| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Grolleg Kaolin

Alternate Names: Grolleg China Clay

Description: Fine White Burning English Kaolin, English China Clay

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| CaO | 0.10% | - | |

| K2O | 1.90% | 0.06 | |

| MgO | 0.30% | 0.02 | |

| Na2O | 0.10% | - | |

| TiO2 | 0.03% | - | |

| Al2O3 | 37.00% | 1.00 | |

| SiO2 | 48.00% | 2.20 | |

| Fe2O3 | 0.70% | 0.01 | |

| LOI | 12.01% | n/a | |

| Oxide Weight | 242.95 | ||

| Formula Weight | 276.11 | ||

Notes

A blended English china clay, combining moderate plasticity, low titania content and relatively high flux content, low shrinkage and blue-white fired color. The low TiO2 content is a key factor for the usefulness of Grolleg. It is excellent for making translucent throwing or casting porcelains. The pottery community uses many Grolleg based porcelains.

Its chemistry is different from a typical North American kaolin, it contains some fluxing oxides (e.g. it has almost 2% K2O). Thus porcelain bodies employing it require quite less feldspar to vitrify (5-10% at cone 10, for example).

For use in plastic porcelains there is a dilemma that body formulators face: This material has a lower plasticity than American materials like EPK and much lower than #6 Tile and Sapphire kaolins. Thus porcelain bodies employing it require additions of a plasticizer like bentonite (up to 5% to get high plasticity). Since raw bentonites having the necessary plasticity are also exceptionally high in iron, people must balance the advantages of using a white burning and more costly material like Grolleg against the lower plasticity that makes the addition of dirty plasticizers necessary. Theoretically making translucent bodies employing 5% bentonite having 5% iron content should only increase iron in the body by 0.25%. This does not sound like much, but it is. Bodies having 0.1% iron burn much whiter than those having 0.2%. Thus either lower plasticity should be tolerated or white plasticizers (like VeeGum or Bentone) should be used.

Glazes: While the chemistry difference between this and more typical kaolins is certainly worth noting for bodies, it is still likely close enough to the theoretical 1:2 alumina:silica to be substituted in recipes that call for kaolin or china clay. Grolleg may also be preferred because the titania in other kaolins can be detrimental to the development of a color (e.g. titanium can turn celadons to a greenish tint). Transparent glazes employing Grolleg as-the-kaolin used over Grolleg-based porcelains can produce very white and even blue-white color in reduction firing. Another factor making this material an excellent glaze suspender is its inherent stickiness, which is exhibited to a degree much in excess of its actual plasticity. This property also makes for great hardening and durability of the dried glaze layer. New Zealand kaolin has similar properties are can normally be substituted for Grolleg.

As far as commonly available materials in North America, Grolleg competes against New Zealand Halloysite where the whitest possible result is desired.

Modulus of Rupture, Kgf/cm2

At 80% Relative Humidity: 10.0

Dried at 110C: 25.7

Casting Rate @ 63% solids (mm2/min): 0.8

% P84 Deflocculant Required for 5 Poise Slip: 0.65

1180C 1280C 1410C

Brightness: 86 86 75

Related Information

A Grolleg based porcelain vs. a ball clay and American kaolin porcelain

This picture has its own page with more detail, click here to see it.

These mugs were fired in the same kiln load at cone 10R and have the same clear glaze, G1947U. The mug on the left is a Grolleg kaolin (52% Grolleg kaolin, 24% silica and 19% Mahavir feldspar, 5% bentonite). The one on the right is 15% M23 ball clay, 40% #6 Tile kaolin, 15% Nepheline, 25% silica, 3% bentonite. Clearly, the Grolleg porcelain fires so much whiter.

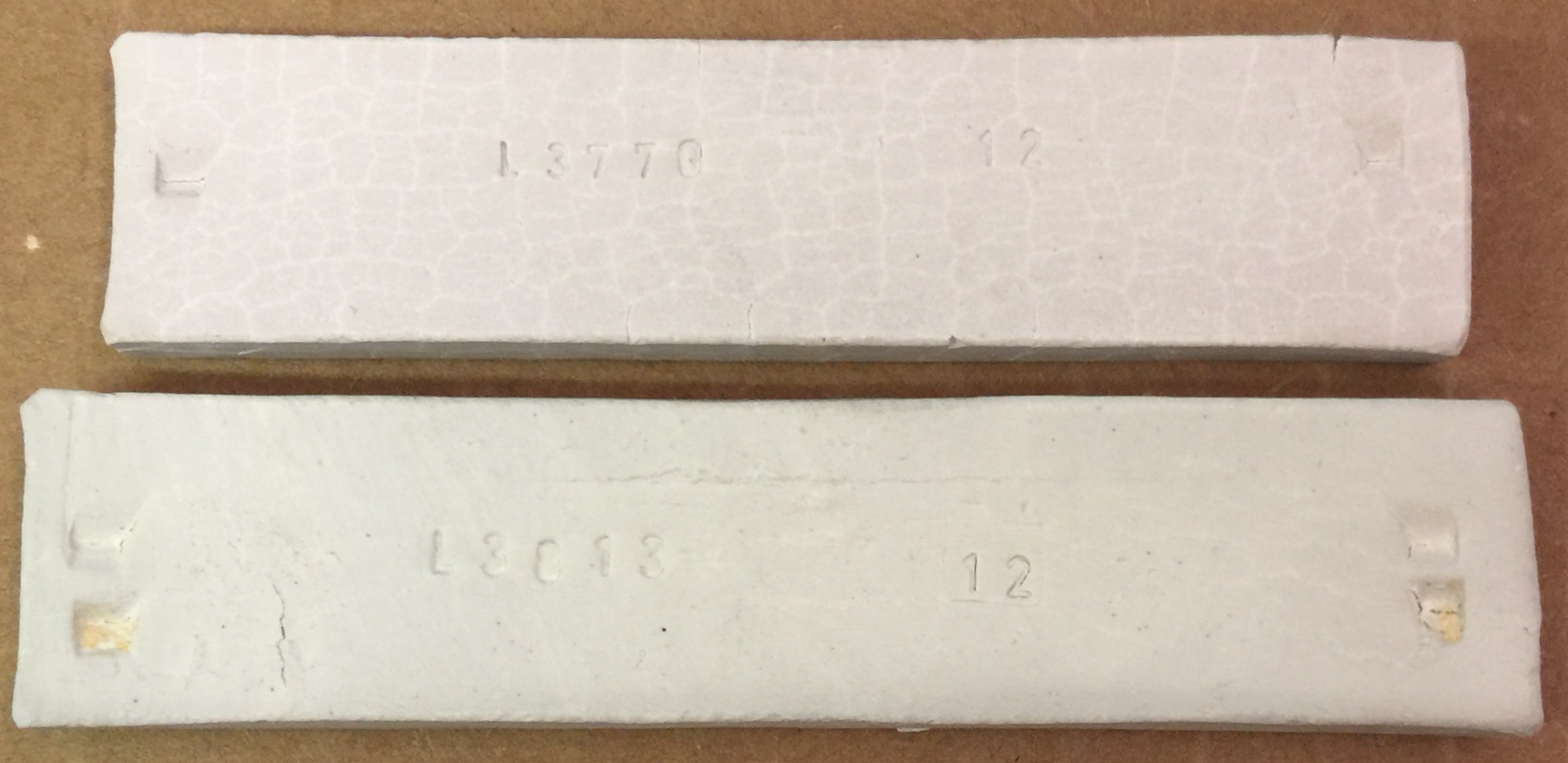

EPK fired bar (top) vs Grolleg kaolin at cone 10R. Why shrinking more?

This picture has its own page with more detail, click here to see it.

From these SHAB test bars EP kaolin appears to have a much higher fired shrinkage. But half of that happened during drying. Still, EPK shrinks 4% more during firing. Yet Grolleg produces more vitrified porcelains. The EPK bar also appears to be whiter. Yet in a porcelain body, Grolleg fires whiter. That higher drying shrinkage proves that EPK is much more plastic, right? Not really. Throwing porcelains containing either require plasticity augmentation using similar percentages of bentonite. What do we learn? To compare materials like this we need to see them "playing on the team", in a recipe working with other materials. Don't rely on material data sheets, do the testing in your recipes.

Zero4 porcelain mugs using New Zealand and Grolleg Kaolins

This picture has its own page with more detail, click here to see it.

Both of these Zero4 fritware porcelain mugs were bisque fired at 1450F and glaze fired at cone 04. The Grolleg version of the porcelain is burning a much pinker color (both the bare body and under our G1916Q3 glaze). In typical feldspar porcelains the color difference between these two kaolins is not nearly so much but here the extra glass development is likely amplifying the presence of even just a little more iron oxide.

Does Grolleg whiten a glaze the same as it does a body?

This picture has its own page with more detail, click here to see it.

Yes. The two specimens are both the same Grolleg-based porcelains. Both of them are glazed with the same glaze: 1947U transparent. But the glaze on the left is using EP Kaolin and the one on the right Grolleg kaolin. The Grolleg glaze is dramatically better, the color has a bluish cast that is more attractive. The Grolleg does not suspend the slurry as well, however it responds well to gelling (using vinegar, for example) more than compensating to create an easy-to-use suspension.

Do not rely on material data sheets, do the testing

This picture has its own page with more detail, click here to see it.

The cone 6 porcelain on the left uses Grolleg kaolin, the right uses Tile #6 kaolin. The Grolleg body needs 5-10% less feldspar to vitrify it to zero porosity. It thus contains more kaolin, yet it fires significantly whiter. Theoretically this seems simple. Tile #6 contains alot more iron than Grolleg. Wrong! According to the data sheets, Grolleg has the more iron of the two. Why does it always fire whiter? I actually do not know. But the point is, do not rely totally on numbers on data sheets, do the testing yourself.

How much feldspar should be used in a Grolleg porcelain?

This picture has its own page with more detail, click here to see it.

These are cone 10R porcelains made using Grolleg kaolin, feldspar and silica. Plainsman P700 (left) has 20% G200 Feldspar. Coleman porcelain (popular among potters in the US) has 30% of the same feldspar. The Coleman porcelain is certainly more vitreous. In fact, it is too vitreous. It is much more likely to warp during firing. And, it is much more problematic with regard to plucking (lower left), foot rings glue to even kiln-washed shelves. But, notice that the Coleman porcelain is not any more translucent than P700 (it appears less so because I could not throw it as thin). So why is 30% feldspar even used? I have a theory: American kaolins do require 30% feldspar to vitrify at cone 10, but not Grolleg. it contains significant natural feldspar, so much so that far less feldspar is needed in the recipe. I think that, in the past, Grolleg was simply substituted for an American kaolin a standard recipe. P700 benefits in a special way by recognizing this different in Grolleg: It dedicates the 10% gain to kaolin, increasing body plasticity. On top of that it adds bentonite, producing a porcelain whose high plasticity would come as a shock to people used to the Coleman body.

Ball clay vs. Kaolin porcelain at cone 6

This picture has its own page with more detail, click here to see it.

Left: A porcelain that is plasticized using only ball clays (Spinx Gleason and Old Hickory #5). Right: Only kaolin (in this case Grolleg). Kaolins are much less plastic so bentonite (e.g. 2-5%) is typically needed to get good plasticity. The color can be alot whiter using a clean kaolin, but there are down sides. Kaolins have double the LOI of ball clays, so there are more gasses that potentially need to bubble up through the glaze (ball clay porcelains can produce brilliantly glassy and clean results in transparent glazes even at fast fire, while pure kaolins can produce tiny dimples in the glaze surface if firings are not soaked long enough). Kaolins plasticized by bentonite often do not dry as well as ball clays even though the drying shrinkage is usually less. Strangely, even though ball clays are so much harder and stronger in the dry state, a porcelain made using only ball clays often still needs some bentonite. If you do not need the very whitest result, it seems that a hibrid using both is still the best general purpose, low cost answer.

Grolleg vs New Zealand - Which kaolin is better for translucency?

This picture has its own page with more detail, click here to see it.

The NZK body, Polar Ice, is on the left. The Grolleg one, L3778D, is on the right. They are not the same recipe, the feldspar content in the L3778D has been adjusted to match the degree of vitrification (Grolleg contains some feldspar). Clearly, the NZK has better translucency. And it fires whiter.

Reduction and oxidation porcelains

This picture has its own page with more detail, click here to see it.

Left: Cone 10R (reduction) Plainsman P700 porcelain (made using Grolleg and G200 Feldspar). Right: Plainsman Cone 6 Plainsman Polar Ice porcelain (made using New Zealand kaolin and Nepheline Syenite). Both are zero porosity. The Polar Ice is very translucent, the P700 much less. The blue coloration of the P700 is mostly a product of the suspended micro-bubbles in the feldspar clear glaze (G1947U). The cone 6 glaze is fritted and much more transparent, but it could be stained to match the blue. These are high quality combinations of glaze and body.

Why mid-fire Grolleg porcelain is ideal for both throwing and casting

This picture has its own page with more detail, click here to see it.

The very whitest porcelains are made from New Zealand kaolin. However, while Grolleg kaolin does not fire quite as white, it requires up to 10% less feldspar to produce a vitreous porcelain (it contains natural feldspar). That 10% less spar can be made up in kaolin, imparting better workability and dry strength to the body (and Grolleg is known for its dry strength). Assuming that 25% silica is needed for glaze fit, one only needs to discover what blend of feldspar and kaolin in the remaining 75% achieves the desired degree of vitrification (e.g. we like zero porosity just-reached at cone 6). We found 25% nepheline was too vitreous (pieces warped) and at 20% porosity was not yet zero. While the Grolleg version fires a little darker, the better workability imparted by the extra kaolin makes up for that. The plasticity needed for good throwing requires the addition of bentonite (4% for NZK and 3% for Grolleg). Both of these can be made into casting bodies by reducing the amount of bentonite (~ 1% for NZK, 0.5% for Grolleg). Do your testing to discover the % of bentonite needed for the leather hard to pull away from a mold without cracking but not take too long to cast.

Links

| Minerals |

Mica

See Muscovite. |

| Minerals |

Kaolinite

The most fundamental clay mineral. This mineral is found in nature in its purest form as kaolin. How |

| Materials |

Standard Porcelain Kaolin

|

| Materials |

Super Standard Porcelain

|

| Materials |

NSC Kaolin

|

| Materials |

Remblend Kaolin

|

| Materials |

Treviscoe Kaolin

|

| Materials |

Kaolin

The purest of all clays in nature. Kaolins are used in porcelains and stonewares to impart whiteness, in glazes to supply Al2O3 and to suspend slurries. |

| Materials |

New Zealand Halloysite

The whitest burning kaolin we have ever seen. It is very sticky when wet, suspends glazes well & makes super white porcelain (with help from a white bentonite). |

| Materials |

KaoPearl CNL30 Kaolin

|

| Typecodes |

Kaolin

Pure clay mineral, there are many brand names of varying purity and iron content. |

Data

| Firing Shrinkage | 1180C 0% 1280C 14% 1410C 18% |

|---|---|

| Frit Softening Point | 3000F |

| Ultimate Particle Size Distribution | >53 microns .05 max >10 microns 10 <2 microns 57 |

| Water absorption | 1180C 14% 1280C 6% 1410C 0.5% |

Mechanisms

| Body Maturity | The use of kaolins containing significant alkalies is an excellent way to achieve greater body maturity coupled with white color. Lower feldspar enables replacing dirty ball clays with kaolin. |

|---|

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy