| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

No. 1 Glaze Ball Clay

Alternate Names: Glaze #1, #1 Glaze Clay

Description: Kentucky Ball Clay, Glaze #1, Glaze Number 1, Glaze No 1

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| CaO | 0.10% | 0.01 | |

| K2O | 0.30% | 0.01 | |

| MgO | 0.30% | 0.03 | |

| Na2O | 0.10% | 0.01 | |

| TiO2 | 2.40% | 0.10 | |

| Al2O3 | 29.40% | 1.00 | |

| SiO2 | 56.30% | 3.25 | |

| Fe2O3 | 0.90% | 0.02 | |

| LOI | 9.90% | n/a | |

| Oxide Weight | 311.55 | ||

| Formula Weight | 345.78 | ||

Notes

This is a high alumina, low iron ball clay (typical ball clays can be less than 25% alumina). As its name suggests, this works well as a suspender and hardener in glazes, especially for whites and transparents where the cleanest possible materials are needed. The Old Hickory No. 5 ball clay is a similar material. Use less than 20% (in glazes having no other clay materials) or excessive gelling could occur.

Crude Color: White

Dry M.O.R. (psi 50% clay/50% flint, cast bars): 400

Wet Sieve Residue, +200 mesh (%): 0.20

Water of Plasticity (%): 32

Linear Dry Shrinkage (%): 6.2

Solubles Sulfates (ppm): 183

Filtration (ml): 26

Specific Surface Area (sq meters per gram): 18.0

CEC/MBI (meq/100 ml): 9.5

pH: 5.7

PCE: 32

Firing Shrinkage (%) Cone 04: 4.1 Cone 3: 5.5 Cone 11: 6.8

Absorption (%) 15.9 12.0 5.4

Particle Size (% finer than):

50 microns: 100

20: 98

10: 95

5: 82

1: 55

0.5: 44

Related Information

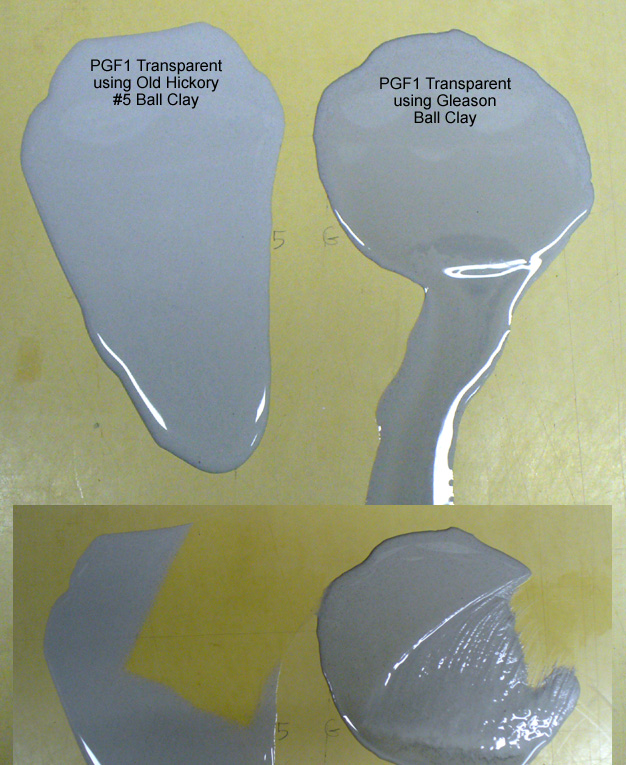

The ball clay you use to suspend your glaze is important!

This picture has its own page with more detail, click here to see it.

I poured 4 teaspoons of two glazes onto a non-absorbent butcher’s board and let them sit for a minute, then inclined the board. The one on the right employs Gleason Ball clay, the left one has Old Hickory #5 ball clay. Neither has any rheology modifier additions. The one on the right has settled and, on incline of the board, the watery upper is running off. The other has gelled and the whole thing is running downward slowly. Below that you can see where I have begun to sponge them off, the one on the right is sticky. The most amazing thing about this: This difference appears despite the fact that there is only 7% ball clay in this heavily fritted recipe.

Links

| Typecodes |

Ball Clay

Ball clays are abundant and very plastic and are used in all types of plastic forming bodies. They are not as white-burning or refractory as kaolins but lower in iron and fluxes than bentonites. |

| Materials |

No. 5 Ball Clay

|

| URLs |

http://oldhickoryclay.com/products/kentucky-clays/no-1-glaze/

No. 1 Glaze ball clay data sheet |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy