| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Epsom Salts

Alternate Names: Magnesium Sulfate, HEPTAHYDRATE, hydrous magnesium sulphate

Description: Flocculant

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| MgO | 16.36% | 1.00 | |

| LOI | 51.14% | n/a | |

| SO3 | 32.51% | n/a | |

| Oxide Weight | 40.30 | ||

| Formula Weight | 246.48 | ||

Notes

Colorless transparent crystals. Also known as magnesium sulfate.

Magnesium sulfate most commonly employed in ceramics as a flocculant. It thickens and gels suspensions by electrostatically charging particles so that they attract each other more. This not only suspends them in the slurry but makes them stay put on non-porous surfaces (by virtue of the gelling mechanism). Even slurries containing no clay particles can be flocculated using this material. Epsom salts is generally better for flocculating ceramic glaze suspensions than vinegar (although less easily obtained). Calcium chloride is better than both (and the least easily obtained).

One strategy is to make a saturated solution (30g dissolved in 100ml of water). If the crystals are added directly it takes time for them to dissolve and act and it is easy to overdo it and thicken the slurry too much (if you do not give the crystals time to dissolve). Notwithstanding this, sprinkling in a pinch of the granules and waiting while the mixer runs for a while is tactile way of being aware how much you are using.

The addition of Epsom salts is commonly done with engobes. A gelled engobe will apply in a even coat and stay in place even though it takes time to dry. Without the epsom salt addition, it will run and drip (even with a low water content). It is better to add epsom salts as a saturated solution (rather than in powderized form) since the system is so sensitive to over-gelling if too much is added.

Epsom salt additions can be invaluable for glazes, its enables creating a thixotropic (gelled) slurry that applies evenly, holds in place and goes on in the right thickness on porous or dense bisque ware. When the slurry has a sympathetic specific gravity, about 2g per gallon of epsom salts is a good starting point (slurries containing CMC gum will not gel this way). Others may fail to gel because they lack adequate surface area to react electrolytically (e.g. they only contain kaolin, no ball clay). Surface area can be greatly increased by incorporating bentonite in the recipe. Kaolin can be substituted gram-for-gram for bentonite (they are both clays) with minimal effect on fired results. Flocculation is a delicate process, thus no recipe should specify an exactly percentage to use, each time a recipe is mixed the amount of Epsom salts should be tuned to get the rheology needed.

Some clay body manufacturers add Epsom salts to their clay mixes to improve plasticity and stabilize bodies against the thixotropic and spontaneous softening effects of certain soluble compounds in the mix (e.g. soda feldspar, nepheline syenite). It is typical to use .2-.3%.

It is sometimes said that epsom salts can be a helpful addition to glazes containing Gerstley Borate to help prevent particle agglomeration of a slurry that causes it to gel (try about 4 g per 100g of Gerstley Borate). However, this is not our experience; Gerstley Borate gels slurries on its own (in fact it is famous for over-gelling them), deflocculation seems a more logical approach.

Related Information

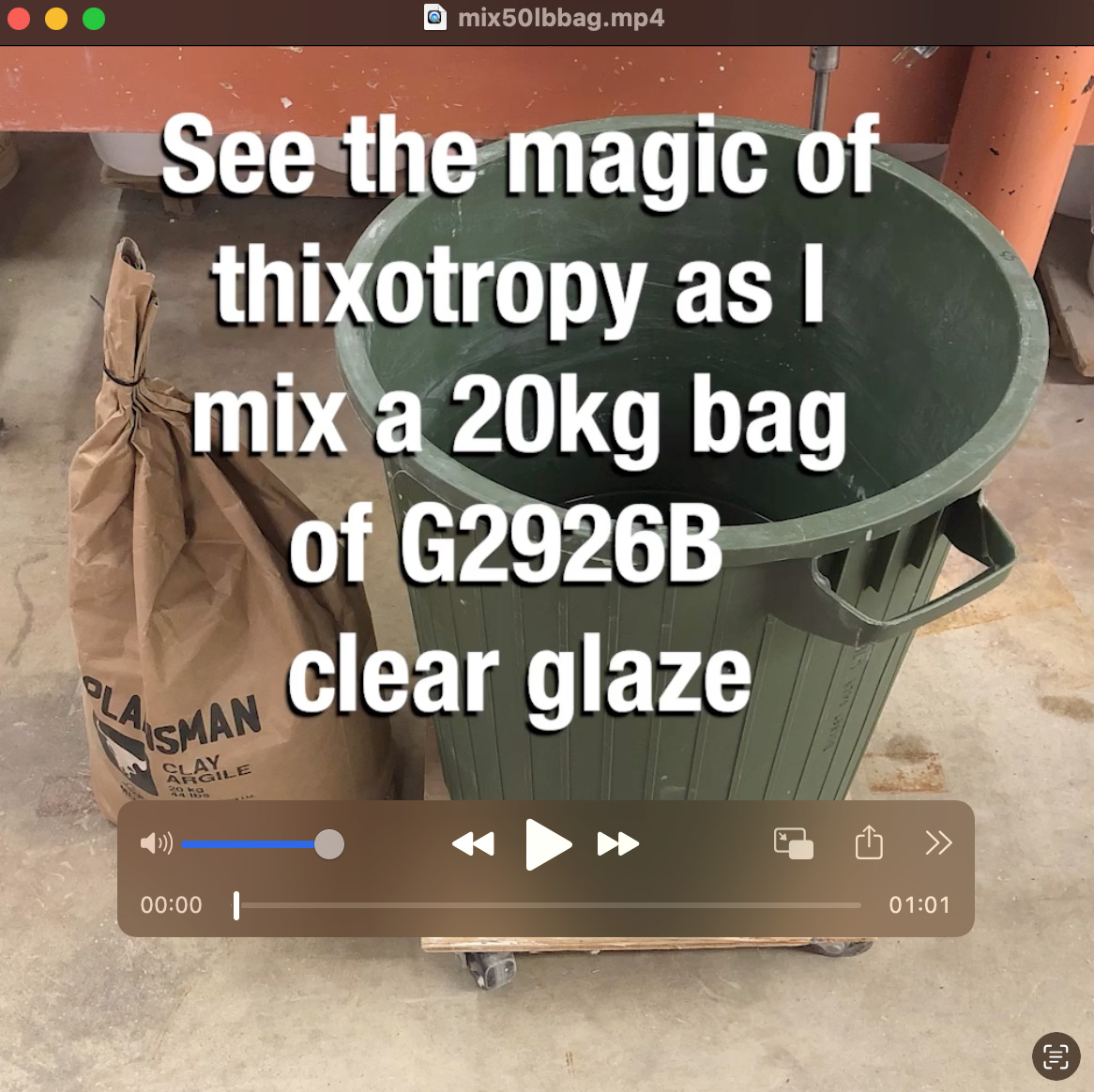

See the magic of thixotropy as I mix a 20kg batch of G2926B glaze

In this video, I mix 20kg of G2926B glaze powder into 20kg of water using our powerful propeller mixer. The resulting slurry is like water, absolutely unusable. Yet on measuring the specific gravity (using a hydrometer because it floats freely) I find that it is too high, I actually have to add more water! How is that even possible? Instead, I add Epsom salts and mix again and the slurry gels and hangs on in a perfectly even layer when I dip the spatula. This is a thixotropic gel, it will apply evenly to bisque ware yet not go on too thickly. We normally recommend a specific gravity of 1.44 for this glaze, but in this case, it seemed watery enough at 1.46 (on use, it will become clear if 1.46 is OK e.g. if it goes onto the ware too thick). If that happens I'll just add water to 1.44 (and more Epson salts if needed). Based on online pricing at this time, coverage is minimum six times and as much as twenty times less expensive than buying jars of transparent brushing glaze (considering both the total powder weight and the specific gravity difference between this and commercial glazes we use).

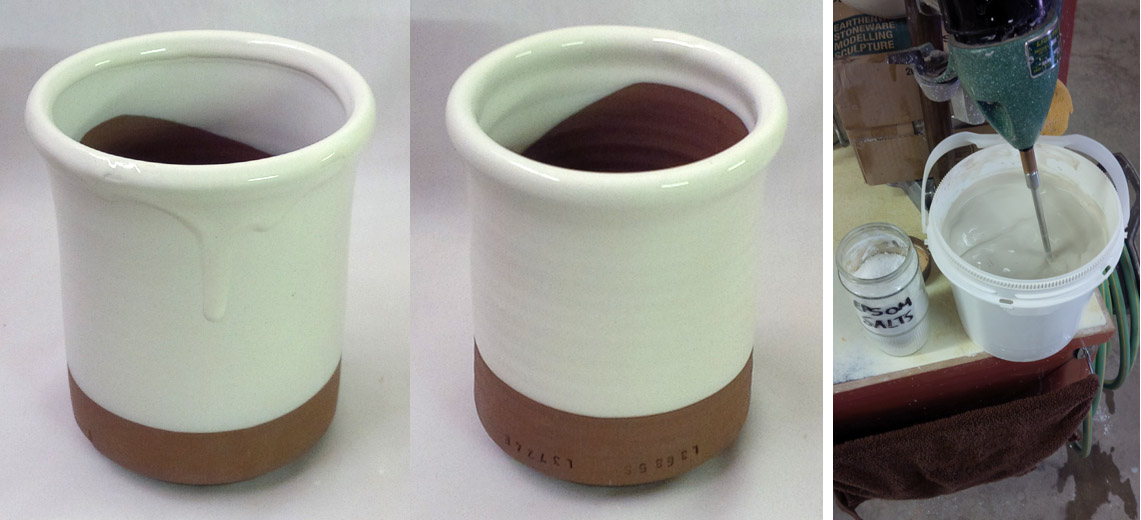

Adding water actually made this white engobe run less? How?

This picture has its own page with more detail, click here to see it.

The white slip (applied to a leather hard cup) on the left is dripping downward from the rim (even though it was held upside down for a couple of minutes!). Yet that slurry was very viscous with a 1.48 specific gravity. Why? Because it was not thixotropic. The fix? I watered it down to 1.46 (making it runny) and added pinches of powdered epsom salts (while mixing vigorously) until it thickened enough to stop motion in about 1-2 seconds on mixer shut-off. But that stop-motion is followed by a bounce-back. That is the thixotropy. It is easy overdo the epsom salts (gelling it too much), I add a drop or two of Darvan to rethin it if needed. When the engobe is right it gels after about 10 seconds of sitting, so I can stir it, dip and extract the mug, shake to drain it and then it gels and holds in place. Keep in mind, this is a pottery project. In industry they deflocculate engobes to reduce water content. But a deflocculated slurry can still be gelled (if it is runny).

The same engobe. Same water content. What is the difference?

This picture has its own page with more detail, click here to see it.

The engobe on the left, even though it has a fairly low water content, is running off the leather hard clay, dripping and drying slowly. The one on the right has been flocculated with epsom salts (powdered), giving it thixotropy (ability to gel when not in motion but flow when in motion). Now there are no drips, there are no thin or thick sections. It gels after a few seconds and can be uprighted and set on the shelf for drying.

The engobe on this stainless steel spoon has not cracked in drying or firing. How?

This picture has its own page with more detail, click here to see it.

This spoon was dipped into a ceramic dipping engobe, L3954B. It contains no CMC gum, it was only flocculated using powdered Epsom salts. Without the Epsom salts, the engobe runs off, leaving only a film. But, when turned into a thixotropic slurry, it stays on the spoon in an even layer (as a gel), then hardens as it dewaters (left) and finally dries completely (right). With no cracks! It also fires to cone 03 with no cracks. Of course, if this were fired high enough, it would begin to shrink, crack, crawl, melt and then craze, ceasing to be an engobe. Of course, special low-expansion frits and additives and mixing, preparation and application techniques make enamels, which do melt, possible for metals.

Pure feldspar applied as a glaze: Possible because of the magic of thixotropy.

This picture has its own page with more detail, click here to see it.

These are pure Custer feldspar and Nepheline Syenite. The coverage is perfectly even on both. No drips. Yet no clay is present. The secret? Epsom salts. I slurried the two powders in water until the flow was like heavy cream. I added more water to thin and then started adding the Epsom salts (powdered). After only a pinch or two, they both gelled. Then I added more water and more Epsom salts until they thickened again and gelled even better. The result is a thixotropic slurry. They both applied beautifully to these porcelains. The gelled consistency prevented them from settling in seconds to a hard layer on the bucket bottom. Could you do this with pure silica? Yes! The lesson: If these will suspend by gelling with Epsom salts, then any glaze will. You never need to tolerate settling or uneven coverage for single-layer dip-glazing again!

When to use vinegar and when to use epsom salts to flocculate a slurry

This picture has its own page with more detail, click here to see it.

Slurries with more clay (like engobes, slips) generally respond better to epsom salts. However the extra clay also makes them more likely to go moldy, so you may need to add a few drops of Dettol to kill the bacteria (if they are stored for any length of time). Vinegar works better for glaze surries, but only if they have sufficient specific gravity. Many people like to make an epsom salts solution and add that, but if you have a good mixer you may find it more intuitive to add the crystals (which you should crush to a powder) and wait 30 seconds for the viscosity to respond.

30g of Epsom salts dissolved in 100cc of water:

Is this the best way to use it?

This picture has its own page with more detail, click here to see it.

That produces a solution that can be added to glazes and clay slurries to flocculate them. This being said, it is not necessarily a good idea to add it to slurries as a solution, especially if you have a variable-speed propeller mixer. Creating a thixotropic slurry is a delicate business. The initial challenge is discovering a specific gravity that is not oversensitive or undersensitive to an Epsom salt addition (for many of our dipping glazes, this is 1.43-1.44, a fairly watery consistency). While discovering the right amount of Epsom salts to add can be done by adding this solution we have a propeller mixer and actually prefer adding the crystals by the pinch from a pre-weighed amount. We set the mixer speed to enable visually detecting differences in thixotropy and do a cycle of adding a pinch per gallon, let it mix for a couple of minutes and then stopping to check bounce-back (thus gel). At times the salts get over-supplied (easily undone with a tiny amount of Darvan).

Links

| Materials |

Calcium Chloride

|

| Materials |

Vinegar

|

| Hazards |

Epsom Salts

|

| Temperatures | Epsom salts decompose to lose water (150-) |

| Typecodes |

Generic Material

Generic materials are those with no brand name. Normally they are theoretical, the chemistry portrays what a specimen would be if it had no contamination. Generic materials are helpful in educational situations where students need to study material theory (later they graduate to dealing with real world materials). They are also helpful where the chemistry of an actual material is not known. Often the accuracy of calculations is sufficient using generic materials. |

| Typecodes |

Additives for Ceramic Glazes

Materials that are added to glazes to impart physical working properties and usually burn away during firing. In industry all glazes, inks and engobes have additives, they are considered essential to control of cohesion, adhesion, suspension, dry hardness, surface leveling, rheology, speed-of-drying, etc. Among potters, it is common for glazes to have zero additives. |

| Glossary |

Thixotropy

Thixotropy is a property of ceramic slurries of high water content. Thixotropic suspensions flow when moving but gel after sitting (for a few moments more depending on application). This phenomenon is helpful in getting even, drip-free glaze coverage. |

Video |

Watch Thixotropy Happen With a 20kg Batch of Dipping Glaze

I mixed 20kg of glaze powder into 20kg of water, turned out super watery. Yet the specific gravity was 1.46, too high. How? But, instead of more water, I added Epsom salts—and boom: A perfect thixotropic gel. It glides on smooth, no drips, no thickness issues. |

Data

| Density (Specific Gravity) | 1.68 |

|---|

Mechanisms

| Glaze Suspender | Used to thicken glaze slurries. |

|---|

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy