| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

CELECG - Celestite Crystalline Glaze

FAAO - Fa's All-Opaque Crystalline Glaze

FAC5 - Crystal Number Five Glaze

FO - Octal Crystalline Glaze

G1214M - 20x5 Cone 6 Base Glossy Glaze

G1214W - Cone 6 Transparent Base

G1214Z1 - Cone 6 Silky CaO matte base glaze

G1215U - Low Expansion Glossy Clear Cone 6

G1216L - Transparent for Cone 6 Porcelains

G1216M - Cone 6 Ultraclear Glaze for Porcelains

G1916Q - Low Fire Highly-Expansion-Adjustable Transparent

G1947U - Cone 10 Glossy transparent glaze

G2000 - LA Matte Cone 6 Matte White

G2240 - Cone 10R Classic Spodumene Matte

- Cone 10 Silky Dolomite Matte glaze

G2826R - Floating Blue Cone 5-6 Original Glaze Recipe

G2826X - Randy's Red Cone 5

g2851H - Ravenscrag Cone 6 High Calcium Matte Blue

G2853B - Cone 04 Clear Ravenscrag School Glaze

G2896 - Ravenscrag Plum Red Cone 6

G2902B - Cone 6 Crystal Glaze

G2902D - Cone 6 Crystalline Development Project

G2916F - Cone 6 Stoneware/Whiteware transparent glaze

G2926B - Cone 6 Whiteware/Porcelain transparent glaze

G2926J - Low Expansion G2926B

G2928C - Ravenscrag Silky Matte for Cone 6

G2931H - Ulexite High Expansion Zero3 Clear Glaze

G2931K - Low Fire Fritted Zero3 Transparent Glaze

G2931L - Low Expansion Low-Fire Clear

G2934 - Matte Glaze Base for Cone 6

G2934Y - Cone 6 Magnesia Matte Low LOI Version

G3806C - Cone 6 Clear Fluid-Melt transparent glaze

G3838A - Low Expansion Transparent for P300 Porcelain

G3879 - Cone 04 Transparent Low-Expansion transparent glaze

GA10-A - Alberta Slip Base Cone 10R

GA10-B - Alberta Slip Tenmoku Cone 10R

GA10-D - Alberta Slip Black Cone 10R

GA10x-A - Alberta Slip Base for cone 10 oxidation

GA6-A - Alberta Slip Cone 6 transparent honey glaze

GA6-B - Alberta Slip Cone 6 transparent honey glaze

GA6-C - Alberta Slip Floating Blue Cone 6

GA6-D - Alberta Slip Glossy Brown Cone 6

GA6-F - Alberta Slip Cone 6 Oatmeal

GA6-G - Alberta Slip Lithium Brown Cone 6

GA6-G1 - Alberta Slip Lithium Brown Cone 6 Low Expansion

GA6-H - Alberta Slip Cone 6 Black

GBCG - Generic Base Crystalline Glaze

GC106 - GC106 Base Crystalline Glaze

GR10-A - Pure Ravenscrag Slip

GR10-B - Ravenscrag Cone 10R Gloss Base

GR10-C - Ravenscrag Cone 10R Silky Talc Matte

GR10-E - Alberta Slip:Ravenscrag Cone 10R Celadon

GR10-G - Ravenscrag Cone 10 Oxidation Variegated White

GR10-J - Ravenscrag Cone 10R Dolomite Matte

GR10-J1 - Ravenscrag Cone 10R Bamboo Matte

GR10-K1 - Ravenscrag Cone 10R Tenmoku

GR10-L - Ravenscrag Iron Crystal

GR6-A - Ravenscrag Cone 6 Clear Glossy Base

GR6-B - Ravenscrag Cone 6 Variegated Light Glossy Blue

GR6-C - Ravenscrag Cone 6 White Glossy

GR6-D - Ravenscrag Cone 6 Glossy Black

GR6-E - Ravenscrag Cone 6 Raspberry Glossy

GR6-H - Ravenscrag Cone 6 Oatmeal Matte

GR6-L - Ravenscrag Cone 6 Transparent Burgundy

GR6-M - Ravenscrag Cone 6 Floating Blue

GR6-N - Ravenscrag Alberta Brilliant Cone 6 Celadon

GRNTCG - GRANITE Crystalline Glaze

L2000 - 25 Porcelain

L3341B - Alberta Slip Iron Crystal Cone 10R

L3685U - Cone 03 White Engobe Recipe

L3724F - Cone 03 Terra Cotta Stoneware

L3924C - Zero3 Porcelain Experimental

L3954B - Cone 6 Engobe (for M340)

L3954N - Cone 10R Base White Engobe Recipe for stonewares

MGBase1 - High Calcium Semimatte 1 (Mastering Glazes)

MGBase2 - High Calcium Semimatte 2 (Mastering Glazes)

MGBase3 - General Purpose Glossy Base 1 (Mastering Glazes)

MGBase4 - Glossy Base 2 Cone 6 (Mastering Glazes)

MGBase5 - Glossy Clear Liner Cone 6 (Mastering Glazes)

MGBase6 - Zinc Semimatte Glossy Base Cone 6

MGBase7 - Raspberry Cone 6 (Mastering Glazes)

MGBase8 - Waxwing Brown Cone 6 (Mastering Glazes)

MGBase9 - Waterfall Brown Cone 6 (Mastering Glazes)

TNF2CG - Tin Foil II Crystalline Glaze

VESUCG - Vesuvius Crystalline Glaze

Insight-Live Shares

Insight-Live Shares (also referencing this recipe)

These add technical detail, development info, variations and improvements.

G2571A - Cone 10 Silky Dolomite Matte glaze

Modified: 2023-07-22 15:00:50

A cone 10R dolomite matte having a pleasant silky surface, it does not cutlery mark, stain or craze on common bodies

| Material | Amount |

|---|---|

| Wollastonite | 5.50 |

| Custer Feldspar | 28.50 |

| EPK | 28.00 |

| Silica | 15.00 |

| Dolomite | 19.00 |

| Gerstley Borate | 4.00 |

| 100.00 | |

Notes

A standard Plainsman Clays cone 10R dolomite matte glaze used for many years. Colorants and opacifiers can be added to create a wide range of beautiful classic earthy reduction effects. The bamboo effect, made by the addition of 3.5 rutile and 10 Zircopax, is probably the most popular.

Many dolomite (or talc) matte glazes do not have a proper chemistry balance and do not melt to a stable glass; crazing, cutlery marking and staining are common problems. This one, by contrast, has a very silky surface yet exhibits none of these problems. An alternative recipe (but very similar chemistry) using Ravenscrag Slip is also available.

If you do not have Gerstley Borate or Wollastonite it is pretty easy to alter the recipe to source CaO calcium carbonate (instead of wollastonite) and B2O3 from a frit instead of GB.

Click the link above to see more detail about this recipe at digitalfire.com.

Related Information

A tin oxide addition improves the visual character of a cone 10R bamboo

This picture has its own page with more detail, click here to see it.

This is the G2571A base dolomite matte recipe. The specimen on the left adds 4% tin and 1% iron oxide. The one on the right has 4% tin oxide and 0.5% iron oxide.

Two G2571A Bamboo versions: With iron, rutile-zircopax

This picture has its own page with more detail, click here to see it.

These mugs are Plainsman H450 fired at cone 10R. Both have a black engobe (L3954N) applied to the insides and half way down the outside during leather hard stage (the insides are glazed with Ravenscrag silky matte and G1947U over the black engobe). The bamboo glazes can thus be seen over the black (upper half) and the raw buff body (lower). The bamboo glaze on the left has 1% iron added to the base G2571A recipe. The one on the right has 3.5% powdered rutile and 10% zircopax added.

The bamboo matte on the left is better:

It does not stain and does not craze.

This picture has its own page with more detail, click here to see it.

These mugs are Plainsman H443. The cone 10R dolomite matte bamboo glaze on the left (A) has 3.5% rutile and 10% Zircopax added to our base G2571A dolomite matte. The one on the right (B) has the same addition but in a base having less CaO/MgO and much more KNaO. This gives it a craze-prone calculated thermal expansion of 7.9 (vs 6.7 for ours). B also stains badly (as can be seen from the felt marker residue that could not be removed using lacquer thinner). Why does A stain only slightly? It has an additional 4% Gerstley Borate, a powerful flux that develops the glass surface better (giving a slightly less matte surface).

Adding Zircopax to G2571A dolomite matte

This picture has its own page with more detail, click here to see it.

On the left: G2571A dolomite matte fired at cone 10R. Right: 10% Zircopax has been added. Both are on a buff stoneware (H550 from Plainsman Clays).

G2571 Cone 10R silky matte glazed mug

This picture has its own page with more detail, click here to see it.

The inside is pure Ravenscrag Slip. The clay is Plainsman H550.

G2571A at cone 10R with a cobalt and chrome addition

This picture has its own page with more detail, click here to see it.

This is G2571A cone 10R dolomite matte glaze with added 1% cobalt oxide, 0.2% chrome oxide. The porcelain is Plainsman P700, the inside glaze is a Ravenscrag Slip clear. This base is very resistant to crazing on most bodies and it does not cutlery mark or stain. It also has very good application properties.

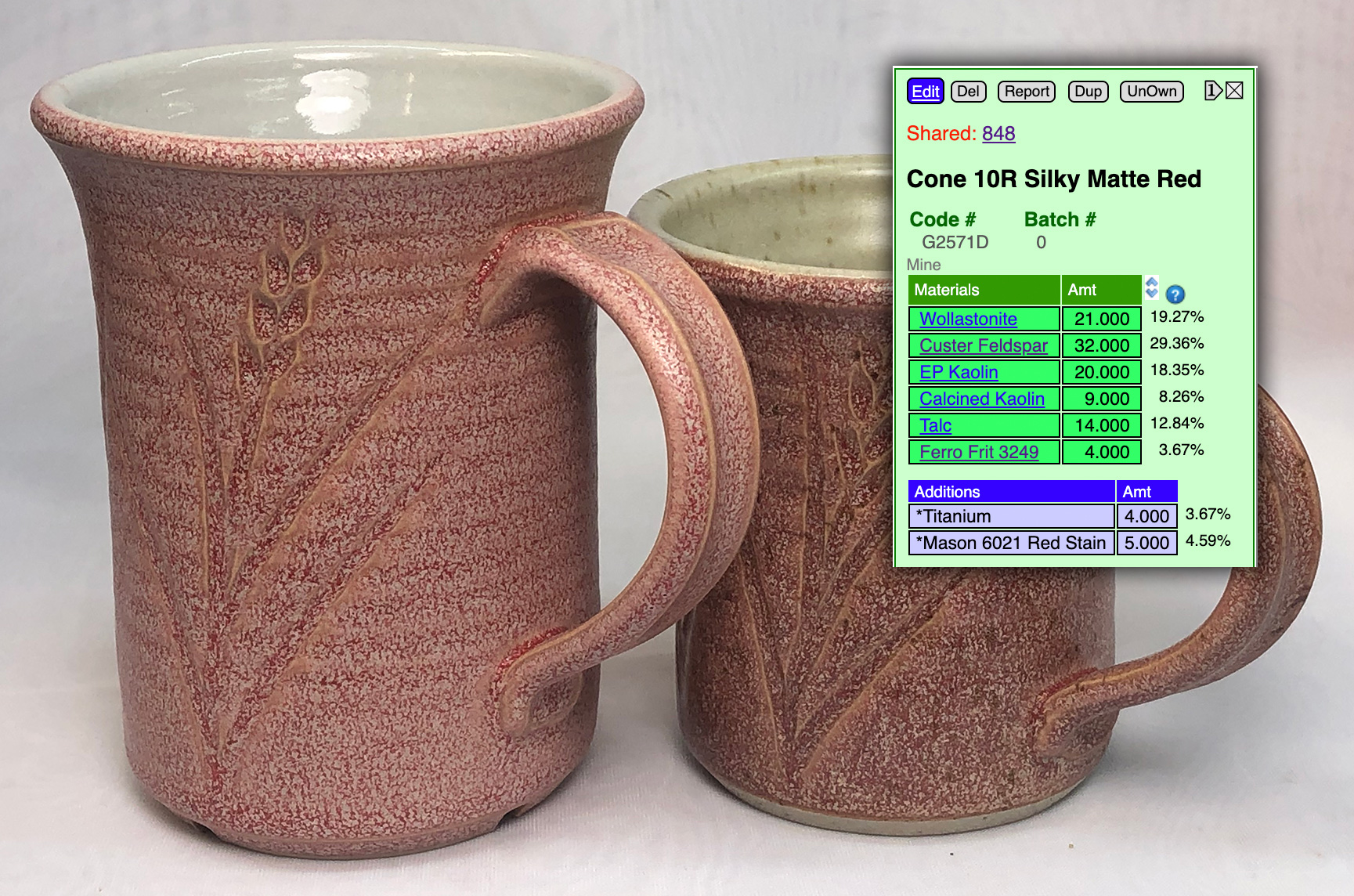

The titanium/stain mechanism at cone 10R

This picture has its own page with more detail, click here to see it.

These are porcelain and stoneware mugs. The glaze is G2571D (based on the fritted G2571B version of G2571A). This project started with calculations to source boron from a frit (instead of Gerstley Borate), MgO from talc and a frit (instead of dolomite). These moves enabled eliminating raw silica from the recipe. This produced a finer silky texture and better melt fluidity (for hosting colors). Adding rutile and zircopax produced a great bamboo. But what about variegating using titanium instead of rutile (it contains no iron so colors should be brighter)? Jackpot with this red stain! The titanium has done it's job even a little too well. Cobalt and titanium also worked.

Multiple kinds of glaze variegation

This picture has its own page with more detail, click here to see it.

The inside glaze of this cone 10 reduction fired mug is a base transparent glossy, G1947U. It has no additives to color, opacify or variegate it. That being said, the speckled body is making for a more interesting aesthetic on that inside surface. The outside glaze is a far different story. It is a base - a silky matte, G2571A. But it has additions of 3% titanium dioxide and 6% Mason 6021 red stain (this version is numbered G2571D). Of course the red coloration is from the stain. But the titanium is making the visual magic here, it is both an opacifier and a variegator. It is clearly producing phase changes and crystallization. One of the glass phases is redder and more transparent (the brighter red spots). Another phase is a much lighter opaque pink.

G2571A at 1.75 specific gravity still works, but goes on very, very thick

This picture has its own page with more detail, click here to see it.

Do not use this glaze unless the specific gravity is optimal. For bisque ware, that will be about 1.43-1.45 (and flocculated to gel slightly). If the SG is too high it will go on too thick. If it is too low, it will shrink too much during drying (and likely cause crawling).

The effect a cone 10R iron stoneware imposes on G2571A matte glaze

This picture has its own page with more detail, click here to see it.

This bamboo glaze (made by adding 4% tin and 1% iron oxide (left) and 0.5% iron oxide (right) to the G2571A base recipe) amplifies the iron speckle in the body beneath (Plainsman H443). Unfortunately this looks good and but is not very functional. The body is quite porous (5% water absorption), this is necessary for the mottled brown visual effect.

15 inch reduction fired bowl by Tony Hansen

This picture has its own page with more detail, click here to see it.

Made in 1982. Clay is Plainsman H443 fired at cone 10R. Glaze is G2571A with 0.25% chrome oxide, 1.0% cobalt oxide and 0.25% manganese granular. The decoration was done using a wax resist and throwing techniques learned from John Porter. During the early years, the big gas reduction kiln in the Plainsman studio was fired every month or two and each firing would have contained half a dozen of these, thus hundreds were made.

G2571C rutile blue cone 10R glaze on stoneware

This picture has its own page with more detail, click here to see it.

The clay is Plainsman H550 buff stoneware. The cone 10R firing schedule was C10RPL. The inside glaze is G1947U. 4% titanium and 0.5% cobalt oxide have been added to the base G2571A recipe. This G2571C thus inherits all the good properties of that parent base glaze.

Sculpture Clay in functional ware? Yes!

This is Plainsman Sculpture-clay. At cone 10R it is vitreous, a deep brown low porosity body. The particles of grog create a beautiful surface. The glaze is G2571A bamboo matte. It was fired using the C10RPL schedule. By Tony Hansen.

Duplicating the G2571A dolomite matte using a Ravenscrag Slip based recipe

This picture has its own page with more detail, click here to see it.

GR10-J Ravenscrag silky matte (right) and G2571A matte (left) on a dark burning iron speckled stoneware at cone 10R. The surfaces have identical feel (the chemistries are very close). The former fires a little darker color because of the iron contributed by the Ravenscrag Slip.

Links

| Firing Schedules |

Plainsman Cone 10R Firing

Six-step oxidize-at-end schedule to 2372F |

| Recipes |

G1947U - Cone 10 Glossy transparent glaze

Reliable widely used glaze for cone 10 porcelains and whitewares. The original recipe was developed from a glaze used for porcelain insulators. |

| Recipes |

GR10-J - Ravenscrag Cone 10R Dolomite Matte

Plainsman Cone 10R Ravenscrag Slip based glaze. It can be found among others at http://ravenscrag.com. |

| Glossary |

Phase Separation

Phase separation is a phenomenon that occurs in transparent ceramic glazes. Discontinuities in the internal glass matrix affect clarity and color. |

| Glossary |

Bamboo Glaze

A high temperature reduction glaze made by adding a small amount of iron oxide to a magnesia matte base glaze |

| Glossary |

Matte Glaze

Random material mixes that melt well overwhelmingly want to be glossy, creating a matte glaze that is also functional is not an easy task. |

| Glossary |

Base Glaze

Understand your a glaze and learn how to adjust and improve it. Build others from that. We have bases for low, medium and high fire. |

| Articles |

Concentrate on One Good Glaze

It is better to understand and have control of one good base glaze than be at the mercy of dozens of imported recipes that do not work. There is a lot more to being a good glaze than fired appearance. |

| Media |

Use Insight-live to substitute materials in a recipe

We will substitute wollastonite for whiting and a frit for Gerstley borate in the G2571A cone 10 matte while maintaining the chemistry of the original recipe. |

| URLs |

https://plainsmanclays.com/products/g2571a

G2571 Dolomite matte recipe at PlainsmanClays.com |

XML to Paste Into Insight-live

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 10 Silky Dolomite Matte glaze" keywords="A cone 10R dolomite matte having a pleasant silky surface, it does not cutlery mark, stain or craze on common bodies" id="39" date="2023-07-22" codenum="G2571A"> <recipelines> <recipeline material="Wollastonite" amount="5.500"/> <recipeline material="Custer Feldspar" amount="28.500"/> <recipeline material="EPK" amount="28.000"/> <recipeline material="Silica" amount="15.000"/> <recipeline material="Dolomite" amount="19.000"/> <recipeline material="Gerstley Borate" amount="4.000"/> <url url="https://digitalfire.com/recipe/39" descrip="https://digitalfire.com/recipe/39"/> </recipelines> <urls/> </recipe> </recipes>

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy