| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Covia Nepheline Syenite

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| CaO | 0.39% | 0.03 | |

| K2O | 4.85% | 0.23 | |

| MgO | 0.02% | - | |

| Na2O | 10.40% | 0.74 | |

| Al2O3 | 23.60% | 1.02 | |

| SiO2 | 60.20% | 4.42 | |

| Fe2O3 | 0.08% | - | |

| LOI | 0.50% | n/a | |

| Oxide Weight | 439.13 | ||

| Formula Weight | 441.34 | ||

Notes

Sieve Analysis ASTM E-11 A-200 A-270 A-400 A-700

(mean % retained on 70 .00 .00

each screen) 100 .01 .01

140 .04 .02

200 .45 .07

270 1.40 .80 .00

325 3.10 1.10 .03

-325 95.00 98.00 99.97 100.00

Sub Sieve Analysis:

% finer than 16 micron 57.0 66.0 88.0

10 micron 37.0 46.0 64.0

5 micron 19.0 25.0 35.0

Property: Test Method Unit Values

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Mineral Petrographic Microcline/Albite/Nepheline

Specific Gravity ASTM C128 2.61

Melting Point ASTM C-24 F/C 1868/1020

Bulk Density ASTM C-29 lbs/cu ft 38-55

Related Information

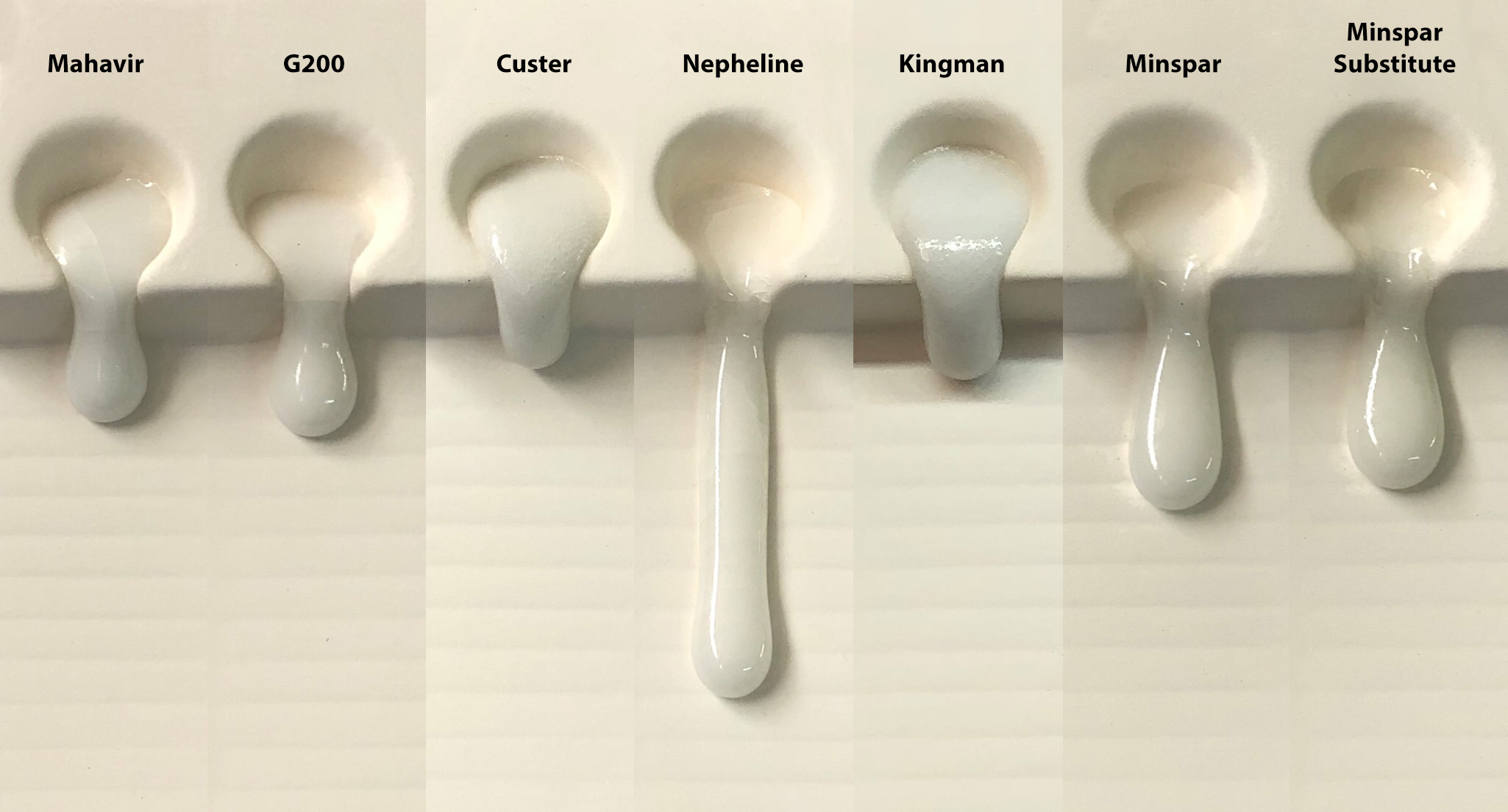

Which is the champion melter of American/Canadian feldspars?

This picture has its own page with more detail, click here to see it.

Feldspars are employed in glaze recipes as melters. So comparing their melt fluidities should be helpful in deciding if one can substitute for another (of course, if possible, a soda-predominant feldspar should be substituted for another soda spar). Feldspars don't melt alone at cone 6 (2200F) so we mixed each with 15% Ferro Frit 3195 (we consider a feldspar a material that sources KNaO). Nepheline Syenite, this is A270, is the champion melter here. Other similar ones can be spotted easily. In the end, degree of melt is a valid consideration in determining if one feldspar is a viable substitute for another in a recipe. Even if the feldspar you want to substitute does not melt as much a little frit can be added to the recipe to make up for the difference (e.g. 3-5%).

Melt fluidity: Cornwall Stone vs. Nepheline Syenite

This picture has its own page with more detail, click here to see it.

Three Cornwall Stone shipments (from 2011 and 2014) fired at cone 8 in melt flow GLFL testers and compared to Nepheline Syenite. Each contains 10% Ferro Frit 3134.

Melt flow comparison between Nepheline Syenite 270 and 400 mesh

This picture has its own page with more detail, click here to see it.

This Nepheline Syenite GLFL test for melt flow did not demonstrate much of a difference in melting at cone 9 between 270 and 400 mesh materials.

Warnings on back of Covia nepheline syenite bag 2021

This picture has its own page with more detail, click here to see it.

It is stated as non-hazardous in accordance with GHS criteria. Although like feldspar in chemistry, mineralogically nepheline syenite powder is a gound igneous rock, it does not contain quartz.

Covia nepheline syenite bag as of 2021

This picture has its own page with more detail, click here to see it.

Casting pure nepheline syenite

This picture has its own page with more detail, click here to see it.

Well, actually, it is not completely pure - I had to mix in 10% bentonite to give it enough shrinkage and leather hard strength to be able to pull itself away from the plaster mold (this bowl was just extracted). It cast without cracks to 3mm thickness in about 15 minutes. The defloculated slip required more water than normal but it pours and drains beautifully. I have made higher-percentage slurries in the past using Veegum but the casting time was too long. On aging, the previous slurry did not change its rheological properties after a month of storage. Nepheline syenite is a fantastic material for pottery bodies Of course, it is not used pure, this is just a demonstration. That being said, firing tests showed a vitreous product around cone 1.

Here is what Covia Nepheline Syenite does from cone 3 down to 05

This picture has its own page with more detail, click here to see it.

These SHAB fired bars are 95% nepheline syenite (5% Veegum added). By cone 02 (bar marked #4) it is self-glazing and glass-like with a total shrinkage (plastic to fired) of 15% (less than some porcelains). At cone 03 (the #5 bar) the porosity is 3% (a stoneware). These are actually melted more than normal because the Veegum is a flux.

Links

| Materials |

Nepheline Syenite

|

| Typecodes |

Feldspar

The most common source of fluxes for high and medium temperature glazes and bodies. |

| URLs |

https://digitalfire.com/4sight/datasheets/SDSNephelineSyenite.pdf

Nepheline Syenite SDS |

| URLs |

https://www.canadiannepheline.ca

About Covia Nepheline Syenite |

| URLs |

https://www.coviacorp.com/media/jxaojiel/spectrum_tds_a200-a400_nephton_060_0619_cer_eng.pdf

Covia Nepheline Syenite data sheet |

| URLs |

https://www.coviacorp.com/

Covia Corp website |

| URLs |

https://www.coviacorp.com/about-us/

About Covia Corp |

| Hazards |

Feldspar

Feldspars are abundant and varied in nature. They contain small amounts of quartz (while nepheline syenite does not). |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy