Notes

Chrome Tin Pink Sphene, a reaction product of high temperature calcination in which Calcium (II) Oxide, Tin (IV) Oxide, Silicon (IV) Oxide, and Chromium (III) Oxide in varying amounts are homogeneously and ionically interdiffused to form a crystalline matrix of tin sphene. Its composition may include either or both of the modifiers B2O3 and PbO.

Related Information

When using stains, customize the percentage, host glaze and firing schedule

This picture has its own page with more detail, click here to see it.

These are G2926B clear glazes with stains added and fired at cone 6. The one on the left has 11% Mason 6021 encapsulated red. It is pebbling the surface (even with 2% zircon), it may be at the upper end of its firing range. Possible solutions are faster firing up and down to give the stain less chance to decompose. Or firing at cone 5 instead. Or a drop-and-hold firing schedule. Or a lower percentage, that could impart a bit of variation where it is thicker and thinner (like the purple one). A different host glaze, perhaps one with less boron. The purple one has 10% Mason 6304, it is not affecting the glossy glaze surface. But the percentage needs to be higher to prevent the wash-out of color where it is applied thinner.

When brushing glazes go on unevenly adding stain can help

This picture has its own page with more detail, click here to see it.

Both of these were glazed by brushing. The inside transparent and white glazes are fairly easy to apply evenly but the bright color on the outside left one certainly is not. The problem is a combination of things. It is difficult to apply it evenly enough using a brush, the slurry is too thin. So it is also difficult to get it on thick enough. And this commercial glaze does not contain enough of the purple stain (so I added 6 grams of Mason 6304 Violet stain powder to the 2/3 of a jar I had left, and mixed thoroughly). That, more careful brushing, and an extra layer produced the piece on the right!

G2926B with 10% Mason 6304 Stain on Polar Ice Casting

This picture has its own page with more detail, click here to see it.

This stain only works on some base glazes, this is clearly one of them. 2% zircon also was also added, it helps prevent micro-bubbling, that keeps the glass transparent and deepens the color. The PLC6DS (drop and soak) firing schedule was used. The G3806 base clear glaze is often better than G2926B for really bright colors but this stain is an exception.

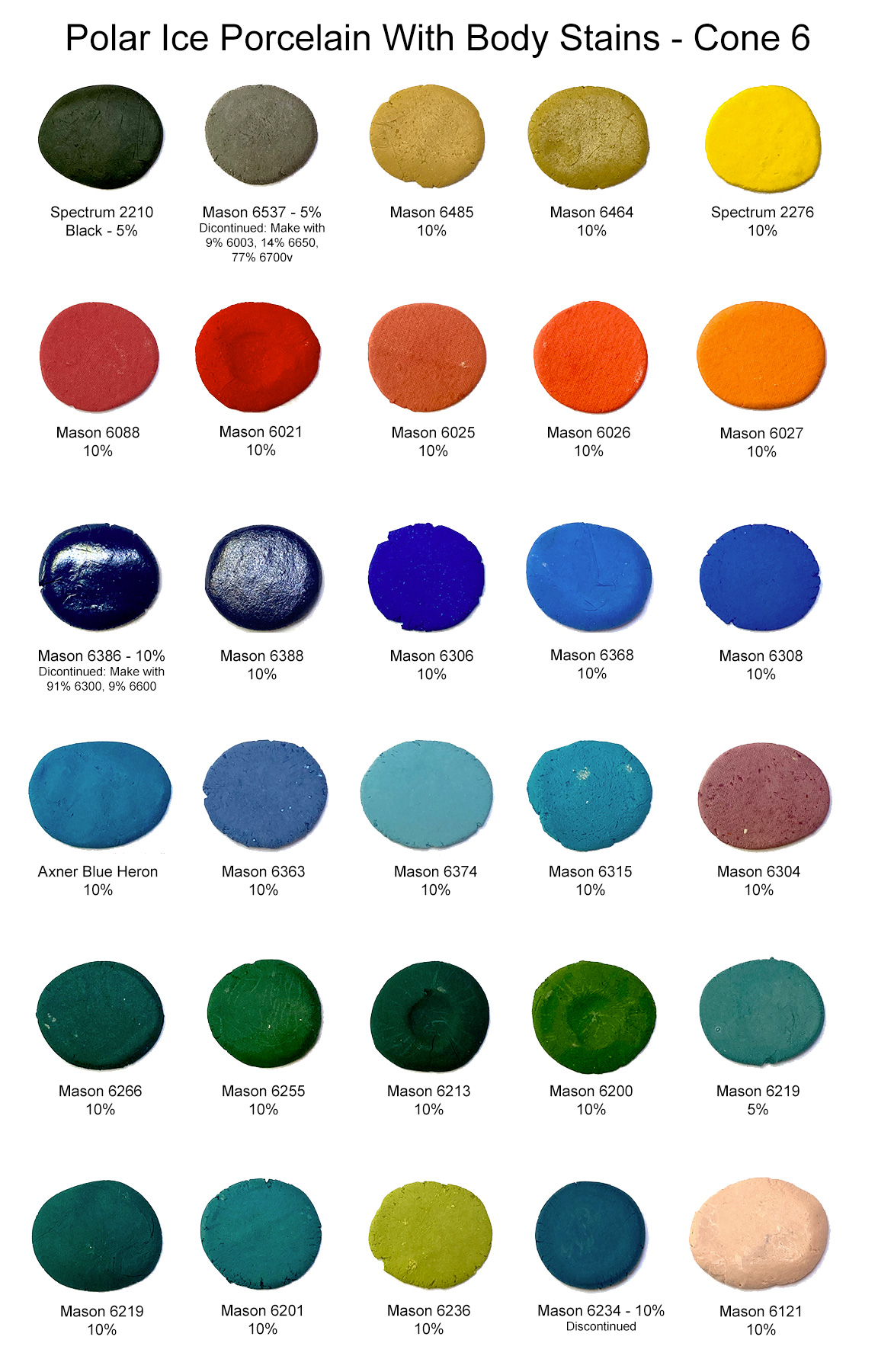

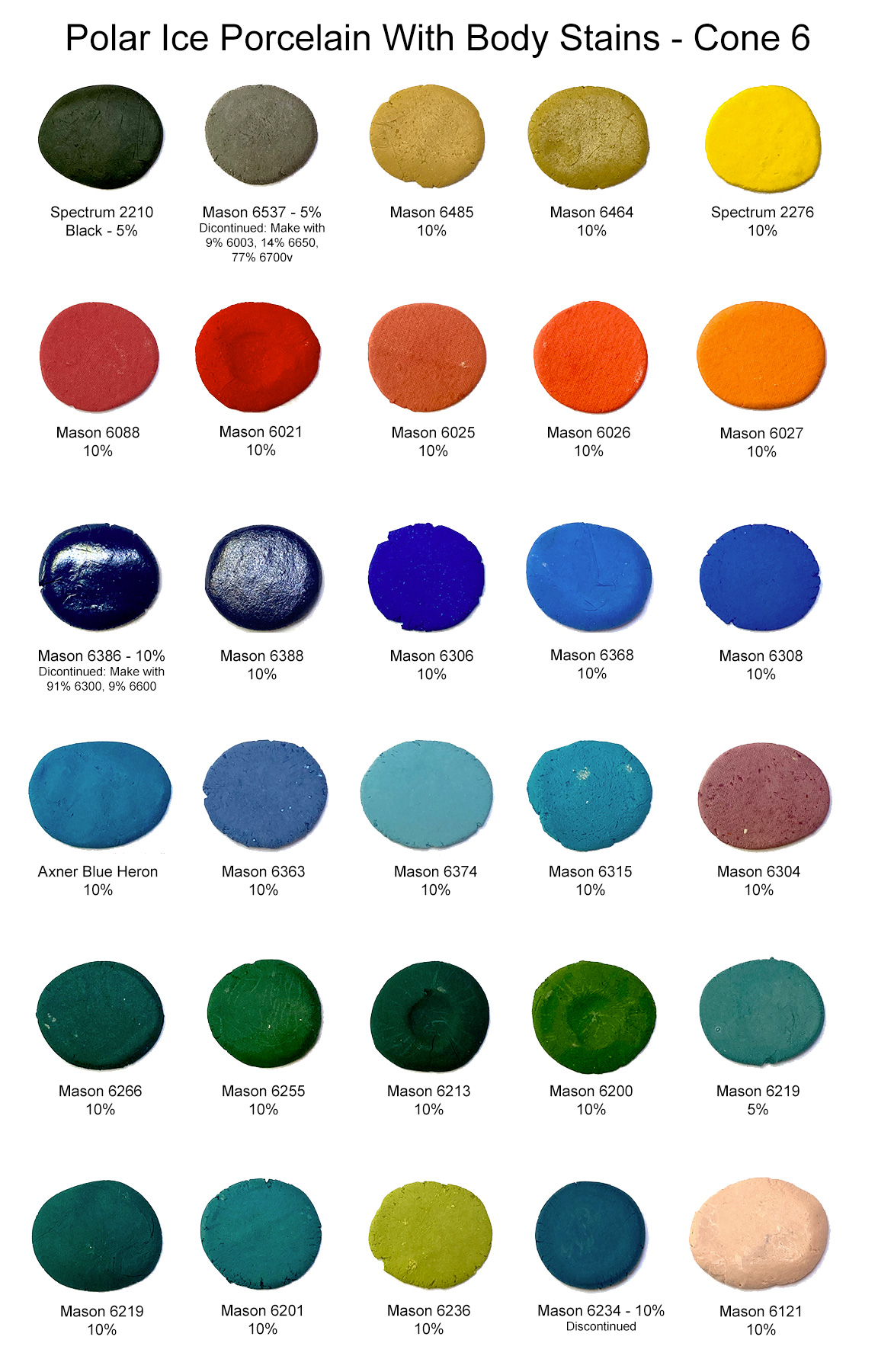

Polar Ice Porcelain with Body Stains - by Robert Barritz

This picture has its own page with more detail, click here to see it.

Robert has done really valuable work in this research, what an amazing range of color! Surfaces are unpolished and unglazed. All are fired to cone 6. Browns are missing, they can be made using iron oxide. For blacks, Mason 6600 is also effective. The blues can be intense using lower percentages than shown here, as low as 2% can be effective. There is an optimal amount for each stain, beyond that, increases in percentage bring little increase in color intensity. There is another reason to keep stain percentages to a minimum: To reduce the impact on body maturity (and firing shrinkage). Blues, for example, can significantly heighten the degree of vitrification, even melting the porcelain. If you plan to marble different colors, keeping stain percentage as low as possible is even more important, unless you can do fired shrinkage compatibility testing, for example, the EBCT test. Need to develop your own white porcelain? See the link below.

Stains in bodies will usually bleed color into glazes used over them, especially if the body is vitreous. This can be leveraged to create or amplify variegation. Strangely, stains can increase micro bubbles in transparent glazes.

Links