| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

3B Clay

Alternate Names: B, PR#3 B, B clay

Description: Buff firing highly vitreous, plastic, very smooth stoneware clay

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| Na2O | 0.10% | 0.01 | |

| Al2O3 | 17.70% | 1.00 | |

| MgO | 0.60% | 0.09 | |

| SiO2 | 67.80% | 6.50 | |

| K2O | 2.70% | 0.17 | |

| CaO | 0.24% | 0.02 | |

| P2O5 | 0.02% | - | |

| TiO2 | 0.70% | 0.05 | |

| Fe2O3 | 1.30% | 0.05 | |

| MnO | 0.01% | - | |

| LOI | 6.50% | n/a | |

| SO3 | 0.10% | n/a | |

| Oxide Weight | 525.39 | ||

| Formula Weight | 562.51 | ||

Notes

A buff firing stoneware clay that densifies to zero porosity around cone 6 (or below). It is mined at Ravenscrag, Saskatchewan, Canada by Plainsman Clays. It is part of the Whitemud formation. It has pottery plasticity (suitable as-is for modelling or on a potter's wheel) and is can be processed to be exceptionally smooth. It makes up a significant percentage of many of the bodies produced by Plainsman Clays.

Online, you might see this referred to as MNP (Mother Nature's Porcelain), this is a reference to how it can be processed (impurity particles removed) to be smooth and vitreous (it does not fire white like porcelain, rather to a light tan). This processed form has extreme stability when fired to temperatures far higher than its initial vitrification range. These properties also make it a good base for making engobes and underglazes.

This material can be synthesized using a 60:40 mix of ball clay and nepheline syenite or feldspar. Tune the degree of fired maturity by adjusting that ratio.

There is some argument about whether the mineralogy of 3B should be muscovite or illite. Here is the comment of one technician: "With regards to illite or muscovite, the only way to categorically differentiate between the two is to determine the layer charge (most easily by electron microscopy), which I didn't do. In this sample, the mica component has no detectable expandability, which suggests a high-charge mica with very little depotassification typical of muscovites. Also, the x-ray scattering domain size is quite large with minimal disorder, which you seldom find in illite, but is expected for muscovite. However, the kaolinite in the sample is extremely fine as one would see in fireclays. 41% quartz in the sample is accurate. You can easily verify this from your chemistry by checking the contributions of muscovite, kaolinite, smectite and K-spar to the total SiO2, and constraining potassium to muscovite and K-spar, and Mg to smectite. From my experience, a high plasticity and the apparent illitic properties that you see in the clay is most likely due to the discrete smectite content (8%). Note that the activity of smectite is several orders of magnitude (up to 10 times) greater than the finest kaolinite or illite."

Major trace elements:

424 Ba ppm

34 Sr pmm

24 Y ppm

10 Sc ppm

249 Zr ppm

1 Be ppm

65 V ppm

Related Information

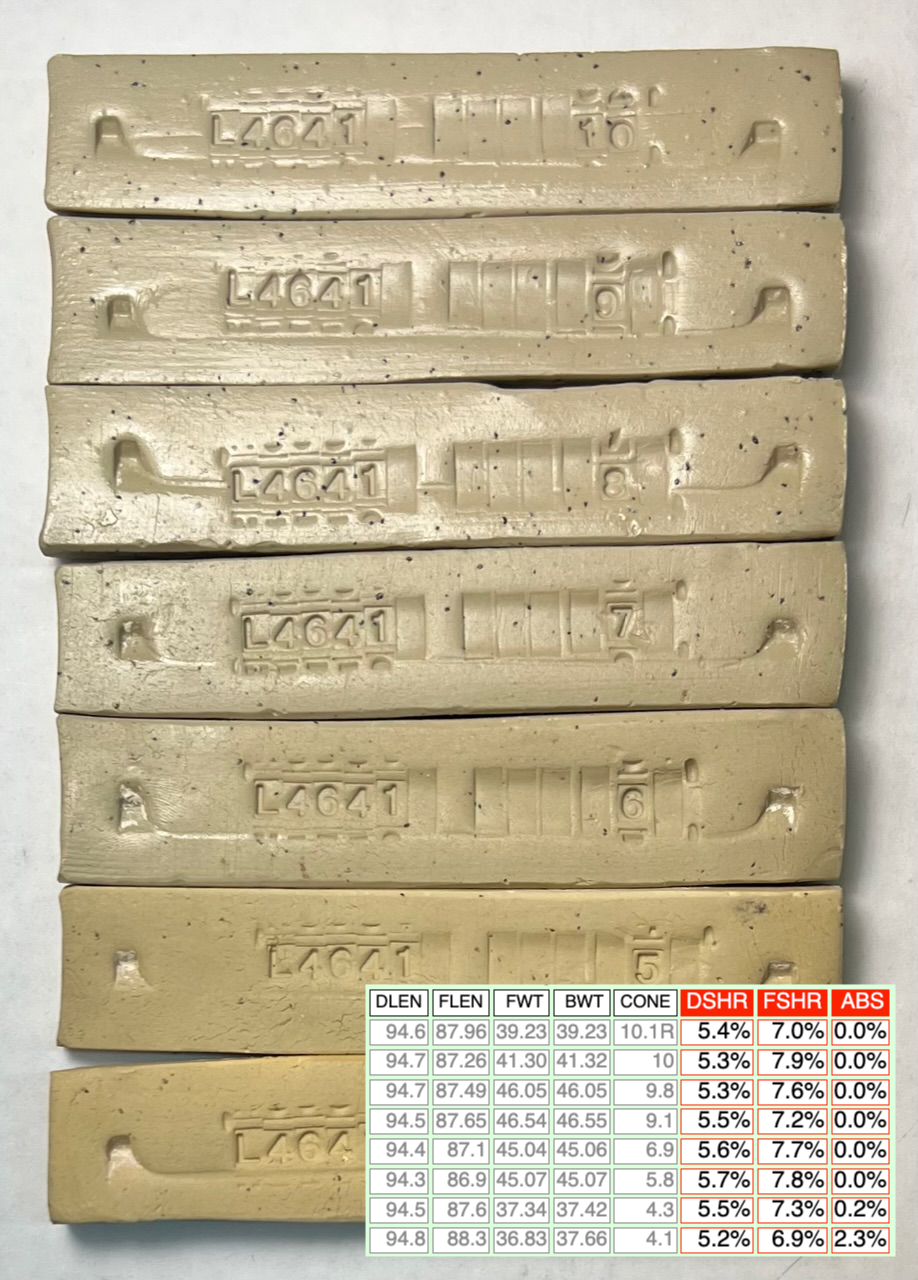

Plainsman 3B fired bars

This picture has its own page with more detail, click here to see it.

These show it to be very vitreous, reaching zero porosity shortly after cone 4. It is also very stable in firing, not melting or bloating all the way to cone 10. This is the raw slaked material so iron specks are visible, these blossom in reduction firing.

Mel Noble at Plainsman Clay's Ravenscrag, Saskatchewan quarry

This picture has its own page with more detail, click here to see it.

Six different sedimentary clays are extracted from this quarry. It was opened in the 1970s, the best location available at the time. These test bars were made by slaking select lumps from each layer (thus exhibiting their best performance). The left-most dried test bars show the layers (top to bottom). The A1 top layer is the most plastic and has the most iron contamination (it is used in the most speckled reduction firing bodies). A2, the second one down, is a ball clay (similar to commercial products, although darker burning), it is very refractory and the base for Plainsman Fireclay. A3, third from top, is a complete buff high-temperature stoneware (like H550), although sandy and over-mature at cone 10. 3B, third from bottom, is a smooth medium-temperature stoneware; it contains significant natural feldspar (although fired color and particulate contamination are the most variable). The second from the bottom, 3C. fires the whitest and is the most refractory (it is the base for H441G). The bottom one, 3D, the best product in the quarry. Although the least plastic and most silty, it is also very fine particled and the cleanest (consistently free of particulate impurities and sand), it pairs very well with a ball clay to make a cone 6 stoneware.

When a DIY black underglaze makes sense

This picture has its own page with more detail, click here to see it.

Black brushwork needs to go on thick enough in one brushstroke. Commercial products we have don't do that - thus my motivation to work on this. Another issue is that they try to cover too wide a firing range (thus they melt too much at the high end and not enough at the low end). I am experimenting on cone 6 Polar Ice porcelain jiggered bowls using G2926B dipping glaze. The base underglaze recipe here is a 90:10 MNP:nepheline syenite mix (you could use your own porcelain instead of MNP and feldspar instead of nepheline). To that, I add 15% black stain, 1.5% CMC gum and 5% bentonite. With the CMC gum and bentonite, and blender mixing, a brushable consistency that stays put can be achieved at a fairly low water content compared to commercial products (enabling it to go on thicker in a single brush stroke). Assuming application at leather hard state, the drying and firing shrinkage can be matched to the body by varying the plasticity of the porcelain used (e.g. the percentage of bentonite it contains). And the percentage of stain can be tuned for enough color but no bleeding, bubble clouding or crystallization. And we can adjust the degree of maturity by varying the proportions of MNP and Nepheline (commercial underglazes often melt too much by cone 6 and fade and diffuse as a result), this one stays opaque black.

Underglazes suitable for making silk screen transfers are another special case. The ideal one needs to cover well like this one. But it also needs to gel and harden enough to hang onto the paper but not so hard that it does not separate and transfer to the ware. Commercial products for brushing are unlikely to be optimal so it makes sense to mix your own and experiment with different amounts of gum.

Mother Nature's porcelain - From the Cretaceous period

This picture has its own page with more detail, click here to see it.

During a 6 week of mining in 2018 in Ravenscrag, Saskatchewan we extracted marine sediment layers of the late Cretaceous period. The center portion of the "B layer", as we call it, is unbelievably fine particled (impossibly smooth, like a body that is pure terra sigillata)! The feldspar and silica are built-in, producing a glassy body surface, starting at cone 4 and lasting to cone 8. Despite this, pieces don't warp in firings! I have not glazed the outside of this mug for demo purposes. I got away with it this time because the Ravenscrag clear glaze GR6-A is very compatible (the thermal expansion is high enough to avoid glaze compression issues and low enough not to craze). With other less compatible glazes these mugs cracked when I poured in hot coffee. To make this body I am slurrying it up as a slip and processing it to 325 mesh (using a vibrating sieve).

Calculating the highest % of 3B clay to create a glaze recipe

This picture has its own page with more detail, click here to see it.

In this screenshot I am comparing the chemistries of two recipes. The recipes are different but the chemistries are the same. On the left, Plainsman 3B (also known as MNP) is being using to source almost all of the Al2O3 (the red box) needed by the recipe (to match our standard cone 10R transparent G1947U, on the right). The KNaO is being sourced from the frit rather than feldspar (this is really good because it has almost no Al2O3 so all of it can be sourced from the 3B clay). Only silica and calcium carbonate are needed to bring the SiO2 and CaO up to match.

Incredible Mother Nature’s porcelain

This picture has its own page with more detail, click here to see it.

This is made from 100% of a natural clay (3B) from the Whitemud formation in Ravenscrag, Saskatchewan. To make this body, which I call MNP, I slake and slurry up the raw clay lumps, sieve it to 200 mesh and then dewater on a plaster table. I rolled the plastic clay into a thin layer, cut it into a cross-shape using a 3D printed cookie-cutter, drape-molded it over a plaster form and then slip-joined the seams. It fires very dense and strong (to zero porosity like glass!). It holds together well and joins well with its own slip. Although not super plastic, it is smooth and fine-grained like a commercial porcelain body. I add 1-2% bentonite to make it more plastic when needed. It can be rolled extremely thin and yet does not warp in the firing! This mug has a weight-to-volume ratio of 2.08 (the weight of water it will hold compared to its own weight).

Ravenscrag Saskatchewan clays fired at cone 10R

This picture has its own page with more detail, click here to see it.

Glazeless (top) and with glaze (bottom): A1 (bentonitic), A2 (ball clay), A3 (stoneware), 3B (porcelains), 3C (lignitic ball clay), 3D (silt). The bottom row has also shows soluble salts (SOLU test).

Links

| Minerals |

Quartz

Quartz is the most abundant mineral on earth, it is the main crystalline mineral form of silica (SiO |

| Minerals |

Kaolinite

The most fundamental clay mineral. This mineral is found in nature in its purest form as kaolin. How |

| Minerals |

Smectite

A highly plastic clay mineral related to montmorillonite (bentonite), more correctly, the name of th |

| Minerals |

Muscovite

A form of mica often found as micro-flakes in processed raw clays. It can often be found in the mine |

| Minerals |

Illite

A clay. A sedimentary weathered alteration of muscovite mica. Some stoneware clays contain illite. I |

| URLs |

https://plainsmanclays.com/data/index.php?product=12901

B Clay Data Sheet |

| Materials |

A3 Stoneware Clay

A buff burning, high temperature somewhat sandy stoneware having ready-to-use plasticity. |

| Typecodes |

Clay Other

Clays that are not kaolins, ball clays or bentonites. For example, stoneware clays are mixtures of all of the above plus quartz, feldspar, mica and other minerals. There are also many clays that have high plasticity like bentonite but are much different mineralogically. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy