| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Frit VO 6200

Description: Reimbold & Strick fast firing opaque frit

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| CaO | 8.00% | 0.36 | |

| Na2O | 1.00% | 0.04 | |

| B2O3 | 6.00% | 0.22 | |

| ZrO2 | 9.00% | 0.18 | |

| K2O | 4.00% | 0.11 | |

| MgO | 2.00% | 0.12 | |

| SiO2 | 53.00% | 2.21 | |

| ZnO | 12.00% | 0.37 | |

| Al2O3 | 5.00% | 0.12 | |

| Oxide Weight | 251.10 | ||

| Formula Weight | 251.10 | ||

Related Information

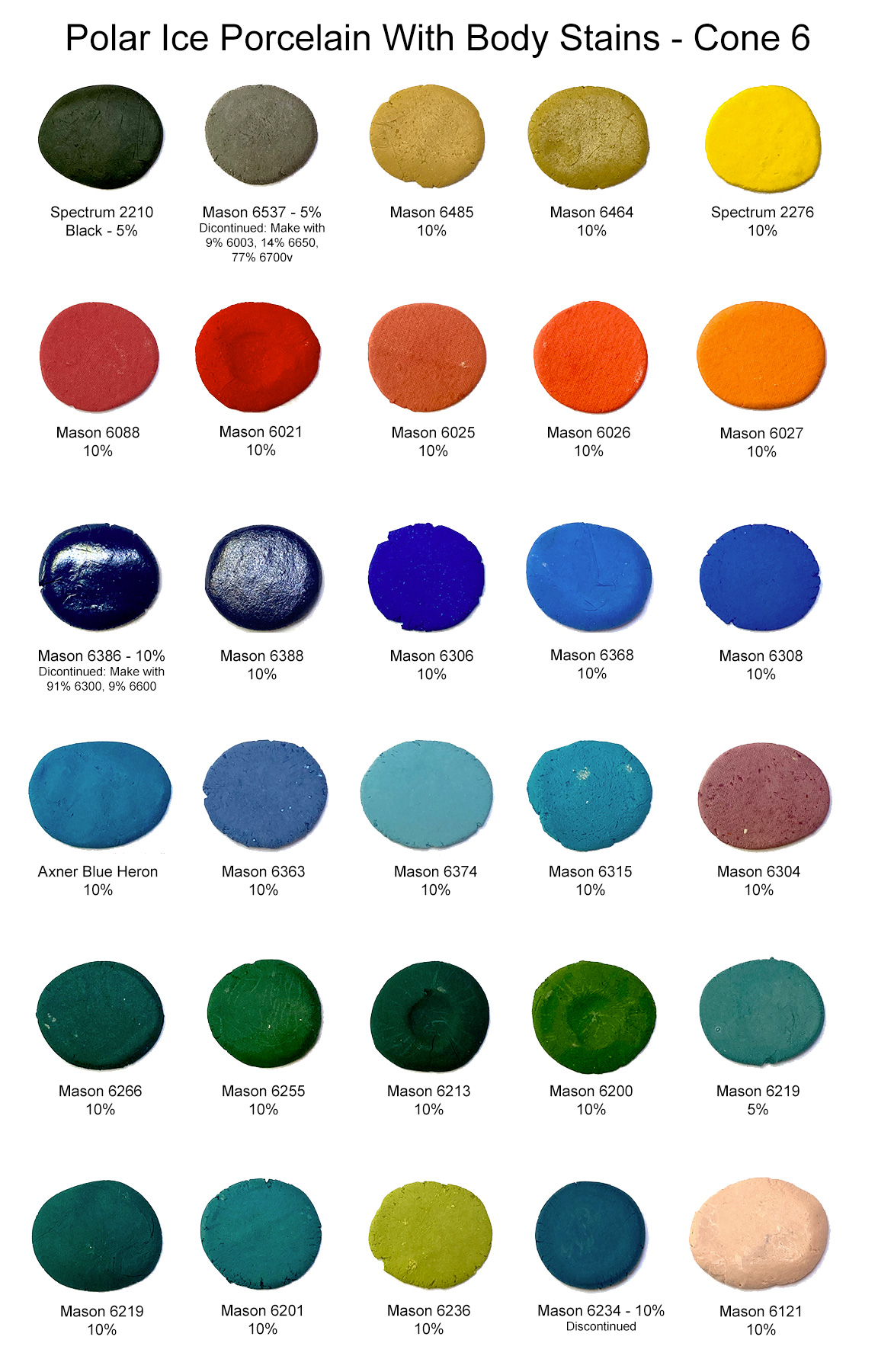

Polar Ice Porcelain with Body Stains - by Robert Barritz

This picture has its own page with more detail, click here to see it.

Robert has done really valuable work in this research, what an amazing range of color! Surfaces are unpolished and unglazed. All are fired to cone 6. Browns are missing, they can be made using iron oxide. For blacks, Mason 6600 is also effective. The blues can be intense using lower percentages than shown here, as low as 2% can be effective. There is an optimal amount for each stain, beyond that, increases in percentage bring little increase in color intensity. There is another reason to keep stain percentages to a minimum: To reduce the impact on body maturity (and firing shrinkage). Blues, for example, can significantly heighten the degree of vitrification, even melting the porcelain. If you plan to marble different colors, keeping stain percentage as low as possible is even more important, unless you can do fired shrinkage compatibility testing, for example, the EBCT test. Need to develop your own white porcelain? See the link below.

Stains in bodies will usually bleed color into glazes used over them, especially if the body is vitreous. This can be leveraged to create or amplify variegation. Strangely, stains can increase micro bubbles in transparent glazes.

Links

| Materials |

Frit

Frits are made by melting mixes of raw materials, quenching the melt in water, grinding the pebbles into a powder. Frits have chemistries raw materials cannot. |

| Typecodes |

Frit

A frit is the powdered form a man-made glass. Frits are premelted, then ground to a glass. They have tightly controlled chemistries, they are available for glazes of all types. |

Data

| Co-efficient of Linear Expansion | 60 x 10-7 (20-400C) |

|---|---|

| Frit Softening Point | 790C |

| Glass Transition Temperature | 620C |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy