| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

CELECG - Celestite Crystalline Glaze

FAAO - Fa's All-Opaque Crystalline Glaze

FAC5 - Crystal Number Five Glaze

FO - Octal Crystalline Glaze

G1214M - 20x5 Cone 6 Base Glossy Glaze

G1214W - Cone 6 Transparent Base

G1214Z1 - Cone 6 Silky CaO matte base glaze

G1215U - Low Expansion Glossy Clear Cone 6

G1216L - Transparent for Cone 6 Porcelains

G1216M - Cone 6 Ultraclear Glaze for Porcelains

G1916Q - Low Fire Highly-Expansion-Adjustable Transparent

G1947U - Cone 10 Glossy transparent glaze

G2000 - LA Matte Cone 6 Matte White

G2240 - Cone 10R Classic Spodumene Matte

G2571A - Cone 10 Silky Dolomite Matte glaze

G2826R - Floating Blue Cone 5-6 Original Glaze Recipe

G2826X - Randy's Red Cone 5

g2851H - Ravenscrag Cone 6 High Calcium Matte Blue

G2853B - Cone 04 Clear Ravenscrag School Glaze

G2896 - Ravenscrag Plum Red Cone 6

G2902B - Cone 6 Crystal Glaze

G2902D - Cone 6 Crystalline Development Project

G2916F - Cone 6 Stoneware/Whiteware transparent glaze

G2926B - Cone 6 Whiteware/Porcelain transparent glaze

G2926J - Low Expansion G2926B

G2928C - Ravenscrag Silky Matte for Cone 6

G2931H - Ulexite High Expansion Zero3 Clear Glaze

G2931K - Low Fire Fritted Zero3 Transparent Glaze

G2931L - Low Expansion Low-Fire Clear

G2934 - Matte Glaze Base for Cone 6

G2934Y - Cone 6 Magnesia Matte Low LOI Version

G3806C - Cone 6 Clear Fluid-Melt transparent glaze

G3838A - Low Expansion Transparent for P300 Porcelain

G3879 - Cone 04 Transparent Low-Expansion transparent glaze

GA10-A - Alberta Slip Base Cone 10R

GA10-B - Alberta Slip Tenmoku Cone 10R

GA10-D - Alberta Slip Black Cone 10R

GA10x-A - Alberta Slip Base for cone 10 oxidation

GA6-A - Alberta Slip Cone 6 transparent honey glaze

GA6-B - Alberta Slip Cone 6 transparent honey glaze

GA6-C - Alberta Slip Floating Blue Cone 6

GA6-D - Alberta Slip Glossy Brown Cone 6

GA6-F - Alberta Slip Cone 6 Oatmeal

GA6-G - Alberta Slip Lithium Brown Cone 6

GA6-G1 - Alberta Slip Lithium Brown Cone 6 Low Expansion

GA6-H - Alberta Slip Cone 6 Black

GBCG - Generic Base Crystalline Glaze

GC106 - GC106 Base Crystalline Glaze

GR10-A - Pure Ravenscrag Slip

GR10-B - Ravenscrag Cone 10R Gloss Base

GR10-C - Ravenscrag Cone 10R Silky Talc Matte

GR10-E - Alberta Slip:Ravenscrag Cone 10R Celadon

GR10-G - Ravenscrag Cone 10 Oxidation Variegated White

GR10-J - Ravenscrag Cone 10R Dolomite Matte

GR10-J1 - Ravenscrag Cone 10R Bamboo Matte

GR10-K1 - Ravenscrag Cone 10R Tenmoku

GR10-L - Ravenscrag Iron Crystal

GR6-A - Ravenscrag Cone 6 Clear Glossy Base

GR6-B - Ravenscrag Cone 6 Variegated Light Glossy Blue

GR6-C - Ravenscrag Cone 6 White Glossy

GR6-D - Ravenscrag Cone 6 Glossy Black

GR6-E - Ravenscrag Cone 6 Raspberry Glossy

GR6-H - Ravenscrag Cone 6 Oatmeal Matte

GR6-L - Ravenscrag Cone 6 Transparent Burgundy

GR6-M - Ravenscrag Cone 6 Floating Blue

GR6-N - Ravenscrag Alberta Brilliant Cone 6 Celadon

GRNTCG - GRANITE Crystalline Glaze

L2000 - 25 Porcelain

L3341B - Alberta Slip Iron Crystal Cone 10R

L3685U - Cone 03 White Engobe Recipe

L3724F - Cone 03 Terra Cotta Stoneware

L3924C - Zero3 Porcelain Experimental

L3954B - Cone 6 Engobe (for M340)

L3954N - Cone 10R Base White Engobe Recipe for stonewares

MGBase1 - High Calcium Semimatte 1 (Mastering Glazes)

MGBase2 - High Calcium Semimatte 2 (Mastering Glazes)

MGBase3 - General Purpose Glossy Base 1 (Mastering Glazes)

MGBase4 - Glossy Base 2 Cone 6 (Mastering Glazes)

MGBase5 - Glossy Clear Liner Cone 6 (Mastering Glazes)

MGBase6 - Zinc Semimatte Glossy Base Cone 6

MGBase7 - Raspberry Cone 6 (Mastering Glazes)

MGBase8 - Waxwing Brown Cone 6 (Mastering Glazes)

MGBase9 - Waterfall Brown Cone 6 (Mastering Glazes)

TNF2CG - Tin Foil II Crystalline Glaze

VESUCG - Vesuvius Crystalline Glaze

Insight-Live Shares (also referencing this recipe)

These add technical detail, development info, variations and improvements.

G1947U - Cone 10 Glossy transparent glaze

Modified: 2023-07-22 15:01:31

Reliable widely used glaze for cone 10 porcelains and whitewares. The original recipe was developed from a glaze used for porcelain insulators.

| Material | Amount |

|---|---|

| Custer Feldspar | 27.00 |

| EPK | 20.50 |

| Silica | 26.50 |

| Wollastonite | 23.50 |

| Zinc Oxide | 2.50 |

| 100.00 | |

Notes

This is is long-time cone 10 transparent base, it is used by many potters around the world. It was originally employed as a high temperature porcelain insulator glaze on a 25-Porcelain body. It used calcium carbonate to supply the CaO but we converted it to using Wollastonite instead (to reduce surface imperfections and avoid the variations inherent with different supplies of calcium carbonate). Unlike many transparent glazes in use by potters today, this one has a low amount of feldspar to keep the thermal expansion down (and therefore avoid crazing). This glaze also has the correct amount of kaolin, not too high to cause cracking during drying, and no so low that it settles out in the bucket.

This recipe is also a good base from which to make a range of different colors and effects (by adding oxides, stains, opacifiers and variegators). The small amount of zinc present is here to get melting started early, it volatilizes at high temperatures. If you are doing fast firing, consider leaving it out (fast fire glazes need to melt as late as possible).

For porcelains, use Grolleg Kaolin instead of EPK, the glaze surface will fire bluer and look better. However Grolleg does not suspend it quite as well as EPK, so you may need to add 1% bentonite (or better yet 0.25-0.5% Veegum, it is cleaner). You might also consider switching to a cleaner soda feldspar (or nepheline syenite) to get better melting and an even more brilliant surface (however you may need to adjust it if crazing occurs).

If you have crazing issues, it is easy to adjust this recipe to lower its thermal expansion (using Digitalfire Insight or your account at Insight-live.com).

The firing schedule is just an example, this will likely work fine with yours.

Related Information

G1947U cone 10 transparent on Plainsman H550 and H570

This picture has its own page with more detail, click here to see it.

This is a base recipe that was originally used for electrical insulators on a 25% porcelain recipe. Since most porcelains and whitewares used in high fire ceramics have this same type of formulation, this glaze recipe has proven to work well. It is not highly fluid, so if refractory colorants are added extra flux may be needed.

Example of a logo done using a polymer plate

This picture has its own page with more detail, click here to see it.

The buff stoneware mug is fired at cone 10R and celadon glazed. The recesses were colored with a tenmoku glaze (on bisque by painting it into the recesses and sponging away the high spots). An outer containment line on the plate prevented the outside line from smearing outward and it provided a definite profile for cut-out after stamping.

Which tenmoku base is better: Alberta Slip or a clear glaze?

This picture has its own page with more detail, click here to see it.

Right: Alberta slip is almost a Tenmoku glaze by itself at cone 10 reduction. To go all the way only 1-2% more iron is needed (plus a little extra flux for melt fluidity, perhaps 5% calcium carbonate). Compare that to crow-baring a clear glaze into a tenmoku (left): This is G1947U plus 11% red iron oxide. That produces a slurry that is miserable to work with (it stains everything it comes into contact with) and turns into a jelly on standing.

G1947U transparent glaze (left) vs. Ravenscrag Slip at cone 10R

This picture has its own page with more detail, click here to see it.

Ravenscrag Slip is not ultra glossy but has a silky surface. It also contains some iron oxide and this colors the glaze somewhat. But the surface is much less sterile and pleasant to touch.

Sterile white vs. pure Ravenscrag Slip as a liner glaze at cone 10R

This picture has its own page with more detail, click here to see it.

This picture does not fully convey how much better the Ravenscrag is as a liner glaze (vs. G1947U). It has depth and looks much richer. It course, it could be opacified somewhat to be whiter and would still retain the surface quality (as long is it is not too opaque). The body is Plainsman H450. The outside glaze is pure Alberta Slip.

Does Grolleg whiten a glaze the same as it does a body?

This picture has its own page with more detail, click here to see it.

Yes. The two specimens are both the same Grolleg-based porcelains. Both of them are glazed with the same glaze: 1947U transparent. But the glaze on the left is using EP Kaolin and the one on the right Grolleg kaolin. The Grolleg glaze is dramatically better, the color has a bluish cast that is more attractive. The Grolleg does not suspend the slurry as well, however it responds well to gelling (using vinegar, for example) more than compensating to create an easy-to-use suspension.

Reduction and oxidation porcelains

This picture has its own page with more detail, click here to see it.

Left: Cone 10R (reduction) Plainsman P700 porcelain (made using Grolleg and G200 Feldspar). Right: Plainsman Cone 6 Plainsman Polar Ice porcelain (made using New Zealand kaolin and Nepheline Syenite). Both are zero porosity. The Polar Ice is very translucent, the P700 much less. The blue coloration of the P700 is mostly a product of the suspended micro-bubbles in the feldspar clear glaze (G1947U). The cone 6 glaze is fritted and much more transparent, but it could be stained to match the blue. These are high quality combinations of glaze and body.

Cone 10R porcelain (left) vs cone 03 porcelain (right)

This picture has its own page with more detail, click here to see it.

Want to make this incredible porcelain and glaze yourself? Read on. The mug on the left is a cone 10R (2350F/1290C) porcelain (#6 Tile kaolin and Nepheline Syenite) with G1947U clear glaze. The other is a fritted cone 03 (1950F or 1065C) porcelain (NZ Kaolin, Ferro Frit 3110) with G2931K clear glaze. We call the body/glaze/firing system "Zero3" (google it or use the links here). The Zero3 porcelain is blue-white instead of grey, the glaze is crystal clear, underglaze colors are so much more vibrant. This Zero3 mug was fired in 3 hours (cold-to-cold). It fits glazes really well, it is very strong and much more translucent. How is this possible? The magic of the frit, it melts so much better than nepheline. It is the most expensive body you will ever make. But from it you may create the highest quality ware you have ever made using the most plastic body you have ever thrown! Follow the instructions carefully.

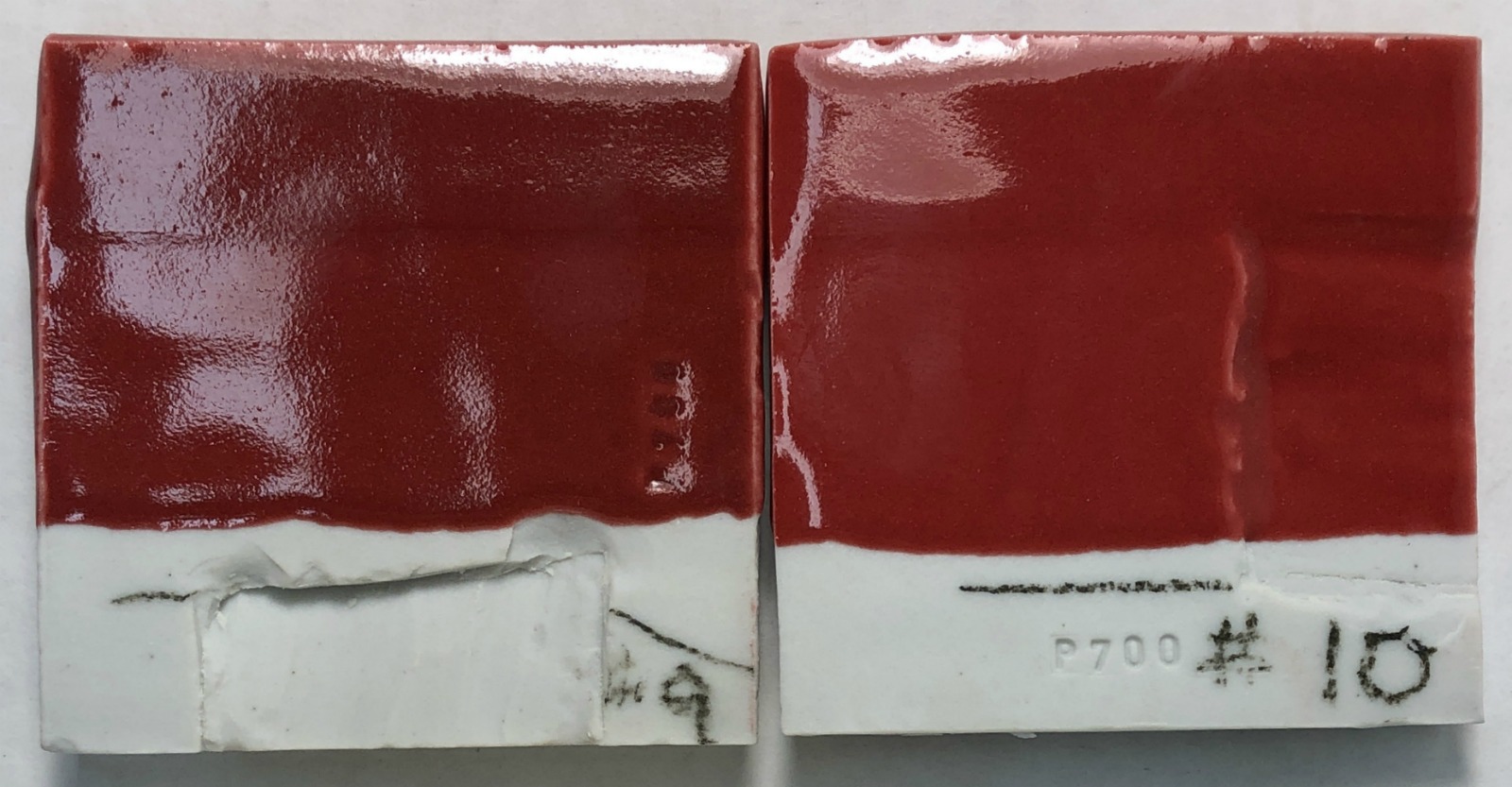

A cone 10R blood red - without copper but with risk

This picture has its own page with more detail, click here to see it.

This is G1947U clear glaze with 8% Mason 6021 encapsulated red stain added. The body is P700, a Grolleg kaolin porcelain. The one on the right, having significantly reduced clouding within, has one tiny addition: 2% Zircopax. It is acting as a micro-bubble fining agent, producing a brighter color and smoother surface. But there is a possible problem: These stains are not recommended for use above 2300F. Even though the color is very good, cone 10 is just on the edge of the limit temperature, so suitability for food surfaces would require careful testing for leaching cadmium.

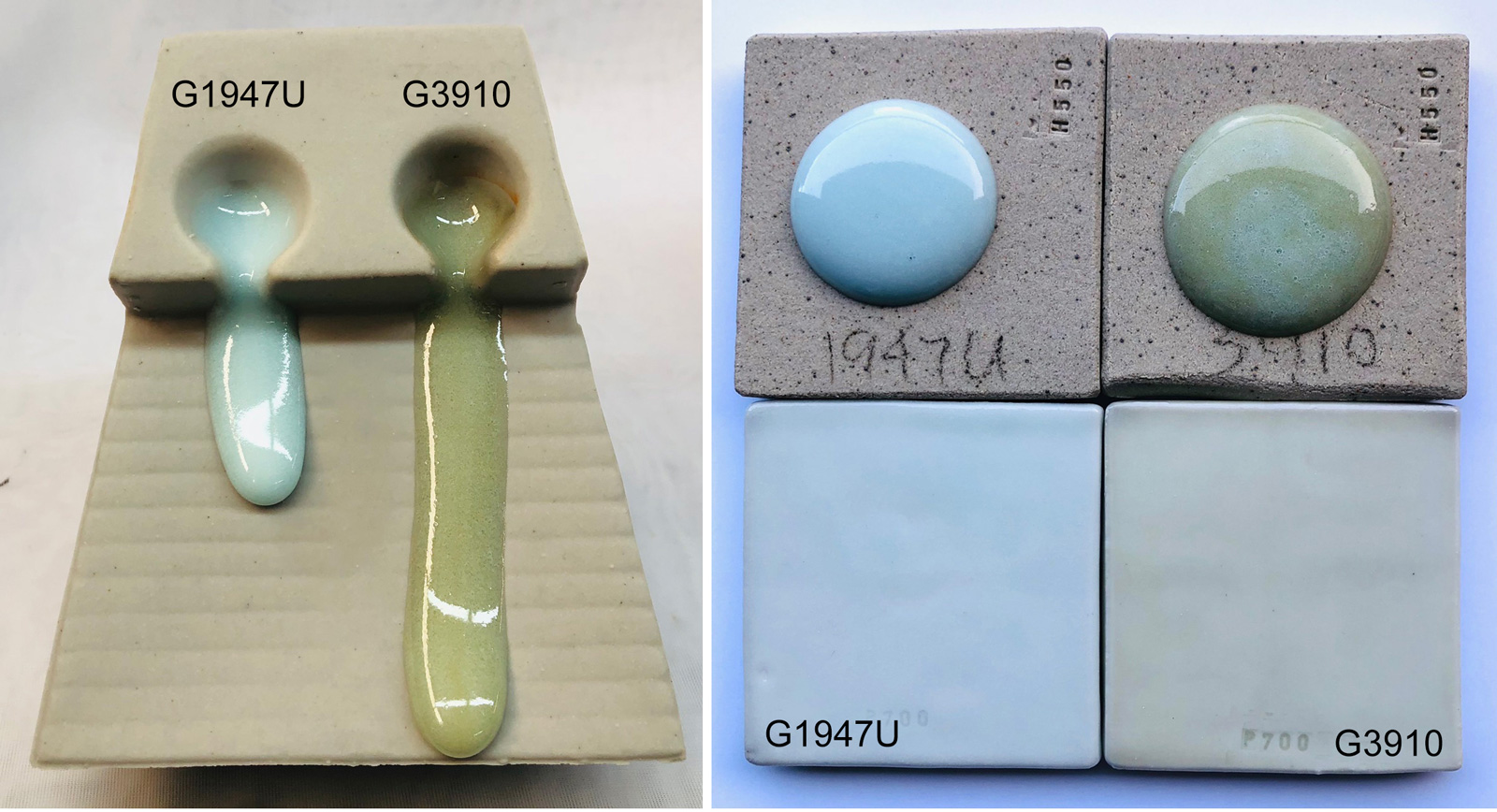

Use a frit instead of feldspar in a cone 10 glaze.

A good reason to do that.

This picture has its own page with more detail, click here to see it.

Using my account at Insight-live.com I calculated a frit-based recipe having an "evolved" chemistry from the original G1947U feldspar-based one. Only after seeing the fired results did I fully realize I made a discovery as well as an improvement. My original approach was just theoretical: Shift KNaO-sourcing from feldspar to frit to get a better melt (just because the frit is a premelted source of KNaO). As calculations took shape it became clear that I could increase KNaO (it is a super-flux for cone 10 brilliant surfaces) because of the multiple options to counterbalance its high thermal expansion. Those options would theoretically supercharge melting more, that gave me confidence the melt could even dissolve additional SiO2 (which would improve durability). When the kiln opened I got the surprise with the original G1947U: It never looked white before! But when seeing it this thick in comparison to the improved version, it looks really cloudy. Why? Likely the melt is not completely dissolving the particles of quartz! The "lead glaze surface brilliance" of the new G3910 blew me away at first, but now that I realize it is also melting all the silica I see how much better it potentially is. One issue: The transparency of G3910 brings with it the amber color of the body:glaze interface.

Calculating the highest % of 3B clay to create a glaze recipe

This picture has its own page with more detail, click here to see it.

In this screenshot I am comparing the chemistries of two recipes. The recipes are different but the chemistries are the same. On the left, Plainsman 3B (also known as MNP) is being using to source almost all of the Al2O3 (the red box) needed by the recipe (to match our standard cone 10R transparent G1947U, on the right). The KNaO is being sourced from the frit rather than feldspar (this is really good because it has almost no Al2O3 so all of it can be sourced from the 3B clay). Only silica and calcium carbonate are needed to bring the SiO2 and CaO up to match.

Links

| Firing Schedules |

Plainsman Cone 10R Firing

Six-step oxidize-at-end schedule to 2372F |

| Recipes |

G2571A - Cone 10 Silky Dolomite Matte glaze

A cone 10R dolomite matte having a pleasant silky surface, it does not cutlery mark, stain or craze on common bodies |

| Typecodes |

High Temperature (Cone 10) Glaze Recipes

Normally reduction gas fired. |

| Typecodes |

INSIGHT Glaze Recipes

These are sample recipes included with INSIGHT software. |

| Typecodes |

Transparent Glaze Recipe

Transparent recipes can be difficult to develop because entrained bubbles, crystals and crazing are not hidden by color and opacity. In addition, they must be well melted to give good results. Generally transparent recipes are sought after as liner glazes or bases to which to add opacifiers and colors. Typically work is required to match a transparent glaze to a specific clay body. |

| Glossary |

Base Glaze

Understand your a glaze and learn how to adjust and improve it. Build others from that. We have bases for low, medium and high fire. |

| Glossary |

Transparent Glazes

Every glossy ceramic glaze is actually a base transparent with added opacifiers and colorants. So understand how to make a good transparent, then build other glazes on it. |

| Glossary |

Tenmoku

Tenmoku is a kind of high temperature reduction firing ceramic glaze. Glossy, very dark brown or maroon, fluxed by iron oxide to have high melt fluidity. |

| Articles |

Concentrate on One Good Glaze

It is better to understand and have control of one good base glaze than be at the mercy of dozens of imported recipes that do not work. There is a lot more to being a good glaze than fired appearance. |

XML to Paste Into Insight-live

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 10 Glossy transparent glaze" keywords="Reliable widely used glaze for cone 10 porcelains and whitewares. The original recipe was developed from a glaze used for porcelain insulators." id="40" date="2023-07-22" codenum="G1947U"> <recipelines> <recipeline material="Custer Feldspar" amount="27.000"/> <recipeline material="EPK" amount="20.500"/> <recipeline material="Silica" amount="26.500"/> <recipeline material="Wollastonite" amount="23.500"/> <recipeline material="Zinc Oxide" amount="2.500"/> <url url="https://digitalfire.com/recipe/40" descrip="https://digitalfire.com/recipe/40"/> </recipelines> <urls/> </recipe> </recipes>

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy