| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

A cereal bowl jigger mold made using 3D printing

Beer Bottle Master Mold via 3D Printing

Better porosity for Brown Sugar Savers

Build a kiln monitoring device

Celebration Project

Coffee Mug Slip Casting Mold via 3D Printing

Comparing the Melt Fluidity of 16 Frits

Cookie Cutting clay with 3D printed cutters

Evaluating a clay's suitability for use in pottery

Make a mold for 4-gallon stackable calciners

Make Your Own Pyrometric Cones

Make your own sieve shaker to process ceramic slurries

Making a high quality ceramic tile

Making a Plaster Table

Making our own kiln posts using a hand extruder

Medalta Ball Pitcher Slip Casting Mold via 3D Printing

Medalta Jug Master Mold Development

Mold Natches

Mother Nature's Porcelain - Plainsman 3B

Mug Handle Casting

Nursery plant pot mold via 3D printing

Pie-Crust Mug-Making Method

Plainsman 3D, Mother Nature's Porcelain/Stoneware

Project to Document a Shimpo Jiggering Attachment

Roll, Cut, Pull, Attach Handle-making Method

Slurry Mixing and Dewatering Your Own Clay Body

Testing a New Load of EP Kaolin

Using milk as a glaze

Making Bricks

A project to use 3D printing to create molds for making bricks. I am inspired by bricks made across the Canadian prairies during the 19th and 20th centuries. I will experiment with making both compressed earth blocks and fired bricks. I am particularly excited about the possibility of making metallic bricks using Plainsman Fire-Red and St. Rose Red materials (firing them at cone 10R). And about using their Kaosand - it is only suitable as a minor ingredient in plastic bodies but has enough plasticity to hold together as a brick (and should dry quickly with minimal shrinkage).

Related Information

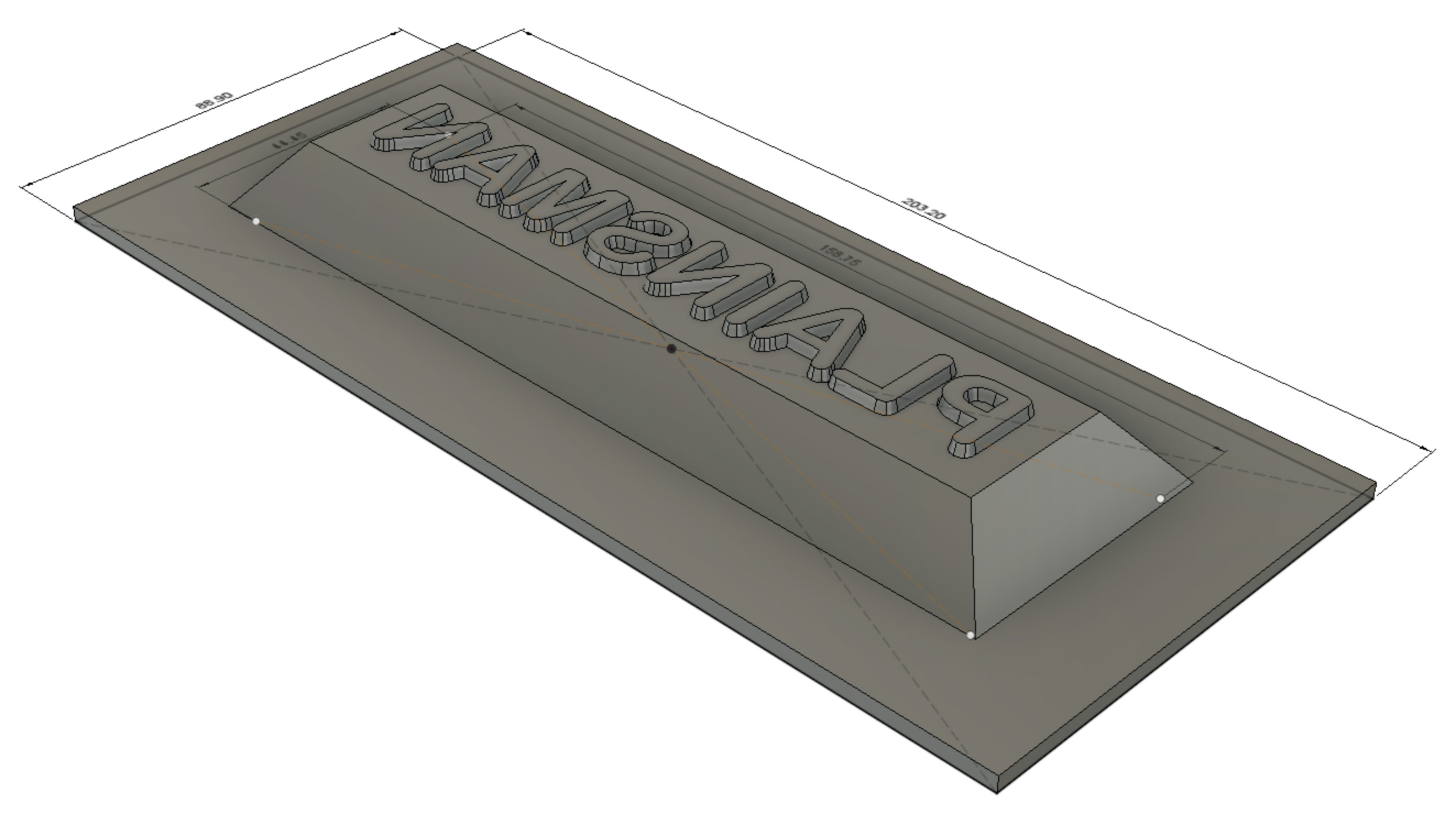

3D drawing of brick frog template

This picture has its own page with more detail, click here to see it.

The "frog" is the indentation in pressed bricks. I drew this design in Fusion 360. For initial testing I was able to oil the 3D printed form (having no infill), compress the clay directly against it and get good extraction. This is version 2, I maximized the amount of draft on the letters (it is a tricky process because of some of the tight angles). This is a very good example of the power that 3D printing puts into the hands of a small business. Thanks to Keeley Haftner for opening my eyes to this possibility.

Why a metal mold is needed for ramming clay into a mold

This picture has its own page with more detail, click here to see it.

I was using a heavy metal tamper to force high-water-content powder (about 12%) into a wooden form to make bricks. I use snug-fitted wooden spacers against the clay itself and deliver the blows to them. It became quickly evident, that even with 3/4 inch wood, my tamper can deliver greater pressure than the mold can withstand. I then switched to 3/4 inch plywood. With the same result! A metal mold seemed to be the next step but that was going to involve considerable expenditure. And were other problems: Removing the brick after pressing it in would be very difficult, metal molds are only practical if you have a machine with both pressing and extraction cycles. Another issue was getting a good logo impression on the frog: The clay is not hard enough to pull away from the mold without edges and pieces breaking off. In the end, for making sample bricks, a plastic mold and wetter clay are a better option.

3/4 inch plywood mold which also split

This picture has its own page with more detail, click here to see it.

The fact that it broke was not the only issue. A mold that I could disassemble seemed like a good idea but the pressure developed during ramming sticks the clay to the wood is such a way it is difficult to part them. This was another step is realizing, that for my goals of just making some demonstration bricks, it would be better to use a plaster mold and softer clay.

First try with my 3D printed frog

This picture has its own page with more detail, click here to see it.

The lettering on the frog does not have enough of a draft to release well. The oil soap I was using as a parting-agent did not work as well as canola oil. And the water content of the clay was too low to make it compress enough to get good surfaces.

Pouring a temporary plaster mold for pressing softer clay

This picture has its own page with more detail, click here to see it.

I 3D printed the yellow shell, it is the dimension into which the frog fits. Also 3D printed the clips to hold the boards in place.

Links

| URLs |

https://en.wikipedia.org/wiki/Compressed_earth_block

Compressed Earth Blocks |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy