| Monthly Tech-Tip | No tracking! No ads! |

CELECG - Celestite Crystalline Glaze

FAAO - Fa's All-Opaque Crystalline Glaze

FAC5 - Crystal Number Five Glaze

FO - Octal Crystalline Glaze

G1214M - 20x5 Cone 6 Base Glossy Glaze

G1214W - Cone 6 Transparent Base

G1214Z1 - Cone 6 Silky CaO matte base glaze

G1215U - Low Expansion Glossy Clear Cone 6

G1216L - Transparent for Cone 6 Porcelains

G1216M - Cone 6 Ultraclear Glaze for Porcelains

G1916Q - Low Fire Highly-Expansion-Adjustable Transparent

G1947U - Cone 10 Glossy transparent glaze

G2000 - LA Matte Cone 6 Matte White

G2240 - Cone 10R Classic Spodumene Matte

G2571A - Cone 10 Silky Dolomite Matte glaze

G2826R - Floating Blue Cone 5-6 Original Glaze Recipe

G2826X - Randy's Red Cone 5

g2851H - Ravenscrag Cone 6 High Calcium Matte Blue

G2853B - Cone 04 Clear Ravenscrag School Glaze

G2896 - Ravenscrag Plum Red Cone 6

G2902B - Cone 6 Crystal Glaze

G2902D - Cone 6 Crystalline Development Project

G2916F - Cone 6 Stoneware/Whiteware transparent glaze

G2926B - Cone 6 Whiteware/Porcelain transparent glaze

G2926J - Low Expansion G2926B

G2928C - Ravenscrag Silky Matte for Cone 6

G2931H - Ulexite High Expansion Zero3 Clear Glaze

G2931K - Low Fire Fritted Zero3 Transparent Glaze

G2931L - Low Expansion Low-Fire Clear

G2934 - Matte Glaze Base for Cone 6

G2934Y - Cone 6 Magnesia Matte Low LOI Version

G3806C - Cone 6 Clear Fluid-Melt transparent glaze

G3838A - Low Expansion Transparent for P300 Porcelain

G3879 - Cone 04 Transparent Low-Expansion transparent glaze

GA10-A - Alberta Slip Base Cone 10R

GA10-B - Alberta Slip Tenmoku Cone 10R

GA10-D - Alberta Slip Black Cone 10R

GA10x-A - Alberta Slip Base for cone 10 oxidation

GA6-A - Alberta Slip Cone 6 transparent honey glaze

GA6-B - Alberta Slip Cone 6 transparent honey glaze

GA6-C - Alberta Slip Floating Blue Cone 6

GA6-D - Alberta Slip Glossy Brown Cone 6

GA6-F - Alberta Slip Cone 6 Oatmeal

GA6-G - Alberta Slip Lithium Brown Cone 6

GA6-G1 - Alberta Slip Lithium Brown Cone 6 Low Expansion

GA6-H - Alberta Slip Cone 6 Black

GBCG - Generic Base Crystalline Glaze

GC106 - GC106 Base Crystalline Glaze

GR10-A - Pure Ravenscrag Slip

GR10-B - Ravenscrag Cone 10R Gloss Base

GR10-C - Ravenscrag Cone 10R Silky Talc Matte

GR10-E - Alberta Slip:Ravenscrag Cone 10R Celadon

GR10-G - Ravenscrag Cone 10 Oxidation Variegated White

GR10-J - Ravenscrag Cone 10R Dolomite Matte

GR10-J1 - Ravenscrag Cone 10R Bamboo Matte

GR10-K1 - Ravenscrag Cone 10R Tenmoku

GR10-L - Ravenscrag Iron Crystal

GR6-A - Ravenscrag Cone 6 Clear Glossy Base

GR6-B - Ravenscrag Cone 6 Variegated Light Glossy Blue

GR6-C - Ravenscrag Cone 6 White Glossy

GR6-D - Ravenscrag Cone 6 Glossy Black

GR6-E - Ravenscrag Cone 6 Raspberry Glossy

GR6-H - Ravenscrag Cone 6 Oatmeal Matte

GR6-L - Ravenscrag Cone 6 Transparent Burgundy

GR6-M - Ravenscrag Cone 6 Floating Blue

GR6-N - Ravenscrag Alberta Brilliant Cone 6 Celadon

GRNTCG - GRANITE Crystalline Glaze

L2000 - 25 Porcelain

L3341B - Alberta Slip Iron Crystal Cone 10R

L3685U - Cone 03 White Engobe Recipe

L3724F - Cone 03 Terra Cotta Stoneware

L3924C - Zero3 Porcelain Experimental

L3954B - Cone 6 Engobe (for M340)

L3954N - Cone 10R Base White Engobe Recipe for stonewares

MGBase1 - High Calcium Semimatte 1 (Mastering Glazes)

MGBase2 - High Calcium Semimatte 2 (Mastering Glazes)

MGBase3 - General Purpose Glossy Base 1 (Mastering Glazes)

MGBase4 - Glossy Base 2 Cone 6 (Mastering Glazes)

MGBase5 - Glossy Clear Liner Cone 6 (Mastering Glazes)

MGBase6 - Zinc Semimatte Glossy Base Cone 6

MGBase7 - Raspberry Cone 6 (Mastering Glazes)

MGBase8 - Waxwing Brown Cone 6 (Mastering Glazes)

MGBase9 - Waterfall Brown Cone 6 (Mastering Glazes)

TNF2CG - Tin Foil II Crystalline Glaze

VESUCG - Vesuvius Crystalline Glaze

Insight-Live Shares

77C04E - 50:30:20 Frit 3134 cone 6 base

77E05B - Cone 10R Celadon - Luke Lindoe

77E06B - Lindoe Dark Celadon - Lower COE

77E14A - Cone 10R Red Mustard - Luke Lindoe

77E15A - Cone 10R Yellow Mustard - Luke Lindoe

84-G-05-S - Cone 10R Matte Crystal Iron - Luke Lindoe

G 304 - Cone 10R Crystal Iron Brown - Luke Lindoe

G1002 - LEACH'S CELADON CONE 10R

G1129 - MEDALTA CLEAR GLAZE CONE 8-10

G1214M - Hansen 20x5 Clear Cone 6 Base Glaze

G1214Z - Cone 6 Calcium Matte Base Glaze

G1214Z1 - Cone 6 Calcium Matte v2

G1214Z2 - Cone 6 Calcium Matte + TiO2

G1847 - Cone 10R Robin's Egg Blue

G1916M - COE Adjustable Low Fire Clear Glaze

G1916Q - Cone 05+ Expansion Adjustable Gloss Base

G1916Q2 - G1916Q glaze + 5% silica

G1916Q3 - G1916Q glaze + 10% silica

G1916QL - Cone 05+ Low Expansion Transparent glaze

G1916QL1 - Cone 05+ Lower Expansion glaze

G1916S - Cone 06-04 MgO Matte

G1916S1 - Cone 06-04 MgO (using talc)

G1916V - Cone 2 Clear (based on G1916Q)

G1916W - G1916Q with Iron Fining Agent

G1947U - Cone 10/10R Transparent Base

G2415E - Classic Albany Lithium Brown Glossy

G2415J - G2415E Alberta Slip Brown (less Li)

G2571A - Original Cone 10R Silky Matte Base Recipe

G2571B - Cone 10R Silky Matte Base (improved)

G2571BB - G2571B Rutile Bamboo

G2571C - Cone 10R Silky Matte Blue

G2571D - Cone 10R Silky Matte Red

G2571D1 - Cone 10 Marbled Red Glaze

G2571E - Cone 10R Silky Matte Black

G2576B - Cone 10R Tenmoku Glossy

G2584 - Cone 10R Blue Celadon

G2826A - 50:30:20 Gerstley Borate Cone 6 base

G2826A1 - 50:30:20 Frit 3134 base (fixed)

G2826A2 - 50:30:20 Gillespie Borate Cone 6 base

G2826A3 - 50:30:20 GB Makeover Pottery Glaze

G2826B - GB:Frit Raku Glaze

G2826F - GB Honey Amber 04

G2826G - GB Lavendar Satin Glaze Cone 6

G2826M - Gerstley Borate Antique Green Cone 5

G2826N - Gerstley Borate Raku Base NS/GB

G2826R - Floating Blue Original Cone 6 Glaze

G2826R1 - Floating Blue Using Gillespie Borate

G2826U - Floating Blue using Frit 3134

G2826V - Gerstley Borate Cream Oatmeal Cone 6 recipe

G2850C - Ravenscrag Cone 6 Black Glossy

G2850M-C - Ravenscrag Cone 6 Light Blue Matte

G2850P - TEAL BLUE CONE 6 KAT

G2851A - RAVENSCRAG SLIP Matte Blue - Cone 6

G2851AB - RAVENS FLOATING BLUE Cone 6

G2851D - KAT'S RC MATTE - Cone 6

G2851H - RAVENSCRAG Brown Gold Matte Cone 6

G2880 - Alberta Slip Tenmoku #1

G2880A - Alberta Slip Tenmoku #2

G2881B - Ravenscrag Alberta Slip Celadon

G2890B - Randy's Red Original Cone 6 Glaze

G2894 - Ravenscrag Tenmoku #1

G2894A - Ravenscrag Tenmoku #2

G2908A - Alberta Slip Floating Blue

G2917 - Ravenscrag Floating Blue

G2926 - Perkins Clear

G2926A - Perkins Clear with Frit 3134

G2926B - Cone 6 Clear Glossy Base

G2926BL - G2926B Cone 6 Gloss Black

G2926J - G2926B Reduced COE (Li2O)

G2926S - G2926B Reduced COE (MgO)

G2931 - Worthington Cone 06-2 Clear

G2931F - Zero3 Ulexite Transparent Glaze

G2931G - Zero3 G Low Expansion Low Fire Clear

G2931H - Zero3 H High Expansion Variant

G2931K - Zero3 K Cone 03 Transparent Glaze

G2931L - Zero3 L Low Expansion Variant

G2931L2 - Zero3 L Low Expansion w/F-69

G2932 - Deb's Clear #1 Cone 04-02

G2932A - Deb's Clear #2

G2933 - Gerstley:PV Clay low fire clear

G2934 - Cone 6 Magnesia Matte Base

G2934A - High Dolomite-Testing glaze

G2934BL - G2934 85:15 Adjustable Matte Black

G2934J - G2934 with ZnO for Brown Stains

G2934J1 - G2934 (glossed using ZnO)

G2934Y - G2934 (lower-LOI)

G2934Y1 - G2934Y (Anti-Crawling)

G2934Y2 - G2934Y (Higher COE/Stony)

G2934Y3 - G2934 Super Durable

G2934Y4 - G2934 Super Durable #2

G2934Z - G2934Y Red Using F-69

G2936 - Ravenscrag Low Expansion Cone 6 Base

G2936B - Ravenscrag Low Expansion White Base 2

G2936C - Ravenscrag Original Cone 6 Base Glaze

G2938 - Wright's Water Blue Base

G2941A - Leach's Satin Clear Original

G2941C - Leach's Satin Clear - Craze fix

G3806 - Panama Blue Cone 6

G3806A - Panama Blue 2 - More clay, Copper Oxide

G3806B - Panama Blue 3 - Copper Carbonate

G3806C - Panama Cone 6 Adjustment 2015

G3806D - Panama c6 - Lower COE #1

G3806E - Panama c6 - Lower COE #2

G3806F - Panama c6 - Lower COE #3

G3806K - Panama c6 - Lower COE #7

G3806N - C6 Fluid Clear Final Recipe #10

G3808 - Cone 6 Bright Clear - Shaun Mollonga

G3808A - Cone 6 Bright Clear using Frits

G3813 - Campana Cone 6 Transparent Glaze

G3813B - Campana Clear Lower Expansion #2

G3813C - Campana Clear Low Expansion (no Spodumene)

G3814 - Low Zinc High Feldspar Fritless base

G3822 - Spectrum Clear 700 Dipping Glaze

G3834 - Tenmoku Cone 6

G3840 - Shino Trial Number 1

G3868 - Gold - Cone 6

G3868A - Gold Using Spodumene

G3868B - Gold Using Fusion Frit 493

G3868C - Gold Using Frit #2

G3875 - Tangerine 4 (Orange)

G3875B - Zinc Clear cone 6

G3875C - Tangerine + Orange Stain

G3879 - Cone 04+ UltraClear Glossy Base

G3879C - Cone 04 UltraClear Low-Expansion

G3879E - Cone 04+ UltraClear Glossy Base

G3879F1 - Cone 04+ UltraClear Glossy Base

G3888 - Kieth Davitt High-fluid-melt copper blue

G3892 - Val Cushing Satin White #71

G3903 - Alberta Slip + Frit FZ-16

G3904 - Original Recipe Using Frit 3124

G3904A - 3134 Mistake Recipe Fixed

G3909 - Ravenscrag Cone 10R Matte Blue

G3910 - Fritted version of G1947U #1

G3910A - Fritted version of G1947U #2

G3912A - Surface Tension White Tin

G3914A - Alberta Slip Gloss Black

G3918 - Red Mustard in G2571A Base #1

G3925 - Perfect Clear

G3925B - Perfect Clear Make-Over #1

G3926B - G2926B with Tin/Zircopax

G3926C - G2934 White Tin/Zircopax

G3933 - G2934:G2926B Oatmeal - Cone 6

G3933A - G2934:G2926B Oatmeal Cone 6

G3933E - G3933 Oatmeal Ravenscrag #2

G3933EF - G3933 Oatmeal Ravenscrag #4

G3933G1 - G3933 Oatmeal Alberta Slip + Li

G3939A - Cone 6 Oxidation Marbled Red

G3948 - Red Orange Glazy Original

G3948A - Plainsman Iron Red Orange

G3948A1 - Red Orange - Plainsman Spodumene

G3948A3 - Red Orange - Plainsman Spodumene #2

G3955 - N505 Base Satin White - Opaque

G3966 - Cone 10R S2 - Luke Lindoe

G3971 - Lead Bisilicate Glaze

G3973 - Hilda Ross Rust

G4546 - Pattis Crystal Clear Cone 6

G4594 - 3B as a glaze

GA6-A - Oringal Alberta Slip Amber/Honey base

GA6-F - Alberta Slip Cone 6 Oatmeal

GR10-A - Ravenscrag Cone 10R Transparent Base

GR10-C - Ravenscrag Talc Matte

GR10-CW - Ravenscrag Cone 10R Talc Matte White

GR6-H - Ravenscrag Cone 6 Oatmeal

H0009 - 1945 MEDALTA FILTER CAKE

L2553B - Imco Carbondale Clay - C-Red

L2596E - H550 Casting Body #5

L2596F - H550 Casting Body #6

L2596G - H550 Casting Body #8

L2626 - Barnard Slip

L3127E - Boraq 1

L3127G - Boraq 2

L3127I - Boraq 3

L3127N - Boraq 5 #4 (available materials)

L3146A - Foundry Hill Creme+Nepheline

L3146B - New Foundry Hill Creme

L3146C - FHC + Kyanite

L3146D - FHC + Pyrax

L3164A - Cordierite Flameware - more bentonite, added grog

L3500 - Alberta Slip Original cone 6 base glaze

L3500G - Alberta Slip + Frit 3249

L3500H - Alberta Slip + Frit 3249 and Silica

L3523 - Cone 04 Gerstley Borate matte base

L3523A - Compare Boraq 5 #1 with GB in a glaze

L3523B - L3523 glaze using Boraq 5 L3127L

L3523C - L3523 glaze using Boraq 5 L3127M

L3523D - L3523 recipe using Boraq 5 L3127N

L3617 - Cornwall Stone substitute #2

L3619 - Cornwall Stone Average Analysis

L3660C - Flameware - Very High Pyrax with Molochite

L3660G - Pyrax/Kaolin Flameware

L3660P - Pyrax Flameware (low fire)

L3664A - PV CLAY Feb 2013 Shipment

L3673 - Laguna Barnard Slip Sub

L3685U1 - Zero3 Engobe Recipe

L3685Y - Cone 03 Terrastone 2 Engobe

L3685Z2 - Z2 White Cone 04 Engobe Base (no frit)

L3685Z3 - Z3 White Cone 04 Engobe (5% frit)

L3685Z5 - White Cone 04 Engobe for L4170B (3% frit)

L3685Z6 - Brown Engobe for Snow

L3685Z7 - Cone 04 Brown Engobe for Snow

L3685Z8 - White Cone 2 Engobe for L215, L210, L4170B (2% frit)

L3693E - Alumina Lining for Crucibles

L3693E1 - Zircon Lining for Crucibles

L3693H1 - Plastic Refractory Alumina Body H1

L3724N2 - Zero3 Stoneware

L3728 - Cone 6 Dolomite Testing Glaze

L3778D - Cone 6 Translucent Grolleg Plastic

L3778D1 - Cone 6 Grolleg Pink/Blue Porcelains

L3778G - Cone 6 Translucent Grolleg Casting

L3798C - M340 Casting Body

L3798G - M340C Casting Body Revision 7

L3802E - Crystal Ice - Cone 10

L3806L - Panama c6 - Lower COE #8

L3840 - Diatomaceous Earth (Ant Killer)

L3868 - Craft Crank - From PotClays, UK

L3868A - Craft Crank - Base

L3868C - Craft Crank Clone 2

L3869 - Crank Industrial - From England

L3869A - Industrial Crank Base

L3894D - PV Calc Mix 4

L3906 - P300 Cone 6 Casting Body

L3911 - Bizen Clay

L3916 - Bizen Duplicate using Plainsman Materials

L3924C - Zero3 Porcelain - Experimental

L3924J - Zero4 Plastic Porcelain

L3924L - Zero4 Casting Porcelain

L3954B - Cone 6 White Engobe Recipe

L3954F - Cone 6 Black Engobe

L3954J - Black Cone 10 Whiteware Engobe Recipe

L3954N - Cone 10 Engobe for H550

L3954R - Super-White Engobe for Cone 6

L3954S2 - White Engobe for M340, M390, L215, L210

L3972 - 98 Mix

L3977 - BGP Low Stoneware Body

L4001 - Plainsman Super Kiln Wash

L4005D - M390 Casting Version 5

L4023F - Proposed H440 Casting Body #5

L4028 - G2571A Rutile Bamboo

L4053B - Cone 6 Black Clay Body - Type 1

L4068 - Barnard Chemical Substitute

L4115J3 - L211 Stnwre 3D:OM4:NS

L4115L2 - L211 3D:OM4:NS:Talc 42 mesh

L4115L2a - L211 3D:OM4:NS:Talc 80 mesh

L4158 - Cimtalc 15 Talc lab test

L4159 - Cimtuff 9115 Talc lab test

L4163 - Red Art Cone 1 Clay Body

L4168G5 - H440C (concentrate) #5

L4168G9 - New H440 Functional Proposal #8

L4170 - L215 Terra Cotta Casting #1

L4170B - Terra Cotta Casting #2

L4170F - Terra Cotta Casting #3

L4208C - MNS Cone 6 Fine Stoneware

L4208D - 3B +200# particles sieved out

L4217G - M370-like Cone 6 Faster Casting

L4227 - Plus Clay

L4228 - Fimo Clay

L4239 - H550 Casting Body #7

L4244 - BGP Clay:Flyash F 50:50 Mix

L4244A - Flyash F:Bentonite 10:90

L4245 - LaFarge Fly Ash F:Bentonite 95:5 Mix

L4245F - Fly Ash F:Bentonite:BallClay 80:10:10

L4246 - A2 +200# particles sieved out

L4247 - A3 +200# particles sieved out

L4248 - Old Hickory M23 Ball Clay

L4249 - 3D +200# particles sieved out

L4249A - 3D MNS 325 Mesh

L4249B - 3D 100 mesh

L4264 - Raku Crackle Glaze Base - Frit 3110

L4264A - Raku Glaze Base #1

L4264B - Raku Glaze Base #2

L4264C - Raku Glaze Base #3

L4264D - Raku Glaze Base #4

L4273 - G3806N1 + 2% Zircopax

L4280 - L215 : M390 Mix for Cone 1 Stoneware

L4287 - Midfield Clay Yukon

L4287A - Catchment Clay Yukon

L4292 - Monte Marte Air Hardening Clay

L4293 - DAS Air Drying Clay

L4294 - Sculpey PE08 Oven Bake Clay

L4398 - Ravenscrag Cone 6 Raspberry

L4404A - Refractory Casting Slip

L4404B - Plastic Refractory (heavy duty)

L4404C - Refractory Plastic (low expansion)

L4404D - Refractory Casting (low expansion)

L4410L - L213 NS:Dolo 30:20

L4410P - L213 40:10 Dolo/NS

L4421 - Seed pelleting clay and binder

L4441A - Minspar

L4441B - Minspar Calculated Substitute

L4453C - 3D:A2 Body Base H550 Blend

L4458 - Lithium Flameware Test

L4482B - Alumina Wadding #2

L4484D - 2018 3B+6% 6666 at 100#

L4498 - Low Expansion Super White Cone 6 Fritware

L4498A - Low Expansion Fritware Casting

L4530 - Carbondale M390 #1

L4530A - Carbondale M390 #2

L4532A - Pyrometric cone pressing body #2

L4532B - Cone pressing body #3

L4532D - Cone pressing body #5

L4532F - Cone 5 Cone-casting v.1

L4543 - Firebrick & kiln post/shelf clay - v1.0

L4543B - Firebrick & kiln post clay v2.0

L4543C - Refractory kiln post clay v4.0

L4557 - Volumetric Screw Feeder Design - ESP32 based

L4558 - M390 Casting (M370+C-Red)

L4558A - M390 Cone 6 C-Red Casting #1

L4558B - M390 Cone 6 C-Red Casting #2

L4567 - Cat Litter

L4575 - SIAL Refractory Slip

L4575A - SIAL refractory slip Duplicate

L4588 - Red NZK Cone 6 Porcelain

L4597 - Luke Lindoe Fired Samples

L4599 - Slip for Slipware

L4599A - Slip for Slipware - #5 Ball Clay

L4608 - Kyanite Bisque-Fix, Kiln-Patch

L4655 - Titanium Dioxide in GA6-C

L4655A - GA6-C Titanium + Iron

L4655B - GA6-C Lower Thermal Expansion

L4696 - Cordierite Flameware

L4697 - Flameware body from French mfgr

L4705A - GA6-C Using Frit 3195 and Titanium

L4768D - Cone 6 Black Casting Body - Type 2

L4768E - Cone 6 Black Casting Body - Type 3.1

L4768H - Cone 6 Black Casting Body - Type 3.3

L4807 - M370-like Super-Fast Casting Porcelain

MHSCUL - MASTER RedArt Sculpture Clay

MRG6B - G2850A Ravenscrag Cone 6 Light Blue

MRG6C - Ravenscrag Cone 6 White Glossy

MRG6E - G2850P Ravenscrag Cone 6 Raspberry

MRG6G - G2851H Ravenscrag Cone 6 Light Blue Matte

P4738A - 98 BGP RETEST

P4808 - 45D

P5867 - Sculpture Clay

P6385 - M2 ST

P6821 - L215 Production Run - Mar 2020

P7088 - H440

PC-32 - Amaco Glaze: PC-32 Albany Brown

Insight-Live Shares (also referencing this recipe)

These add technical detail, development info, variations and improvements.

GR10-A - Pure Ravenscrag Slip

Modified: 2023-09-19 22:34:46

Ravenscrag all by itself makes a great cone 10 reduction semi-gloss glaze. It also has great working properties.

| Material | Amount |

|---|---|

| Ravenscrag Slip 1000F Roast | 50.00 |

| Ravenscrag Slip | 50.00 |

| 100.00 | |

Notes

Ravenscrag Slip is a revolutionary glaze material for stoneware. At cone 10R it can be used pure and produces a functional semi-gloss surface. The possibilities are endless on what you can do by adding things to this base material. You can make additions to gloss it or matte it more, color and variegate it and/or opacify it. Most will contain 90% Ravenscrag (you can make bamboo, tenmoku, celadon, iron crystal, white, matte, glossy, and much more).

Ravenscrag Slip is a clay, so it shrinks. We recommend starting a 50:50 raw:roast mix in recipes that call for a high percentage of the material (use the roast instructions at http://ravenscrag.com). Adjust the proportion to get the fastest drying possible while still drying hard and having good slurry suspension. Ravenscrag glazes resist settling in the bucket and go on even (when mixed correctly).

Glazes having a high percentage of Ravenscrag Slip are most often prepared using the traditional method of simply adding water until the preferred viscosity is achieved (the material has inherent properties that produce functional slurries for dipping). Control of drying shrinkage and slurry character is achieved by varying the proportion roast and raw powder in the recipe. For us, a weight ratio of 88 water to 100 powder (2200 tap water for 2.5kg of powder) produces a creamy slurry that gives the right thickness on 1-2 second dip on 1850F bisque-ware (with minimal dripping), it has 1.45-1.47-specific-gravity. Using your water you will likely find some variation in this. This recipe actually does not respond to flocculant additions that gel traditional mineral-blend glazes to a thixotropic state.

3000 grams of powder mix makes about 1 Canadian gallon.

Related Information

Sterile white vs. pure Ravenscrag Slip as a liner glaze at cone 10R

This picture has its own page with more detail, click here to see it.

This picture does not fully convey how much better the Ravenscrag is as a liner glaze (vs. G1947U). It has depth and looks much richer. It course, it could be opacified somewhat to be whiter and would still retain the surface quality (as long is it is not too opaque). The body is Plainsman H450. The outside glaze is pure Alberta Slip.

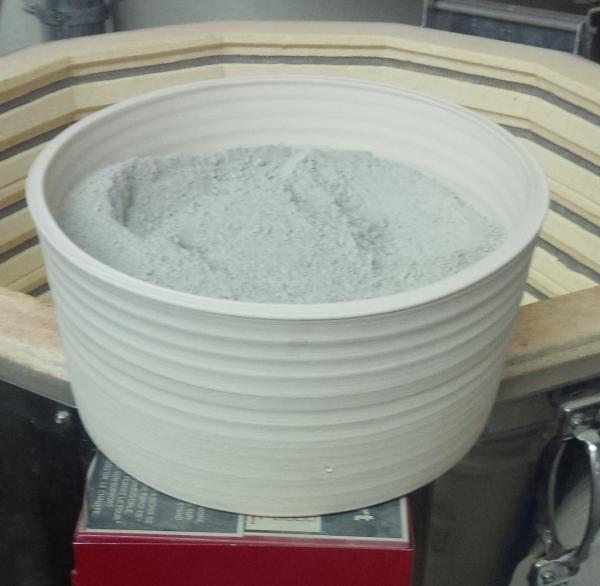

Roast or calcine your Ravenscrag Slip (or other clays) for much better results

This picture has its own page with more detail, click here to see it.

Calcined or roasted clays are indispensable in making many types of glazes, they reduce drying shrinkage (and thus cracking and crawling) compared to those made using raw clay. In a glaze, you can fine-tune a mix of raw and roast clay to achieve a compromise between dry hardness and low shrinkage.

This is Ravenscrag Slip, we roast it to 1000F (roasting is adequate to destroy plasticity and produces a smoother powder than calcining at higher temperatures). To make sure the heat penetrates for this size vessel I hold it for 2 hours at 1000F. Calcined koalin is getting harder to find, this same process can be used to make your own from a raw kaolin powder. One thing is worth noting: Weight lost on firing actually means that less of the roasted powder is needed to yield the same amount of material to the glaze melt, it can be anywhere from 5-12% less.

G1947U transparent glaze (left) vs. Ravenscrag Slip at cone 10R

This picture has its own page with more detail, click here to see it.

Ravenscrag Slip is not ultra glossy but has a silky surface. It also contains some iron oxide and this colors the glaze somewhat. But the surface is much less sterile and pleasant to touch.

100% Ravenscrag slip on Plainsman H550 stoneware fired to cone 10R

This picture has its own page with more detail, click here to see it.

The surface is between silky and glossy.

CaO is a strong flux but it can cause crazing

This picture has its own page with more detail, click here to see it.

2, 5, 10, 15% calcium carbonate added to Ravenscrag Slip on a buff stoneware fired at cone 10R. It gets progressively glossier toward 15%, crazing starts at 10% (test by Kat Valenzuela). Adding a flux only reduces the SiO2 and Al2O3, this pushes the thermal expansion upwards. 5% is actually sufficient. An alternative would be to use wollastonite, it supplies SiO2 also.

How to matte Ravenscrag Slip at cone 10 by adding talc

This picture has its own page with more detail, click here to see it.

2,5,10,15% talc added to Ravenscrag Slip on a buff stoneware fired at cone 10R. Matting begins at 10%. By Kat Valenzuela.

2, 5, 10, 15% dolomite added to Ravenscrag Slip at cone 10R

This picture has its own page with more detail, click here to see it.

This is a buff stoneware clay. Crystal development toward a dolomite matte begins at 15%. By Kat Valenzuela.

2, 5, 10 and 15% alumina hydrate added to Ravenscrag Slip

This picture has its own page with more detail, click here to see it.

Pure Ravenscrag Slip is glaze-like by itself (thus tolerating the alumina addition while still melting as a glaze). It was applied on a buff stoneware which was then fired at cone 10R (by Kat Valenzuela). This same test was done using equal additions of calcined alumina. The results suggest that the hydrated version is decomposing to yield some of its Al2O3, as an oxide, to the glaze melt. By 15% it is matting and producing a silky surface. However crazing also starts at 10%. The more Al2O3 added the lower the glaze expansion should be, so why is this happening? It appears that the disassociation is not complete, raw material remains to impose its high expansion.

Ravenscrag Slip pure: Oxidation vs. Reduction

This picture has its own page with more detail, click here to see it.

Pure Ravenscrag Slip on a porcelain at cone 10 oxidation (left) and cone 10 reduction (right). The reduction fired sample is a very smooth pleasant semi-matte, the other is glossier but dimpled.

Laguna B-Mix, B-Mix+Fireclay with Ravenscrag GR10-A, GR10-C glazes

This picture has its own page with more detail, click here to see it.

Left two mugs are glazed with pure Ravenscrag Slip (roast:raw combo), far right one is RavenTalc silky matte (GR10-C). The speckled mugs have 10% of a Plainsman Fire-Red (a blend of a red fireclay, M2 and a heavily speckled ball clay). Ravenscrag Slip is an ideal base for cone 10R glazes, so many glazes can be made by adding pigments, opacifiers, variegators and matting agents.

B-Mix with Ravenscrag Slip inside and Alberta Slip outside

This picture has its own page with more detail, click here to see it.

Fired cone 10R. The one on the right contains 10% of Plainsman A1:St Rose Red mix to add speckle.

2, 5, 10 and 15% calcined alumina added to Ravenscrag Slip

This picture has its own page with more detail, click here to see it.

The Ravenscag:Alumina mix was applied to a buff stoneware fired at cone 10R (by Kat Valenzuela). Matting begins at only 5% producing a very dry surface by 15%. This "psuedo matte" surface is simply a product of the refractory nature of the alumina as a material, it does not disassociate in the melt to yield its Al2O3 as an oxide (as would a feldspar, frit or clay). The same test using alumina hydrate demonstrates that it disassociates somewhat better (although not completely).

Laguna B-Mix Cone 10R mugs with Alberta and Ravenscrag glazes

This picture has its own page with more detail, click here to see it.

B-Mix is a popular high-ball clay very plastic grey cone 10R stoneware in North America. The two mugs on the left have pure Ravenscrag Slip on the inside (the middle on the outside also), it fires almost transparent with a slightly silky surface. Pure Alberta Slip is employed on the outside of the left one and the inside of the right one. The outside of the right one is RavenTalc silky matte. In all cases the Ravenscrag and Alberta Slip are mixed half-and-half calcined and raw. B-Mix fires dark enough and with enough specks that a normal transparent glaze is not very interesting. But these Ravenscrag ones look much better (for use as a liner glaze).

Links

| URLs |

https://plainsmanclays.com/data/index.php?product=12911

Ravenscrag Data Sheet at Plainsman Clays |

| URLs |

http://ravenscrag.com

Ravenscrag web site |

| Firing Schedules |

Plainsman Cone 10R Firing

Six-step oxidize-at-end schedule to 2372F |

| Typecodes |

Ravenscrag Slip Recipes

Recipes based on Ravenscrag Slip from Plainsman Clays. |

| Typecodes |

High Temperature (Cone 10) Glaze Recipes

Normally reduction gas fired. |

| Recipes |

GR10-C - Ravenscrag Cone 10R Silky Talc Matte

Just Ravenscrag Slip plus 10% talc produces a visually variegated surface that feels silky and looks stunning! |

XML to Paste Into Insight-live

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Pure Ravenscrag Slip" keywords="Ravenscrag all by itself makes a great cone 10 reduction semi-gloss glaze. It also has great working properties." id="58" date="2023-09-19" codenum="GR10-A"> <recipelines> <recipeline material="Ravenscrag Slip 1000F Roast" amount="50.000"/> <recipeline material="Ravenscrag Slip" amount="50.000"/> <url url="https://digitalfire.com/recipe/58" descrip="https://digitalfire.com/recipe/58"/> </recipelines> <urls/> </recipe> </recipes>

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy