| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Gleason Ball Clay

Description: Fine grainding plastic ball clay

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| CaO | 0.09% | 0.01 | |

| K2O | 0.32% | 0.01 | |

| MgO | 0.04% | - | |

| Na2O | 0.07% | - | |

| TiO2 | 1.48% | 0.07 | |

| Al2O3 | 26.28% | 1.00 | |

| P2O5 | 0.11% | - | |

| SiO2 | 58.80% | 3.80 | |

| Fe2O3 | 1.41% | 0.03 | |

| MnO | 0.01% | - | |

| LOI | 11.60% | n/a | |

| SO3 | 0.02% | n/a | |

| Oxide Weight | 343.92 | ||

| Formula Weight | 389.14 | ||

Notes

The manufacturer describes it as a fine-grained engineered blend offering excellent bonding and forming characteristics. Ideally suited for extrusion, dry and wet pressing applications. This material is an alternative to, for example, OM#4, it has a lower coal content and fires a little lighter in color.

Related Information

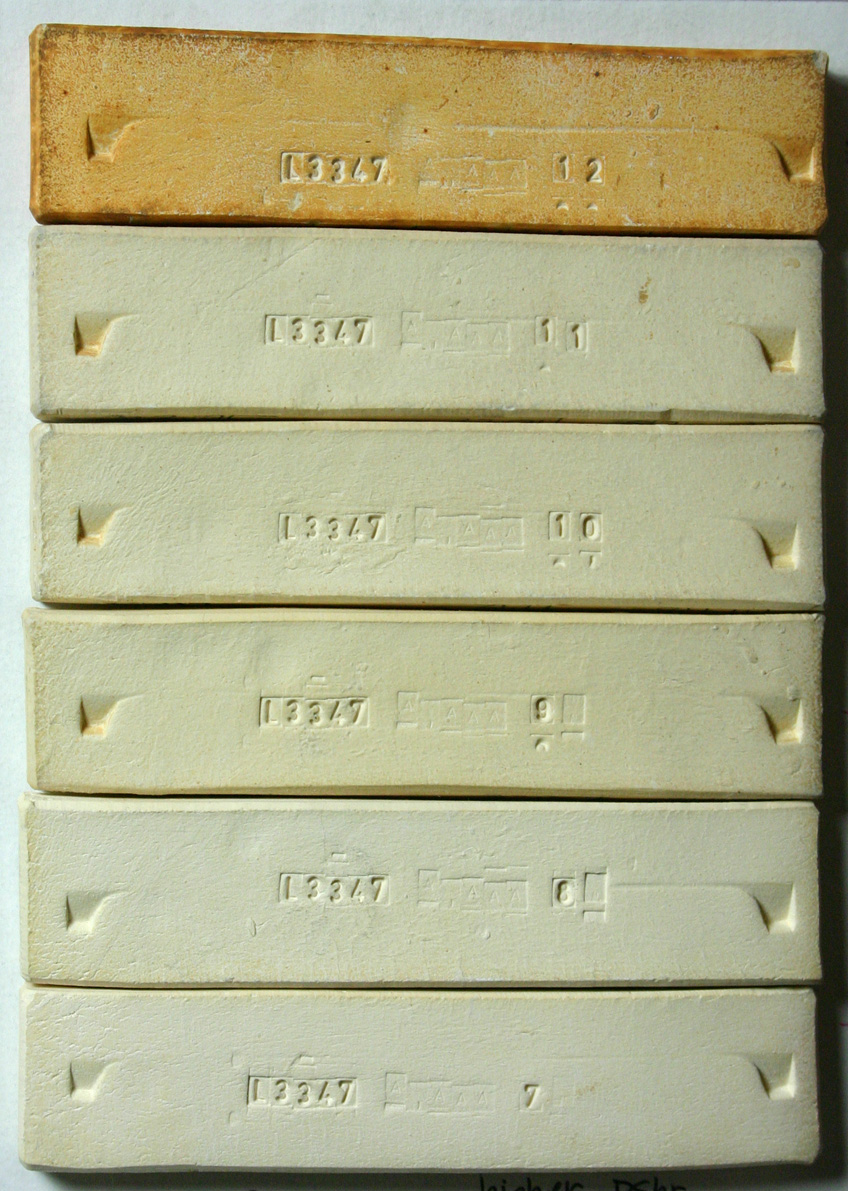

Gleason ball clay fired test bars from cone 7-11 oxidation and cone 10 reduction

This picture has its own page with more detail, click here to see it.

The oxidation bars (lower) are typical of most ball clays. They burn off-white and darken slightly in color as they approach maturity (above cone 10). Ball clays are fairly refractory, often as much more more than common fireclays. Ball clays almost always have some soluble salts and these reveal themselves in reduction firing (top bar).

Links

| Typecodes |

Ball Clay

Ball clays are abundant and very plastic and are used in all types of plastic forming bodies. They are not as white-burning or refractory as kaolins but lower in iron and fluxes than bentonites. |

| Materials |

OM #4 Ball Clay

|

| Materials |

Foundry Hill Creme

|

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy