| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

CELECG - Celestite Crystalline Glaze

FAAO - Fa's All-Opaque Crystalline Glaze

FAC5 - Crystal Number Five Glaze

FO - Octal Crystalline Glaze

G1214M - 20x5 Cone 6 Base Glossy Glaze

G1214W - Cone 6 Transparent Base

G1214Z1 - Cone 6 Silky CaO matte base glaze

G1215U - Low Expansion Glossy Clear Cone 6

G1216L - Transparent for Cone 6 Porcelains

G1216M - Cone 6 Ultraclear Glaze for Porcelains

G1916Q - Low Fire Highly-Expansion-Adjustable Transparent

G1947U - Cone 10 Glossy transparent glaze

G2000 - LA Matte Cone 6 Matte White

G2240 - Cone 10R Classic Spodumene Matte

G2571A - Cone 10 Silky Dolomite Matte glaze

G2826R - Floating Blue Cone 5-6 Original Glaze Recipe

G2826X - Randy's Red Cone 5

g2851H - Ravenscrag Cone 6 High Calcium Matte Blue

G2853B - Cone 04 Clear Ravenscrag School Glaze

G2896 - Ravenscrag Plum Red Cone 6

G2902B - Cone 6 Crystal Glaze

G2902D - Cone 6 Crystalline Development Project

G2916F - Cone 6 Stoneware/Whiteware transparent glaze

G2926B - Cone 6 Whiteware/Porcelain transparent glaze

G2926J - Low Expansion G2926B

G2928C - Ravenscrag Silky Matte for Cone 6

G2931H - Ulexite High Expansion Zero3 Clear Glaze

G2931K - Low Fire Fritted Zero3 Transparent Glaze

G2931L - Low Expansion Low-Fire Clear

G2934 - Matte Glaze Base for Cone 6

G2934Y - Cone 6 Magnesia Matte Low LOI Version

G3806C - Cone 6 Clear Fluid-Melt transparent glaze

G3838A - Low Expansion Transparent for P300 Porcelain

G3879 - Cone 04 Transparent Low-Expansion transparent glaze

GA10-A - Alberta Slip Base Cone 10R

GA10-B - Alberta Slip Tenmoku Cone 10R

GA10-D - Alberta Slip Black Cone 10R

GA10x-A - Alberta Slip Base for cone 10 oxidation

GA6-A - Alberta Slip Cone 6 transparent honey glaze

GA6-B - Alberta Slip Cone 6 transparent honey glaze

GA6-C - Alberta Slip Floating Blue Cone 6

GA6-D - Alberta Slip Glossy Brown Cone 6

GA6-F - Alberta Slip Cone 6 Oatmeal

GA6-G - Alberta Slip Lithium Brown Cone 6

GA6-G1 - Alberta Slip Lithium Brown Cone 6 Low Expansion

GA6-H - Alberta Slip Cone 6 Black

GBCG - Generic Base Crystalline Glaze

GC106 - GC106 Base Crystalline Glaze

GR10-A - Pure Ravenscrag Slip

GR10-B - Ravenscrag Cone 10R Gloss Base

GR10-C - Ravenscrag Cone 10R Silky Talc Matte

GR10-E - Alberta Slip:Ravenscrag Cone 10R Celadon

GR10-G - Ravenscrag Cone 10 Oxidation Variegated White

GR10-J - Ravenscrag Cone 10R Dolomite Matte

GR10-J1 - Ravenscrag Cone 10R Bamboo Matte

GR10-K1 - Ravenscrag Cone 10R Tenmoku

GR10-L - Ravenscrag Iron Crystal

GR6-A - Ravenscrag Cone 6 Clear Glossy Base

GR6-B - Ravenscrag Cone 6 Variegated Light Glossy Blue

GR6-C - Ravenscrag Cone 6 White Glossy

GR6-D - Ravenscrag Cone 6 Glossy Black

GR6-E - Ravenscrag Cone 6 Raspberry Glossy

GR6-H - Ravenscrag Cone 6 Oatmeal Matte

GR6-L - Ravenscrag Cone 6 Transparent Burgundy

GR6-M - Ravenscrag Cone 6 Floating Blue

GR6-N - Ravenscrag Alberta Brilliant Cone 6 Celadon

GRNTCG - GRANITE Crystalline Glaze

L2000 - 25 Porcelain

L3341B - Alberta Slip Iron Crystal Cone 10R

L3685U - Cone 03 White Engobe Recipe

L3724F - Cone 03 Terra Cotta Stoneware

L3924C - Zero3 Porcelain Experimental

L3954B - Cone 6 Engobe (for M340)

L3954N - Cone 10R Base White Engobe Recipe for stonewares

MGBase1 - High Calcium Semimatte 1 (Mastering Glazes)

MGBase2 - High Calcium Semimatte 2 (Mastering Glazes)

MGBase3 - General Purpose Glossy Base 1 (Mastering Glazes)

MGBase4 - Glossy Base 2 Cone 6 (Mastering Glazes)

MGBase5 - Glossy Clear Liner Cone 6 (Mastering Glazes)

MGBase6 - Zinc Semimatte Glossy Base Cone 6

MGBase7 - Raspberry Cone 6 (Mastering Glazes)

MGBase8 - Waxwing Brown Cone 6 (Mastering Glazes)

MGBase9 - Waterfall Brown Cone 6 (Mastering Glazes)

TNF2CG - Tin Foil II Crystalline Glaze

VESUCG - Vesuvius Crystalline Glaze

Insight-Live Shares (also referencing this recipe)

These add technical detail, development info, variations and improvements.

G3806C - Panama Cone 6 Adjustment 2015

Modified: 2024-07-24 17:59:11

High fluid melt glaze for reactive effects and super gloss colors

| Material | Amount |

|---|---|

| Silica | 26.30 |

| Kaolin | 19.70 |

| Dolomite | 8.70 |

| Strontium Carbonate | 4.40 |

| Ferro Frit 3110 | 31.10 |

| Ferro Frit 3134 | 6.60 |

| Zinc Oxide | 3.30 |

| Added | |

| Copper Oxide | 2.00 |

| Tin Oxide | 2.50 |

| 104.60 | |

Notes

This is work I did in 2015 (in 2019 a much bigger project developed this further).

The copper and tin produce the turquoise celadon effect.

This recipe is for a brilliant fluid-melt transparent base glaze, initially for copper blues and greens, but later for stains. "Fluid-melt" means it runs down off ware if applied too thickly, this is a key for achieving many visual effects.

Initiailly I compared a number of recipes I found on line and finally selected Panama Blue. I removed the colorants and made adjustments to improve slurry properties and lower the thermal expansion (it has serious crazing issues). Fluid-melts have a down side: Crazing is an issue (because the fluid melt requires more fluxes, these have higher thermal expansions).

Then I did three adjustments, each lowering the thermal expansion more than the last. While keeping the same brilliant visual appearance. The recipe ended up being quite different (two materials were eliminated from the recipe, their oxides supplied by the others). The chemistry of this one moves much of the KNaO to low-expansion MgO. This makes it melt a little less, but visually it is the same. Higher ZnO helps melting (since MgO is not nearly as powerful a flux as KNaO). I was even able to add extra SiO2. The calculated thermal expansion has gone from 7.7 down to 7.3.

This worked well on stonewares but still crazed on Plainsman P300 and M370 (but was OK on Polar Ice). Fluid melt glazes look best on porcelains so this was obviously a problem. So I continued development in pursuit of a fluid melt having a lower thermal expansion (see subsequent articles, recipes and posts).

Related Information

Cone 6 copper glaze works because of the fluid-melting base recipe

This picture has its own page with more detail, click here to see it.

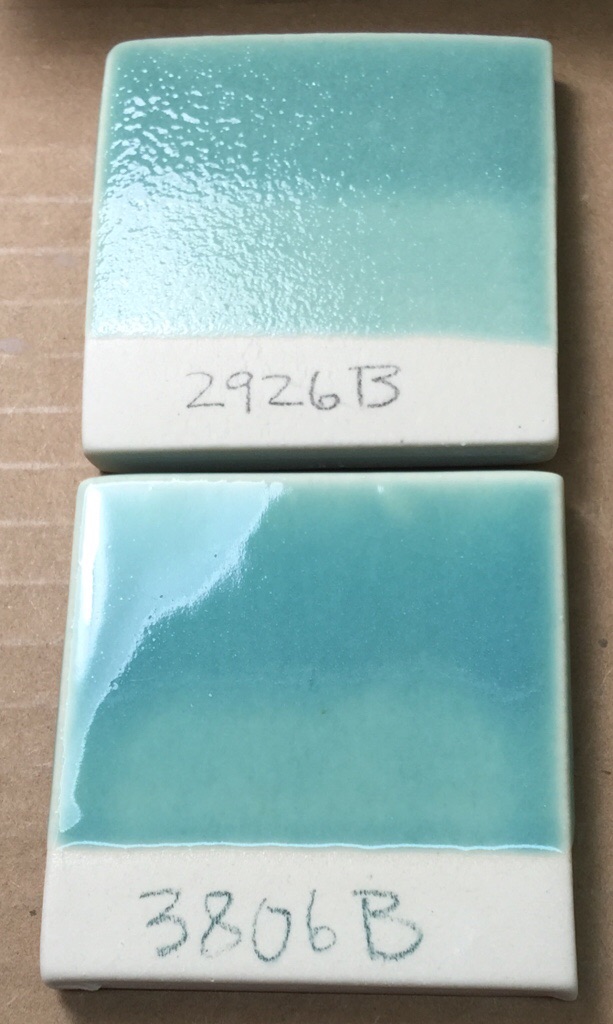

This is not just a typical transparent cone 6 glaze with 2% copper carbonate added (and 2.5% tin oxide). Knowing what is different about this clear base, its trade-offs and how it was developed are important. The porcelains are Plainsman P300 and M370. The liner glaze is G2926B, it is a gloss but has a much lower melt fluidity than the outer glaze, G3806C (as a functional transparent its main job is to fit the body and be hard and durable). But in order for that outer glaze to accommodate the copper and still be super glossy it must have a much higher melt fluidity. It was tricky to develop since that fluidity comes with high sodium and lower silica, that raises the thermal expansion and moves it toward crazing.

More copper can produce fewer bubbles!

This picture has its own page with more detail, click here to see it.

The first glaze, G2926B, is a standard functional transparent glaze with added copper. The other three are part of a project to find a copper blue (L3806B has the best color and the best compromise of flow and bubble-clearing ability).

The GLFL testers for melt flow at the back, and the GBMF test melt-down-balls contain 1% copper carbonate. The glazed samples in front have 2% copper carbonate. But why do the recipes containing half the amount of copper have far more bubbles? Because they are thinner? Not really, in use on ware, they also have fewer bubbles. Why? A small CuO addition can change where and how bubbles nucleate and how viscous the melt is. At some point between 1% and 2%, a threshold is crossed that affects nucleation and coalescence. For example, a little copper could encourage lots of tiny bubbles to form and stay trapped, while more changes the melt chemistry enough that they coalesce and escape (or simply aren’t nucleated the same way). Phase separation could produce Cu-rich droplets that enable copper to be its own fining agent.

Our G2926B glaze may not work on dark burning clays

This picture has its own page with more detail, click here to see it.

These two glazes, applied to the outsides of these mugs, both fire as brilliant glass-like super-transparents. But on this high-iron stoneware, from which both pieces are made, only one is working well. G3806C (on the outside of the piece on the left) melts more, it is fluid and much more runny. This melt fluidity gives it the capacity to pass the micro-bubbles generated as the body gases during firing. G2926B (right) works great on porcelain and buff stoneware but it cannot clear the clouds of bubbles coming out of this body (the bubbles are actually partially opacifying it). Even the normal glassy smooth surface has been affected. The moral: Potters need more than one base transparent recipe. Being able to host colors, opacifiers and variegators is nice, but sometimes just a transparent that works well is needed. An interesting trade-off of reactive melt-fluid glazes is that, while they develop more interesting surfaces, their lower SiO2 and Al2O3 contents make them susceptible to crazing, settling of the slurry and cutlery marking.

An ultra-clear brilliantly-glossy cone 6 clear base glaze? Yes!

This picture has its own page with more detail, click here to see it.

I am comparing 6 well known cone 6 fluid melt base glazes and have found some surprising things. The top row are 10 gram GBMF test balls of each melted down onto a tile to demonstrate melt fluidity and bubble populations. Second, third, fourth rows show them on porcelain, buff, brown stonewares. The first column is a typical cone 6 boron-fluxed clear. The others add strontium, lithium and zinc or super-size the boron. They have more glassy smooth surfaces, less bubbles and would should give brilliant colors and reactive visual effects. The cost? They settle, crack, dust, gel, run during firing, craze or risk leaching. Out of this work came the G3806E and G3806F.

Almost final recipe for cone 6 copper blue - G3806B

This picture has its own page with more detail, click here to see it.

This is the winner of a five-way cone 6 copper blue glaze comparison that started with my dissatisfaction with Panama blue. When I compared these glazes I did not just eyeball them on a tile. I compared the melt flow, thermal expansion and slurry performance of the bases (without the copper and tin). Ball-melt GBMF tests also showed bubble and color development for very thick sections. Then I tried more copper and did more flow tests. I also did leaching tests. Where needed I adjusted recipes to increase clay content (while maintaining chemistry) so the slurries would work better. Without my account at insight-live.com to keep all of this organized it would have been so much more difficult, actually, I probably would not even have bothered with the project. The final recipe, G3806C, was an adjustment to reduce the thermal expansion of this one.

A problem with brilliantly colored fluid-melt glazes: Micro-crystals

This picture has its own page with more detail, click here to see it.

Crystallization (also called devritrification). You can see the tiny crystals on the surface of this copper stained cone 6 glaze (G3806C). The preferred orientation of metallic oxides is crystalline. When kilns cool quickly there is simply not enough time for oxides in an average glaze to organize themselves in the preferred way and therefore crystals do not grow. But if the glaze has a fluid melt and it cools slowly through the temperature at which the crystals like to form, they will. There is another issue here also: There are tiny dimples in the surface. This is because copper carbonate was used here instead of copper oxide. During firing, it generates carbon dioxide (because it is a carbonate) that bubbles out of the melt, leaving behind dimples that may or may not heal during cooling.

Underglazes require a fluid melt transparent

But extra melt fluidity comes at a cost

This picture has its own page with more detail, click here to see it.

These porcelain mugs were decorated with the same Amaco Velvet underglazes (applied at leather hard), then bisque fired, dipped in clear glaze and fired to cone 6 (using a drop-and-hold schedule). While the G2926B clear glaze (left) is normally a great glossy transparent for general use, its melt fluidity is not enough to clear the micro-bubble clouds that dull the colors below (while these bubbles are a product of the LOI of body and glaze, underglaze colors can really generate them too). However, the G3806C recipe (right) has a more fluid melt that better enables bubble escape. But such glazes have downsides. The melt fluidity requires care not to get it too thick (or it will run). Its high flux content means it is not as durable. And, its high KNaO content raises the thermal expansion (COE) considerably (and thus the danger of crazing). This porcelain has a high enough COE to fit this, but this glaze crazes on others (that's why I always use the G2926B on the insides of ware). To get even better transparency a thinner layer could be applied (by mixing it as a brushing glaze).

In pursuit of a reactive cone 6 base that I can live with

This picture has its own page with more detail, click here to see it.

These GLFL tests and GBMF tests for melt-flow compare 6 unconventionally fluxed glazes with a traditional cone 6 moderately boron fluxed (+soda/calcia/magnesia) base (far left Plainsman G2926B). The objective is to achieve higher melt fluidity for a more brilliant surface and for more reactive response with colorant and variegator additions (with awareness of downsides of this). Classified by most active fluxes they are:

G3814 - Moderate zinc, no boron

G2938 - High-soda+lithia+strontium

G3808 - High boron+soda (Gerstley Borate based)

G3808A - 3808 chemistry sourced from frits

G3813 - Boron+zinc+lithia

G3806B - Soda+zinc+strontium+boron (mixed oxide effect)

This series of tests was done to choose a recipe, that while more fluid, will have a minimum of the problems associated with such (e.g. crazing, blistering, low run volatility, susceptibility to leaching). As a final step the recipe will be adjusted as needed. We eventually evolved the G3806B, after many iterations settled on G3806E or G3806F as best for now.

2% Copper carbonate in two different cone 6 copper-blues

This picture has its own page with more detail, click here to see it.

The top base glaze has just enough melt fluidity to produce a brilliant transparent (without colorant additions). However it does not have enough fluidity to pass the bubbles and heal over from the decomposition of this added copper carbonate! Why is lower glaze passing the bubbles? How can it melt better yet have 65% less boron? How can it not be crazing when the COE calculates to 7.7 (vs. 6.4)? First, it has 40% less Al2O3 and SiO2 (which normally stiffen the melt). Second, it has higher flux content that is more diversified (it adds two new ones: SrO, ZnO). That zinc is a key to why it is melting so well and why it starts melting later (enabling unimpeded gas escape until then). It also benefits from the mixed-oxide-effect, the diversity itself improves the melt. And the crazing? The ZnO obviously pushes the COE down disproportionately to its percentage.

Two base clear glazes with 2% copper:

One is bubbling and one is not.

This picture has its own page with more detail, click here to see it.

By itself, without copper, the G2926B recipe (right) produces a better and more durable glass (comparing the cups in the back). But a 2% copper addition, front, turns its surface to a mass of unhealed bubble-escapes. The G3808A recipe, on the left, develops much more melt fluidity, the extra mobility enables the bubbles, created by the decomposing copper, to coalesce, grow, break at the surface and heal before the melt stiffens too much.

Copper oxide needs a fluid-melt transparent to produce a glossy glaze

This picture has its own page with more detail, click here to see it.

Fired at cone 6. A melt fluidity comparison (behind) shows the G3808A clear base is much more fluid. While G2926B is a very good crystal clear transparent by itself (and with some colorants), with 2% added copper oxide it is unable to heal all the surface defects (caused by the escaping gases as the copper decomposes). The G3808A, by itself, is too fluid (to the point it will run down off the ware onto the shelf during firing). But that fluidity is needed to develop the copper blue effect (actually, this one is a little more fluid that it needs to be). Because copper blue and green glazes need fluid bases, strategies are needed to avoid them running off the ware. That normally involves thinner application, use on more horizontal surfaces or away from the lower parts of verticals.

A fluid melt glaze bleeds much more into adjoining ones

This picture has its own page with more detail, click here to see it.

The outer green glaze on these cone 6 porcelain mugs has a high melt fluidity. The liner on the upper mug is G3806C, a fluid melt high gloss clear. The liner glaze on the lower one, G2926B, is high gloss but not highly melt fluid. Thus, when both the outer and inner glazes have high melt fluidity (upper mug), they bleed together forming a fuzzy boundary. But when even one of them is not, a crisp boundary is achieved (lower mug).

G3806D cone 6 glaze with copper carbonate, copper oxide

This picture has its own page with more detail, click here to see it.

This G3806D fluid melt glaze recipe demonstates the different color characteristics imparted by copper carbonate (left) and copper oxide (at 2%). The carbonate version is bluer and less intense. Copper carbonate is about 65% CuO while the oxide version is 100%. Our supply of the oxide version is not producing any specking (if yours does you may need to sieve or blender mix the slurry).

Why do these cone 04 and 6 clear glazes have so similar a chemistry?

This picture has its own page with more detail, click here to see it.

The glaze on the left (as shown in my account at insight-live.com) is a crystal clear at cone 04. The high frit content minimizes micro-bubbles. The high B2O3 melts it very well (this has 0.66 B2O3, that is three times as high as a typical cone 6 glaze). The recipe on the right is the product of a project to develop a low-thermal-expansion fluid-melt transparent for cone 6 (with added colorants fluid melts produce brilliant and even metallic results and they variegate well). While the balance of fluxes (the red numbers in the formula) is pretty different, look how similar the B2O3, Al2O3 and SiO2 levels are (yellow, red and blue backgrounded numbers in the formula), these mainly determine the melting range. That means that a fluid-melt cone 6 glaze may actually be just a low temperature glaze being overfired to cone 6.

Links

| Recipes |

G2926B - Cone 6 Whiteware/Porcelain transparent glaze

A base transparent glaze recipe created by Tony Hansen, it fires high gloss and ultra clear with low melt mobility. |

| Recipes |

GR6-A - Ravenscrag Cone 6 Clear Glossy Base

This Plainsman Cone 6 Ravenscrag Slip base is just the pure material with 20% added frit to make it melt to a glossy natural clear. |

| Glossary |

Glossy Glaze

|

| Glossary |

Thixotropy

Thixotropy is a property of ceramic slurries of high water content. Thixotropic suspensions flow when moving but gel after sitting (for a few moments more depending on application). This phenomenon is helpful in getting even, drip-free glaze coverage. |

| Glossary |

Limit Formula

A way of establishing guideline for each oxide in the chemistry for different ceramic glaze types. Understanding the roles of each oxide and the limits of this approach are a key to effectively using these guidelines. |

| Glossary |

Surface Tension

In ceramics, surface tension is discussed in two contexts: The glaze melt and the glaze suspension. In both, the quality of the glaze surface is impacted. |

| Glossary |

Base Glaze

Understand your a glaze and learn how to adjust and improve it. Build others from that. We have bases for low, medium and high fire. |

| URLs |

https://insight-live.com/insight/share.php?z=DEdcwWAZ6K

G3806C/G2926B Cone 6 Transparent Glazes |

| URLs |

https://insight-live.com/insight/share.php?z=gbcM8HXmX2

2019 Development of G3806 melt-fluid low-expansion clear base glaze |

XML to Paste Into Insight-live

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Panama Cone 6 Adjustment 2015" keywords="High fluid melt glaze for reactive effects and super gloss colors" id="125" date="2024-07-24" codenum="G3806C"> <recipelines> <recipeline material="Silica" amount="26.300"/> <recipeline material="Kaolin" amount="19.700"/> <recipeline material="Dolomite" amount="8.700"/> <recipeline material="Strontium Carbonate" amount="4.400"/> <recipeline material="Ferro Frit 3110" amount="31.100"/> <recipeline material="Ferro Frit 3134" amount="6.600"/> <recipeline material="Zinc Oxide" amount="3.300"/> <recipeline material="Copper Oxide" amount="2.000" added="1"/> <recipeline material="Tin Oxide" amount="2.500" added="1"/> <url url="https://digitalfire.com/recipe/125" descrip="https://digitalfire.com/recipe/125"/> </recipelines> <urls/> </recipe> </recipes>

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy