| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Fusion Frit F-15

Alternate Names: Fusion Frit F15

Description: Low expansion frit

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| K2O | 3.60% | 0.48 | |

| Na2O | 2.60% | 0.52 | |

| B2O3 | 23.00% | 4.12 | |

| Al2O3 | 3.80% | 0.46 | |

| SiO2 | 67.00% | 13.91 | |

| Oxide Weight | 1,247.63 | ||

| Formula Weight | 1,247.63 | ||

Related Information

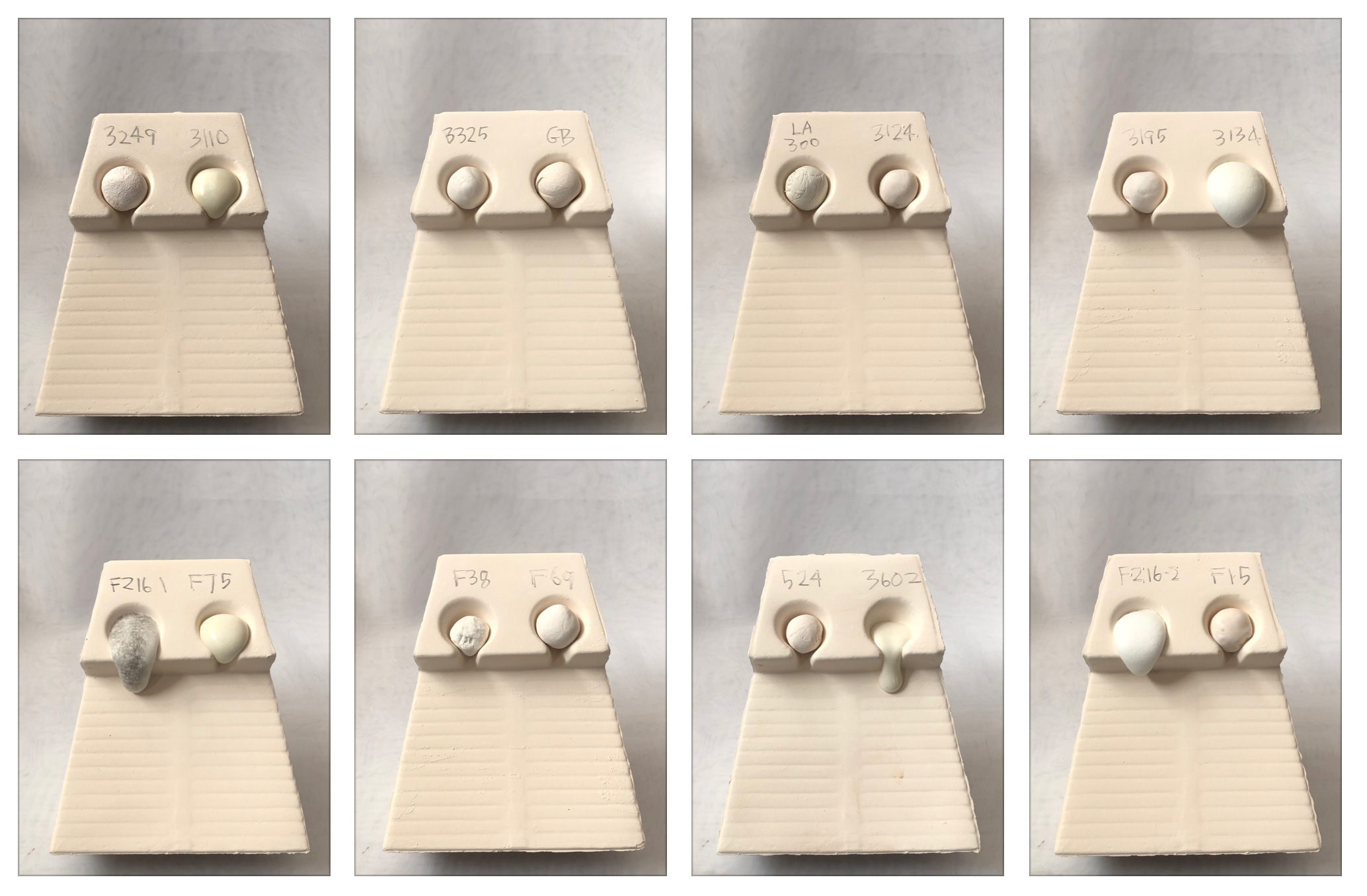

Various frits fired at 1950F

This picture has its own page with more detail, click here to see it.

These sixteen GBMF test balls have melted down onto a slab of grogged clay. Kiln fired at 108F/hr for the last 100 degrees F and held for 15 minutes. This demonstrates the comparison value of this test and how various frits compare in their melting character.

Frits fired to 2050F

This picture has its own page with more detail, click here to see it.

These are higher temperature frits. 10 gram balls were melted on to this tile.

Various frits fired at 1850F

This picture has its own page with more detail, click here to see it.

16 GBMF tests on a slab of grogged clay. Kiln fired at 108F/hr for last 100 degrees F and held for 15 minutes.

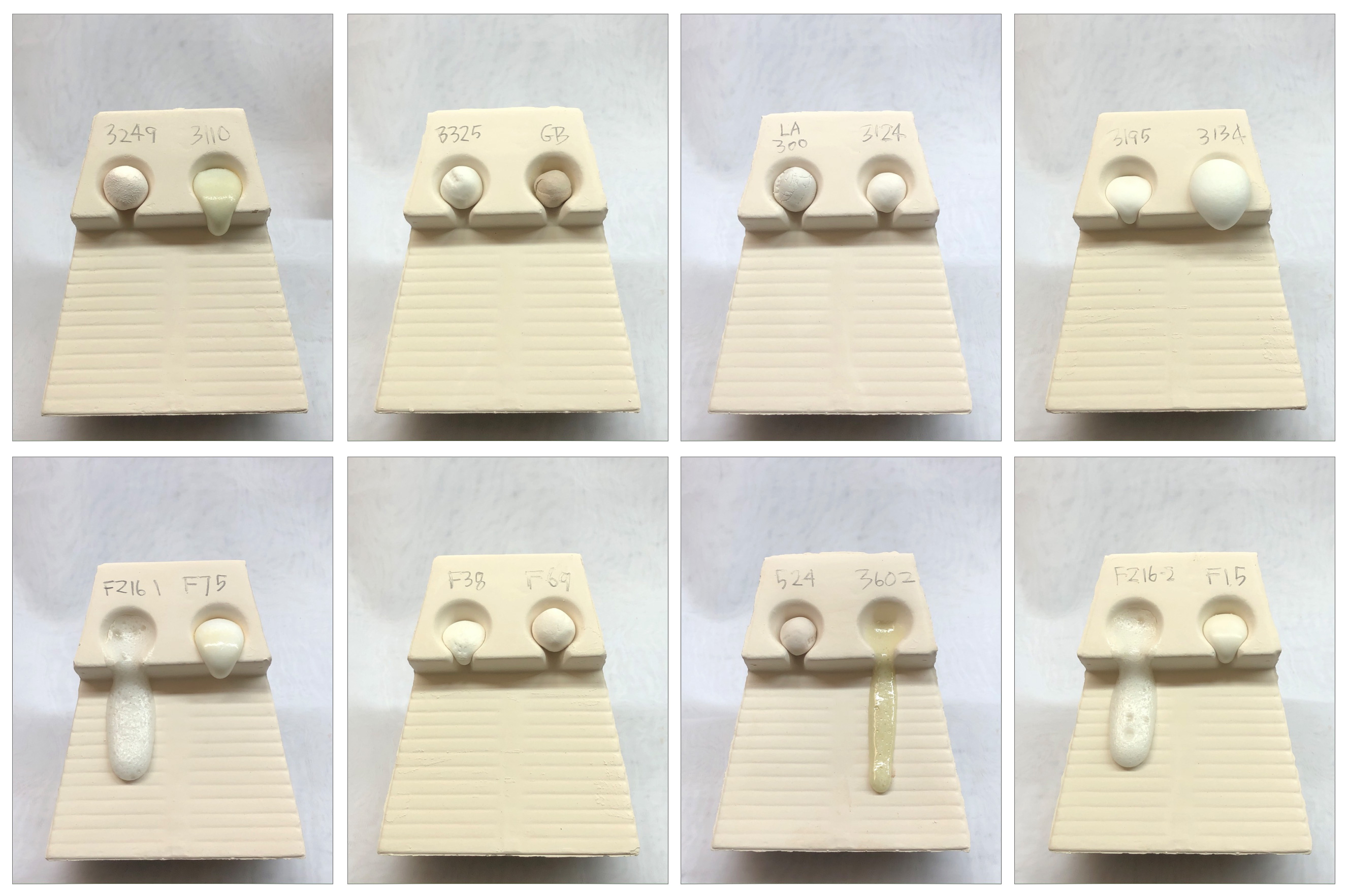

Frit Melt Fluidity Comparison - 1800F

This picture has its own page with more detail, click here to see it.

Fired at 350F/hr to 1800F and held for 15 minutes (I already did firings from 1300F-1750F in 50 degree increments, all of them are visible in the parent project). Frit 3110, 3134, 3195, F75 have run all the way down. All of the frits have softened and melted slowly over a range of temperatures (hundreds of degrees). By contrast, Gerstley Borate, the only raw material here, suddenly melted and flowed right over the cliff (between 1600 and1650)! But not before Frit 3602 and FZ16 had done so earlier. Frit 3249 is just starting to soften but F69 (the Fusion Frits equivalent) is a little ahead of it. LA300 and Frit 3124 are starting also. F524, F38, F15 will all be over the end by the next firing. The melt surface tension is evident by the way in which the melts spread out or hold together.

Frit melt fluidity comparison - 1300F

This picture has its own page with more detail, click here to see it.

Fired at 350F/hr to 1300F and held for 15 minutes. Some are still burning off carbon (which seems strange). There are two early leaders: Ferro frit 3110 and Fusion frit F75 are starting to deform (they have almost the same chemistry). Amazingly, these two frits have low boron, they rely on high soda as the flux.

Melt fluidity comparison of frits - 1350F

This picture has its own page with more detail, click here to see it.

Fired at 350F/hr to 1350F and held for 15 minutes. Some are still burning off carbon (which seems strange). The two FZ16s are starting to move. Frit 3134 is expanding. 3602 is also starting to melt.

Melt fluidity comparison of frits - 1400F

This picture has its own page with more detail, click here to see it.

Fired at 350F/hr to 1400F and held for 15 minutes. Frit 3134 is still expanding. 3602 is also starting to flow. A number of them are shrinking and densifying like a porcelain would.

Melt fluidity comparison of frits - 1450F

This picture has its own page with more detail, click here to see it.

Fired at 350F/hr to 1450F and held for 15 minutes. Frit 3134 is still expanding. 3602 is blasting out of the gate, taking the lead. F75 is starting to flow.

Melt fluidity comparison of frits - 1500F

This picture has its own page with more detail, click here to see it.

Fired at 350F/hr to 1500F and held for 15 minutes. Frit 3134 is still expanding. 3602 and FZ16 are really starting to move. 3195, F38 and F15 are softening.

Melt fluidity comparison of frits - 1550F

This picture has its own page with more detail, click here to see it.

Fired at 350F/hr to 1550F and held for 15 minutes. Frit 3134 is still expanding. 3602 and FZ16 are going to be off-ramp by next firing.

Melt fluidity comparison of frits - 1650F

This picture has its own page with more detail, click here to see it.

Fired at 350F/hr to 1650F and held for 15 minutes. FZ16 has turned crystal clear and spread out across the runway (has low surface tension). Frit 3110 has so much surface tension that the flow can be lifted off the tester. Since 1600F Gerstley Borate has gone from unmelted to passing all the rest!

Melt fluidity comparison of frits - 1700F

This picture has its own page with more detail, click here to see it.

Fired at 350F/hr to 1700F and held for 15 minutes. 3110 is finally starting to move. 3134 also (being full of bubbles). Gerstley Borate has turned almost transparent (because the Colemanite portion of it is now melting). 3195 is looking very well behaved compared to most others, forming a bubble free glass of high surface tension (F15 and F524 are starting to do the same).

Frit Melt Fluidity Comparison - 1850F

This picture has its own page with more detail, click here to see it.

These melt flow tests were fired at 350F/hr to 1850F and held for 15 minutes (I did firings at 50-degree increments across a wide range). It is amazing how active some frits are, even well below normal bisque temperatures! Frit 3110, Frit 3134, Frit 3195, Frit F-75 have all flowed all the way down for many previous temperatures. LA300 and Frit 3124 were just starting at 1800F, look at them now! Frit F-524 and Frit F-38 have gone from half-way at 1800F to water-falling over the end. Frit 3249 is still not out-of-the-gate but Frit F-69 (the Fusion Frits equivalent of 3249) is half-way. Note how the melt surface tension is evident by the way in which the melts spread out or hold together. By contrast, Gerstley Borate (labelled "GB"), the only raw material here, suddenly melted and flowed right over-the-cliff between 1600 and 1650! The best melter of all of them is high-boron high-zinc Frit FZ-16.

Links

| Materials |

Fusion Frit F-524

A low fire base glaze, add 10% kaolin, adjust thermal expansion using other frits. |

| Materials |

Frit

Frits are made by melting mixes of raw materials, quenching the melt in water, grinding the pebbles into a powder. Frits have chemistries raw materials cannot. |

| Typecodes |

Frit

A frit is the powdered form a man-made glass. Frits are premelted, then ground to a glass. They have tightly controlled chemistries, they are available for glazes of all types. |

Data

| Co-efficient of Linear Expansion | 4.42 |

|---|---|

| Frit Softening Point | 1675F |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy