjecting a piece of thin-walled ware to boiling-water-into-ice-water (and vice versa) immersion. This will reveal a misfit that will happen with time.

There can be issues with clouding. While it is well known that high boron glazes, which this is, have issues with clouding, by experience we know that this most often fires crystal clear (likely because of its unusually high silica:alumina content). Thinner application is the best way to deal with the problem. If a dipping glaze goes on too thick using normal techniques consider bisquing higher to reduce its porosity.

This recipe employs #5 ball clay, a material known to produce good glaze slurries. No. 1 Glaze ball clay is another. We have made quite a few adjustments to this recipe (involving switching to kaolin as a suspender, adding more silica, opacifying, adjusting temperature), these include G1916Q2, G1916Q3, G3916, even G1916V for cone 2).

To achieve even coverage it is a good idea to employ a thixotropic slurry (one that gels slightly). The 15% ball clay is plenty to suspend the slurry. But if you switch to kaolin a little bentonite might be needed.

Related Information

4% rutile in a low temperature transparent glaze

This picture has its own page with more detail, click here to see it.

The glaze is G191T (a variation of G1916Q). Firing was cone 04 drop-and-hold with slow cool. Sometimes a raw colorant is advisable over a ceramic stain. At low temperatures stains are almost universal. But in this case, the orangey-yellow color that rutile produces merits further testing. On the red body (Plainsman L215) the color is barely perceptible, but on the light Buffstone body it is working well. The variations in thickness highlight contours better than what a stain would do.

How to adjust the G1916Q low fire clear glaze when it crazes

This picture has its own page with more detail, click here to see it.

This is Plainsman Buffstone, fired at cone 04. The piece emerged from the kiln without crazing. The mug was heated to 300F and plunged into ice water (the 300F-to-ice-water IWCT test). This is what happened. Water is being absorbed into the porous body through the craze lines. This is G1916J, a variation on the G1916Q recipe. J is just two materials, 85% Ferro Frit 3195 and 15% EPK. What recipe adjustment is needed? Substitute some of the Frit 3195 for low expansion Frit 3249. We have found that a 55:30:15 of 3195:3249:EPK recipe will work. Since both 3195 and 3249 melt transparent at cone 04, blending them together does not change the appearance (actually 3249 is glossier and actually improves the surface).

High thermal expansion talc body cannot be COE-calculated

This picture has its own page with more detail, click here to see it.

Talc is employed in low-fire bodies to raise their thermal expansion (to put the squeeze on glazes to prevent crazing). These dilatometer curves make it very clear just how effective that strategy is! The talc body was fired at cone 04 and the stoneware at cone 6. The former is porous and completely non-vitreous and the latter is semi-vitreous. This demonstrates something else interesting: The impracticality of calculating the thermal expansion of clay bodies based on their oxide chemistry. Talc sources MgO and low fire bodies containing it would calculate to a low thermal expansion. But the opposite happens. Why? Because these bodies are composed of mineral particles loosely sintered together. A few melt somewhat, some change their mineral form, many remain unchanged. The body's COE is the additive sum of the proportionate populations of all the particles. Good luck calculating that!

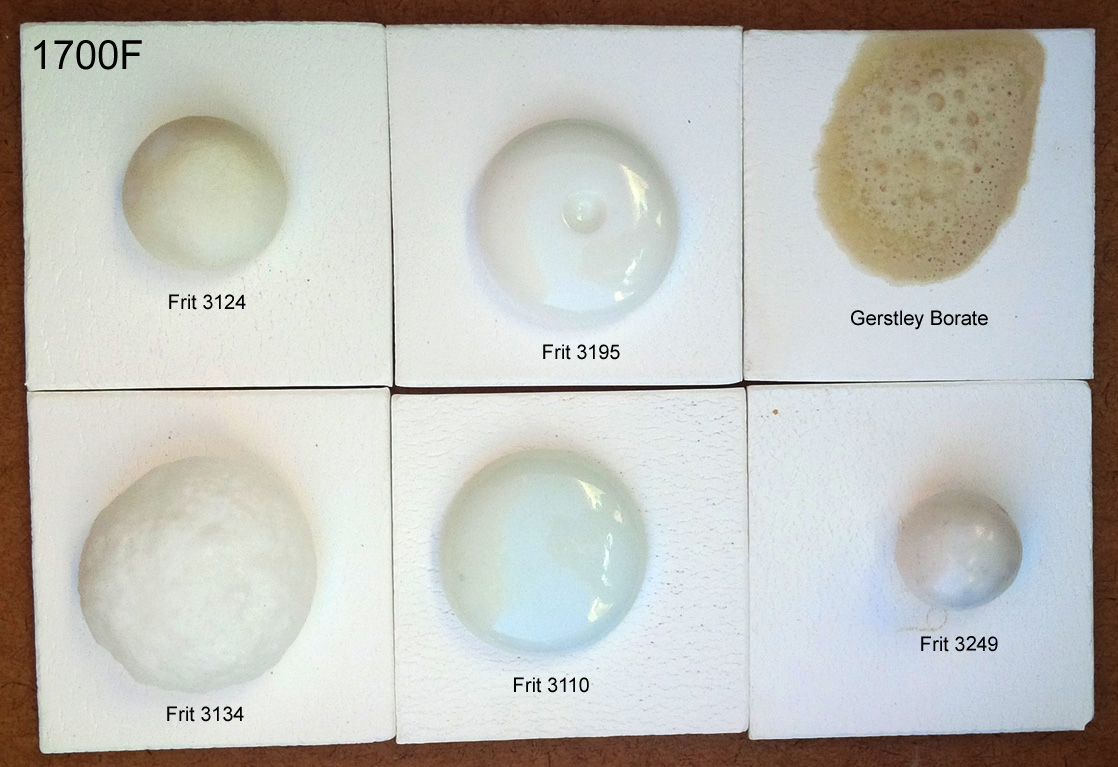

These common Ferro frits have distinct uses in traditional ceramics

This picture has its own page with more detail, click here to see it.

I used Veegum to form 10 gram GBMF test balls and fired them at cone 08 (1700F). Frits melt really well, they do have an LOI like raw materials. These contain boron (B2O3), it is a low expansion super-melter that raw materials don’t have. Frit 3124 (glossy) and 3195 (silky matte) are balanced-chemistry bases (just add 10-15% kaolin for a cone 04 glaze, or more silica+kaolin to go higher). Consider Frit 3110 a man-made low-Al2O3 super feldspar. Its high-sodium makes it high thermal expansion. It works really well in bodies and is great to make glazes that craze. The high-MgO Frit 3249 (made for the abrasives industry) has a very-low expansion, it is great for fixing crazing glazes. Frit 3134 is similar to 3124 but without Al2O3. Use it where the glaze does not need more Al2O3 (e.g. already has enough clay). It is no accident that these are used by potters in North America, they complement each other well (equivalents are made around the world by others). The Gerstley Borate is a natural source of boron (with issues frits do not have).

Micro bubbles in low fire glaze. Why?

This picture has its own page with more detail, click here to see it.

Left: G1916Q transparent fired at cone 03 over a black engobe (L3685T plus stain) and a kaolin-based low fire stoneware (L3685T). The micro-bubbles are proliferating when the glaze is too thick. Right: A commercial low fire transparent (two coats lower and 3 coats upper). A crystal clear glaze result is needed and it appears that the body is generating gases that cause this problem. Likely the kaolin is the guilty material, the recipe contains almost 50%. Kaolin has a 12% LOI. To cut this LOI it will be necessary to replace some or all of the kaolin with a low carbon ball clay. This will mean a loss in whiteness. Another solution would be diluting the kaolin with feldspar and adding more bentonite to make up for lost plasticity.

What does it take to get a crystal-clear low fire transparent? A lot!

This picture has its own page with more detail, click here to see it.

These three cups are glazed with G1916S at cone 03. The glaze is the most crystal clear achieved so far because it contains almost no gas producing materials (not even raw kaolin). It contains Ferro frits 3195 and 3110 plus 11 calcined kaolin and 3 VeeGum. Left is a low fire stoneware (L3685T), center is Plainsman L212 and right a vitreous terra cotta (L3724F). It is almost crystal clear, it has few bubbles compared to the kaolin-suspended version. These all survived a 300F/icewater IWCT test without crazing!

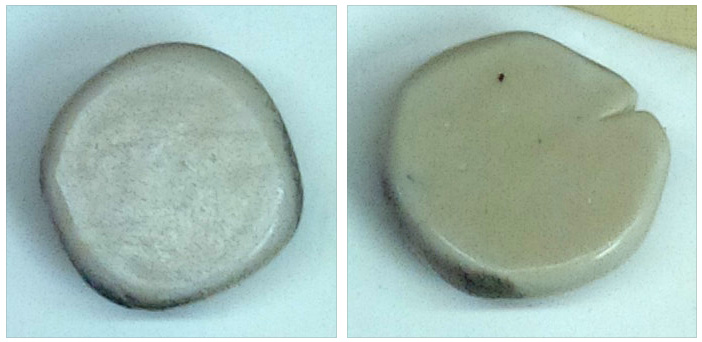

How much does a glaze need to melt before it sticks to the body well?

This picture has its own page with more detail, click here to see it.

The back flat side of balls of 1916J and Q low fire glaze that melted into a dome shape after being fired to 1550F. They have been turned over to see the back side (the front side is still stained by volatilizing carbon). Clearly they have reached zero porosity and are beginning to melt, yet they have not adhered to the vitreous porcelain tile! This demonstrates the degree to which an engobe must melt to secure itself well to the underlying body.

Turning delayed crazing into immediate crazing

This picture has its own page with more detail, click here to see it.

This is a cone 04 clay (Plainsman Buffstone) with a transparent glaze (G1916Q which is 65% Frit 3195, 20% Frit 3110, 15% EPK). On coming out of the kiln, the glaze looked fine, crystal clear, no crazing. However, when heated to 300F and then immersed into ice water this happens. This is the IWCT test. At lower temperatures, where bodies are porous, water immediately penetrates the cracks and begins to waterlog the body below. Fixing the problem was easy: Substitute the low expansion Frit 3249 for high expansion Frit 3110.

G1916Q on L215, L212, L210, L213, Buffstone at cone 03

This picture has its own page with more detail, click here to see it.

The G1916Q recipe uses common Ferro frits and can be made to fit any low fire clay body (the thermal expansion is adjustable). And it melts well down to cone 05. And we have a strategy to reduce clouding and micro-bubbling. These five test tiles were fired using the 04DSDH schedule (drop-and-hold) firing schedule. All exited the kiln without crazing. The L215, L213, L210 and L212 samples subsequently survived a 300F/Icewater test without crazing, but the Buffstone did not - it needs a lower thermal expansion (by increasing Frit 3249 and reducing Frit 3110, e.g. 15:5 instead of 10:10). The L213 would not likely survive a cold-to-hot test without shivering - it needs a higher thermal expansion (by increasing Frit 3110 at the expense of Frit 3249).

There is a secret to the clarity of this terra cotta glaze

This picture has its own page with more detail, click here to see it.

The body is Plainsman L215 and the glaze is G1916Q. Both were thinly applied and fired using the 04DSDH schedule. The glaze has 2% iron oxide added and sieved to 80 mesh. The iron reddens the color and its particles act as a fining agent to reduce micro-bubble population. The one fired to cone 03 (left) is considerably stronger, better surviving the stress of successive impacts with a hammer. However, it has minute surface dimples, likely from decomposition beginning in the body. The mug on the right fired to cone 04, only slightly above the 05 bisque. The glaze surface is much better, almost crystal clear. A big advantage of cone 04 and cooler is that ware can be fired on stilts (enabling glazing the bottoms).

2% iron oxide in a glossy terra cotta glaze gives better color, less clouding

This picture has its own page with more detail, click here to see it.

Both pieces are the same clay body, Plansman L215. Both are fired to cone 03. Both are glazed using G1916Q borosilicate recipe. The glaze on the piece on the left has 2% added iron oxide (sieved to 80 mesh). Each particle or agglomerate of iron (which is refractory in this situation) acts to congregate the micro-bubbles so they can better exit the glaze layer. Notice also how much richer the color is as a result. The piece on the right, without the added iron oxide, is neither as red nor as transparent. Of course, I had to be careful not to apply the glaze too thickly on both.

G1916Q transparent on terra cotta body at cone 06, 05, 03

This picture has its own page with more detail, click here to see it.

The body is Plainsman L215. We used the 04DSDH firing schedule. The G1916Q glaze is inexpensive to make so we have a 2-gallon bucket. It has dipping properties much like a stoneware glaze (because of the 15% ball clay it is thixotropic) so it is easy to apply quickly and evenly. For most terra cottas, body strength increases dramatically by cone 03. However, the most transparent and glassy glaze surface happens at cone 06. Terra cotta bodies need to be bisque-fired fairly low (e.g. cone 06) to have enough porosity to work well with dipping glazes. After cone 04 they generate increasing amounts of gases (as various particle species decompose within), for this reason the glazes can have more micro-bubble clouding or tiny dimples in the surface. This glaze has 2% iron oxide added as a fining agent to remove the bubbles. That iron also reddens the color and variegates the surface somewhat. Even though the surface character at cone 03 is not as smooth, it has a natural charm, and the color is very rich. And that piece has stoneware durability and strength.

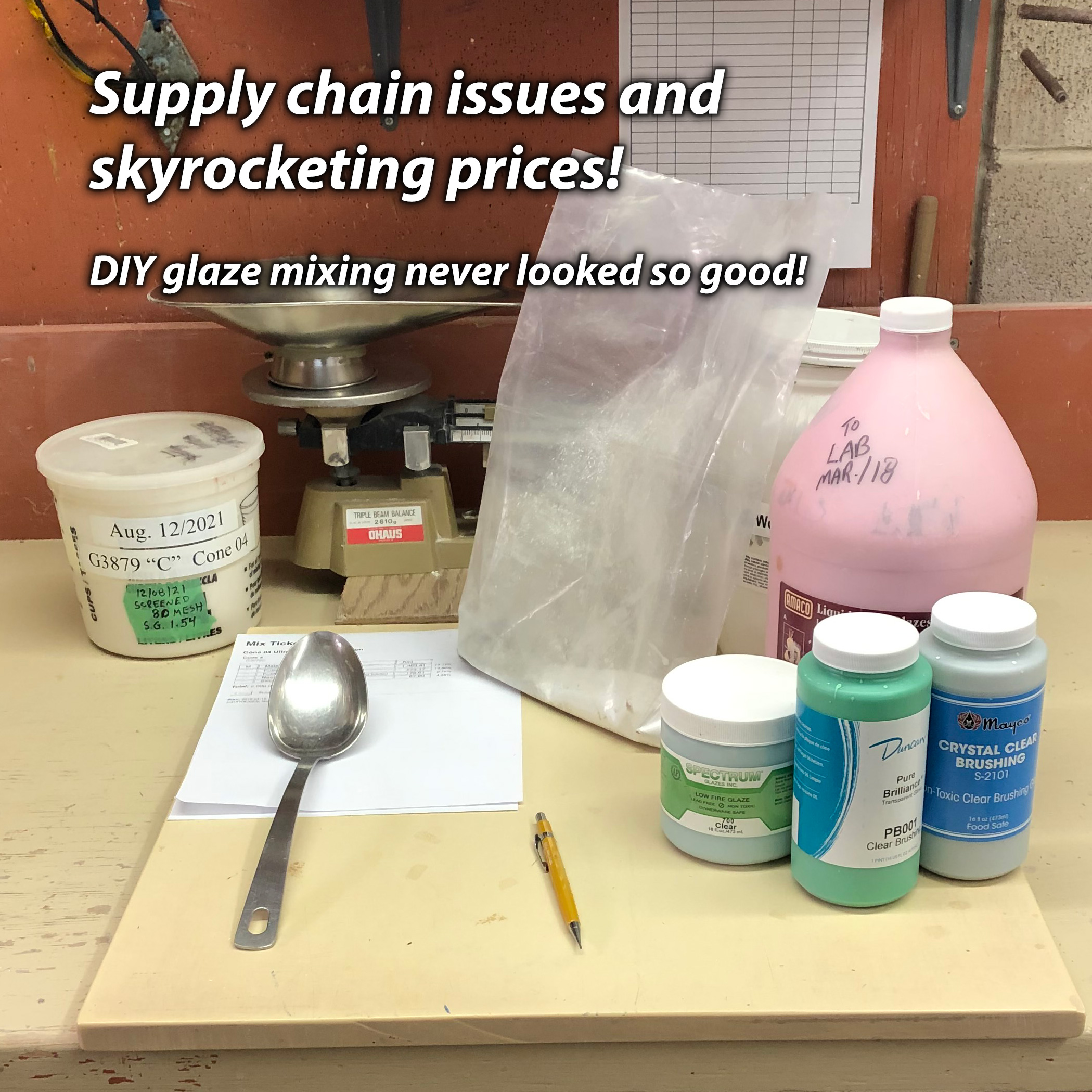

When Supply Chains Broke, Prices Soared.

We haven’t forgotten. Time for DIY!

This picture has its own page with more detail, click here to see it.

Material prices began skyrocketing during COVID. No one is affected more than prepared glaze manufacturers; they have complex supply chains that affect not only price but also availability and consistency of their products. Now might be the time for DIY, to start learning how to weigh out the ingredients to make at least some of your own, especially brushing glazes. You could be armed with good base recipes that fit your clay bodies, without crazing or shivering, by design, not by accident, as with commercial products. And you will be more resilient to supply issues. Add stains, opacifiers and variegators to the bases to make anything you want. Admittedly, ingredients in your recipes can also become unavailable! But DIY give you options. When you "understand" glaze ingredients and what each contributes to the recipe and oxide chemistry, you are equipped to go well beyond weathering material supply issues. You will improve recipes at the same time as adjusting them to accommodate alternative materials. It is not rocket science; it is just work accompanied by organized record-keeping and good labelling.

Low fire heaven: Use commercial underglazes but make your own clear over glaze

This picture has its own page with more detail, click here to see it.

Decorate ware with the underglazes at the leather hard stage, dry and bisque fire it and then dip-glaze in a transparent that you make yourself (and thus control). These mugs are fired at cone 03. All have the same transparent glaze (G2931K), all were decorated with the same underglazes. Notice how bright the colors are compared to middle or high temperature. On the left is a porous talc/stoneware blend (Plainsman L212), rear is a fritted Zero3 stoneware and right is Zero3 fritted porcelain. When mixed properly you can dip ware in this glaze and it covers evenly, does not drip and dries enough to handle in seconds! Follow the Zero3 firing schedule and you will have ware of amazing quality.

Glow in the dark glazes

This picture has its own page with more detail, click here to see it.

While these are available as commercial products you may want to mix your own to get maximum flexibility in surface character and color intensity. The key is phosphorescent pigments added to a transparent base recipe. The pigments are often made from strontium aluminate doped with rare earth elements like europium and dysprosium. This eBay search reveals they are readily available (using the search 'strontium aluminate glow powder'). While expensive, they are much less so than materials like cobalt oxide or lithium carbonate. These pigments are known for their long-lasting glow compared to older zinc sulfide-based products. It would be best to start at low temperatures, cone 04-06. Consider trying the G1916Q glaze base recipe first (then G3879, if you can get the frit). The Q recipe is temperature, thermal expansion and gloss adjustable (using different frits and frit mixtures). A common starting point is 10-20% pigment by weight.

Links

| Recipes |

L3685U - Cone 03 White Engobe Recipe

A white burning body with enough added frit to produce a cone 03 stoneware or white slip for use on the matching red Zero3 stoneware. |

| Recipes |

L3724F - Cone 03 Terra Cotta Stoneware

An experimental Zero3 using Plainsman 3D clay |

| Recipes |

G2931K - Low Fire Fritted Zero3 Transparent Glaze

A cone 03-02 clear medium-expansio glaze developed from Worthington Clear. |

| Glossary |

Flocculation

The flocculation process enables technicians in ceramics to create an engobe or glaze slurry that gels and goes on to ware in a thick yet even, non-dripping layer. |

| Glossary |

Thixotropy

Thixotropy is a property of ceramic slurries of high water content. Thixotropic suspensions flow when moving but gel after sitting (for a few moments more depending on application). This phenomenon is helpful in getting even, drip-free glaze coverage. |

| Glossary |

Glaze shivering

Shivering is a ceramic glaze defect that results in tiny flakes of glaze peeling off edges of ceramic ware. It happens because the thermal expansion of the body is too much higher than the glaze. |

| Glossary |

Glaze fit

In ceramics, glaze fit refers to the thermal expansion compatibility between glaze and clay body. When the fit is not good the glaze forms a crack pattern or flakes off on contours. |

| Glossary |

Transparent Glazes

Every glossy ceramic glaze is actually a base transparent with added opacifiers and colorants. So understand how to make a good transparent, then build other glazes on it. |

| Glossary |

Low Temperature Glaze

In ceramics, glazes are loosely classified as low, medium and high temperature. Low temperature is in the cone 06-2 range (about 1800F-2000F). |

| Glossary |

Base Glaze

Understand your a glaze and learn how to adjust and improve it. Build others from that. We have bases for low, medium and high fire. |

| Articles |

G1916M Cone 06-04 transparent glaze

This is a frit based boron glaze that is easily adjustable in thermal expansion, a good base for color and a starting point to go on to more specialized glazes. |

| Materials |

Ferro Frit 3195

A commonly used boron frit, it is a balanced glaze all along at cone 06-02 (with the addition of 10-15% kaolin). Not fully glossy. |

XML to Paste Into Insight-live

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Low Fire Highly-Expansion-Adjustable Transparent" keywords="An expansion-adjustable cone 04 transparent glaze made using three common Ferro frits (low and high expansion), it produces an easy-to-use slurry." id="122" date="2022-04-08" codenum="G1916Q"> <recipelines> <recipeline material="Ferro Frit 3195" amount="65.000"/> <recipeline material="Ferro Frit 3110" amount="10.000"/> <recipeline material="Ferro Frit 3249" amount="10.000"/> <recipeline material="No. 5 Ball Clay" amount="15.000"/> <url url="https://digitalfire.com/recipe/122" descrip="https://digitalfire.com/recipe/122"/> </recipelines> <urls/> </recipe> </recipes>

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy