| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

LDW - LOI/Density/Water Content Test

This test is most valuable to measure the water content of wet clay samples. Knowing water content is especially important when doing SHAB tests. This is because, while drying shrinkage is dependent mainly on plasticity, the water content of a clay can significantly affect it. Thus, for an accurate drying shrinkage comparison between two or more clays, they should have water contents that are as close to the same as possible. As a bonus for this test, more data can be collected after firing to calculate the LOI of the clay.

Video: Making SHAB, DFAC, LDW clay body test bars

This picture has its own page with more detail, click here to see it.

One-minute video. It demonstrates how to make the test bars for measuring plastic clay body (or clay material) drying and firing shrinkage, fired absorption, a bar for measuring water content and loss-on-ignition and a disk for measuring drying performance and soluble salts content. This method requires no expensive equipment and is within the reach of any technician.

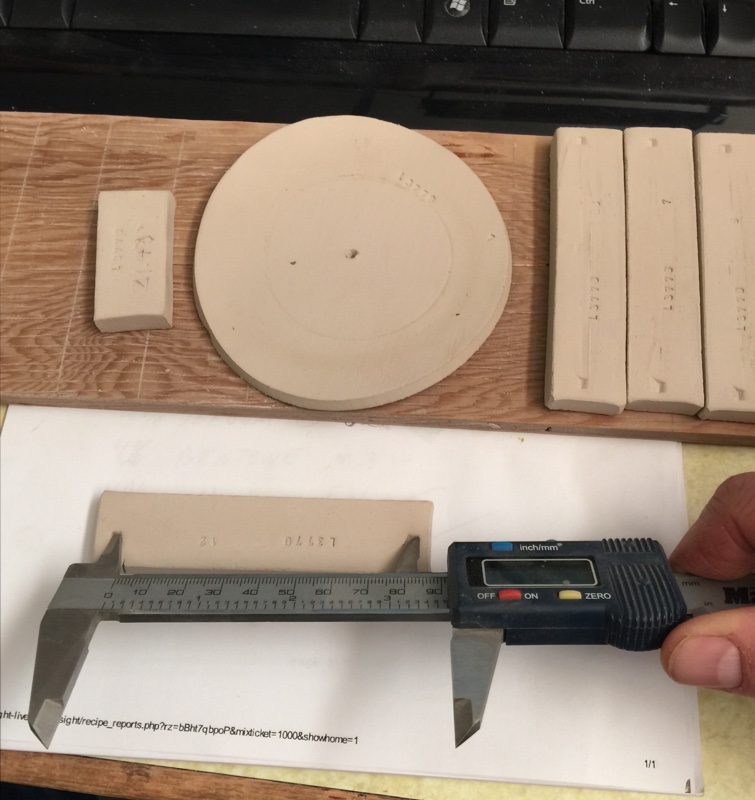

EPK test specimens made (SHAB bars, LDW bar, DFAC disk)

They are ready for drying

This picture has its own page with more detail, click here to see it.

I have cut bars for an SHAB test, they are 1 inch wide (for firing to cone 7, 8, 9, 10 and 10R). A smaller half-length bar for the LDW test has been made and weighed. The disk is 12cm in diameter and 3/16in thick and used for the DFAC test.

Step 8: Measuring the clay test bars after drying

This picture has its own page with more detail, click here to see it.

These test specimens dried overnight (this in itself is pertinent - quick drying indicates low levels of superfine particles e.g. bentonite). Here, I am measuring the length of the SHAB test bars, weighing the LDW test sample and recording the crack pattern and soluble salts on the DFAC test disk. All of this data plugs into the recipe I have allocated for this project in my account at Insight-live.com, you can it here on the inset screenshot. Next I’ll set these on our staging shelf for firing in the test kiln (we accumulate test bars for 16 temperatures).

Measuring the length of an EPK test bar to get its drying shrinkage

This picture has its own page with more detail, click here to see it.

A 10cm mark was made in the plastic bar during preparation (we dip the ends of the marker-tool into talc powder, as a parting agent, to get a crisp mark). These bars are made from the same clay, a shipment of EPK kaolin, each bar is measured dry, fired at its assigned temperature and measured again (to supply data for the SHAB test). As fired length numbers become available and are entered into the recipe record, Insight-live is able to calculate and display more of the drying and fired shrinkages. Values for the DFAC test disk and the LDW test bar can also be assessed an entered at this time.

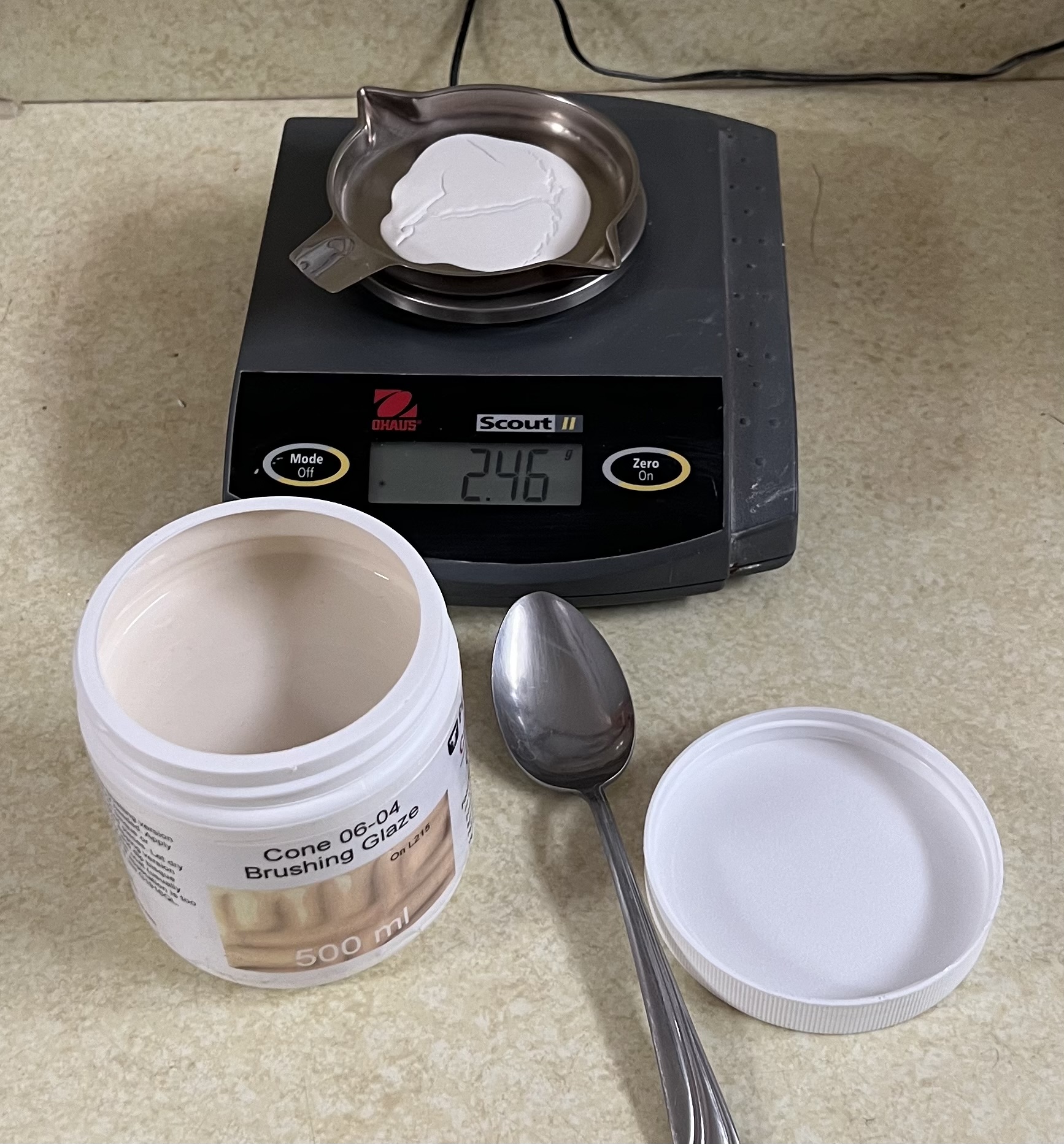

Testing the water content of a ceramic glaze

This picture has its own page with more detail, click here to see it.

In this case I need to know the water content of a glaze to know how many grams of CMC gum to add to achieve a 0.5% addition (to improve brushing properties). I put a teaspoon of the glaze (well stirred) on the tray. It weighed 5.04g (this 0.01g scale is accurate to 1/100th of a gram). Then I dried it under a heat lamp and now it weighs 2.46g. The water content of the slurry is thus (5.04 - 2.46) / 5.04 * 100 = 51.2%. That means the solids content is 100 - 51.2 = 48.8%. I want to blender mix 0.5% CMC into this brushing glaze (because it is drying too fast). The jar with glaze weighs 680g and the jar itself weighs 35g. Thus 680-35=645. 48.8% of 645 is 315g of powder. 0.5% of 315 is 315 * .005 = 1.6g of CMC gum.

Variables

H2O - % Water (C)

Wet Weight - Dry Weight / Wet Weight * 100

LOI - LOI (C)

Dry Weight - Fired Weight / Dry Weight * 100

DENS - Grams/cc (C)

Oil Weight / (Oil Weight - Immersed Weight)

WWGT - Wet Weight (V)

Enter the weight of the freshly prepared sample. This should have been written on the sample when it was made.

DWGT - Dry Weight (V)

Enter the weight of the sample after thorough drying. This should be written on the sample in ceramic pencil. It is important that the specimen be dried for several hours in at 100C+. Failure to do this can easily result in 0.5% errors.

Very fine clays (i.e. mix of 10% raw bentonite with 90% calcined bentonite) can have a water content of 40%. Coarser clays will have good workability at 18-20%.

Enter the weight of the specimen after firing. Specimens must be fired to a consistent temperature, i.e. cone 06.

OWGT - Oiled Weight (V)

Enter the weight of the specimen after it has dried after being immersed in a liquid the will prevent water absorption during weighing under water (i.e. silicone sealant, wax emulsion, brick or concrete sealer).

IWGT - Immersed Weight (V)

Enter the weight of the sample under water. When weighing, be sure the scale is zeroed, the sample is completely under the surface, and no air bubbles are trapped on its lower surface.

Procedure

1. Purpose

This test measures water content, LOI, and density all from the same test specimen. It should be done using small samples which are big enough to stamp and write weights on, but small enough to be able to weigh on a scale designed to provide the ability to suspend objects under water. Density is measured on the principle that water buoys up an object by a force equal to the weight of the water it displaces. That means the difference between the weight of an object in air and under water equals the weight of the water it displaces. Since water weighs 1 gram/cc, the difference is also the objects volume in cc.

L.O.I. is expressed as a percent loss in weight. This figure is derived by preparing clay bars, drying thoroughly above the boiling point, weighing, firing past sintering, (about cone 04) then weighing again, and calculating the percent loss in weight. This loss in weight can be due to organic material in the clay (coal, wood etc), water of crystallization, and the liberation of various gases by chemical processes taking place on heating. Different types of clay minerals have different LOI's. (ie. Kaolin loses 13-15% of crystal water) A typical L.O.I. for a native pottery clay is between 4 and 8%. If the bulk of weight loss is from coal and carbonaceous matter, problems like pinholing, pitting of the surface, and black coring in reduction can result (black coring causes weakening and changes in thermal expansion). Ball clays are commonly high in carbon and organic content. Keeping an eye on LOI helps to note differences in mineralogy, likelihood to pinhole or bloat, and tendency to produce fumes during firing.

It is best to intermesh the procedure for this test with the SOLU and SHAB tests, making the specimens for each at the same time.

Related information on the theory, purpose, procedure and interpretation for this test is available in the Magic of Fire II book.

Related Information

Videos

Links

| Articles |

Simple Physical Testing of Clays

Learn to test your clay bodies and clay materials and record the results in an organized way, understanding the purpose of each test and how to relate its results to changes that need to be made in process, recipe and materials. |

| Articles |

Formulating a Porcelain

The principles behind formulating a porcelain are quite simple. You just need to know the purpose of each material, a starting recipe and a testing regimen. |

| Articles |

Setting up a Clay Testing Program in Your Company or Studio

Set up a routine testing pipeline and start generating historical data that will enable your staff to understand your source materials and maintain, adjust and troubleshoot your clay body recipes. |

| Tests |

Borate LOI

|

| Tests |

Clay Water Content - Powder, Plastic

|

| Tests |

Shrinkage/Absorption Test

SHAB Shrinkage and absorption test procedure for plastic clay bodies and materials |

| Tests |

LOI (100-1000C)

Measure how much weight a dried clay test bar loses as it is fired in a kiln |

| Tests |

Moisture Content - Powder

|

| Tests |

Density (Specific Gravity)

Measure the density of a dried clay test bar |

| Tests |

Wet Sieve Residue

Make a quick determination of oversize particles by washing a measured amount of powder through a 150 or 200 mesh sieve. |

| Tests |

Drying Factor

The DFAC Drying Factor test visually displays a plastic clay's response to very uneven drying. It is beneficial to show the relative drying performance of different clays. |

| Glossary |

LOI

Loss on Ignition is a number that appears on the data sheets of ceramic materials. It refers to the amount of weight the material loses as it decomposes to release water vapor and various gases during firing. |

| Glossary |

Water Content

|

| URLs |

https://insight-live.com/insight/help/It+Starts+With+a+Lump+of+Clay-433.html

Case Study: Testing a Native Clay Using Insight-Live.com |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy