| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Insight-Live Shares (also referencing this recipe)

These add technical detail, development info, variations and improvements.

GR10-A - Pure Ravenscrag Slip

Modified: 2023-09-19 22:34:46

Ravenscrag all by itself makes a great cone 10 reduction semi-gloss glaze. It also has great working properties.

| Material | Amount |

|---|---|

| Ravenscrag Slip 1000F Roast | 50.00 |

| Ravenscrag Slip | 50.00 |

| 100.00 | |

Notes

Ravenscrag Slip is a revolutionary glaze material for stoneware. At cone 10R it can be used pure and produces a functional semi-gloss surface. The possibilities are endless on what you can do by adding things to this base material. You can make additions to gloss it or matte it more, color and variegate it and/or opacify it. Most will contain 90% Ravenscrag (you can make bamboo, tenmoku, celadon, iron crystal, white, matte, glossy, and much more).

Ravenscrag Slip is a clay, so it shrinks. We recommend starting a 50:50 raw:roast mix in recipes that call for a high percentage of the material (use the roast instructions at http://ravenscrag.com). Adjust the proportion to get the fastest drying possible while still drying hard and having good slurry suspension. Ravenscrag glazes resist settling in the bucket and go on even (when mixed correctly).

Glazes having a high percentage of Ravenscrag Slip are most often prepared using the traditional method of simply adding water until the preferred viscosity is achieved (the material has inherent properties that produce functional slurries for dipping). Control of drying shrinkage and slurry character is achieved by varying the proportion roast and raw powder in the recipe. For us, a weight ratio of 88 water to 100 powder (2200 tap water for 2.5kg of powder) produces a creamy slurry that gives the right thickness on 1-2 second dip on 1850F bisque-ware (with minimal dripping), it has 1.45-1.47-specific-gravity. Using your water you will likely find some variation in this. This recipe actually does not respond to flocculant additions that gel traditional mineral-blend glazes to a thixotropic state.

3000 grams of powder mix makes about 1 Canadian gallon.

Related Information

Sterile white vs. pure Ravenscrag Slip as a liner glaze at cone 10R

This picture has its own page with more detail, click here to see it.

This picture does not fully convey how much better the Ravenscrag is as a liner glaze (vs. G1947U). It has depth and looks much richer. It course, it could be opacified somewhat to be whiter and would still retain the surface quality (as long is it is not too opaque). The body is Plainsman H450. The outside glaze is pure Alberta Slip.

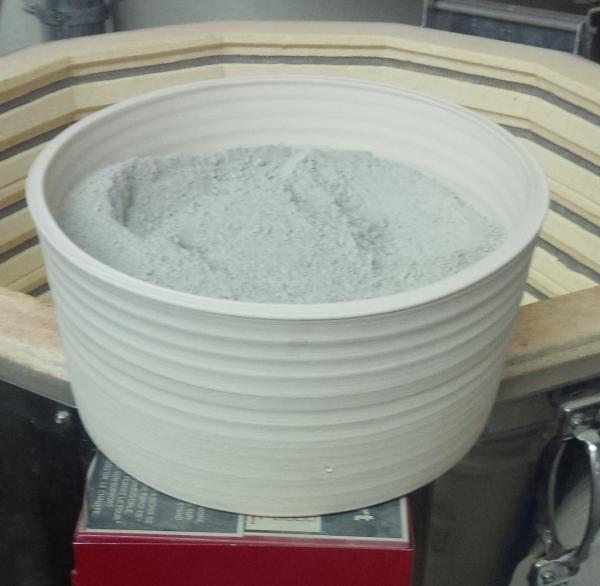

Roast or calcine your Ravenscrag Slip (or other clays) for much better results

This picture has its own page with more detail, click here to see it.

Calcined or roasted clays are indispensable in making many types of glazes, they reduce drying shrinkage (and thus cracking and crawling) compared to those made using raw clay. In a glaze, you can fine-tune a mix of raw and roast clay to achieve a compromise between dry hardness and low shrinkage.

This is Ravenscrag Slip, we roast it to 1000F (roasting is adequate to destroy plasticity and produces a smoother powder than calcining at higher temperatures). To make sure the heat penetrates for this size vessel I hold it for 2 hours at 1000F. Calcined koalin is getting harder to find, this same process can be used to make your own from a raw kaolin powder. One thing is worth noting: Weight lost on firing actually means that less of the roasted powder is needed to yield the same amount of material to the glaze melt, it can be anywhere from 5-12% less.

G1947U transparent glaze (left) vs. Ravenscrag Slip at cone 10R

This picture has its own page with more detail, click here to see it.

Ravenscrag Slip is not ultra glossy but has a silky surface. It also contains some iron oxide and this colors the glaze somewhat. But the surface is much less sterile and pleasant to touch.

100% Ravenscrag slip on Plainsman H550 stoneware fired to cone 10R

This picture has its own page with more detail, click here to see it.

The surface is between silky and glossy.

CaO is a strong flux but it can cause crazing

This picture has its own page with more detail, click here to see it.

2, 5, 10, 15% calcium carbonate added to Ravenscrag Slip on a buff stoneware fired at cone 10R. It gets progressively glossier toward 15%, crazing starts at 10% (test by Kat Valenzuela). Adding a flux only reduces the SiO2 and Al2O3, this pushes the thermal expansion upwards. 5% is actually sufficient. An alternative would be to use wollastonite, it supplies SiO2 also.

How to matte Ravenscrag Slip at cone 10 by adding talc

This picture has its own page with more detail, click here to see it.

2,5,10,15% talc added to Ravenscrag Slip on a buff stoneware fired at cone 10R. Matting begins at 10%. By Kat Valenzuela.

2, 5, 10, 15% dolomite added to Ravenscrag Slip at cone 10R

This picture has its own page with more detail, click here to see it.

This is a buff stoneware clay. Crystal development toward a dolomite matte begins at 15%. By Kat Valenzuela.

2, 5, 10 and 15% alumina hydrate added to Ravenscrag Slip

This picture has its own page with more detail, click here to see it.

Pure Ravenscrag Slip is glaze-like by itself (thus tolerating the alumina addition while still melting as a glaze). It was applied on a buff stoneware which was then fired at cone 10R (by Kat Valenzuela). This same test was done using equal additions of calcined alumina. The results suggest that the hydrated version is decomposing to yield some of its Al2O3, as an oxide, to the glaze melt. By 15% it is matting and producing a silky surface. However crazing also starts at 10%. The more Al2O3 added the lower the glaze expansion should be, so why is this happening? It appears that the disassociation is not complete, raw material remains to impose its high expansion.

Ravenscrag Slip pure: Oxidation vs. Reduction

This picture has its own page with more detail, click here to see it.

Pure Ravenscrag Slip on a porcelain at cone 10 oxidation (left) and cone 10 reduction (right). The reduction fired sample is a very smooth pleasant semi-matte, the other is glossier but dimpled.

Laguna B-Mix, B-Mix+Fireclay with Ravenscrag GR10-A, GR10-C glazes

This picture has its own page with more detail, click here to see it.

Left two mugs are glazed with pure Ravenscrag Slip (roast:raw combo), far right one is RavenTalc silky matte (GR10-C). The speckled mugs have 10% of a Plainsman Fire-Red (a blend of a red fireclay, M2 and a heavily speckled ball clay). Ravenscrag Slip is an ideal base for cone 10R glazes, so many glazes can be made by adding pigments, opacifiers, variegators and matting agents.

B-Mix with Ravenscrag Slip inside and Alberta Slip outside

This picture has its own page with more detail, click here to see it.

Fired cone 10R. The one on the right contains 10% of Plainsman A1:St Rose Red mix to add speckle.

2, 5, 10 and 15% calcined alumina added to Ravenscrag Slip

This picture has its own page with more detail, click here to see it.

The Ravenscag:Alumina mix was applied to a buff stoneware fired at cone 10R (by Kat Valenzuela). Matting begins at only 5% producing a very dry surface by 15%. This "psuedo matte" surface is simply a product of the refractory nature of the alumina as a material, it does not disassociate in the melt to yield its Al2O3 as an oxide (as would a feldspar, frit or clay). The same test using alumina hydrate demonstrates that it disassociates somewhat better (although not completely).

Laguna B-Mix Cone 10R mugs with Alberta and Ravenscrag glazes

This picture has its own page with more detail, click here to see it.

B-Mix is a popular high-ball clay very plastic grey cone 10R stoneware in North America. The two mugs on the left have pure Ravenscrag Slip on the inside (the middle on the outside also), it fires almost transparent with a slightly silky surface. Pure Alberta Slip is employed on the outside of the left one and the inside of the right one. The outside of the right one is RavenTalc silky matte. In all cases the Ravenscrag and Alberta Slip are mixed half-and-half calcined and raw. B-Mix fires dark enough and with enough specks that a normal transparent glaze is not very interesting. But these Ravenscrag ones look much better (for use as a liner glaze).

Links

| URLs |

https://plainsmanclays.com/data/index.php?product=12911

Ravenscrag Data Sheet at Plainsman Clays |

| URLs |

http://ravenscrag.com

Ravenscrag web site |

| Firing Schedules |

Plainsman Cone 10R Firing

Six-step oxidize-at-end schedule to 2372F |

| Typecodes |

Ravenscrag Slip Recipes

Recipes based on Ravenscrag Slip from Plainsman Clays. |

| Typecodes |

High Temperature (Cone 10) Glaze Recipes

Normally reduction gas fired. |

| Recipes |

GR10-C - Ravenscrag Cone 10R Silky Talc Matte

Just Ravenscrag Slip plus 10% talc produces a visually variegated surface that feels silky and looks stunning! |

XML to Paste Into Insight-live

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Pure Ravenscrag Slip" keywords="Ravenscrag all by itself makes a great cone 10 reduction semi-gloss glaze. It also has great working properties." id="58" date="2023-09-19" codenum="GR10-A"> <recipelines> <recipeline material="Ravenscrag Slip 1000F Roast" amount="50.000"/> <recipeline material="Ravenscrag Slip" amount="50.000"/> <url url="https://digitalfire.com/recipe/58" descrip="https://digitalfire.com/recipe/58"/> </recipelines> <urls/> </recipe> </recipes>

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy