| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

CELECG - Celestite Crystalline Glaze

FAAO - Fa's All-Opaque Crystalline Glaze

FAC5 - Crystal Number Five Glaze

FO - Octal Crystalline Glaze

G1214M - 20x5 Cone 6 Base Glossy Glaze

G1214W - Cone 6 Transparent Base

G1214Z1 - Cone 6 Silky CaO matte base glaze

G1215U - Low Expansion Glossy Clear Cone 6

G1216L - Transparent for Cone 6 Porcelains

G1216M - Cone 6 Ultraclear Glaze for Porcelains

G1916Q - Low Fire Highly-Expansion-Adjustable Transparent

G1947U - Cone 10 Glossy transparent glaze

G2000 - LA Matte Cone 6 Matte White

G2240 - Cone 10R Classic Spodumene Matte

G2571A - Cone 10 Silky Dolomite Matte glaze

G2826R - Floating Blue Cone 5-6 Original Glaze Recipe

G2826X - Randy's Red Cone 5

g2851H - Ravenscrag Cone 6 High Calcium Matte Blue

G2853B - Cone 04 Clear Ravenscrag School Glaze

G2896 - Ravenscrag Plum Red Cone 6

G2902B - Cone 6 Crystal Glaze

G2902D - Cone 6 Crystalline Development Project

G2916F - Cone 6 Stoneware/Whiteware transparent glaze

G2926B - Cone 6 Whiteware/Porcelain transparent glaze

G2926J - Low Expansion G2926B

G2928C - Ravenscrag Silky Matte for Cone 6

G2931H - Ulexite High Expansion Zero3 Clear Glaze

G2931K - Low Fire Fritted Zero3 Transparent Glaze

G2931L - Low Expansion Low-Fire Clear

G2934 - Matte Glaze Base for Cone 6

G2934Y - Cone 6 Magnesia Matte Low LOI Version

G3806C - Cone 6 Clear Fluid-Melt transparent glaze

G3838A - Low Expansion Transparent for P300 Porcelain

G3879 - Cone 04 Transparent Low-Expansion transparent glaze

GA10-A - Alberta Slip Base Cone 10R

GA10-B - Alberta Slip Tenmoku Cone 10R

GA10-D - Alberta Slip Black Cone 10R

GA10x-A - Alberta Slip Base for cone 10 oxidation

GA6-A - Alberta Slip Cone 6 transparent honey glaze

GA6-B - Alberta Slip Cone 6 transparent honey glaze

GA6-C - Alberta Slip Floating Blue Cone 6

GA6-D - Alberta Slip Glossy Brown Cone 6

GA6-F - Alberta Slip Cone 6 Oatmeal

GA6-G - Alberta Slip Lithium Brown Cone 6

GA6-G1 - Alberta Slip Lithium Brown Cone 6 Low Expansion

GA6-H - Alberta Slip Cone 6 Black

GBCG - Generic Base Crystalline Glaze

GC106 - GC106 Base Crystalline Glaze

GR10-A - Pure Ravenscrag Slip

GR10-B - Ravenscrag Cone 10R Gloss Base

GR10-C - Ravenscrag Cone 10R Silky Talc Matte

GR10-E - Alberta Slip:Ravenscrag Cone 10R Celadon

GR10-G - Ravenscrag Cone 10 Oxidation Variegated White

GR10-J - Ravenscrag Cone 10R Dolomite Matte

GR10-J1 - Ravenscrag Cone 10R Bamboo Matte

GR10-K1 - Ravenscrag Cone 10R Tenmoku

GR10-L - Ravenscrag Iron Crystal

GR6-A - Ravenscrag Cone 6 Clear Glossy Base

GR6-B - Ravenscrag Cone 6 Variegated Light Glossy Blue

GR6-C - Ravenscrag Cone 6 White Glossy

GR6-D - Ravenscrag Cone 6 Glossy Black

GR6-E - Ravenscrag Cone 6 Raspberry Glossy

GR6-H - Ravenscrag Cone 6 Oatmeal Matte

GR6-L - Ravenscrag Cone 6 Transparent Burgundy

GR6-M - Ravenscrag Cone 6 Floating Blue

GR6-N - Ravenscrag Alberta Brilliant Cone 6 Celadon

GRNTCG - GRANITE Crystalline Glaze

L2000 - 25 Porcelain

L3341B - Alberta Slip Iron Crystal Cone 10R

L3685U - Cone 03 White Engobe Recipe

L3724F - Cone 03 Terra Cotta Stoneware

L3924C - Zero3 Porcelain Experimental

L3954B - Cone 6 Engobe (for M340)

L3954N - Cone 10R Base White Engobe Recipe for stonewares

MGBase1 - High Calcium Semimatte 1 (Mastering Glazes)

MGBase2 - High Calcium Semimatte 2 (Mastering Glazes)

MGBase3 - General Purpose Glossy Base 1 (Mastering Glazes)

MGBase4 - Glossy Base 2 Cone 6 (Mastering Glazes)

MGBase5 - Glossy Clear Liner Cone 6 (Mastering Glazes)

MGBase6 - Zinc Semimatte Glossy Base Cone 6

MGBase7 - Raspberry Cone 6 (Mastering Glazes)

MGBase8 - Waxwing Brown Cone 6 (Mastering Glazes)

MGBase9 - Waterfall Brown Cone 6 (Mastering Glazes)

TNF2CG - Tin Foil II Crystalline Glaze

VESUCG - Vesuvius Crystalline Glaze

GR6-A - Ravenscrag Cone 6 Clear Glossy Base

Modified: 2023-04-15 23:01:04

This Plainsman Cone 6 Ravenscrag Slip base is just the pure material with 20% added frit to make it melt to a glossy natural clear.

| Material | Amount |

|---|---|

| Ravenscrag Slip | 50.00 |

| Ravenscrag Slip 1000F Roast | 30.00 |

| Ferro Frit 3134 | 20.00 |

| 100.00 | |

Notes

Also known as G2936C.

This is the base cone 6 Ravenscrag recipe, it fires as a transparent glossy. It has an addition of the most common North American borate frit, enough to produce a good glass at cone 6. Most other glazes based on Ravenscrag use this as a starting point (although they might substitute the frit for another).

The character of this is not the same as transparent glazes made from materials like feldspar, kaolin, silica, wollastonite and frit. This is a natural clay material having some iron content and particles you can feel (up to 42 mesh). So it forms a less sterile glaze, one having some variegation, fine speckle and slight blush or amber coloration. It is most glossy at a complete cone 6 (for a lower temperature you may need to increase the frit a little).

It is best to at least hold the temperature at the end of the firing to minimize firing defects. Even better, use the C6DHSC firing schedule.

As a transparent, this glaze is best suited for use on light-burning stonewares (e.g. Plainsman M340). On whiter porcelains and stonewares, it may not fire to a sufficiently transparent glass (consider using G2926B or G3806C instead). On darker clay bodies this recipe may fire too cloudy. Is has a low enough thermal expansion to fit most bodies, but if it does craze consider substituting Ferro Frit 3195.

As noted, this is a base recipe, well suited to additions of opacifiers, variegators and colors. Add zircopax to get a white (about 10%). The white produced will be somewhat variegated (non-toilet-bowl-like). For variation-with-thickness, to highlight edges of contours, use a lower percentage of zircopax. For even better variegation, add some titanium dioxide (1-2% to a mix already containing 6-8 zircopax). Add colorants and variegators (with or without opacifier). If colorant additions affect melt fluidity, add or reduce the frit percentage to compensate.

If it cracks during drying, increase the roast clay at the expense of raw clay.

Glazes having a high percentage of Ravenscrag Slip are most often prepared using the traditional method of simply adding water until the preferred viscosity is achieved (the material has inherent properties that produce functional slurries for dipping). Control of drying shrinkage and slurry character is achieved by varying the proportion of roast and raw powder in the recipe. For us, a weight ratio of 80 water to 100 powder (2000 water for 2.5kg of powder) produces a 1.5-specific-gravity slurry that, although fairly runny, gives the right thickness on 1-2 second dip on 1850F bisque-ware (there is some dripping, but coverage is even and it is quick-drying). This recipe actually does not respond to flocculant additions that gel traditional mineral-blend glazes to a thixotropic state.

Related Information

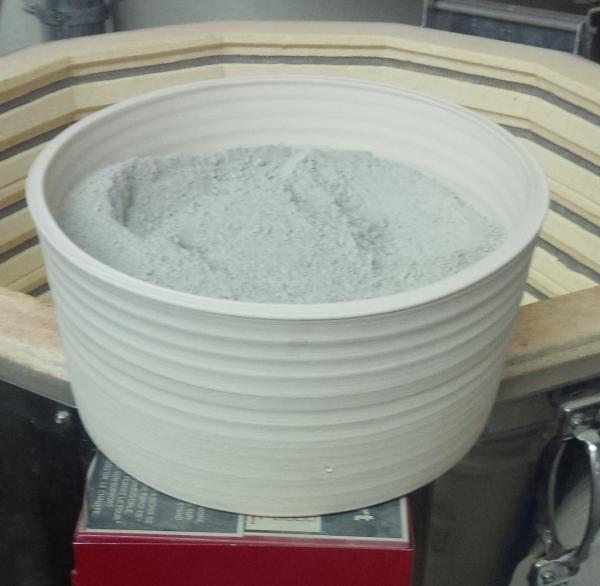

Roast or calcine your Ravenscrag Slip (or other clays) for much better results

This picture has its own page with more detail, click here to see it.

Calcined or roasted clays are indispensable in making many types of glazes, they reduce drying shrinkage (and thus cracking and crawling) compared to those made using raw clay. In a glaze, you can fine-tune a mix of raw and roast clay to achieve a compromise between dry hardness and low shrinkage.

This is Ravenscrag Slip, we roast it to 1000F (roasting is adequate to destroy plasticity and produces a smoother powder than calcining at higher temperatures). To make sure the heat penetrates for this size vessel I hold it for 2 hours at 1000F. Calcined koalin is getting harder to find, this same process can be used to make your own from a raw kaolin powder. One thing is worth noting: Weight lost on firing actually means that less of the roasted powder is needed to yield the same amount of material to the glaze melt, it can be anywhere from 5-12% less.

Ravenscrag Slip at cone 5R and 10R

This picture has its own page with more detail, click here to see it.

Cone 5 GR6-A glaze at cone 5R on Plainsman M340 (left) and pure Ravenscrag Slip at cone 10R on H550 (right).

Ravenscrag Slip transparent and Alberta Slip blue glazes by Tony Hansen

This picture has its own page with more detail, click here to see it.

The mug is the buff stoneware Plainsman M340. Firing is cone 6. On the inside is the GR6-A Ravenscrag transparent base glaze. The outside glaze is GA6-C Alberta Slip rutile blue on the outside. The transparent, although slightly amber in color compared to a frit-based transparent, does look better on buff burning stoneware bodies this.

Cone 5R mug with GR6-A Ravenscrag glaze

This picture has its own page with more detail, click here to see it.

Emulating a speckled reduction fired stoneware in oxidation

This picture has its own page with more detail, click here to see it.

The body is Plainsman M340S. Cone 6. Left to right: G1214Z1 calciua matte base glaze with 6% titanium dioxide added. GR6-A Ravenscrag base with 10% zircopax (zircon). G2926B glossy transparent base with 10% zircon (this one produces the white "Kohler Toilet Bowl" appearance we are seeking to better). G2934Y silky magnesia matte base with 10% zircon.

Ravenscrag GR6-A glaze with Frit 3134 and Fusion F-12

This picture has its own page with more detail, click here to see it.

As this cone 6 melt flow test demonstrates, the Fusion F-12 is giving very similar performance to the Ferro. The GR6-A recipe is just 80% Ravenscrag Slip and 20% frit (10% zircopax has also been added to opacify). The degree-of-melt on the glazed tiles in also very similar, however notice that some of the whiteness has been lost on the second F-12 tile (the first is frit 3134). We are attributing this to the better melting of F-12, that is amplifying the color of iron present in the Ravenscrag Slip. For the third tile we reduced the frit to 15%, that has whitened it somewhat. Likely an increase in the zircon and would whiten it more.

Links

| Firing Schedules |

Plainsman Cone 6 Electric Standard

Used in the Plainsman lab to fire clay test bars in our small kilns |

| Typecodes |

Ravenscrag Slip Recipes

Recipes based on Ravenscrag Slip from Plainsman Clays. |

| Typecodes |

Medium Temperature Glaze Recipes

Normally fired at cone 5-7 in electric kilns. |

| Typecodes |

Transparent Glaze Recipe

Transparent recipes can be difficult to develop because entrained bubbles, crystals and crazing are not hidden by color and opacity. In addition, they must be well melted to give good results. Generally transparent recipes are sought after as liner glazes or bases to which to add opacifiers and colors. Typically work is required to match a transparent glaze to a specific clay body. |

| Recipes |

GR6-C - Ravenscrag Cone 6 White Glossy

Plainsman Cone 6 Ravenscrag Slip based white glossy glaze. It can be found among others at http://ravenscrag.com. |

| Recipes |

GR6-L - Ravenscrag Cone 6 Transparent Burgundy

A stain-based method to achieve this color using the Ravenscrag base recipe. |

| Recipes |

G2926B - Cone 6 Whiteware/Porcelain transparent glaze

A base transparent glaze recipe created by Tony Hansen, it fires high gloss and ultra clear with low melt mobility. |

| Recipes |

G3806C - Cone 6 Clear Fluid-Melt transparent glaze

A base fluid-melt glaze recipe developed by Tony Hansen. With colorant additions it forms reactive melts that variegate and run. It is more resistant to crazing than others. |

| Recipes |

GA6-A - Alberta Slip Cone 6 transparent honey glaze

An amber-colored glaze that produces a clean, micro bubble free transparent glass on brown and red burning stonewares. |

| Recipes |

GR6-M - Ravenscrag Cone 6 Floating Blue

Plainsman Cone 6 Ravenscrag Slip based version of the popular floating blue recipe. |

| Recipes |

GR6-D - Ravenscrag Cone 6 Glossy Black

|

| Recipes |

GR6-E - Ravenscrag Cone 6 Raspberry Glossy

A chrome-tin burgundy glaze using the Ravenscrag cone 6 base recipe. |

| Recipes |

GR6-N - Ravenscrag Alberta Brilliant Cone 6 Celadon

Plainsman Cone 6 Ravenscrag Slip based glaze. It can be found among others at http://ravenscrag.com. |

| Recipes |

GR6-H - Ravenscrag Cone 6 Oatmeal Matte

Plainsman Cone 6 Ravenscrag Slip glaze. See more at ravenscrag.com. |

XML to Paste Into Insight-live

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Ravenscrag Cone 6 Clear Glossy Base" keywords="This Plainsman Cone 6 Ravenscrag Slip base is just the pure material with 20% added frit to make it melt to a glossy natural clear." id="5" date="2023-04-15" codenum="GR6-A" altcodenum="G2936C"> <recipelines> <recipeline material="Ravenscrag Slip" amount="50.000"/> <recipeline material="Ravenscrag Slip 1000F Roast" amount="30.000"/> <recipeline material="Ferro Frit 3134" amount="20.000"/> <url url="https://digitalfire.com/recipe/5" descrip="https://digitalfire.com/recipe/5"/> </recipelines> <urls/> </recipe> </recipes>

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy