| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

CuO (Cupric Oxide)

Data

| Frit Softening Point | 1336C (From The Oxide Handbook) |

|---|

Notes

-Copper can be produced from many different raw materials, the main being black tenorite (CuO), deep red cuprite (Cu2O), bright green malachite (CuCO3.Cu(OH)2), and bright blue azurite (2CuCO3.Cu(OH)2).

-Under normal oxidizing conditions the CuO molecule remains unchanged and produces clear green colors in oxidation glazes. The shade of copper greens can vary with firing rate and soaking changes. The best colors are generally obtained with fast firing and little soaking. CaO is unlikely to affect the color of copper in a glaze.

-Copper is well-known for its ability to produce blood-red and fire-red colors in reduction atmosphere firings where it is altered to Cu2O (see Cu2O). Purple copper reduction glazes are the result of a mixture of copper in its green oxidized and red reduced forms. This effect appears most frequently in high lime glazes or where early stages of firing are oxidizing or latter stages are light or neutral.

-Copper is a strong flux and even 2% can considerably increase the melt fluidity of a glaze.

-Generally additions of copper to a glaze will reduce its thermal expansion. That means that the base clear might craze, yet the version with significant copper added will not.

-Crystalline glazes can be attractive when done with copper.

-Copper and titanium can produce beautiful blotching and specking effects.

-Pure copper metal filings can make an extremely potent specking material (and contaminant, depending on your viewpoint) in reduction firing for both bodies and glazes.

-Leaching: When added to low lead solubility glazes copper can cause the solubility of the lead to be greatly increased. Copper is well known for this effect in glazes at other temperatures also. Do a leaching test to be sure.

-In the enameling industry, copper is used in combination with small quantities of cobalt, manganese, or nickel in making black where the black is produced in the smelter.

The same copper red glaze on the inside and outside of a vase

This picture has its own page with more detail, click here to see it.

The Copper Red effect shows the importance of correct firing to achieve a specific effect with certain glaze recipes. The inside of this vase was more heavily and consistently reduced, simply because it was isolated somewhat from the outside kiln atmosphere. The outside of the vase, by contrast, is grey (a product of periods of oxidation during the firing).

Copper oxide (2%) in an otherwise stable cone 6 oxidation glaze fluxes it

This picture has its own page with more detail, click here to see it.

How do metal oxides compare in their degrees of melting?

This picture has its own page with more detail, click here to see it.

These metal oxides have been mixed with 50% Ferro frit 3134 and fired to cone 6 oxidation. Chrome and rutile have not melted, copper and cobalt are extremely active melters, frothing and boiling. Cobalt and copper have crystallized during cooling. Manganese has formed an iridescent glass.

Copper can destabilize a glaze and make it soluble

This picture has its own page with more detail, click here to see it.

A closeup of a glossy Cone 6 glaze having 4% added copper carbonate. The bottom section has leached in lemon juice after 24 hours. This photo has been adjusted to spread the color gamut to highlight the difference. The leached section is now matte.

Copper carbonate powder

This picture has its own page with more detail, click here to see it.

Ceramic Oxide Periodic Table

Pretty well all common traditional ceramic base glazes are made from less than a dozen elements (plus oxygen). Go to the full picture of this table and click or tap each of the oxides to learn more (on its page at digitalfire.com). When materials melt, they decompose, sourcing these elements in oxide form. The kiln builds the glaze from them, it does not care what material sources what oxide (assuming, of course, that all materials do melt or dissolve completely into the melt to release those oxides). Each of these oxides contributes specific properties to the glass. So, you can look at a formula and make a good prediction of the properties of the fired glaze. And know what specific oxide to increase or decrease to move a property in a given direction (e.g. melting behavior, hardness, durability, thermal expansion, color, gloss, crystallization). And know about how they interact (affecting each other). This is powerful. A lot of ceramic materials are available, hundreds - that is complicated when individual materials source multiple oxides. Viewing a glaze as a simple unity formula of ceramic oxides is just simpler.

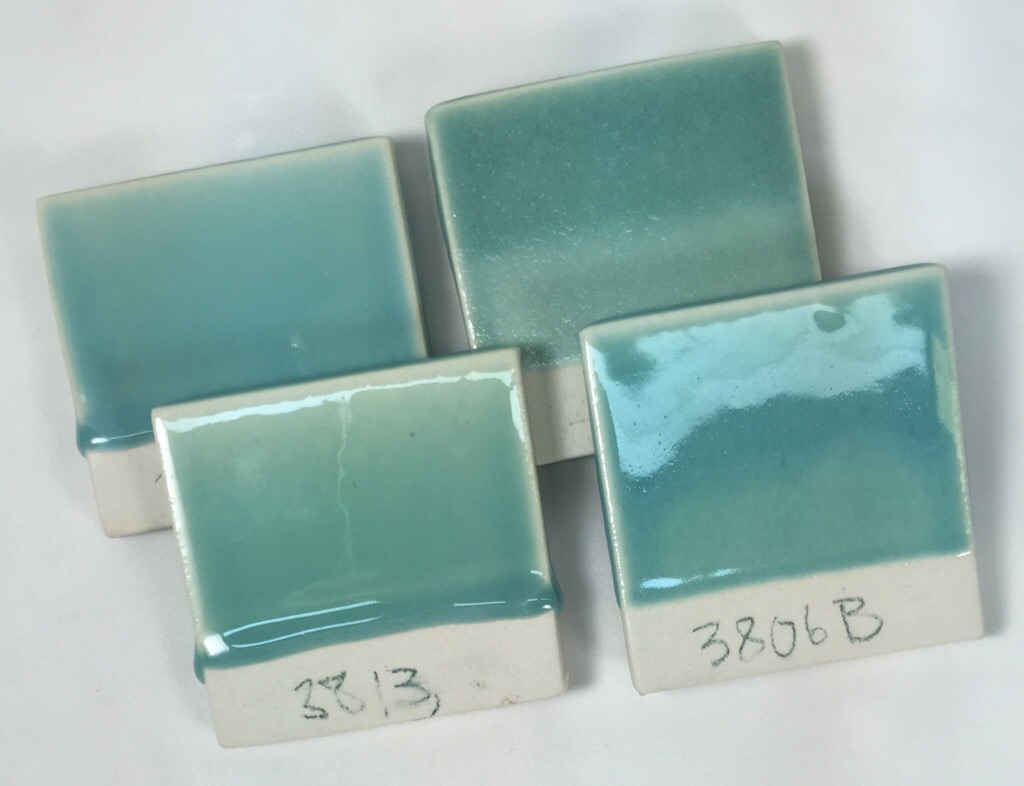

Copper does not necessarily cause glazes to leach if used in moderate amounts

This picture has its own page with more detail, click here to see it.

These are four cone 6 glazes of diverse chemistry. They have varying melt fluidities. They are soaked (halfway up) in lemon juice overnight. None show any evidence of surface changes. All contain 2% copper carbonate. If the copper was increased, especially to the point of going metallic or crystallizing, the leaching test would produce different results (especially on the ones that are running, they lack SiO2 and Al2O3). So, if you use copper sensibly (in moderate amounts), there is a good chance of making a glaze that resists leaching.

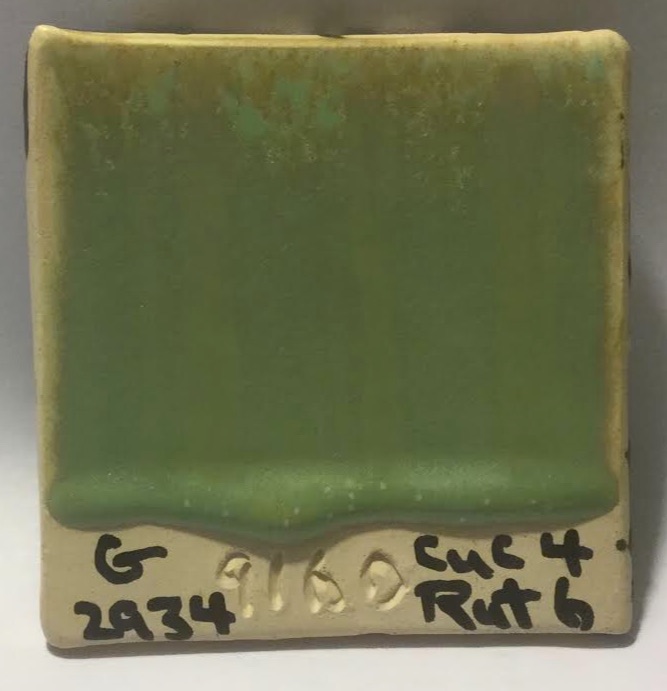

Copper fluxes a matte glaze at cone 6

This picture has its own page with more detail, click here to see it.

4% copper carbonate and 6% rutile have been added to G2934 cone 6 matte base. Using a green stain should prevent this. Or some B2O3 could be substituted with SiO2 (via glaze chemistry).

Links

| Materials |

Copper Oxide Black

The purest source of CuO copper oxide pigment used in ceramic glazes. |

| Materials |

Copper Oxide Red

|

| Materials |

Stain

|

| Materials |

Copper Carbonate

A source of CuO copper oxide used in ceramic glazes to produce a variety of colors (used only or with other colorants). |

| Materials |

Copper Carbonate Basic

This form of copper carbonate is the article of commerce, a mixture of theoretical copper carbonate and copper hydroxide. |

| Oxides | Cu2O - Cuprous Oxide |

| Tests |

Glaze Leaching Test

Simple tests to evaluate the stability of a ceramic or pottery glaze against leaching metals in food or drink. |

Mechanisms

| Glaze Color | 7% copper in glossy oxidation glazes can produce striking metallic green colors. |

|---|---|

| Glaze Color | Under normal oxidizing conditions CuO produces clear green colors in most glazes. The shade of green depends not only on the amount but also on other oxides present (i.e. lead in larger amounts will enhance and darken the green, the presence of alkalies or high boron will shift it toward blue). Copper in calcium/magnesium glazes gives a green very different from that produced with lead. |

| Glaze Color | Combinations of CuO with tin or zircon will give turquoise or blue-greens when the glaze is alkaline (KNaO) and low alumina. Look for a frit with this profile for best results. Glazes of this type often craze. |

| Glaze Color | K2O can turn a copper glaze yellowish. If Na2O or PbO are present, K2O should not exceed 0.15 equivalent. |

| Glaze Color | Copper in a barium/zinc/sodium glaze gives a blue. Color can also be enhanced by lithia. Tin and copper can produce turquoise to robin's egg blue. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy